Abstract

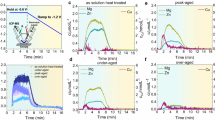

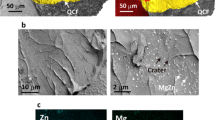

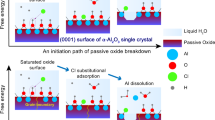

High-temperature alloys are crucial to many important technologies that underpin our civilization. All these materials rely on forming an external oxide layer (scale) for corrosion protection. Despite decades of research on oxide scale growth, many open questions remain, including the crucial role of the so-called reactive elements and water. Here, we reveal the hitherto unknown interplay between reactive elements and water during alumina scale growth, causing a metastable ‘messy’ nano-structured alumina layer to form. We propose that reactive-element-decorated, hydroxylated interfaces between alumina nanograins enable water to access an inner cathode in the bottom of the scale, at odds with the established scale growth scenario. As evidence, hydride-nanodomains and reactive element/hydrogen (deuterium) co-variation are observed in the alumina scale. The defect-rich alumina subsequently recrystallizes to form a protective scale. First-principles modelling is also performed to validate the RE effect. Our findings open up promising avenues in oxidation research and suggest ways to improve alloy properties.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Marriott, G. B., Merz, M., Nihoul, J. & Ward J. High Temperature Alloys – Their Exploitable Potential (Elsevier, London/New York, 1987).

Meetham, G. W. High-temperature materials – a general review. J. Mater. Sci. 26, 853–860 (1991).

Singhal, S. C. & Kendall, K. High-Temperature Solid Oxide Fuel Cells: Fundamentals, Design, and Applications (Elsevier, Oxford, 2003).

Shirzadi, A. & Jackson, S. Structural Alloys for Power Plants – Operational Challenges and High-Temperature Materials (Woodhead, Cambridge, 2014).

Kofstad, P. High Temperature Corrosion (Elsevier, London/New York, 1988).

Young, D. J. High Temperature Oxidation and Corrosion of Metals (Elsevier, Amsterdam, 2016).

Birks, N., Meier, G. H. & Pettit, F. S. Introduction to the High-Temperature Oxidation of Metals (Cambridge Univ. Press, Cambridge, 2006).

Task, M. N., Gleeson, B., Pettit, F. S. & Meier, G. H. The effect of microstructure on the type II hot corrosion of Ni-base MCrAlY alloys. Oxid. Met. 80, 125–146 (2013).

Heuer, A. H., Hovis, D. B., Smialek, J. L. & Gleeson, B. Alumina scale formation: a new perspective. J. Am. Ceram. Soc. 94, 2698–2698 (2011).

Gheno, T. et al. A thermodynamic approach to guide reactive element doping: Hf additions to NiCrAl. Oxid. Met. 87, 297–310 (2017).

Whittle, D. P. & Stringer, J. Improvements in high temperature oxidation resistance by additions of reactive elements or oxide dispersions. Philos. Trans. R. Soc. Lond. 295, 309–329 (1980).

Stringer, J. The reactive element effect in high-temperature corrosion. Mater. Sci. Eng. A 120, 129–137 (1989).

Pint, B. A. Optimization of reactive-element additions to improve oxidation performance of alumina-forming alloys. J. Ceram. Soc. 86, 686–695 (2003).

Naumenko, D., Pint, B. A. & Quadakkers, W. J. Current thoughts on reactive element effects in alumina-forming systems: In memory of John Stringer. Oxid. Met. 86, 1–43 (2016).

Wagner, C. The theory of the warm-up process. Z. Phys. Chem. 21B, 25–41 (1933).

Pint, B. A., Leibowitz, J. & Devan, J. H. The effect of an oxide dispersion on the critical Al content in Fe–Al alloys. Oxid. Met. 51, 181–97 (1999).

Saunders, S. R. J., Monteiro, M. & Rizzo, F. The oxidation behaviour of metals and alloys at high temperatures in atmospheres containing water vapour: A review. Prog. Mater. Sci. 53, 775–837 (2008).

Pint, B. A., Garratt-Reed, A. J. & Hobbs, L. W. The reactive element effect in commercial ODS FeCrAI alloys. Mater. High. Temp. 13, 3–16 (2016).

Pint, B. A., Martin, J. R. & Hobbs, L. W. 18O/SIMS characterization of the growth mechanism of doped and undoped α-Al2O3. Oxid. Met. 39, 167–195 (1993).

Pint, B. A., More, K. L. & Wright, I. G. The use of two reactive elements to optimize oxidation performance of alumina-forming alloys. Mater. High. Temp. 20, 375–386 (2003).

