Abstract

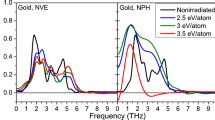

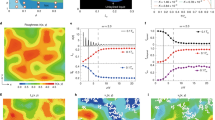

Pure metals can have ultrafast growth rates from their melts, such as a crystal of pure nickel that grows at a rate reaching 70 m s−1. These extraordinary growth rates suggest that metallic crystals might provide the next generation of phase-change materials. The huge crystal growth rates of metals are the consequence of kinetics without activated control, in sharp contrast to the prediction of the ‘classic’ theory of crystal growth. While the existence of barrierless growth kinetics is now well established in atomic melts, the physical explanation for the absence of an activation barrier to ordering remains unclear. It is something of a paradox that diffusion in the liquid metal is governed by thermal activation while the movement of the same atoms organizing into a crystal is not. Here we use computer simulations of crystallization in pure metals to explicitly resolve the origin of the barrierless growth kinetics.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data sets generated and/or analysed during the current study are available from the corresponding author upon reasonable request.

References

Langer, L. Instabilities and pattern-formation in crystal-growth. Rev. Mod. Phys. 52, 1–28 (1980).

Herlach, D. M. Containerless undercooling and solidification of pure metals. Ann. Rev. Mater. Sci. 21, 23–44 (1991).

Wilson, H. A. On the velocity of solidification and the viscosity of super-cooled liquids. Philos. Mag. 50, 238–250 (1900).

Frenkel, J. Kinetic Theory of Liquids (Oxford Univ. Press, Oxford, 1946).

Ediger, M., Harrowell, P. & Yu, L. Crystal growth kinetics exhibit a fragility-dependent decoupling from viscosity. J. Chem. Phys. 128, 034709 (2008).

Coriell, S. R. & Turnbull, D. Relative roles of heat transport and interface rearrangement rates in the rapid growth of crystals in undercooled melts. Acta Metall. 30, 2135–2139 (1982).

Broughton, J. Q., Gilmer, G. H. & Jackson, K. A. Crystallization rates of a Lennard-Jones liquid. Phys. Rev. Lett. 49, 1496–1500 (1982).

Mikheev, L. V. & Chernov, A. A. Mobility of a diffuse simple crystal melt interface. J. Cryst. Growth 112, 591–596 (1991).

Wu, K. A., Wang, C. H., Hoyt, J. J. & Karma, A. Ginzburg–Landau theory of the bcc-liquid interface kinetic coefficient. Phys. Rev. B 91, 014107 (2015).

Wu, K. A., Lin, S. C. & Karma, A. Two-mode Ginzburg–Landau theory of crystalline anisotropy for fcc-liquid interfaces. Phys. Rev. B 93, 054114 (2016).

Hoyt, J. J., Asta, M. & Karma, A. Atomistic and continuum modelling of dendritic solidification. Mater. Sci. Eng. R41, 121–163 (2003).

Ashkenazy, Y. & Averback, R. S. Atomic mechanisms controlling crystallization behaviour in metals at deep undercoolings. Europhys. Lett. 79, 26005 (2007). (1-6).

Ashkenazy, Y. & Averback, R. S. Kinetic stages in the crystallization of deeply undercooled body-centered-cubic and face-centered-cubic metals. Acta Mater. 58, 524–530 (2010).

Mendelev, M. I. Molecular dynamics simulation of solidification and devitrification in a one-component system, M. I. Mendelev. Modelling Simul. Mater. Sci. Eng. 20, 045014 (2012).

Stratt, R. M. The instantaneous normal-modes of liquids. Acc. Chem. Res. 28, 201–207 (1995).

Stillinger, F. H. & Weber, T. A. Hidden structure in liquids. Phys. Rev. A 25, 978–989 (1982).

Jackson, K. A. The interface kinetics of crystal growth processes. Interface Sci. 10, 159–169 (2002).

Lechner, W. & Dellago, C. Accurate determination of crystal structures based on averaged local bond order parameters. J. Chem. Phys. 129, 114707 (2008).

Mickel, W., Kapfer, S. C., Schröder-Turk, G. E. & Mecke, K. Shortcomings of the bond orientational order parameters for the analysis of disordered particulate matter. J. Chem. Phys. 138, 044501 (2013).

Press, W. H. et al. Numerical Recipes: The Art of Scientific Computing (Cambridge Univ., Cambridge, 1986).

Jacobsen, K. W., Norskov, J. K. & Puska, M. J. Interatomic interactions in the effective-medium theory. Phys. Rev. B 35, 7423–7442 (1987).

Foiles, S. M., Baskes, M. I. & Daw, M. S. Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B 33, 7983–7991 (1986).

Zhou, X. W., Johnson, R. A. & Wadley, H. N. G. Misfit-energy-increasing dislocations in vapor-deposited CoFe/NiFe multilayers. Phys. Rev. B 69, 144113 (2004).

Burke, E., Broughton, J. Q. & Gilmer, G. H. Crystallization of fcc (111) and (100) crystal‐melt interfaces: A comparison by molecular dynamics for the Lennard‐Jones system. J. Chem. Phys. 89, 1030–1041 (1988).

Plimpton, S. J. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117, 1–19 (1995).

Acknowledgements

We gratefully acknowledge programing assistance from C. Tang. This work has been supported by a Discovery grant from the Australian Research Council.

Author information

Authors and Affiliations

Contributions

G.S. carried out the majority of calculations, designed and prepared all of the figures, contributed to the writing of the paper, and was involved in assessing the outcomes of the various computational approaches. J.X. carried out a number of preliminary calculations. P.H. conceived the project, designed the overall computational strategy, assessed the outcomes and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables 1–3, Supplementary Figures 1–12 and Supplementary References 1–3

Rights and permissions

About this article

Cite this article

Sun, G., Xu, J. & Harrowell, P. The mechanism of the ultrafast crystal growth of pure metals from their melts. Nature Mater 17, 881–886 (2018). https://doi.org/10.1038/s41563-018-0174-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-018-0174-6

This article is cited by

-

Homogeneous Growth of 3C-SiC Crystal Surface at Solid–Liquid Interface and Its Competitive Relationship

JOM (2024)

-

Spatiotemporal observation of quantum crystallization of electrons

Nature Communications (2023)

-

Fast crystal growth of ice VII owing to the decoupling of translational and rotational ordering

Communications Physics (2023)

-

Microscopic ordering of supercooled water on the ice basal face

Communications Materials (2023)

-

Revealing the role of liquid preordering in crystallisation of supercooled liquids

Nature Communications (2022)