Abstract

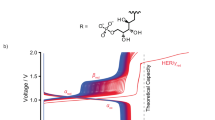

Aqueous organic redox flow batteries offer a safe and potentially inexpensive solution to the problem of storing massive amounts of electricity produced from intermittent renewables. However, molecular decomposition represents a major barrier to commercialization—and although structural modifications can improve stability, it comes at the expense of synthetic cost and molecular weight. Now, utilizing 2,6-dihydroxy-anthraquinone (DHAQ) without further structural modification, we demonstrate that the regeneration of the original molecule after decomposition represents a viable route to achieve low-cost, long-lifetime aqueous organic redox flow batteries. We used in situ (online) NMR and electron paramagnetic resonance, and complementary electrochemical analyses to show that the decomposition compound 2,6-dihydroxy-anthrone (DHA) and its tautomer, 2,6-dihydroxy-anthranol (DHAL) can be recomposed to DHAQ electrochemically through two steps: oxidation of DHA(L)2− to the dimer (DHA)24− by one-electron transfer followed by oxidation of (DHA)24− to DHAQ2− by three-electron transfer per DHAQ molecule. This electrochemical regeneration process also rejuvenates the positive electrolyte—rebalancing the states of charge of both electrolytes without introducing extra ions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data in the main paper and its Supplementary Information are available from https://doi.org/10.6084/m9.figshare.19612128. Source Data are provided with this paper.

References

Huskinson, B. T. et al. A metal-free organic–inorganic aqueous flow battery. Nature 505, 195–198 (2014).

Lin, K. et al. Alkaline quinone flow battery. Science 349, 1529–1532 (2015).

Kwabi, D. G., Ji, Y. & Aziz, M. J. Electrolyte lifetime in aqueous organic redox flow batteries: a critical review. Chem. Rev. 120, 6467 (2020).

Beh, E. S. et al. A neutral pH aqueous organic–organometallic redox flow battery with extremely high capacity retention. ACS Energy Lett. 2, 639–644 (2017).

Kwabi, D. G. et al. Alkaline quinone flow battery with long lifetime at pH 12. Joule 2, 1894–1906 (2018).

Ji, Y. et al. A phosphonate-functionalized quinone redox flow battery at near-neutral pH with record capacity retention rate. Adv. Energy Mater. 9, 1900039 (2019).

Wu, M. et al. Extremely stable anthraquinone negolytes synthesized from common precursors. Chem 6, 1432–1442 (2020).

Jin, S. et al. Near neutral pH redox flow battery with low permeability and long-lifetime phosphonated viologen active species. Adv. Energy Mater. 10, 2000100 (2020).

Pang, S., Wang, X., Wang, P. & Ji, Y. Biomimetic amino acid functionalized phenazine flow batteries with long lifetime at near-neutral pH. Angew. Chem. Int. Ed. 60, 5289 (2021).

Xu, J., Pang, S., Wang, X., Wang, P. & Ji, Y. Ultrastable aqueous phenazine flow batteries with high capacity operated at elevated temperatures. Joule 5, 2437–2449 (2021).

Gregory, T. D., Perry, M. L. & Albertus, P. Cost and price projections of synthetic active materials for redox flow batteries. J. Power Sources 499, 229965 (2021).

Goulet, M.-A. et al. Extending the lifetime of organic flow batteries via redox state management. J. Am. Chem. Soc. 141, 8014–8019 (2019).

Zhao, E. W. et al. In situ NMR metrology reveals reaction mechanisms in redox flow batteries. Nature 579, 224–228 (2020).

Zhao, E. W. et al. Coupled In situ NMR and EPR studies reveal the electron transfer rate and electrolyte decomposition in redox flow batteries. J. Am. Chem. Soc. 143, 1885–1895 (2021).

Jing, Y. et al. In situ electrosynthesis of anthraquinone electrolytes in aqueous flow batteries. Green Chem. 22, 6084–6092 (2020).

Goulet, M. A. et al. Correction to “Extending the lifetime of organic flow batteries via redox state management.”. J. Am. Chem. Soc. 143, 14019 (2021).

McCann, G. M., McDonnell, C. M., Magris, L. & O’Ferrall, R. A. M. Enol–keto tautomerism of 9-anthrol and hydrolysis of its methyl ether. J. Chem. Soc. 2, 784–795 (2002).

Zhao, E. W., Shellard, E. J. K., Klusener, P. A. A. & Grey, C. P. In situ bulk magnetization measurements reveal the state of charge of redox flow batteries. Chem. Commun. 58, 1342–1345 (2022).

Mitra, A., Seaton, P. J., Assarpour, R. A. & Williamson, T. Unprecedented concentration dependent chemical shift variation in 1H-NMR studies: a caveat in the investigations of molecular recognition and structure elucidation. Tetrahedron 54, 15489 (1998).

