Abstract

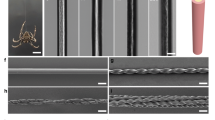

Recently, Bombyx mori silk fibroin (SF) has played a crucial role in biomedical applications. However, due to the highly ordered β-sheet structure in SF, the flexibility of SF fiber is relatively poor, which limits its application in biomaterials. In this paper, a SF-polyurethane (PU) composite fiber was prepared to increase the flexibility of SF fiber. PU prepared by a reaction of mainly a copolymer of polyhexamethylene carbonate diol and polycaprolactone diol (PHC/PCL-diol) with 4,4’-diphenylmethane diisocyanate (MDI) was used. First, the 1H and 13C solution NMR peaks of PU were assigned to groups in detail. In addition, the 13C solid-state NMR spectrum of PU was analyzed. Then, regenerated SF-PU composite fiber was prepared by the wet spinning method. The elongation at break of the fiber increased by 1.3-1.8 times compared with that of regenerated SF fiber, although there was no significant increase in tensile strength. The main reason for the increased flexibility of the SF-PU composite fiber is the increase in the fraction of random coils in SF, which was clearly observed by 13C solid-state NMR.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Asakura T, Kaplan DL Silk production and processing. In: Arutzen CJ (ed). Encyclopedia of Agricultural Science. Academic Press: New York, 1994, pp 1–11.

O’Brien JP, Fahnestock SR, Termonia Y, Gardner KH. Nylons from nature: synthetic analogs to spider silk. Adv Mater. 1998;10:1185–95.

Fu C, Shao Z, Fritz V. Animal silks: their structures, properties and artificial production. Chem Commun. 2009;37:6515–29.

Vepari C, Kaplan DL. Silk as a biomaterial. Prog Polym Sci. 2007;32:991–1007.

Asakura T, Miller T. Biotechnology of Silk. Springer Netherlands: Dordrecht, 2014 https://doi.org/10.1007/978-94-007-7119-2.

Koh L-D, Cheng Y, Teng C-P, Khin Y-W, Loh X-J, Tee S-Y, et al. Structures, mechanical properties and applications of silk fibroin materials. Prog Polym Sci. 2015;46:86–110.

Kundu B, Kurland NE, Bano S, Patra C, Engel FB, Yadavalli VK, et al. Silk proteins for biomedical applications: bioengineering perspectives. Prog Polym Sci. 2014;39:251–67.

Pereira RFP, Silva MM, de Zea Bermudez V. Bombyx mori silk fibers: an outstanding family of materials. Macromol Mater Eng. 2015;300:1171–98.

Thurber AE, Omenetto FG, Kaplan DL. In vivo bioresponses to silk proteins. Biomaterials. 2015;71:145–57.

Holland C, Numata K, Rnjak-Kovacina J, Seib FP. The biomedical use of silk: past, present, future. Adv Healthcare Mater. 2019;8:1800465.

Tamara AB, DeSimone E, Scheibel T. Biomedical applications of recombinant silk‐based materials. Adv Mater. 2018;30:1704636.

Asakura T, Tanaka T, Tanaka R. Advanced silk fibroin biomaterials and application to small-diameter silk vascular grafts. ACS Biomater Sci Eng. 2019;5:5561–77.

Zhou F, Zhang X, Cai D, Li J, Mu Q, Zhang W, et al. Silk fibroin-chondroitin sulfate scaffold with immuno-inhibition property for articular cartilage repair. Acta Biomater. 2017;63:64–75.

Du J, Zhu T, Yu H, Zhu J, Sun C, Wang J, et al. Potential applications of three-dimensional structure of silk fibroin/poly(ester-urethane) urea nanofibrous scaffold in heart valve tissue engineering. Appl Surf Sci. 2018;447:269–78.

Nguyen TP, Nguyen QV, Nguyen V-H, Le T-H, Huynh VQN, Vo D-VN, et al. Silk fibroin-based biomaterials for biomedical applications: a review. Polym (Basel). 2019;11:1933.

Chattopadhyay DK, Raju KVSN. Structural engineering of polyurethane coatings for high performance applications. Prog Polym Sci. 2007;32:352–418.

Madbouly SA, Otaigbe JU. Recent advances in synthesis, characterization and rheological properties of polyurethanes and POSS/polyurethane nanocomposites dispersions and films. Prog Polym Sci. 2009;34:1283–332.

