Abstract

This review focuses on recent developments in electropolymerization that use bipolar electrochemistry. A bipolar electrode (BPE), which is driven under the influence of an electric field, can be used for electrochemical reactions with interesting features such as wireless and site-selective reactions. In this context, bipolar electropolymerization is a powerful method for wirelessly achieving site-selective anisotropic modification of BPEs with conducting polymers. In addition, alternating current (AC) bipolar electropolymerization was developed to induce conducting polymer fibers from the terminals of BPEs that propagate parallel to the direction of the electric field. Bipolar electropolymerization is a class of next-generation electropolymerization for obtaining hybrid materials of conducting polymers and conductive objects.

Similar content being viewed by others

Introduction

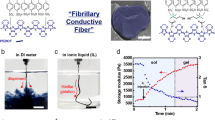

Electrochemical polymerization (or electropolymerization) is a type of electroorganic reaction in which organic compounds undergo electron transfer at an electrode surface to generate active species (radical ions and radicals) for initiation of chain polymerization [1] or are polymerized by coupling with themselves [2]. Among these reactions, the electrooxidative coupling polymerization of aromatic monomers affords π-conjugated polymers (intrinsically conducting polymers) via aromatic C–H coupling, as shown in Scheme 1 [3]. Anodic oxidation of (hetero)aromatic monomers such as furan, thiophene, pyrrole, and their derivatives yields radical cation species that undergo coupling with each other and subsequent deprotonation to produce dimers. A π-extended dimer has lower oxidation potential than the corresponding monomer; therefore, further polycondensation proceeds under oxidative conditions. Conducting polymers are generally insoluble in solvents, and are thus deposited on the surface of an anode during polymerization. This film formation is one advantage of electropolymerization (Fig. 1a) because the chemical oxidative polymerization of aromatic monomers using chemical oxidants affords only insoluble powder or bulk of the corresponding polymers. This advantage is potentially useful for a wide variety of applications, such as in electronics and sensors [4,5,6].

Recently, bipolar electrodes (BPEs) have become available as wireless electrodes that undergo anodic and cathodic reactions at their terminals [7]. When electropolymerization of aromatic monomers is conducted on a BPE, which is known as bipolar electropolymerization, wireless site-selective formation of conducting polymer films or clusters occurs at one terminal of the BPE (Fig. 1b). The alternating current (AC) bipolar electropolymerization of 3,4-ethylenedioxythiophene (EDOT) successfully produces microfibers of the corresponding polymer, poly(3,4-ethylenedioxythiophene) (PEDOT), from both terminals of the BPE (Fig. 1c). In this context, the bipolar method is next-generation electropolymerization that can site-selectively modify wireless electrodes with conducting polymers to afford novel hybrid materials. In this focus review, the concept of bipolar electropolymerization and recent examples are described.

Results and discussion

Bipolar electrochemistry

In a conventional electrolytic system containing a high concentration of supporting electrolytes (>0.1 M), a voltage applied between two electrodes is distributed to the electrode potentials at the electrode/solution interfaces, where electrical double layers are formed. This system can drive redox reactions at the anode and cathode when the applied electrode potentials are sufficiently high (Fig. 2a) [8]. On the other hand, in a low concentration of supporting electrolytes, an applied voltage between two electrodes generates poor electrode potentials and instead generates an electric field in the electrolytic solution. In this configuration, redox reactions do not readily proceed at the electrode surfaces; however, a conductor (e.g., metal or carbon) placed in between the electrodes can act as a BPE that simultaneously involves oxidation and reduction at its terminals (Fig. 2b) [9]. The sum of the interface potential differences at both edges of a conductor (ΔVBPE) is an important factor driving the redox reactions of substrates in solution, i.e., ΔVBPE should be larger than the potential difference between the target redox reactions.

Bipolar electrochemistry is a technology that has existed for a long time [10, 11], but has recently garnered attention due to the interesting features of BPEs [12] because (i) the wireless nature of a BPE is useful for sensors [13] and material synthesis [14], (ii) the gradient potential distribution on BPEs is a powerful tool for the preparation of gradient surfaces [15] and materials [16], and (iii) electrophoresis is available for effective electrolysis [17]. A wide variety of conductors of any size and shape are available as BPE materials for potential use in wide variety of applications in various fields.

Site-selective modification of conducting objects by bipolar electropolymerization

In a bipolar electrochemistry system, the electropolymerization of aromatic monomers on one terminal of a BPE is possible, providing a BPE that is modified site-selectively with a conducting polymer film. Compared to conventional electropolymerization, which forms a uniform thin film on an anode surface, bipolar electropolymerization is recognized as a novel technique.

