Abstract

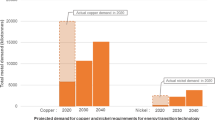

The climate change impacts of mining are often not fully accounted for, although the environmental impact of mineral extraction more generally is widely studied. Copper mining can serve as a case study to analyse the measurable pathways by which mining contributes to climate change through direct and indirect greenhouse gas emissions. For example, mining, processing and transportation require fuel and electricity, and the decomposition of carbonate minerals, employed to reduce environmental impacts, also releases carbon dioxide. Overall, we estimate that greenhouse gas emissions associated with primary mineral and metal production was equivalent to approximately 10% of the total global energy-related greenhouse gas emissions in 2018. For copper mining, fuel consumption increased by 130% and electricity consumption increased by 32% per unit of mined copper in Chile from 2001 to 2017, largely due to decreasing ore grade. This trend of increasing energy demand to produce the same quantity of some metals compounds the problems of increased metal demand due to the pressures of new technologies and increasing population. For green technologies to be implemented effectively, it is necessary that the mining industry and regulators accurately and transparently account for greenhouse gas emissions to implement mitigation strategies.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its supplementary information files.

References

Global Mitigation of Non-CO2 Greenhouse Gases 2010–2030 (US EPA, 2013).

Climate Smart Mining: Minerals for Climate Action (The World Bank Group, 2019); www.worldbank.org/en/topic/extractiveindustries/brief/climate-smart-mining-minerals-for-climate-action

Northey, S., Haque, N. & Mudd, G. Using sustainability reporting to assess the environmental footprint of copper mining. J. Clean. Prod. 40, 118–128 (2013).

Norgate, T. & Haque, N. Energy and greenhouse gas impacts of mining and mineral processing operations. J. Clean. Prod. 18, 266–274 (2010).

Koppelaar, R. H. E. M. & Koppelaar, H. The ore grade and depth influence on copper energy inputs. Biophys. Econ. Resour. Qual. 1, 11 (2016).

Olympic Dam Expansion: Draft Environmental Impact Statement 2009 Ch. 13 (BHP Billiton, 2009).

Global Energy & CO2 Status Report 2018 (OECD/IEA, 2018).

McLellan, B. C., Corder, G. D., Giurco, D. P. & Ishihara, K. N. Renewable energy in the minerals industry: a review of global potential. J. Clean. Prod. 32, 32–44 (2012).

Maennling, N. & Toledano, P. The Renewable Power of the Mine, Accelerating Renewable Energy Integration (Columbia University Center on Sustainable Investment, 2018).

The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries (IVL Swedish Environmental Research Institute, 2017).

Cabernard, L., Pfister, S. & Hellweg, S. A new method for analyzing sustainability performance of global supply chains and its application to material resources. Sci. Total Environ. 684, 164–177 (2019).

Life Cycle Inventory Study (World Steel Association, 2018).

Life Cycle Inventory Data and Environmental Metrics for the Primary Aluminium Industry: 2015 Data. Final (International Aluminium Institute, 2017).

World Energy Outlook 2016 (OECD/IEA, 2016).

CO2 Emissions from FuelCombustion: Overview (OECD/IEA, 2017).

SunSHIFT Pty Ltd Renewable Energy in the Australian Mining Sector Australian Government White Paper (Australian Renewable Energy Agency, 2017).

Goswami, T. & Brent, G. Blasting approaches to decrease greenhouse gas emissions in mining. AusIMM Bull. 44–47 (February 2016).

Mudd, G. M. An analysis of historic production trends in Australian base metal mining. Ore Geol. Rev. 32, 227–261 (2007).

Zheng, C., Jiang, B., Xue, S., Chen, Z. & Li, H. Coalbed methane emissions and drainage methods in underground mining for mining safety and environmental benefits: a review. Process Saf. Environ. Prot. 127, 103–124 (2019).

Shahbazi, M., Najafi, M. & Marji, M. F. On the mitigating environmental aspects of a vertical well in underground coal gasification method. Mitig. Adapt. Strateg. Glob. Change 24, 373–398 (2019).

Diesel Emissions Management in Underground Coal Mines, Best Practices and Recommendations (Department of Natural Resources, Mines and Energy, 2019).

Hao, C., Cheng, Y., Wang, L., Liu, H. & Shang, Z. A novel technology for enhancing coalbed methane extraction: hydraulic cavitating assisted fracturing. J. Nat. Gas Sci. Eng. 72, 103040 (2019).

Liu, Z., Cheng, Y., Wang, Y., Wang, L. & Li, W. Experimental investigation of CO2 injection into coal seam reservoir at in-situ stress conditions for enhanced coalbed methane recovery. Fuel 236, 709–716 (2019).

Quarton, C. J. & Samsatli, S. The value of hydrogen and carbon capture, storage and utilisation in decarbonising energy: insights from integrated value chain optimisation. Appl. Energy 257, 113936 (2020).

