Abstract

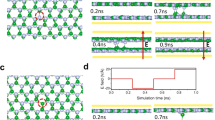

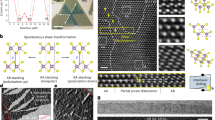

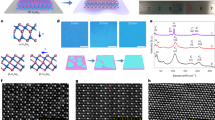

Transition metal dichalcogenides have attracted attention as potential building blocks for various electronic applications due to their atomically thin nature and polymorphism. Here, we report an electric-field-induced structural transition from a 2H semiconducting to a distorted transient structure (2Hd) and orthorhombic Td conducting phase in vertical 2H-MoTe2- and Mo1−xWxTe2-based resistive random access memory (RRAM) devices. RRAM programming voltages are tunable by the transition metal dichalcogenide thickness and show a distinctive trend of requiring lower electric fields for Mo1−xWxTe2 alloys versus MoTe2 compounds. Devices showed reproducible resistive switching within 10 ns between a high resistive state and a low resistive state. Moreover, using an Al2O3/MoTe2 stack, On/off current ratios of 106 with programming currents lower than 1 μA were achieved in a selectorless RRAM architecture. The sum of these findings demonstrates that controlled electrical state switching in two-dimensional materials is achievable and highlights the potential of transition metal dichalcogenides for memory applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper are available from the corresponding author upon request.

References

Wuttig, M. & Yamada, N. Phase-change materials for rewriteable data storage. Nat. Mater. 6, 824–832 (2007).

Liu, K. et al. Powerful, multifunctional torsional micromuscles activated by phase transition. Adv. Mater. 26, 1746–1750 (2014).

Gu, Q., Falk, A., Wu, J., Ouyang, L. & Park, H. Current-driven phase oscillation and domain-wall propagation in WxV1 –xO2 nanobeams. Nano Lett. 7, 363–366 (2007).

Strelcov, E., Lilach, Y. & Kolmakov, A. Gas sensor based on metal−insulator transition in VO2 nanowire thermistor. Nano Lett. 9, 2322–2326 (2009).

Zhou, Y. & Ramanathan, S. Mott memory and neuromorphic devices. Proc. IEEE 103, 1289–1310 (2015).

Wong, H. S. P. et al. Phase change memory. Proc. IEEE 98, 2201–2227 (2010).

Duerloo, K.-A. N., Li, Y. & Reed, E. J. Structural phase transitions in two-dimensional Mo- and W-dichalcogenide monolayers. Nat. Commun. 5, 4214 (2014).

Duerloo, K.-A. N. & Reed, E. J. Structural phase transitions by design in monolayer alloys. ACS Nano 10, 289–297 (2016).

Lin, Y.-C., Dumcenco, D. O., Huang, Y.-S. & Suenaga, K. Atomic mechanism of the semiconducting-to-metallic phase transition in single-layered MoS2. Nat. Nanotech. 9, 391–396 (2014).

Py, M. A. & Haering, R. R. Structural destabilization induced by lithium intercalation in MoS2 and related compounds. Can. J. Phys. 61, 76–84 (1983).

Song, S. et al. Room temperature semiconductor–metal transition of MoTe2 thin films engineered by strain. Nano Lett. 16, 188–193 (2016).

Tsipas, P. et al. Direct observation at room temperature of the orthorhombic weyl semimetal phase in thin epitaxial MoTe2. Adv. Funct. Mater. 28, 1802084 (2018).

Park, J. C. et al. Phase-engineered synthesis of centimeter-scale 1T′- and 2H-molybdenum ditelluride thin films. ACS Nano 9, 6548–6554 (2015).

Vellinga, M. B., de Jonge, R. & Haas, C. Semiconductor to metal transition in MoTe2. J. Solid State Chem. 2, 299–302 (1970).

Keum, D. H. et al. Bandgap opening in few-layered monoclinic MoTe2. Nat. Phys. 11, 482–486 (2015).

Empante, T. A. et al. Chemical vapor deposition growth of few-layer MoTe2 in the 2H, 1T′ and 1T phases: tunable properties of MoTe2 films. ACS Nano 11, 900–905 (2017).

