Abstract

As porous polymer materials with continuous epoxy skeletons and pores, epoxy monoliths are used as column fillers in HPLC, separators in lithium-ion batteries, and precursor polymers for monolith adhesion and co-continuous network polymer fabrication. Due to their unique mechanical properties and fracture behavior, epoxy monoliths can incur large deformation and are different from the bulk thermoset of epoxy resins that exhibit hard and brittle features. In this study, we prepared an epoxy monolith using 2,2’-bis(4’-glycidyloxaphenyl)propane (BADGE) and tripropylene glycol diglycidyl ether (TPGD) as epoxy resins, 4,4’-methylenebis(cyclohexylamine) (BACM) as a crosslinker, and poly(ethylene glycol) (PEG) as a porogen, and TPGD-induced effects on the pore structure and properties of the obtained monoliths were investigated. To clarify the relationship between the pore structure and the mechanical properties of the monolith, scanning electron microscopy (SEM) observations and tensile and compression tests were performed. In addition, X-ray CT imaging nondestructively revealed a change in the inner porous structure of the monolith after a large deformation occurred under various compression conditions. We clarified the effects of the TPGD addition on the monolith structure and the mechanical properties with tensile and compressive deformation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Petrie EM. Handbook of adhesives and sealants. 2nd ed. New York: McGrow-Hill; 2007.

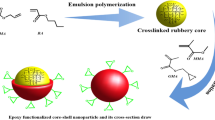

Sprenger S. Epoxy resins modified with elastomers and surface-modified silica nanoparticles. Polymer. 2013;54:4790–7.

Jin F-L, Li X, Park S-J. Synthesis and application of epoxy resins: a review. J Ind Eng Chem. 2015;29:1–11.

Mashouf Roudsari G, Mohanty AK, Misra M. Green approaches to engineer tough biobased epoxies: a review. ACS Sustain Chem Eng. 2017;5:9528–41.

Kumar S, Krishnan S, Samal SK, Mohanty S, Nayak SK. Toughening of petroleum based (DGEBA) epoxy resins with various renewable resources based flexible chains for high performance applications: a review. Ind Eng Chem Res. 2018;57:2711–26.

Ahmadi Z. Nanostructured epoxy adhesives: a review. Prog Org Coat. 2019;135:449–53.

Wei H, Xia J, Zhou W, Zhou L, Hussain G, Li Q, et al. Adhesion and cohesion of epoxy-based industrial composite coatings. Comp B. 2020;193:108035.

Shundo A, Yamamoto S, Tanaka K. Network formation and physical properties of epoxy resins for future practical applications. JACS Au. 2022;2:1522.

Kinloch AJ. Mechanics and mechanisms of fracture of thermosetting epoxy polymers. Adv Polym Sci. 1985;72:45–67.

Chikhi N, Fellahi S, Bakar M. Modification of epoxy resin using reactive liquid (ATBN) rubber. Eur Polym J. 2001;38:251–64.

Kishi H, Matsuda S, Imade J, Shimoda Y, Nakagawa T, Furukawa Y. The effects of the toughening mechanism and the molecular weights between cross-links on the fatigue resistance of epoxy polymer blends. Polymer. 2021;223:123712.

Tanaka N, Kobayashi H, Nakanishi K, Minakuchi H, Ishizuka N. Monolithic LC columns. Anal Chem. 2001;73:420A–9A.

Aoki H, Tanaka N, Kubo T, Hosoya K. Polymer-based monolithic columns in capillary format tailored by using controlled in situ polymerization. J Sep Sci. 2009;32:341–58.

Nguyen AM, Irgum K. Epoxy-based monoliths. A novel hydrophilic separation material for liquid chromatography of biomolecules. Chem Mater. 2006;18:6308–15.

Tsujioka N, Ishizuka N, Tanaka N, Kubo T, Hosoya K. Well-controlled 3D skeletal epoxy-based monoliths obtained by polymerization induced phase separation. J Polym Sci Part A Polym Chem. 2008;46:3272–81.

Sakakibara K, Kagata H, Ishizuka N, Sato T, Tsujii Y. Fabrication of surface skinless membranes of epoxy resin-based mesoporous monoliths toward advanced separators for lithium-ion batteries. J Mater Chem A. 2017;5:6866–73.

Uehara F, Matsumoto A. Metal-resin bonding mediated by epoxy monolith layer. Appl Adhes Sci. 2016;4:18.

Sugimoto Y, Nishimura Y, Uehara F, Matsumoto A. Dissimilar materials bonding using epoxy monolith. ACS Omega. 2018;3:7532–41.

Sakata N, Takeda Y, Kotera S, Suzuki Y, Matsumoto A. Interfacial structure control and three-dimensional X-ray imaging of an epoxy monolith bonding system with surface modification. Langmuir. 2020;36:10923–32.

Tominaga R, Nishimura Y, Suzuki Y, Takeda Y, Kotera M, Matsumoto A. Co-continuous network polymes using epoxy monolith for the design of tough materials. Sci Rep. 2021;11:1431.

Tominaga R, Takeda Y, Kotera M, Suzuki Y, Matsumoto A. Non-destructive observation of internal structures of epoxy monolith and co-continuous network polymer using X-ray CT imaging for elucidation of their unique mechanical features and fracture mechanism. Polymer. 2022;263:125433.

Maire E, Withers PJ. Quantitative X-ray tomography. Inter Mater Rev. 2014;59:1–43.

Garcea SC, Wang Y, Withers PJ. X-ray computed tomography of polymer composites. Comp Sci Technol. 2018;156:305–19.

Mi Y, Zhou W, Li Q, Zhang D, Zhang R, Ma G, et al. Detailed exploration of structure formation of an epoxy-based monolith with three-dimensional bicontinuous structure. RSC Adv. 2015;5:55419.

Nakanishi K, Tanaka N. Sol-gel with phase separation. Hierarchically porous materials optimized for high-performance liquid chromatography separations. Acc Chem Res. 2007;40:863–73.

Svec F. Porous polymer monoliths: amazingly wide variety of techniques enabling their preparation. J Chromatogr A 2010;1217:902–24.

Watanabe M, Takeda Y, Maruyama T, Ikeda J, Kawai M, Mitsumata T. Chain structure in a cross-linked polyurethane magnetic elastomer under a magnetic field. Int J Mol Sci. 2019;20:2879.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aragishi, K., Takeda, Y., Suzuki, Y. et al. Study on the deformation and fracture of epoxy monoliths through mechanical tensile and compressive tests and X-ray CT imaging. Polym J 56, 529–540 (2024). https://doi.org/10.1038/s41428-023-00872-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00872-8