Abstract

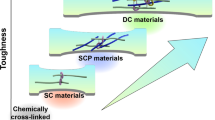

Graft polymers are gaining increasing interest because of their unique architectural characteristics. We recently reported a novel type of depolymerizable graft polymer based on poly(trans-cyclobutane fused cyclooctene), in an effort to address the trade-off between depolymerizability and controlled grafting-through polymerization. In this work, we examine the thermal, mechanical, and morphological properties of a graft copolymer thermoplastic material prepared by copolymerizing poly(L-lactide) and margaric acid-based macromonomers. A copolymerization kinetics study reveals that the two macromonomers are incorporated almost randomly and that the domain spacing measured from small-angle X-ray scattering is consistent with the random distribution. An investigation of the crystallization behavior suggests that proper thermal treatment is required to maximize, or to even observe crystallinity. The physical states of the soft and hard domains, whether melt, glassy, or semicrystalline, significantly impact the tensile properties of the resulting copolymer materials. Finally, the rheological properties and morphological features are discussed.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Duan Y, Thunga M, Schlegel R, Schneider K, Rettler E, Weidisch R, et al. Morphology and deformation mechanisms and tensile properties of tetrafunctional multigraft copolymers. Macromolecules. 2009;42:4155–64.

Fournier L, Rivera Mirabal DM, Hillmyer MA. Toward sustainable elastomers from the grafting-through polymerization of lactone-containing polyester macromonomers. Macromolecules. 2022;55:1003–14.

Zhang J, Schneiderman DK, Li T, Hillmyer MA, Bates FS. Design of graft block polymer thermoplastics. Macromolecules. 2016;49:9108–18.

Vatankhah-Varnosfaderani M, Daniel WFM, Everhart MH, Pandya AA, Liang H, Matyjaszewski K, et al. Mimicking biological stress-strain behaviour with synthetic elastomers. Nature. 2017;549:497–501.

Vatankhah-Varnosfaderani M, Keith AN, Cong Y, Liang H, Rosenthal M, Sztucki M, et al. Chameleon-like elastomers with molecularly encoded strain-adaptive stiffening and coloration. Science. 2018;359:1509–13.

Zhang D, Dashtimoghadam E, Fahimipour F, Hu X, Li Q, Bersenev EA, et al. Tissue-adaptive materials with independently regulated modulus and transition temperature. Adv Mater 2020;32:1–11.

Xiong H, Zhang L, Wu Q, Zhang H, Peng Y, Zhao L, et al. A strain-adaptive, self-healing, breathable and perceptive bottle-brush material inspired by skin. J Mater Chem A. 2020;8:24645–54.

Dashtimoghadam E, Maw M, Keith AN, Vashahi F, Kempkes V, Gordievskaya YD, et al. Super-soft, firm, and strong elastomers toward replication of tissue viscoelastic response. Mater Horiz 2022;9:3022–30.

Sveinbjörnsson BR, Weitekamp RA, Miyake GM, Xia Y, Atwater HA, Grubbs RH. Rapid self-assembly of brush block copolymers to photonic crystals. Proc Natl Acad Sci USA. 2012;109:14332–6.

Guo T, Yu X, Zhao Y, Yuan X, Li J, Ren L. Structure memory photonic crystals prepared by hierarchical self-assembly of semicrystalline bottlebrush block copolymers. Macromolecules. 2020;53:3602–10.

Zhao TH, Jacucci G, Chen X, Song DP, Vignolini S, Parker RM. Angular-independent photonic pigments via the controlled micellization of amphiphilic bottlebrush block copolymers. Adv Mater 2020;32:1–8.

Zhang J, Li T, Mannion AM, Schneiderman DK, Hillmyer MA, Bates FS. Tough and sustainable graft block copolymer thermoplastics. ACS Macro Lett. 2016;5:407–12.

Haugan IN, Maher MJ, Chang AB, Lin TP, Grubbs RH, Hillmyer MA, et al. Consequences of grafting density on the linear viscoelastic behavior of graft polymers. ACS Macro Lett. 2018;7:525–30.