Wang, Y. et al. Structural phase transition in monolayer MoTe2 driven by electrostatic doping. Nature 550, 487–491 (2017).

Li, Y., Duerloo, K. A., Wauson, K. & Reed, E. J. Structural semiconductor-to-semimetal phase transition in two-dimensional materials induced by electrostatic gating. Nat. Commun. 7, 10671 (2016).

Zhang, C. et al. Charge mediated reversible metal–insulator transition in monolayer MoTe2 and WxMo1–xTe2 alloy. ACS Nano 10, 7370–7375 (2016).

Sean, M. O. et al. The structural phases and vibrational properties of Mo1−xWxTe2 alloys. 2D Mater. 4, 045008 (2017).

Lv, Y.-Y. et al. Composition and temperature-dependent phase transition in miscible Mo1−xWxTe2 single crystals. Sci. Rep. 7, 44587 (2017).

Wong, H. S. P. et al. Metal-oxide RRAM. Proc. IEEE 100, 1951–1970 (2012).

Berger, A. N. et al. Temperature-driven topological transition in 1T′-MoTe2. NPJ Quantum Mater. 3, 2 (2018).

Liang, J. & Wong, H. S. P. Cross-point memory array without cell selectors—device characteristics and data storage pattern dependencies. IEEE Trans. Electron. Dev. 57, 2531–2538 (2010).

Brewer, L. & Lamoreaux, R. H. in Binary Alloy Phase Diagrams 2nd edn, Vol. 3 (eds. Massalski, T. B., Okamoto, H., Subramanian, P. R. & Kacprzak, L.) 2675–2676 (ASM International, Russell Township, 1990).

Acknowledgements

This work was supported in part by the Semiconductor Research Corporation (SRC) at the NEWLIMITS Center and National Institute of Standards and Technology (NIST) through award no. 70NANB17H041. S.K. acknowledges support from the US Department of Commerce, NIST under financial assistance award 70NANB16H043. H.Z. acknowledges support from the US Department of Commerce, NIST under financial assistance awards 70NANB15H025 and 70NANB17H249. A.V.D., S.K. and B.P.B. acknowledge support from Material Genome Initiative funding allocated to NIST. The authors thank I. Kalish (NIST) for conducting XRD and EDS measurements on Mo1–xWxTe2 samples. Certain commercial equipment, instruments or materials are identified in this paper to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by NIST, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

Author information

Authors and Affiliations

Contributions

F.Z. and J.A. designed the experiments. F.Z. fabricated, measured the devices and performed the conductive AFM measurement. S.K. and A.V.D. synthesized Mo1–xWxTe2 alloy samples. C.A.M. and D.Y.Z. performed the STM and STS measurements. D.Y.Z. contributed the STM surface analysis. H.Z. prepared TEM samples using SEM/FIB and performed TEM/STEM measurements. H.Z., L.A.B. and A.V.D. performed the TEM/STEM analysis. B.P.B. conducted ab initio modelling of energetics for the 2H, 2Hd and 1T′ MoTe2. Y.Z. and J.A. carried out the model simulation for vertical electrical transport. F.Z., H.Z., L.A.B., A.V.D. and J.A. wrote the manuscript and discussed the results at all stages.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Sections 1–14, Supplementary References 1–14, Supplementary Table 1, Supplementary Figures 1–17

Rights and permissions

About this article

Cite this article

Zhang, F., Zhang, H., Krylyuk, S. et al. Electric-field induced structural transition in vertical MoTe2- and Mo1–xWxTe2-based resistive memories. Nature Mater 18, 55–61 (2019). https://doi.org/10.1038/s41563-018-0234-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-018-0234-y

This article is cited by

-

Phase-selective in-plane heteroepitaxial growth of H-phase CrSe2

Nature Communications (2024)

-

On-device phase engineering

Nature Materials (2024)

-

Recent Advances in In-Memory Computing: Exploring Memristor and Memtransistor Arrays with 2D Materials

Nano-Micro Letters (2024)

-

Comparative analysis of frictional behavior and mechanism of molybdenum ditelluride with different structures

Friction (2024)

-

Regulating the conductance of tungsten diselenide by oxygen plasma and improving its electrical stability by encapsulation

Nano Research (2024)