Míguez, J. L., Porteiro, J., Pérez-Orozco, R., Patiño, D. & Gómez, M. Á. Biological systems for CCS: patent review as a criterion for technological development. Appl. Energy 257, 114032 (2020).

Bobicki, E. R., Liu, Q. & Xu, Z. Mineral carbon storage in pre-treated ultramafic ores. Miner. Eng. 70, 43–54 (2015).

Sanna, A., Uibu, M., Caramanna, G., Kuusik, R. & Maroto-Valer, M. M. A review of mineral carbonation technologies to sequester CO2. Chem. Soc. Rev. 43, 8049–8080 (2014).

Azadi, M., Edraki, M., Farhang, F. & Ahn, J. Opportunities for mineral carbonation in Australia’s mining industry. Sustainability 11, 1250 (2019).

Bobicki, E. R., Liu, Q., Xu, Z. & Zeng, H. Carbon capture and storage using alkaline industrial wastes. Prog. Energy Combust. Sci. 38, 302–320 (2012).

Sanna, A., Dri, M., Hall, M. R. & Maroto-Valer, M. Waste materials for carbon capture and storage by mineralisation (CCSM) — a UK perspective. Appl. Energy 99, 545–554 (2012).

Arnaiz del Pozo, C., Cloete, S., Hendrik Cloete, J., Jiménez Álvaro, Á. & Amini, S. The oxygen production pre-combustion (OPPC) IGCC plant for efficient power production with CO2 capture. Energy Convers. Manag. 201, 112109 (2019).

Jaszczur, M., Dudek, M., Rosen, M. A. & Kolenda, Z. An analysis of integration of a power plant with a lignite superheated steam drying unit. J. Clean. Prod. 243, 118635 (2020).

Wang, T. & Stiegel, G. Integrated Gasification Combined Cycle (IGCC) Technologies (Woodhead Publishing, 2016).

Scala, F. Fluidized Bed Technologies for Near-Zero Emission Combustion and Gasification (Woodhead Publishing, 2013).

Lishchuk, V., Koch, P. H., Ghorbani, Y. & Butcher, A. R. Towards integrated geometallurgical approach: critical review of current practices and future trends. Miner. Eng. 145, 106072 (2020).

Zhang, M. M., Li, H. X., Andrade, M., Xuan, W. & Correa, A. Feasible bioprocessing technologies for low-grade iron ores. Miner. Metall. Process. 32, 78–87 (2015).

Behera, S. K. & Mulaba-Bafubiandi, A. F. Microbes assisted mineral flotation a future prospective for mineral processing industries: a review. Miner. Process. Extr. Metall. Rev. 38, 96–105 (2017).

Yang, Y., Chu, M., Hao, C. & Zhou, L. Preparation of low silicon ultra clean coal by flotation pretreatment followed by alkali-acid leaching combined process. Energy Sources A https://doi.org/10.1080/15567036.2019.1665149 (2019).

Rahman, M., Pudasainee, D. & Gupta, R. Review on chemical upgrading of coal: production processes, potential applications and recent developments. Fuel Process. Technol. 158, 35–56 (2017).

Clarkson, L. & Williams, D. Critical review of tailings dam monitoring best practice. Int. J. Min. Reclam. Environ. 34, 119–148 (2019).

Park, I. et al. A review of recent strategies for acid mine drainage prevention and mine tailings recycling. Chemosphere 219, 588–606 (2019).

Sun, W. et al. An extensive review on restoration technologies for mining tailings. Environ. Sci. Pollut. Res. Int. 25, 33911–33925 (2018).

Qi, C. & Fourie, A. Cemented paste backfill for mineral tailings management: review and future perspectives. Miner. Eng. 144, 106025 (2019).

Edraki, M. et al. Designing mine tailings for better environmental, social and economic outcomes: a review of alternative approaches. J. Clean. Prod. 84, 411–420 (2014).

Botelho, A. B. Jr, Dreisinger, D. B. & Espinosa, D. C. R. A review of nickel, copper, and cobalt recovery by chelating ion exchange resins from mining processes and mining tailings. Min. Metall. Explor. 36, 199–213 (2019).

Peelman, S., Kooijman, D., Sietsma, J. & Yang, Y. Hydrometallurgical recovery of rare earth elements from mine tailings and WEEE. J. Sustain. Metall. 4, 367–377 (2018).

Naidu, G. et al. A critical review on remediation, reuse, and resource recovery from acid mine drainage. Environ. Pollut. 247, 1110–1124 (2019).

Report on Rare Earth Elements from Coal and Coal Byproducts (US Department of Energy, 2017).

Falagán, C., Grail, B. M. & Johnson, D. B. New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 106, 71–78 (2017).

Peelman, S., Sun, Z. H. I., Sietsma, J. & Yang, Y. in Rare Earths Industry: Technological, Economic, and Environmental Implications (eds Borges De Lima, I. & Filho, W. L.) 319–334 (Elsevier, 2017).

Allwood, J. M. & Cullen, J. M. Sustainable Materials with Both Eyes Open (UIT Cambridge, 2012).