Fang J, Ye S-H, Shankarraman V, Huang Y, Mo X, Wagner WR. Biodegradable poly(ester urethane)urea elastomers with variable amino content for subsequent functionalization with phosphorylcholine. Acta Biomater. 2014;10:4639–49.

Ercolani E, Del Gaudio C, Bianco A. Vascular tissue engineering of small-diameter blood vessels: reviewing the electrospinning approach. J Tissue Eng Regen Med. 2015;9:861–88.

Adipurnama I, Yang M-C, Ciach T, Butruk-Raszeja B. Surface modification and endothelialization of polyurethane for vascular tissue engineering applications: a review. Biomater Sci. 2017;5:22–37.

Zhu T, Yu K, Bhutto MA, Guo X, Shen W, Wang J, et al. Synthesis of RGD-peptide modified poly(ester-urethane) urea electrospun nanofibers as a potential application for vascular tissue engineering. Chem Eng J. 2017;315:177–90.

Król P, Uram Ł, Król B, Pielichowska K, Sochacka-Piętal M, Walczak M. Synthesis and property of polyurethane elastomer for biomedical applications based on nonaromatic isocyanates, polyesters, and ethylene glycol. Colloid Polym Sci. 2020;298:1077–93.

Iizuka E, Sawada K, Motojima K. Physical properties of fibroin-blended polyurethane films. J Sericultural Sci Jpn. 1998;67:217–21.

Liu X-Y, Zhang C-C, Xu W-L, Ouyang C. Controlled release of heparin from blended polyurethane and silk fibroin film. Mater Lett. 2009;63:263–5.

Tao Y, Yan Y, Xu W. Physical characteristics and properties of waterborne polyurethane materials reinforced with silk fibroin powder. J Polym Sci Part B Polym Phys. 2010;48:940–50.

Hardy JG, Scheibel TR. Composite materials based on silk proteins. Prog Polym Sci. 2010;35:1093–115.

Nakazawa Y, Asano A, Nakazawa CT, Tsukatani T, Asakura T. Structural characterization of silk-polyurethane composite material for biomaterials using solid-state NMR. Polym J. 2012;44:802–7.

Park H, Gong M-S, Park J-H, Moon S-I, Wall IB, Kim H-W, et al. Silk fibroin-polyurethane blends: physical properties and effect of silk fibroin content on viscoelasticity, biocompatibility and myoblast differentiation. Acta Biomater. 2013;9:8962–71.

Suzuki Y, Nakazawa Y, Derya A, Komatsu T, Miyazaki K, Yamazaki S, et al. Development of silk/polyurethane small-diameter vascular graft by electrospinning. Seikei-Kakou. 2013;25:181–7.

Yu E, Mi H-Y, Zhang J, Thomson JA, Turng L-S. Development of biomimetic thermoplastic polyurethane/fibroin small-diameter vascular grafts via a novel electrospinning approach. J Biomed Mater Res Part A. 2018;106:985–96.

Shimada K, Higuchi A, Kubo R, Murakami T, Nakazawa Y, Tanaka R. The effect of a silk Fibroin/Polyurethane blend patch on rat Vessels. Organogenesis. 2017;13:115–24.

Nakazawa CT, Higuchi A, Asano A, Kameda T, Aytemiz D, Nakazawa Y. Solid-state NMR studies for the development of non-woven biomaterials based on silk fibroin and polyurethane. Polym J. 2017;49:583–6.

Venkatesan H, Hu J, Chen J. Bioinspired fabrication of polyurethane/regenerated silk fibroin composite fibres with tubuliform silk-like flat stress–strain behaviour. Polym (Basel). 2018;10:333.

Aytemiz D, Fukuda Y, Higuchi A, Asano A, Nakazawa CT, Kameda T, et al. Compatibility evaluation of non-woven sheet composite of silk fibroin and polyurethane in the wet state. Polym (Basel). 2018;10:874.

Li F, Tan Y, Chen L, Jing L, Wu D, Wang T. High fibre-volume silkworm cocoon composites with strong structure bonded by polyurethane elastomer for high toughness. Compos Part A Appl Sci Manuf. 2019;125:105553.

van Uden S, Catto V, Perotto G, Athanassiou A, Redaelli ACL, Greco FG, et al. Electrospun fibroin/polyurethane hybrid meshes: manufacturing, characterization, and potentialities as substrates for haemodialysis arteriovenous grafts. J Biomed Mater Res Part B Appl Biomater. 2019;107:807–17.