Ecer, G. M. & Meier, G. H. The effect of cerium on the oxidation of Ni-50Cr alloys. Oxid. Met. 13, 159–180 (1979).

Heuer, A. H. et al. The band structure of polycrystalline Al2O3 and its influence on transport phenomena. J. Am. Ceram. Soc. 99, 733–747 (2016).

Nakagawa, T. et al. Yttrium doping effect on oxygen grain boundary diffusion in α-Al2O3. Acta. Mater. 55, 6627–6633 (2007).

Cho, J., Wang, C. M., Chan, H. M., Rickman, J. M. & Harmer, P. Role of segregating dopants on the improved creep resistance of aluminum oxide. Acta Mater. 47, 4197–4207 (1999).

Yoshida, H., Ikuhara, Y. & Sakuma, T. High-temperature creep resistance in rare-earth-doped, fine-grained Al2O3. J. Mater. Res. 13, 2597–2601 (1998).

Young, D. J. et al. Oxidation kinetics of Y-doped FeCrAl-alloys in low and high pO2 gases. Mater. Corros. 61, 838–844 (2010).

Jönsson, Bo & Westerlund, A. Oxidation comparison of alumina-forming and chromia-forming commercial alloys at 1100 and 1200 °C. Oxid. Met. 88, 315–326 (2017).

Unocic, K. A., Yamamoto, Y. & Pint, B. A. Effect of Al and Cr content on air and steam oxidation of FeCrAl alloys and commercial APMT alloy. Oxid. Met. 87, 431–441 (2017).

Whittle, D. P., Boone, D. H. & Allam, I. M. Morphology of Al2O3 scales on doped Co–Cr–A1 coatings. Thin Solid Films 73, 359–364 (1980).

Young, D. J., Naumenko, D., Wessel, E., Singheiser, L. & Quadakkers, W. J. Effect of Zr additions on the oxidation kinetics of FeCrAlY alloys in low and high pO2 gases. Metall. Mater. Trans. A 42a, 1173–1183 (2011).

Allam, I. M., Whittle, D. P. & Stringer, J. The oxidation behavior of CoCrAI systems containing active element additions. Oxid. Met. 12, 35–66 (1978).

Hindam, H. & Whittle, D. P. Peg formation by short-circuit diffusion in Al2O3 scales containing oxide dispersions. J. Electro Chem. Soc. 129, 1147–1149 (1982).

Klöwer, J. Factors affecting the oxidation behaviour of thin Fe–Cr–Al foils. Part II: The effect of alloying elements: Overdoping. Mater. Corros. 51, 373–385 (2000).

Liu, F., Götlind, H., Svensson, J. E., Johansson, L. G. & Halvarsson, M. TEM investigation of the microstructure of the scale formed on a FeCrAlRE alloy at 900 °C: the effect of Y-rich RE particles. Oxid. Met. 74, 11–32 (2010).

Hou, P. Y. Impurity effects on alumina scale growth. J. Am. Ceram. Soc. 86, 660–668 (2003).

Pint, B. A. Experimental observations in support of the dynamic-segregation theory to explain the reactive-element effect. Oxid. Met. 45, 1–37 (1996).

Tatsumi, K., Muto, S., Ikeda, K. & Orimo, S. Chemical bonding of AlH3 hydride by Al-L2,3 electron energy-loss spectra and first-principles calculations. Materials 5, 566–574 (2012).

Jiang, N. & Spence, J. C. In situ EELS study of dehydration of Al(OH)3 by electron beam irradiation. Ultramicroscopy 111, 860–864 (2011).

Subanovic, M. et al. Blistering of MCrAlY-coatings in H2/H2O-atmospheres. Corros. Sci. 51, 446–450 (2009).

Johnson, J. R. T. & Panas, I. Hydrolysis on transition metal oxide clusters and the stabilities of M−O−M bridges. Inorg. Chem. 39, 3192–3204 (2000).

Johnson, J. R. T. & Panas, I. Reaction enthalpies for the hydrolysis of 3p, 4p and early 3d oxide bridges – how unique are the oligophosphates? Chem. Phys. Lett. 348, 433–439 (2001).

Lindgren, M. et al. Toward a comprehensive mechanistic understanding of hydrogen uptake in zirconium alloys by combining atom probe analysis with electronic structure calculations. ASTM Spec. Tech. Publ. 1543, 515–539 (2015).

Babic, V., Geers, C., Jönsson, B. & Panas, I. Fates of hydrogen during alumina growth below yttria nodules in FeCrAl (RE) at low partial pressures of water. Electrocatalysis 8, 565–576 (2017).

Lindgren, M. & Panas, I. Impact of additives on zirconium oxidation by water: Mechanistic insights from first principles. RSC Adv. 3, 21613–21619 (2013).