Yao, Y., Lei, J., Shi, Y., Ai, F. & Lu, Y.-C. Assessment methods and performance metrics for redox flow batteries. Nat. Energy 6, 582–588 (2021).

Fain, V. Y., Zaitsev, B. E. & Ryabov, M. A. Anthraquinones tautomerism: VII. Hydroxy-substituted anthraquinones. Russ. J. Org. Chem. 43, 1460 (2007).

Páez, T., Martínez-Cuezva, A., Palma, J. & Ventosa, E. Revisiting the cycling stability of ferrocyanide in alkaline media for redox flow batteries. J. Power Sources 471, 228453 (2020).

Páez, T., Martínez-Cuezva, A., Marcilla, R., Palma, J. & Ventosa, E. Mitigating capacity fading in aqueous organic redox flow batteries through a simple electrochemical charge balancing protocol. J. Power Sources 512, 230516 (2021).

Dieterich, V. et al. Estimating the cost of organic battery active materials: a case study on anthraquinone disulfonic acid. Translational Mater. Res. 5, 034001 (2018).

Goulet, M.-A. & Aziz, M. J. Flow battery molecular reactant stability determined by symmetric cell cycling methods. J. Electrochem. Soc. 165, A1466 (2018).

Wang, F. et al. Stable tetrasubstituted quinone redox reservoir for enhancing decoupled hydrogen and oxygen evolution. ACS Energy Lett. 6, 1533–1539 (2021).

Brushett, F. R., Aziz, M. J. & Rodby, K. E. On lifetime and cost of redox-active organics for aqueous flow batteries. ACS Energy Lett. 5, 879–884 (2020).

Shaw, A. A. S., Christophe, Dauphin, Jean-Francois & Ancian, Bernard Artifact-free PFG-enhanced double-quantum-filtered COSY experiments. J. Magn. Reson. A 120, 110–115 (1996).

Acknowledgements

Research at Harvard was supported by the US National Science Foundation through grant no. CBET-1914543, by a US DOE award no. DE-AC05-76RL01830 through PNNL subcontract no. 535264, and by a grant from the Massachusetts Clean Energy Center. Research at University of Cambridge was supported by Centre of Advanced Materials for Integrated Energy Systems (CAM-IES), via EPSRC grant no. EP/P007767/1 and Shell. E.W.Z acknowledges the STFC Futures Early Career Award, grant no. ST/R006873/1. The funders had no role in study design, data collection and analysis, decision to publish or preparation of the manuscript. We acknowledge P.A.A. Klusener from Shell for useful discussions. We thank D. A. Pollack, and K. Amini for useful discussions.

Author information

Authors and Affiliations

Contributions

M.J.A., R.G.G., C.P.G. supervised the project. Y.J., E.W.Z., M.-A.G., M.J.A., R.G.G. and C.P.G. conceived the idea. Y.J., E.W.Z. and M.-A.G. designed the experiment. E.W.Z. performed the in situ NMR and EPR experiments and analysis. Y.J. performed the ex situ NMR experiments and analysis. M.-A.G., M.B., E.M.F. and Y.J. performed DHA(L), ADS elctrochemical oxidation, and DHAQ and AQDS cell cycling. M.B. performed three-electrode cell tests. M.-A.G., S.J. and Y.J. performed postmortem CV, NMR, LC-NMR experiments and a cell cycling. M.B. performed t-cell cycling with periodic aeration. E.J. made intellectual contributions. M.W. and Y.J. synthesized DHA(L) and ADS, respectively. All authors contributed to the discussion of the project. Y.J., E.W.Z, M.-A.G., M.J.A., C.P.G. wrote the manuscript with input from all co-authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Chemistry thanks Antoni Forner-Cuenca, Yi-Chun Lu and Edgar Ventosa for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Electrochemical oxidation of DHA(L)2−.

a & b, Linear sweep voltammetry (LSV) and the 1st order differential of 10 mM DHA(L)2− in 1 M KOH supporting electrolyte indicating a peak for dimerization reaction around −260 mV vs. SHE and a second oxidation reaction starting around +300 mV vs. SHE, before being overshadowed by oxygen evolution at around +650 mV vs. SHE. We consider the potentials (−0.32 V, + 0.57 V) at the 1st order differential peak current as the approximations of oxidation potentials of [DHA(L)2− to (DHA)24−] and [(DHA)24− to DHAQ2−]. The 1st order differential was from the LSV curve obtained at 20 mV/s. c & d, Cyclic voltammograms of 10 mM pure DHA in 1 M KOH before and after a + 110 mV vs. SHE 10-minute potential hold with a highly porous Zoltek PXFB working electrode. New peaks match those of dimer observed in a previous study[2]; cyclic voltammograms of 10 mM pure DHA in 1 M KOH before and after +410 mV vs. SHE 10-minute potential hold with a highly porous working electrode. New peaks match those of DHAQ2−. e, Potential hold of 0.1 M DHA(L)2− in 1.2 M KOH negolyte in full cell containing a 2X excess of 50 mM K4[Fe(CN)6] and 50 mM K3[Fe(CN)6] posolyte. The Y-axis represent the number of coulombs extracted from DHA(L)2− electrolyte over electrochemical oxidation. f, 1H NMR spectra of DHA(L)2− negolyte before and after 30-min hold at different cell voltages.