Riboldi SA, Tozzi M, Bagardi M, Ravasio G, Cigalino G, Crippa L, et al. A novel hybrid silk fibroin/polyurethane arteriovenous graft for hemodialysis: proof‐of‐concept animal study in an ovine model. Adv Health Mater. 2020;9:2000794.

Asakura T, Ibe Y, Jono T, Matsuda H, Kuwabara N, Naito A. Structural investigations of polyurethane and silk-polyurethane composite fiber studied by 13C solid-state NMR spectroscopy. J Appl Polym Sci. 2021;138:51178.

Eceiza A, de la Caba K, Kortaberria G, Gabilondo N, Marieta C, Corcuera MA, et al. Influence of molecular weight and chemical structure of soft segment in reaction kinetics of polycarbonate diols with 4,4′-diphenylmethane diisocyanate. Eur Polym J. 2005;41:3051–9.

Eceiza A, Martin MD, de la Caba K, Kortaberria G, Gabilondo N, Corcuera MA, et al. Thermoplastic polyurethane elastomers based on polycarbonate diols with different soft segment molecular weight and chemical structure: mechanical and thermal properties. Polym Eng Sci. 2008;48:297–306.

Fernández-d’Arlas B, Alonso-Varona A, Palomares T, Corcuera MA, Eceiza A. Studies on the morphology, properties and biocompatibility of aliphatic diisocyanate-polycarbonate polyurethanes. Polym Degrad Stab. 2015;122:153–60.

Asakura T, Saotome T, Aytemiz D, Shimokawatoko H, Yagi T, Fukayama T, et al. Characterization of silk sponge in the wet state using 13C solid state NMR for development of a porous silk vascular graft with small diameter. RSC Adv. 2014;4:4427–34.

Zhao C, Yao J, Masuda H, Raghuvansh K, Asakura T. Structural characterization and artificial fiber formation of Bombyx mori silk fibroin in hexafluoro-iso-propanol solvent system. Biopolymers. 2003;69:253–9.

Zhu ZH, Ohgo K, Asakura T. Preparation and characterization of regenerated Bombyx mori silk fibroin fiber with high strength. Express Polym Lett. 2008;2:885–9.

Zhu Z, Ohgo K, Watanabe R, Takezawa T, Asakura T. Preparation and characterization of regenerated Bombyx mori silk fibroin fiber containing recombinant cell-adhesive proteins; Nonwoven fiber and monofilament. J Appl Polym Sci. 2008;109:2956–63.

Zhu Z, Kikuchi Y, Kojima K, Tamura T, Kuwabara N, Nakamura T, et al. Mechanical properties of regenerated bombyx mori silk fibers and recombinant silk fibers produced by transgenic silkworms. J Biomater Sci Polym Ed. 2010;21:395–411.

Asakura T, Ibe Y, Jono T, Naito A. Structure and dynamics of biodegradable polyurethane-silk fibroin composite materials in the dry and hydrated states studied using 13C solid-state NMR spectroscopy. Polym Degrad Stab. 2021;190:109645.

Tasei Y, Nishimura A, Suzuki YY, Sato TK, Sugahara J, Asakura T. NMR investigation about heterogeneous structure and dynamics of recombinant spider silk in the dry and hydrated states. Macromolecules. 2017;50:8117–28.

Asakura T, Endo M, Fukuhara R, Tasei Y. 13C NMR characterization of hydrated 13C labeled Bombyx mori silk fibroin sponges prepared using glycerin, poly(ethylene glycol diglycidyl ether) and poly(ethylene glycol) as porogens. J Mater Chem B. 2017;5:2152–60.

Asakura T, Tasei Y, Aoki A, Nishimura A. Mixture of rectangular and staggered packing arrangements of polyalanine region in spider dragline silk in dry and hydrated states as revealed by 13C NMR and X-ray diffraction. Macromolecules. 2018;51:1058–68.

Nishimura A, Matsuda H, Tasei Y, Asakura T. Effect of water on the structure and dynamics of regenerated [3-13C] Ser, [3-13C], and [3-13C] Ala-Bombyx mori silk fibroin studied with 13C solid-state nuclear magnetic resonance. Biomacromolecules. 2018;19:563–75.

Tanaka T, Uemura A, Tanaka R, Tasei Y, Asakura T. Comparison of the knitted silk vascular grafts coated with fibroin sponges prepared using glycerin, poly(ethylene glycol diglycidyl ether) and poly(ethylene glycol) as porogens. J Biomater Appl. 2018;32:1239–52.

