Abstract

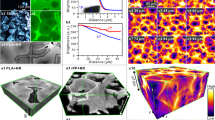

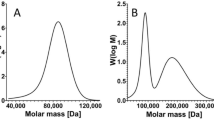

Water-insoluble micropatterned films were prepared from poly(vinyl alcohol) (PVA) (or ethylene-vinyl alcohol copolymer (EVOH)) and poly(methacrylic acid) (poly(MAAc)). The carboxy groups in poly(MAAc) underwent dehydration reactions with the hydroxy groups in the vinyl alcohol units during heating at 135 °C, which resulted in crosslinking with ester bonds and formation of a polymeric network in the micropatterned films. The surface structures of the micropatterned films and the shapes of the peeled microplastics in the supernatant were measured after decomposition in an oxidizing environment, after ultrasonic irradiation, and with both. The results revealed that the micropatterns could be peeled off from the films after they were subjected to appropriate decomposition conditions and maintained their patterned shapes.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Alimba CG, Faggio C. Microplastics in the marine environment: current trends in environmental pollution and mechanisms of toxicological profile. Environ Toxicol Pharmacol. 2019;68:61–74.

Du S, Zhu R, Cai Y, Xu N, Yap P-S, Zhang Y, et al. Environmental fate and impacts of microplastics in aquatic ecosystems: a review. RSC Adv. 2021;11:15762–84.

López APA, Trilleras J, Arana VA, Garcia-Alzate LS, Grande-Tovar CD. Atmospheric microplastics: exposure, toxicity, and detrimental health effects. RSC Adv. 2023;13:7468–89.

Watt E, Picard M, Maldonado B, Abdelwahab MA, Mielewski DF, Drzal LT, et al. Ocean plastics: environmental implications and potential routes for mitigation – a perspective. RSC Adv. 2021;11:21447–62.

Wei X-F, Capezza AJ, Cui Y, Li L, Hakonen A, Liu B, et al. Millions of microplastics released from a biodegradable polymer during biodegradation/enzymatic hydrolysis. Water Res. 2022;211:118068.

Song YK, Hong SH, Eo S, Han GM, Shim WJ. Rapid production of micro- and nanoplastics by fragmentation of expanded polystyrene exposed to sunlight. Environ Sci Technol. 2020;54:11191–200.

Kiran BR, Kopperi H, Mohan SV. Micro/nano-plastics occurrence, identification, risk analysis and mitigation: challenges and perspectives. Rev Environ Sci Biotechnol. 2022;21:169–203.

Lu Y, Zhang Y, Deng Y, Jiang W, Zhao Y, Geng J, et al. Uptake and accumulation of polystyrene microplastics in zebrafish (Danio rerio) and toxic effects in liver. Environ Sci Technol. 2016;50:4054–60.

Choi D, Hwang J, Bang J, Han S, Kim T, Oh Y, et al. In vitro toxicity from a physical perspective of polyethylene microplastics based on statistical curvature change analysis. Sci Total Environ. 2021;752:142242.

del Campo A, Arzt E. Fabrication approaches for generating complex micro- and nanopatterns on polymeric surfaces. Chem Rev. 2008;108:911–45.

Yabu H, Saito Y, Nakamichi Y, Hirai Y, Fujinami S, Nakajima K, et al. Self-assembled porous templates allow pattern transfer to poly(dimethyl siloxane) sheets through surface wrinkling. Polym J. 2012;44:573–8.

Rodríguez-Hernández J. Wrinkled interfaces: taking advantage of surface instabilities to pattern polymer surfaces. Prog Polym Sci. 2015;42:1–4.

Lehner R, Weder C, Petri-Fink A, Rothen-Rutishauser B. Emergence of nanoplastic in the environment and possible impact on human health. Environ Sci Technol. 2019;53:1748–65.

Hamad D, Mehrvar M, Dhib R. Experimental study of polyvinyl alcohol degradation in aqueous solution by UV/H2O2 process. Polym Degrad Stab. 2014;103:75–82.

Su Y, Li M, Gao Q, Li X, Ju A, Lu Y, et al. Degradation and kinetic modeling of polyvinyl alcohol in aqueous solutions by a H2O2/Mn(II) system. Fibers Polym. 2017;18:2269–77.

Lin Y-P, Dhib R, Mehrvar M. Recent advances in dynamic modeling and process control of PVA degradation by biological and advanced oxidation processes: a review on trends and advances. Environments. 2021;8:116.

Hakuto N, Saito K, Kirihara M, Kotsuchibashi Y. Preparation of cross-linked poly(vinyl alcohol) films from copolymers with benzoxaborole and carboxylic acid groups, and their degradability in an oxidizing environment. Polym Chem. 2020;11:2469–74.

Fujimoto K, Yamawaki-Ogata A, Narita Y, Kotsuchibashi Y. Fabrication of cationic poly(vinyl alcohol) films cross-linked using copolymers containing quaternary ammonium cations, benzoxaborole, and carboxy groups. ACS Omega. 2021;6:17531–44.

Kobayashi D, Uchida H, Ishibane M, Kurita E, Kirihara M, Kotsuchibashi Y. Fabrication of thermally cross-linked poly(methacrylic acid)-based sponges with nanolayered structures and their degradation. Polym J. 2023;55:163–70.