Lindgren, M. & Panas, I. Confinement dependence of electro-catalysts for hydrogen evolution from water splitting. Beilstein J. Nanotechnol. 5, 195–201 (2014).

Heuer, A. H. et al. On the growth of Al2O3 scales. Acta Mater. 61, 6670–6683 (2013).

Yang, M. Y. et al. Charge-dependent oxygen vacancy diffusion in Al2O3-based resistive-random-access-memories. Appl. Phys. Lett. 103, 093504 (2013).

Jönsson, B., Berglund, R., Magnusson, J., Henning, P. & Hättestrand, M. High temperature properties of a new powder metallurgical FeCrAl alloy. Mater. Sci. Forum 461-464, 455–462 (2004).

Mortazavi, N., Esmaily, M. & Halvarsson, M. The capability of transmission Kikuchi diffraction technique for characterizing nano-grained oxide scales formed on a FeCrAl stainless steel. Mater. Lett. 147, 42–45 (2015).

Rogerson, P. A. Statistical Methods for Geography – A Student’s Guide (SAGE, Los Angeles, CA, 2001).

Zhu, Z. H., Shutthanandan, V. & Engelhard, M. Surf. Interface Anal. 44, 232–237 (2012).

Thompson, K. et al. In situ site-specific specimen preparation for atom probe tomography. Ultramicroscopy 107, 131–139 (2007).

Hohenberg, P. & Kohn, W. Inhomogeneous electron gas. Phys. Rev. B 136, B864–B871 (1964).

Kohn, W. & Sham, L. J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 140, A1133–A1138 (1965).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 41, 7892–7895 (1990).

Clark, S. J. et al. First principles methods using CASTEP. Z. Krist. Krist. 220, 567–570 (2005).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H–Pu. J. Chem. Phys. 132, 154104–154119 (2010).

Materials Studio 6.0 (Accelrys Inc.).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Acknowledgements

Financial support from the Swedish Energy Agency is gratefully acknowledged. The authors are grateful to T. Helander of Sandvik Heating Technology for helpful advice during the research, M. Thuvander (Division for Materials Microstructure in the Department of Physics at Chalmers University of Technology) for interpretation of the APT results, and M. Norell (Division of Materials and Manufacture in the Department of Industrial and Materials Science at Chalmers University of Technology) for his help in conducting AES analysis. This research was conducted in the Swedish High Temperature Corrosion Centre (HTC) at Chalmers University of Technology, Gothenburg, Sweden.

Author information

Authors and Affiliations

Contributions

N.M. carried out the FIB/BIB/SEM/(S)TEM/EDX, TEM diffraction, EBSD, TKD and some parts of the statistical analyses. M.H. assisted with data interpretation. N.M. and M.H. developed and utilized the mTKD technique to characterize the microstructure of the ultra-fine grained (‘messy/thick’) oxide scale forming around RE particles. C.G. designed and carried out the controlled exposures. I.P. and V.B. carried out the density functional theory calculations. M.S. carried out some of the HR-(S)TEM and EELS analyses. N.M prepared FIB-prepared thin foils and cross marks and P.M. conducted the (nano/TOF)SIMS analyses. K.L. conducted the APT investigations. M.E. and B.J. performed some parts of the statistical analyses and M.E. also contributed in TOF-SIMS experiments. N.M., M.E., I.P., J.E.S. and L.G.J. wrote the manuscript. All the authors contributed to interpretation of the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Tables: S1–S2, Supplementary Figures: Figures S1–S21, Supplementary References 1–28

Supplementary Videos

Interplay of water and reactive elements

Rights and permissions

About this article

Cite this article

Mortazavi, N., Geers, C., Esmaily, M. et al. Interplay of water and reactive elements in oxidation of alumina-forming alloys. Nature Mater 17, 610–617 (2018). https://doi.org/10.1038/s41563-018-0105-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-018-0105-6

This article is cited by

-

Oxidation Behavior and Outward Diffusion of Al Along Oxide Grain Boundaries of FeCrAl Alloys Overdoped with Zr and Hf

High Temperature Corrosion of Materials (2024)

-

Oxidation Behaviors of Different Grades of Ferritic Heat Resistant Steels in High-Temperature Steam and Flue Gas Environments

Acta Metallurgica Sinica (English Letters) (2022)

-

A Comparison of the Oxidation and Nitridation Properties of Selected Chromia- and Alumina-Forming Alloys at 800 °C

Oxidation of Metals (2022)

-

Unusual layer-by-layer growth of epitaxial oxide islands during Cu oxidation

Nature Communications (2021)

-

Exploring the Effect of Silicon on the High Temperature Corrosion of Lean FeCrAl Alloys in Humid Air

Oxidation of Metals (2021)