Abstract

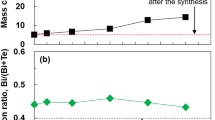

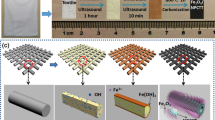

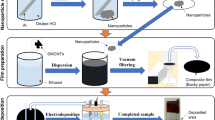

Inorganic chalcogenides are traditional high-performance thermoelectric materials. However, they suffer from intrinsic brittleness and it is very difficult to obtain materials with both high thermoelectric ability and good flexibility. Here, we report a flexible thermoelectric material comprising highly ordered Bi2Te3 nanocrystals anchored on a single-walled carbon nanotube (SWCNT) network, where a crystallographic relationship exists between the Bi2Te3 <\(\bar{1}2\bar{1}0\)> orientation and SWCNT bundle axis. This material has a power factor of ~1,600 μW m−1 K−2 at room temperature, decreasing to 1,100 μW m−1 K−2 at 473 K. With a low in-plane lattice thermal conductivity of 0.26 ± 0.03 W m−1 K−1, a maximum thermoelectric figure of merit (ZT) of 0.89 at room temperature is achieved, originating from a strong phonon scattering effect. The origin of the excellent flexibility and thermoelectric performance of the Bi2Te3–SWCNT material is attributed, by experimental and computational evidence, to its crystal orientation, interface and nanopore structure. Our results provide insight into the design and fabrication of high-performance flexible thermoelectric materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data supporting the findings of this study are available within the paper and its Supplementary Information. Additional data are available from the corresponding author upon request.

References

Bahk, J. H., Fang, H., Yazawa, K. & Shakouri, A. Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 3, 10362–10374 (2015).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Wan, C. et al. Flexible n-type thermoelectric materials by organic intercalation of layered transition metal dichalcogenide TiS2. Nat. Mater. 14, 622–627 (2015).

Alvarez-Quintana, J. Impact of the substrate on the efficiency of thin film thermoelectric technology. Appl. Therm. Eng. 84, 206–210 (2015).

Glatz, W., Schwyter, E., Durrer, L. & Hierold, C. Bi2Te3-based flexible micro thermoelectric generator with optimized design. J. Microelectromech. Syst. 18, 763–772 (2009).

Zhang, Q., Sun, Y., Xu, W. & Zhu, D. Organic thermoelectric materials: emerging green energy materials converting heat to electricity directly and efficiently. Adv. Mater. 26, 6829–6851 (2014).

Park, T., Park, C., Kim, B., Shin, H. & Kim, E. Flexible PEDOT electrodes with large thermoelectric power factors to generate electricity by the touch of fingertips. Energy Environ. Sci. 6, 788–792 (2013).

Hung, N. T., Nugraha, A. R. T., Hasdeo, E. H., Dresselhaus, M. S. & Saito, R. Diameter dependence of thermoelectric power of semiconducting carbon nanotubes. Phys. Rev. B 92, 165426(R) (2015).

Macleod, B. A. et al. Large n- and p-type thermoelectric power factors from doped semiconducting single-walled carbon nanotube thin films. Energy Environ. Sci. 10, 2168–2179 (2017).

Cho, C. et al. Outstanding low temperature thermoelectric power factor from completely organic thin films enabled by multidimensional conjugated nanomaterials. Adv. Energy Mater. 6, 1502168 (2016).

Wang, H. et al. Thermally driven large n-type voltage responses from hybrids of carbon nanotubes and poly(3,4-ethylenedioxythiophene) with tetrakis(dimethylamino)ethylene. Adv. Mater. 27, 6855–6861 (2015).

Zhao, W. et al. n-type carbon nanotubes/silver telluride nanohybrid buckypaper with a high-thermoelectric figure of merit. ACS Appl. Mater. Interfaces 6, 4940–4940 (2014).

Rowe, D. M. Thermoelectrics Handbook: Macro to Nano (CRC, Boca Raton, 2006).

Morrow, B. H. & Striolo, A. Morphology and diffusion mechanism of platinum nanoparticles on carbon nanotube bundles. J. Phys. Chem. C 111, 17905–17913 (2007).