Extended Data Fig. 2 DHAQ regeneration hysteresis.

a, Repeated application of electrochemical regeneration of negolyte in battery composed of 6 mL 100 mM DHAQ2− in the negolyte and a mixture of 35 mL 100 mM K4[Fe(CN)6] and 50 mM K3[Fe(CN)6] in the posolyte. Galvanostatic cycling at ±50 mA/cm2 with potential holds at 1.0 and 1.5 V and current cutoff of ±1 mA/cm2 during normal cycles. Every 50 cycles an additional discharge step at −2 mA/cm2 until potential limit and a further hold until current decreases to −0.2 mA/cm2. b, Aggregate data for 3 cell replicates with varying potential limits for regeneration treatment indicating partial dependence of recovery ratio on recovery from prior treatment.

Extended Data Fig. 3 Energetic cost of electrochemical regeneration in Fig. 4a and c.

a, Integrated areas above and below 0 V of the cell discharge voltage profile with electrochemical regeneration in Fig. 4c. b, Integrated areas above and below 0 V of the cell discharge voltage profiles with 13 regeneration processes in Fig. 4a. The area ratio (%) represents the percentage of discharged electrical energy that is subsequently used for regeneration during a single discharge process, reflecting the energetic cost. It is, on average, 1.30%. Note that the electrochemical regeneration step is not performed in every cycle, but rather once every 51 cycles. Relative to the total electricity discharged during 51 cycles, the energetic cost for regeneration is only 0.025%.

Extended Data Fig. 4 DHAQ concentration tracking.

a, Cycling of battery composed of 5 mL 100 mM DHAQ2− in the negolyte and 20 mL of a mixture of 100 mM K4[Fe(CN)6] and 50 mM K3[Fe(CN)6] in the posolyte. Galvanostatic cycling at ±50 mA/cm2 with potential holds at 1.0 V and 1.5 V and current cutoff of ±1 mA/cm2 during normal cycles. Three electrochemical oxidation treatments before an aliquot was removed from negolyte reservoir on day 10 for concentration measurement. b, Cyclic voltammograms of 20 mM DHAQ2− in 1 M KOH on glassy carbon working electrode. Pristine DHAQ2− electrolyte measured before and after dilution by 10% to verify resolution of measurement. Cycled DHAQ2− data refers to an aliquot removed from negolyte in part a, after ~25% capacity had been lost. No change in peak current suggests DHAQ2− concentration has not changed during cycling after regeneration treatment. c & d, Comparison of DHAQ2− NMR peak integral with respect to DMSO internal standard. Similarity of the peak integral of cycled electrolyte which had lost ~25% of capacity to that of pristine DHAQ2− does not indicate overall decrease in DHAQ2− concentration. An aliquot of the cycled DHAQ2− was taken for 1H NMR measurement when ~25% capacity was lost on day 10.5. e, LC−MS result of the cycled DHAQ2−. The peak at 10.8–11.1 min is from DHAQ2−, which is the sole compound detected. Other peaks are from background, which can be ignored.

Supplementary information

Supplementary Information

Supplementary Figs. 1–15 and Discussion after some captions.

Source data

Source Data Fig. 1

Unprocessed excel data for DHAQ regeneration hysteresis.

Source Data Fig. 2

Unprocessed in situ NMR data.

Source Data Fig. 3

Unprocessed in situ NMR data.

Source Data Fig. 4

Unprocessed excel and.csv data for flow battery tests.

Rights and permissions

About this article

Cite this article

Jing, Y., Zhao, E.W., Goulet, MA. et al. In situ electrochemical recomposition of decomposed redox-active species in aqueous organic flow batteries. Nat. Chem. 14, 1103–1109 (2022). https://doi.org/10.1038/s41557-022-00967-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41557-022-00967-4

This article is cited by

-

Understanding capacity fade in organic redox-flow batteries by combining spectroscopy with statistical inference techniques

Nature Communications (2023)

-

Modular dimerization of organic radicals for stable and dense flow battery catholyte

Nature Energy (2023)

-

Developing in situ electron paramagnetic resonance characterization for understanding electron transfer of rechargeable batteries

Nano Research (2023)

-

Designing modern aqueous batteries

Nature Reviews Materials (2022)

-

Bringing redox organics back to life

Nature Chemistry (2022)