Momose T, Takeuchi K, Uchida H, Saito S, Nakada K, Mutsuga M, et al. Fabrication of pH-responsive poly(vinyl alcohol)-based microfibers crosslinked with copolymers containing benzoxaborole and carboxy groups. Polymer. 2023;283:126236.

Fujimoto K, Saito A, Kotsuchibashi Y. Cicada-wing-inspired nanopillar hydrogels consisting of poly(vinyl alcohol) and poly(methacrylic acid) for capturing bacteria through their flexibility and wide range of motion. ACS Macro Lett. 2022;11:727–32.

Li A, Si Y, Wang X, Jia X, Guo X, Xu Y. Poly(vinyl alcohol) nanocrystal-assisted hydrogels with high toughness and elastic modulus for three-dimensional printing. ACS Appl Nano Mater. 2019;2:707–15.

Uslu I, Daştan H, Altaş A, Yayli A, Atakol O, Aksu ML. Preparation and characterization of PVA/boron polymer produced by an electrospinning technique. e-Polym. 2007;7:133.

He M, Zhang B, Dou Y, Yin G, Cui Y, Chen X. Fabrication and characterization of electrospun feather keratin/poly(vinyl alcohol) composite nanofibers. RSC Adv. 2017;7:9854–61.

Kirihara M, Okada T, Sugiyama Y, Akiyoshi M, Matsunaga T, Kimura Y. Sodium hypochlorite pentahydrate crystals(NaOCl·5H2O): a convenient and environmentally benign oxidant for organic synthesis. Org Process Res Dev. 2017;21:1925–37.

Kirihara M, Osugi R, Saito K, Adachi K, Yamazaki K, Matsushima R, et al. Sodium hypochlorite pentahydrate as a reagent for the cleavage of trans-cyclic glycols. J Org Chem. 2019;84:8330–6.

van Dijk-Wolthuis WNE, Hoogeboom JAM, van Steenbergen MJ, Tsang SKY, Hennink WE. Degradation and release behavior of dextran-based hydrogels. Macromolecules. 1997;30:4639–45.

Hiemstra C, van der Aa LJ, Zhong Z, Dijkstra PJ, Feijen J. Novel in situ forming, degradable dextran hydrogels by Michael addition chemistry: synthesis, rheology, and degradation. Macromolecules. 2007;40:1165–73.

Park KM, Shin YM, Joung YK, Shin H, Park KD. In situ forming hydrogels based on tyramine conjugated 4-arm-PPO-PEO via enzymatic oxidative reaction. Biomacromolecules. 2010;11:706–12.

Brandl F, Hammer N, Blunk T, Tessmar J, Goepferich A. Biodegradable hydrogels for time-controlled release of tethered peptides or proteins. Biomacromolecules. 2010;11:496–504.

Kim MS, Chang H, Zheng L, Yan Q, Pfleger BF, Klier J, et al. A review of biodegradable plastics: chemistry, applications, properties, and future research needs. Chem Rev. 2023;123:9915–39.

Alvarez VA, Ruseckaite RA, Vázquez A. Kinetic analysis of thermal degradation in poly(ethylene–vinyl alcohol) copolymers. J Appl Polym Sci. 2003;90:3157–63.

Lagaron JM, Giménez E, Saura JJ. Degradation of high barrier ethylene–vinyl alcohol copolymer under mild thermal-oxidative conditions studied by thermal analysis and infrared spectroscopy. Polym Int. 2001;50:635–42.

Carlsson DJ, Chmela S, Wiles DM. The oxidative degradation of ethylene/vinyl alcohol copolymers. Polym Degrad Stab. 1991;31:255–67.

Mejía GAI, López OBL, Sierra L. Biodegradation of poly(vinyl alcohol-co-ethylene) with the fungus Phanerochaete chrysosporium. Mater Res Innov. 2001;4:148–54.

Mayumi J, Nakagawa A, Matsuhisa K, Takahashi H, Takahashi H, Iijima M. Material design and manufacture of a new thermoplastic polyester elastomer. Polym J. 2008;40:1–9.

Ayer MA, Verde-Sesto E, Liu CH, Weder C, Lattuada M, Simon YC. Modeling ultrasound-induced molecular weight decrease of polymers with multiple scissile azo-mechanophores. Polym Chem. 2021;12:4093–103.

Mohod AV, Gogate PR. Ultrasonic degradation of polymers: effect of operating parameters and intensification using additives for carboxymethyl cellulose (CMC) and polyvinyl alcohol (PVA). Ultrason Sonochem. 2011;18:727–34.

Acknowledgements

This work was partially supported by the Technical Research Aid Projects 2019 (JFE 21st Century Foundation) and Research Grant 2021 (Iketani Science and Technology Foundation). We are grateful to Nippon Light Metal Co., Ltd, for providing NaClO·5H2O. We are grateful to Dr. Take-aki Koizumi and Dr. Naohiro Sugasawa of the Advanced Instrumental Analysis Center at the Shizuoka Institute of Science and Technology for their technical support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Uchida, H., Uchiyama, W., Kurita, E. et al. Micropatterned microplastic generation via degradation of polymeric films with micropatterned structures. Polym J (2024). https://doi.org/10.1038/s41428-024-00897-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41428-024-00897-7