Mang, K. C. & Ntushelo, K. Phytoextraction and phytostabilisation approaches of heavy metal remediation in acid mine drainage with case studies: a review. Appl. Ecol. Environ. Res. 17, 6129–6149 (2019).

IPCC Climate Change 2014: Mitigation of Climate Change (eds Edenhofer, O. et al.) (Cambridge Univ. Press, 2014).

Meijer, K. et al. ULCOS: ultra-low CO2 steelmaking. Ironmak. Steelmak. 36, 249–251 (2009).

ULCOS = ultra low CO2 steelmaking. Bouwen met Staal https://www.sustainableinsteel.eu/p/532/ulcos_=_ultra_low_co2_steel_making.html (2020).

Jahanshahi, S. et al. Development of low-emission integrated steelmaking process. J. Sustain. Metall. 1, 94–114 (2015).

Ballantyne, G. R. & Powell, M. S. Benchmarking comminution energy consumption for the processing of copper and gold ores. Miner. Eng. 65, 109–114 (2014).

Nuss, P. & Eckelman, M. J. Life cycle assessment of metals: a scientific synthesis. PLoS ONE 9, e101298 (2014).

Mineral Commodity Summaries (US Department of the Interior, US Geological Survey, 2019).

Brown, T. et al. World Mineral Production 2013–2017 (British Geological Survey, 2019).

“Anuario De Estadistacas del Cobre y Otros Minerales”, Yearbook: Copper and other Mineral Statistics, 1998–2017 (Comision Chilena del Cobre, Ministerio de Mineria, Gobierno de Chile, 2017).

“Anuario De Estadistacas del Cobre y Otros Minerales”, Yearbook: Copper and other Mineral Statistics, 1993–2012 (Comision Chilena del Cobre, Ministerio de Mineria, Gobierno de Chile, 2012).

Acknowledgements

We acknowledge the financial support secured by J.-W. Ahn through her grant on the National Strategic Project-Carbon Upcycling of the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (MSIT), the Ministry of Environment (ME) and the Ministry of Trade, Industry and Energy (MOTIE) (2017M3D8A2084752), and the Sustainable Minerals Institute, University of Queensland for funding for this study. We also thank P. Nuss for providing the data used to recalculate the contribution of life-cycle stages to global warming potential that is shown in the Supplementary Information.

Author information

Authors and Affiliations

Contributions

M.A., S.H.A. and M.E. conceived the study. S.A.N. synthesized data from multiple sources and incorporated that into M.A.’s schematic model of impacts. M.A., S.H.A. and S.A.N. wrote the final narrative of the article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Primary Handling Editor: Rebecca Neely

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1. Estimated greenhouse gas emissions of primary mined material production in 2018.

Estimated greenhouse gas emissions of primary mined material production in 2018. Excludes energy carriers (coal, uranium) and mineral aggregates. Estimated based upon data from Nuss and Eckelman (2014)58 and 2018 production data derived from U.S. Geological Survey (2019)59 and the British Geological Survey60. 95% confidence intervals are shown. See notes in electronic supplementary Table S1 for derivation of the “Total” confidence interval.

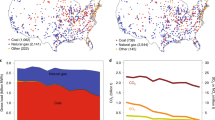

Extended Data Fig. 4. Scope 1 (direct, on-site) and scope 2 (indirect, electricity generation) greenhouse gas emissions associated with copper mines.

Scope 1 (direct, on-site) and scope 2 (indirect, electricity generation) greenhouse gas emissions associated with copper mines. Error bars show the minimum and maximum annual greenhouse gas emissions from each mine. Data updated from Northey et al. (2013)3 to increase industry coverage. Economic allocation updated to account for copper concentrate and anode treatment costs (TC) and refining costs (RC).

Supplementary information

Supplementary Table 1

Estimated greenhouse gas (GHG) emissions associated with the 2018 production of primary materials derived from mining, excluding energy carriers (coal and uranium) and mineral aggregates.

Source data

Source Data Extended Data Fig. 4

Average annual scope 1 and scope 2 greenhouse gas emissions, and annual average production rates of individual copper mines, derived from data collected by Northey et al.3 with some updates.

Rights and permissions

About this article

Cite this article

Azadi, M., Northey, S.A., Ali, S.H. et al. Transparency on greenhouse gas emissions from mining to enable climate change mitigation. Nat. Geosci. 13, 100–104 (2020). https://doi.org/10.1038/s41561-020-0531-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41561-020-0531-3

This article is cited by

-

Constructing soils for climate-smart mining

Communications Earth & Environment (2023)

-

Tracing metal footprints via global renewable power value chains

Nature Communications (2023)

-

Win-Win: Anthropogenic circularity for metal criticality and carbon neutrality

Frontiers of Environmental Science & Engineering (2023)

-

Environmental, Social, and Governance Considerations in Production Scheduling Optimisation for Sublevel Stoping Mining Operations: a Review of Relevant Works and Future Directions

Mining, Metallurgy & Exploration (2023)

-

On the security of graphite supply

Mineralogy and Petrology (2023)