Asakura T, Matsuda H, Naito A. Acetylation of Bombyx mori silk fibroin and their characterization in the dry and hydrated states using 13C solid-state NMR. Int J Biol Macromol. 2020;155:1410–9.

Asakura T. Structure and dynamics of spider silk studied with solid-state nuclear magnetic resonance and molecular dynamics simulation. Molecules. 2020;25:2634.

Sait H, Tuzi S, Tanio M, Naito A. Dynamic aspects of membrane proteins and membrane-associated peptides as revealed by 13C NMR: Lessons from bacteriorhodopsin as an intact protein. In: Annual Reports on NMR Spectroscopy. Academic Press, 2002, pp 39–108.

Saitô H, Ando I. High-resolution solid-state NMR studies of synthetic and biological macromolecules. Annu Rep. NMR Spectrosc. 1989;21:209–90.

Spera S, Bax A. Empirical correlation between protein backbone conformation and Cα and Cβ 13C nuclear magnetic resonance chemical shifts. J Am Chem Soc. 1991;113:5490–2.

Asakura T, Iwadate M, Demura M, Williamson MP. Structural analysis of silk with 13C NMR chemical shift contour plots. Int J Biol Macromol. 1999;24:167–71.

Asakura T, Okushita K, Williamson MP. Analysis of the structure of Bombyx mori silk fibroin by NMR. Macromolecules. 2015;48:2345–57.

Asakura T. Structure of Silk I (Bombyx mori Silk Fibroin before Spinning) -Type II β-Turn, Not α-Helix-. molecules. 2021;26:3706.

Asakura T, Yao J, Yamane T, Umemura K, Ulrich AS. Heterogeneous structure of silk fibers from bombyx mori resolved by 13C solid-state NMR spectroscopy. J Am Chem Soc. 2002;124:8794–5.

Asakura T, Aoki A, Komatsu K, Ito C, Suzuki I, Naito A, et al. Lamellar structure in alanine–glycine copolypeptides studied by solid-state NMR spectroscopy: a model for the crystalline domain of bombyx mori silk fibroin in silk II form. Biomacromolecules. 2020;21:3102–11.

Asakura T, Ogawa T, Naito A, Williamson MP. Chain-folded lamellar structure and dynamics of the crystalline fraction of Bombyx mori silk fibroin and of (Ala-Gly-Ser-Gly-Ala-Gly)n model peptides. Int J Biol Macromol. 2020;164:3974–83.

Asakura T, Demura M, Date T, Miyashita N, Ogawa K, Williamson MP. NMR study of silk I structure of Bombyx mori silk fibroin with 15N- and 13C-NMR chemical shift contour plots. Biopolymers. 1997;41:193–203.

Iwadate M, Asakura T, Williamson MP. Cα and Cβ Carbon-13 chemical shifts in proteins from an empirical database. J Biomol NMR. 1999;13:199–211.

Liu H, Xu W, Zou H, Ke G, Li W, Ouyang C. Feasibility of wet spinning of silk-inspired polyurethane elastic biofiber. Mater Lett. 2008;62:1949–52.

Um I-C, Kweon H-Y, Hwang CM, Min B-G, Park Y-H. Structural characteristics and properties of silk fibroin/polyurethane blend films. Int J Ind Entomol. 2002;5:163–70.

Tanaka T, Ibe Y, Jono T, Tanaka R, Naito A, Asakura T. Characterization of a water-dispersed biodegradable polyurethane-silk composite sponge using 13C solid-state nuclear magnetic resonance as coating material for silk vascular grafts with small diameters. molecules. 2021;26:4649.

Acknowledgements

We acknowledge Mr. Y. Ibe and Mr. K. Jono (Tosoh Co.) for kindly providing polyurethanes that they had synthesized. T.A. also acknowledges support by a JSPS KAKENHI Grant-in-Aid for Scientific Research 599 (C), grant number JP19K05609.

Author information

Authors and Affiliations

Contributions

KS: Data collection and analysis, writing-original draft. TA: Conceptualization and analysis, writing-original draft, review & editing. HM: Data collection and analysis, review & editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Suganuma, K., Matsuda, H. & Asakura, T. Characterization of polyurethane and a silk fibroin-polyurethane composite fiber studied with NMR spectroscopies. Polym J 54, 803–813 (2022). https://doi.org/10.1038/s41428-022-00629-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-022-00629-9