Nunna, R. et al. Ultrahigh thermoelectric performance in Cu2Se-based hybrid materials with highly dispersed molecular CNTs. Energy Environ. Sci. 10, 1928–1935 (2017).

Kim, K. T. et al. The influence of CNTs on the thermoelectric properties of a CNT/Bi2Te3 composite. Carbon 52, 541–549 (2013).

Collins, P. G., Bradley, K., Ishigami, M. & Zettl, A. Extreme oxygen sensitivity of electronic properties of carbon nanotubes. Science 287, 1801–1804 (2000).

Lu, Z. et al. Fabrication of flexible thermoelectric thin film devices by inkjet printing. Small 10, 3551–3554 (2014).

Ashcroft, N. W. & Mermin, N. D. Solid State Physics (Pergamon Press, New York, 1976).

Chang, H. C., Chen, C. H. & Kuo, Y. K. Great enhancements in the thermoelectric power factor of BiSbTe nanostructured films with well-ordered interfaces. Nanoscale 5, 7017–7025 (2013).

Jin, Q. et al. Enhanced thermoelectric properties of bismuth telluride films with in-plane and out-of-plane well-ordered microstructures. Scripta Mater. 119, 33–37 (2016).

Tai, K., Lawrence, A., Harmer, M. P. & Dillon, S. J. Misorientation dependence of Al2O3 grain boundary thermal resistance. Appl. Phys. Lett. 102, 034101 (2013).

Zhang, Q. et al. Constructing nanoporous carbon nanotubes/Bi2Te3 composite for synchronous regulation of the electrical and thermal performances. J. Appl. Phys. 121, 055104 (2017).

Larson, P., Mahanti, S. D. & Kanatzidis, M. G. Electronic structure and transport of Bi2Te3 and BaBiTe3. Phys. Rev. B 61, 8162–8171 (2000).

Hu, L. P. et al. Shifting up the optimum figure of merit of p-type bismuth telluride-based thermoelectric materials for power generation by suppressing intrinsic conduction. NPG Asia Mater. 6, e88 (2014).

Bubnova, O. et al. Optimization of the thermoelectric figure of merit in the conducting polymer poly(3,4-ethylenedioxythiophene). Nat. Mater. 10, 429–433 (2011).

Kim, G. H., Shao, L., Zhang, K. & Pipe, K. P. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency. Nat. Mater. 12, 719–723 (2013).

Mehta, R. J. et al. A new class of doped nanobulk high-figure-of-merit thermoelectrics by scalable bottom-up assembly. Nat. Mater. 11, 233–240 (2012).

Lee, S. H. et al. Transparent and flexible organic semiconductor nanofilms with enhanced thermoelectric efficiency. J. Mater. Chem. A 2, 7288–7294 (2014).

Sun, Y. et al. Organic thermoelectric materials and devices based on p- and n-type poly(metal 1,1,2,2-ethenetetrathiolate)s. Adv. Mater. 24, 932–937 (2012).

Wan, C. et al. Flexible thermoelectric foil for wearable energy harvesting. Nano Energy 30, 840–845 (2016).

Yang, C. et al. Transparent flexible thermoelectric material based on non-toxic earth-abundant p-type copper iodide thin film. Nat. Commun. 8, 16076 (2017).

An, C. J. et al. Foldable thermoelectric materials: improvement of the thermoelectric performance of directly spun CNT webs by individual control of electrical and thermal conductivity. ACS Appl. Mater. Interfaces 8, 22142–22150 (2016).

Zhou, W. et al. High-performance and compact-designed flexible thermoelectric modules enabled by a reticulate carbon nanotube architecture. Nat. Commun. 8, 14886 (2017).

Sun, J. K., Ju, H. W. & Cho, B. J. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 7, 1959–1965 (2014).

Venkatasubramanian, R., Siivola, E., Colpitts, T. & O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413, 597–602 (2001).

Wang, Y. G., Qiu, B., McGaughey, A. J. H., Ruan, X. & Xu, X. Mode-wise thermal conductivity of bismuth telluride. J. Heat Transfer 135, 091102 (2013).

Avery, A. D. et al. Tailored semiconducting carbon nanotube networks with enhanced thermoelectric properties. Nat. Energy 1, 16033 (2016).