Bradley, Gogotsi and coworkers demonstrated that a carbon nanotube (CNT) can function as a BPE for the electropolymerization of pyrrole for polypyrrole (PPy) deposition at one terminal of the CNT [18]. CNTs (5–60 μm diameter, 250 ± 25 nm long) were immobilized on a porous polyester film from a dispersed toluene solution, which was immersed in an acetonitrile (MeCN)/toluene solution containing sodium p-toluenesulfonate and pyrrole. A pulsed voltage was applied between two platinum (Pt) wires (driving electrodes) to generate an electric field between the wires (Fig. 3a). Randomly oriented CNTs behaved as BPEs when a sufficient ΔVBPE was applied between the terminals, and the anodic polymerization of the pyrrole and the reduction of the electrolyte/solvent/proton occurred simultaneously. Therefore, polyprrole (PPy) was successfully deposited in a site-selective manner (Fig. 3b). The amount of deposition was controlled well by the electrolysis time, which ranged from partial deposition to complete capping of one tip of the CNTs (Fig. 3c). For application, the partially attached hydrophilic PPy acted as a guide for water to enter the CNT wall, similar to a nanopipette, which was evidenced by scanning electron microscopy (SEM) analysis [19].

a Schematic illustration of the setup for the bipolar electropolymerization of pyrrole on a CNT as a BPE. b, c SEM images of CNTs modified with PPy after bipolar electropolymerization. Adapted with permission from [ref. 18]. Copyright 2005 Springer

Based on the principle of bipolar electrochemistry, the length of a BPE parallel to the direction of an electric field is important to effectively drive the BPE. For the site-selective modification of CNTs, their orientation in between the driving electrodes should be carefully considered to obtain reproducible products.

To fulfill this requirement, Kuhn and coworkers employed a capillary electrophoresis procedure in which CNTs were successfully passed through a reaction chamber while maintaining alignment [20, 21]. When a high voltage was applied from both sides of a silica capillary (100 μm in diameter, 24 cm in length) containing an electrolyte, electroosmotic flow was generated inside the capillary, transporting a CNT suspension from the anodic capillary inlet toward the cathodic compartment while maintaining the orientation of the CNTs. As shown in Fig. 4a, a water suspension of CNTs/pyrrole monomer/copper iodide (CuI) was introduced into the chamber, in which the CNTs acted as BPEs for the electropolymerization of pyrrole on one side and for the electroreductive reaction of Cu+ to Cu0 on the other side during the course of the capillary electrophoresis of the CNTs. As a result, CNTs modified with PPy and Cu0 clusters on both ends were obtained (Fig. 4b) [21]. Similarly, a Janus-type modification of carbon microfibers with polythiophene and gold (Au) in a MeCN solution was reported [22].

a Bipolar electropolymerization of pyrrole and reduction of Cu+ on a CNT as a BPE in a capillary electrophoresis cell. b SEM image of a modified Janus CNT with PPy and Cu. Adapted with permission from [ref. 21]. Copyright 2011 American Chemical Society

AC-bipolar electropolymerization for anisotropic growth of conducting polymer fibers and films

Inagi and coworkers demonstrated that AC bipolar electropolymerization of EDOT as a monomer resulted in the microfiber formation of the corresponding PEDOT from both terminals of the BPEs [23]. As shown in Fig. 5, Au wires (50 μm in diameter, 2.0 cm in length) were placed in between Pt driving electrodes in an electrolytic cell containing EDOT, benzoquinone (BQ), and tetrabutylammonium perchlorate (Bu4NClO4). An AC voltage was applied between the driving electrodes to activate the Au wires as BPEs, which simultaneously involved the electropolymerization of EDOT and sacrificial reduction of BQ at both poles. As a consequence of the AC electrolysis, both terminals of the Au wires were modified with PEDOT; however, PEDOT microfibers (5 μm in diameter) propagated dendritically from the tips of the BPEs parallel to the direction of the electric field. Finally, the two Au wires were connected with the PEDOT fibers (1 mm gap closed by PEDOT microfibers after 90 s).

Optimization of the electrolytic conditions, such as the applied voltage, frequency, solvent, and electrolyte concentration, revealed that the electrophoretic effect plays a key role in the PEDOT fiber structure. Electrogenerated PEDOT or corresponding oligomers should have cationic charges in the polymer chains (p-doped state), which move towards a driving cathode along with the direction of the electric field, resulting in anisotropic deposition of the PEDOT fibers. This methodology is a very new approach to obtaining conducting polymer fibers using an electric field as a template. For a monomer scope, other heteroaromatic monomers such as thiophene and pyrrole were tested for polymerization, resulting in the formation of the corresponding polymer films covering the terminals of the BPEs. This result is explained by the inactivation of the BPEs covered with polymers with relatively low-electric conductivity compared with that of PEDOT. In contrast, alkylated EDOT monomers successfully produced similar fibers with specific morphologies.