Leng X, Wei Z, Bian Y, Ren Y, Wang Y, Wang Q, et al. Rheological properties and crystallization behavior of comb-like graft poly(L-lactide): influences of graft length and graft density. RSC Adv. 2016;6:30320–9.

Hu M, Xia Y, McKenna GB, Kornfield JA, Grubbs RH. Linear rheological response of a series of densely branched brush polymers. Macromolecules. 2011;44:6935–43.

López-Barrón CR, Tsou AH, Younker JM, Norman AI, Schaefer JJ, Hagadorn JR, et al. Microstructure of crystallizable α-olefin molecular bottlebrushes: isotactic and atactic poly(1-octadecene). Macromolecules. 2018;51:872–83.

Xiang M, Lyu D, Qin Y, Chen R, Liu L, Men Y. Microstructure of bottlebrush poly(n-alkyl methacrylate)s beyond side chain packing. Polymer. 2020;210:123034.

López-Barrón CR, Hagadorn JR, Mattler SJ, Throckmorton JA. Syndiotactic α-olefin molecular bottlebrushes: crystallization, melting, and hierarchical microstructure. Macromolecules. 2020;53:3778–88.

Wang Z, Yoon S, Wang J. Breaking the paradox between grafting-through and depolymerization to access recyclable graft polymers. Macromolecules. 2022;55:9249–56.

Zografos A, Lynd NA, Bates FS, Hillmyer MA. Impact of macromonomer molar mass and feed composition on branch distributions in model graft copolymerizations. ACS Macro Lett. 2021;10:1622–8.

Zhao C, Wu D, Huang N, Zhao H. Crystallization and thermal properties of PLLA comb polymer. J Polym Sci B Polym Phys. 2008;46:589–98.

Neugebauer D, Theis M, Pakula T, Wegner G, Matyjaszewski K. Densely heterografted brush macromolecules with crystallizable grafts. Synthesis and bulk properties. Macromolecules. 2006;39:584–93.

Fischer EW, Sterzel HJ, Wegner G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid-Z Z Für Polym. 1973;251:980–90.

Xia Y, Olsen BD, Kornfield JA, Grubbs RH. Efficient synthesis of narrowly dispersed brush copolymers and study of their assemblies: the importance of side chain arrangement. J Am Chem Soc. 2009;131:18525–32.

Javni I, Bilić O, Bilić N, Petrović ZS, Eastwood EA, Zhang F, et al. Thermoplastic polyurethanes with controlled morphology based on methylenediphenyldiisocyanate/isosorbide/butanediol hard segments. Polym Int. 2015;64:1607–16.

Heeley, EL, Billimoria, K, Parsons, N, Figiel, Ł, Keating, EM, Cafolla, CT, et al. In-situ uniaxial drawing of poly-L-lactic acid (PLLA): following the crystalline morphology development using time-resolved SAXS/WAXS. Polymer. 193;2020, https://doi.org/10.1016/j.polymer.2020.122353.

Acknowledgements

This work was supported by the University of Akron and the National Science Foundation under Grant No. DMR-2042494. We thank Prof. James M. Eagan for glovebox access and Prof. Kevin Cavicchi for helpful discussion. We acknowledge access to the X-ray scattering facility at the Advanced Materials and Liquid Crystal Institute (AMLCI) at Kent State University, which was financially supported by the National Science Foundation (DMR-2017845), the State of Ohio (The Ohio Department of Higher Education Action Fund), and Kent State University. We thank the Ohio Board of Regents and the National Science Foundation (CHE-0341701 and DMR-0414599) for the funds used to purchase the NMR instrument used in this work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Foster, M.D. & Wang, J. Thermal, mechanical, and morphological studies of a depolymerizable graft copolymer thermoplastic. Polym J 55, 1171–1178 (2023). https://doi.org/10.1038/s41428-023-00826-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00826-0