Nan, C. W., Liu, G., Lin, Y. & Li, M. Interface effect on thermal conductivity of carbon nanotube composites. Appl. Phys. Lett. 85, 3549–3551 (2004).

Huxtable, S. et al. Interfacial heat flow in carbon nanotube suspensions. Nat. Mater. 2, 731–734 (2003).

Suo, Z., Ma, E. Y., Gleskova, H. & Wagner, S. Mechanics of rollable and foldable film-on-foil electronics. Appl. Phys. Lett. 74, 1177–1179 (1999).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Yang, W. et al. Large-deformation and high-strength amorphous porous carbon nanospheres. Sci. Rep. 6, 24187 (2016).

Tang, D. M. et al. Nanomechanical cleavage of molybdenum disulphide atomic layers. Nat. Commun. 5, 3631 (2014).

Liu, C. & Cheng, H. M. Controlled growth of semiconducting and metallic single-wall carbon nanotubes. J. Am. Chem. Soc. 138, 6690–6698 (2016).

Sultan, R., Avery, A. D., Stiehl, G. & Zink, B. L. Thermal conductivity of micromachined low-stress silicon-nitride beams from 77 to 325 K. J. Appl. Phys. 105, 043501 (2009).

Qiu, B. & Ruan, X. Molecular dynamics simulations of lattice thermal conductivity of bismuth telluride using two-body interatomic potentials. Phys. Rev. B 80, 165203 (2009).

Güler, E. & Güler, M. Theoretical prediction of the structural, elastic, mechanical and phonon properties of bismuth telluride under pressure. Int. J. Mod. Phys. B 29, 1550222 (2015).

Yu, C., Zhang, G., Zhang, Y. W. & Peng, L. M. Strain engineering on the thermal conductivity and heat flux of thermoelectric Bi2Te3 nanofilm. Nano Energy 17, 104–110 (2015).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 177, 1–19 (1995).

Acknowledgements

The authors acknowledge financial support from the Ministry of Science and Technology of China (grants 2017YFA0700702 and 2016YFA0200101), the National Natural Science Foundation of China (grants 51402310, 51571193, 51625203, 51532008 and 51521091) and the Hundred Talents Program of the Chinese Academy of Sciences, the Equipment Development Project of the Chinese Academy of Sciences and Innovation Foundation of Institute of Metal Research.

Author information

Authors and Affiliations

Contributions

Q.J., S.J., Y.Z., K.T. and C.L. conceived and designed the experiments. Q.J. fabricated the hybrids and characterized their thermoelectric properties and microstructures. S.J. prepared the free-standing high-quality SWCNT scaffold and carried out its characterization. Y.Z. and J.T. fabricated the thermal conductivity test devices and measured the thermal conductivity of the hybrids and pure SWCNTs. D.W. and N.G. conducted the MD simulations. D.T. carried out the in situ TEM nanomechanical test. D.S., P.H., X.C. and X.J. proposed ideas for materials synthesis, characterization and simulation. Q.J., S.J., J.Q., K.T., C.L. and H.M.C. analysed the data and wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–9, Supplementary Figures 1–23, Supplementary Table 1, Supplementary References 1–54

Supplementary Video 1

Reversible bending of hybrid Bi2Te3 flexible film performed using a non-contact electrostatic approach

Rights and permissions

About this article

Cite this article

Jin, Q., Jiang, S., Zhao, Y. et al. Flexible layer-structured Bi2Te3 thermoelectric on a carbon nanotube scaffold. Nature Mater 18, 62–68 (2019). https://doi.org/10.1038/s41563-018-0217-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-018-0217-z

This article is cited by

-

Flexible temperature-pressure dual sensor based on 3D spiral thermoelectric Bi2Te3 films

Nature Communications (2024)

-

Fully inkjet-printed Ag2Se flexible thermoelectric devices for sustainable power generation

Nature Communications (2024)

-

Full-landscape selection rules of electrons and phonons and temperature-induced effects in 2D silicon and germanium allotropes

npj Computational Materials (2024)

-

Pulse irradiation synthesis of metal chalcogenides on flexible substrates for enhanced photothermoelectric performance

Nature Communications (2024)

-

On-Chip Micro Temperature Controllers Based on Freestanding Thermoelectric Nano Films for Low-Power Electronics

Nano-Micro Letters (2024)