The same group demonstrated dimensional control of the PEDOT fibers by the use of the microspace around the BPE terminal [24]. Under a condition that limits the supply of EDOT monomer to the active BPE tip, quasi one-dimensional PEDOT fibers were obtained, which are potentially useful for circuit wiring applications.

The former AC-bipolar electropolymerization employed a sacrificial cathodic reaction of BQ. On the other hand, simultaneous electrosynthesis using oxidative electropolymerization and the reduction of metal ions to afford metal nanoparticles (NPs) was reported by Inagi and coworkers [25]. The replacement of BQ with hexachloroplatinic(IV) acid (H2PtCl6) did not significantly affect the propagation behavior of the PEDOT fibers; however, well-dispersed PtNPs (5–10 nm in diameter) were incorporated within the PEDOT fibers, as evidenced by field emission-SEM and transmission electron microscopy (TEM) analyses (Fig. 6). This PEDOT:PtNPs hybrid fiber was obtained by a subsequent process. In the p-doped state of electrogenerated PEDOT, an anionic dopant ([PtCl6]2−) must be incorporated into the polymer chain to achieve electroneutrality. In the polarity change step (AC voltage application), these anions are reduced to form well-dispersed PtNPs, which are trapped within the growing polymer fiber matrix.

Optical microscopy, SEM and TEM images of PEDOT:PtNPs hybrid fibers obtained by the AC-bipolar electropolymerization method. Adapted with permission from [ref. 25]. Copyright 2018 American Chemical Society

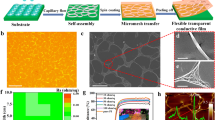

The same group also demonstrated in-plane growth of PEDOT thin films (ca. 3 μm thick) by the AC-bipolar electropolymerization method with slight modification of the conditions (concentration of monomers and electrolyte and applied frequency) for the formation of PEDOT fibers [26]. The PEDOT films grown from the Au wire have good electrical conductivity; therefore, the films can behave as BPEs for subsequent bipolar electropolymerization of other monomers. After replacement of the electrolytic solution of EDOT with that of EDOT-C1 (methylated EDOT), further bipolar electropolymerization was conducted to successfully prepare a second segment of PEDOT-C1 film from the edges of the first segment of the PEDOT film. It was possible to prepare thin films on various substrate materials, such as glass, poly(vinyl chloride), polypropylene, and poly(ethylene terephthalate) (Fig. 7). This technique could be used to draw conducting polymer patterns on a nonconductive substrate, guided by an externally applied electric field.

Optical microscopy images of PEDOT thin films grown from an Au BPE on insulating substrates of a glass, b PVC, c PP, and d PET. Adapted with permission from [ref. 26]. Copyright 2018 American Chemical Society

Summary

This focus review summarized next-generation electropolymerization based on bipolar electrochemistry. The bipolar nature of BPEs enables the site-selective and anisotropic modification of BPE objects with conducting polymers by the wireless electropolymerization of aromatic monomers. CNTs were successfully modified with PPy on one side. Janus-type modification of BPE objects was achieved by the simultaneous bipolar electropolymerization of a monomer and electroreductive reaction of metal ions. AC-bipolar electropolymerization of EDOT afforded unusual microfiber and in-plane film growth of PEDOT generated from the terminals of BPEs. Paired synthesis based on the AC-bipolar electropolymerization of monomers and electroreduction of metal successfully produced PEDOT:Pt hybrid microfibers. The anisotropic fiber growth was explained by the electrophoretic effect of charged PEDOT under the influence of an electric field. The synergetic effect of electrophoresis and electrolysis is a new tool for the design and fabrication of functional materials.

References

Funt BL. Electrochemical polymerization. Organic Electrochemistry. 3rd edition. New York: Marcel Dekker; 1990. Chapter 32.

Heinze J. Electrochemistry of conducting polymers. Organic Electrochemistry. 5th edition. Boca Raton: CRC Press; 2016. Chapter 41.

Fuchigami T, Inagi S. Organic electrosynthesis. Fundamentals and Applications of Organic Electrochemistry: Synthesis, Materials, Devices. Hoboken: Wiley; 2014. Chapter 5.

Inzelt G. Conducting Polymers—A New Era of Electrochemistry. Heidelberg: Springer; 2008.

Heinze J, Frontana-Uribe BA, Ludwigs S. Electrochemistry of conducting polymers–persistent models and new concepts. Chem Rev. 2010;110:4724–71.

Beaujuge PM, Reynolds JR. Color control in π-conjugated organic polymers for use in electrochromic devices. Chem Rev. 2010;110:268–310.

Fosdick SE, Knust KN, Scida K, Crooks RM. Bipolar electrochemistry. Angew Chem Int Ed. 2013;52:10438–56.

Atobe M. Fundamental principles of organic electrochemistry: fundamental aspects of electrochemistry dealing with organic molecules. Fundamentals and Applications of Organic Electrochemistry: Synthesis, Materials, Devices. Hoboken: Wiley; 2014. Chapter 1.

Crooks RM. Principles of bipolar electrochemistry. ChemElectroChem. 2016;3:357–9.

Goodridge F, King CJH, Wright AR. Performance studies on a bipolar fluidised bed electrode. Electrochim Acta. 1977;22:1087–91.

Aust, N. Organic electrochemistry, industrial aspects. Encycl Appl Electrochem. 2014; 1392–7.

Kuhn A, Crooks RM, Inagi S. A compelling case for bipolar electrochemistry. ChemElectroChem. 2016;3:351–2.

Chow K–F, Mavré F, Crooks RM. Wireless electrochemical DNA microarray sensor. J Am Chem Soc. 2008;130:7544–5.

Loget G, Zigah D, Bouffier L, Sojic N, Kuhn A. Bipolar electrochemistry: from materials science to motion and beyond. Acc Chem Res. 2013;46:2513–23.

Ulrich C, Andersson O, Nyholm L, Björefors F. Formation of molecular gradients on bipolar electrodes. Angew Chem Int Ed. 2008;47:3034–6.

Inagi S. Fabrication of gradient polymer surfaces using bipolar electrochemistry. Polym J. 2016;48:39–44.

Koizumi Y, Nishiyama H, Tomita I, Inagi S. Templated bipolar electrolysis for fabrication of robust Co and Pt nanorods. Chem Commun. 2018;54:10475–8.

Babu S, Ndungu P, Bradley J-C, Rossi MP, Gogotsi Y. Guiding water into carbon nanopipes with the aid of bipolar electrochemistry. Microfluid Nanofluid. 2005;1:284–8.

Rossi MP, Ye H, Gogotsi Y, Babu S, Ndungu P, Bradley J-C. Environmental scanning electron microscopy study of water in carbon nanopipes. Nano Lett. 2004;4:989–93.

Warakulwit C, Nguyen T, Majimel J, Delville M, Lapeyre V, Garrigue P, Ravaine V, Limtrakul J, Kuhn A. Disymmetric carbon nanotubes by bipolar electrochemistry. Nano Lett. 2008;8:500–4.

Loget G, Lapeyre V, Garrigue P, Warakulwit C, Limtrakul J, Delville M–H, Kuhn A. Versatile procedure for synthesis of Janus-type carbon tubes. Chem Mater. 2011;23:2595–9.

Ongaro M, Gambirasi A, Favaro M, Kuhn A, Ugo P. Asymmetrical modification of carbon microfibers by bipolar electrochemistry in acetonitrile. Electrochim Acta. 2014;116:421–8.

Koizumi Y, Shida N, Ohira M, Nishiyama H, Tomita I, Inagi S. Electropolymerization on wireless electrodes towards conducting polymer microfibre networks. Nat Commun. 2016;7:10404.

Ohira M, Koizumi Y, Nishiyama H, Tomita I, Inagi I. Synthesis of linear PEDOT fibers by AC-bipolar electropolymerization in a micro-space. Polym J. 2017;49:163–7.

Koizumi Y, Ohira M, Watanabe T, Nishiyama H, Tomita I, Inagi S. Synthesis of poly(3,4-ethylenedioxythiophene)-platinum and poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) hybrid fibers by alternating current bipolar electropolymerization. Langmuir. 2018;34:7598–603.

Watanabe T, Ohira M, Koizumi Y, Nishiyama H, Tomita I, Inagi S. In-plane growth of poly(3,4-ethylenedioxythiophene) films on a substrate surface by bipolar electropolymerization. ACS Macro Lett. 2018;7:551–5.

Acknowledgements

This research was supported by a Kakenhi Grant-in-Aid (No. JP17H03095) from the Japan Society for the Promotion of Science (JSPS), the Murata Science Foundation, and Casio Science Promotion Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Inagi, S. Site-selective anisotropic modification of conductive objects by bipolar electropolymerization. Polym J 51, 975–981 (2019). https://doi.org/10.1038/s41428-019-0223-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0223-2

This article is cited by

-

Analog programing of conducting-polymer dendritic interconnections and control of their morphology

Nature Communications (2021)