Abstract

To overcome a bottleneck in spintronic applications such as those of ultralow-power magnetoresistive random-access memory devices, the electric-field control of magnetization vectors in ferromagnetic electrodes has shown much promise. Here, we show the giant converse magnetoelectric (CME) effect in a multiferroic heterostructure consisting of the ferromagnetic Heusler alloy Co2FeSi and ferroelectric-oxide Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-PT) for electric-field control of magnetization vectors. Using an in-plane uniaxial magnetic anisotropy of polycrystalline Co2FeSi film grown on PMN-PT(011), the nonvolatile and repeatable magnetization vector switchings in remanent states are demonstrated. The CME coupling coefficient of the polycrystalline Co2FeSi/PMN-PT(011) is over 1.0 × 10−5 s/m at room temperature, comparable to those of single-crystalline Fe1-xGax/PMN-PT systems. The giant CME effect has been demonstrated by the strain-induced variation in the magnetic anisotropy energy of Co2FeSi with an L21-ordered structure. This approach can lead to a new solution to the reduction in the write power in spintronic memory architectures at room temperature.

Similar content being viewed by others

Introduction

Switching the magnetization vectors via spin transfer torque using an electric current has been utilized as a method of writing information for next-generation spintronic nonvolatile memories such as magnetoresistive random-access memory (MRAM) devices1,2,3,4. In general, a high electric current density is required to switch the magnetization vectors of ferromagnetic electrodes in magnetic tunnel junctions (MTJs) during the information writing process, and it is a serious bottleneck in the application of spintronic devices. For this problem, several methods for manipulating magnetization vector via an electric field are expected to markedly reduce the power consumption5. However, there are limitations on the usage environment of ferromagnetic semiconductors6,7 and ultrathin ferromagnets8,9 to control and/or change the magnetization vectors. In practical applications, it is very desirable to switch the magnetization vectors by an electric field without using an assist-magnetic field above room temperature.

The realization of these requirements has been the focus of numerous studies on multiferroic materials10,11,12,13. For robust operation above room temperature and a wide variety of material selections, artificial ferromagnetic (FM)/ferroelectric (FE) multiferroic heterostructures have been explored because of their potential advantages, such as high operation temperatures14,15,16,17,18,19,20,21,22,23,24. In particular, when Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-PT) was utilized as an FE material, relatively high magnetostriction through the piezostrain and repeatable switching of the remanent magnetization states with a nonvolatile nature were experimentally observed25,26,27,28,29,30. Recently, nonvolatile switching of the magnetization vector via an electric field was repeatedly demonstrated in MTJs with high magnetoresistance ratios at room temperature31,32. By sequentially applying uniaxial stress in FM/PMN-PT systems33, complete 180° magnetization reversal of FM on PMN-PT and large magnetoresistance (MR) changes can be performed without using an assist-magnetic field, even for MTJs32. The combination of the above technique and giant magnetoelectric (ME) coupling coefficients of more than 1.0 × 10−5 s/m are required for future spintronic logic and memory architectures to efficiently switch the magnetization vectors via an electric field23,24,25.

With respect to the giant ME coupling coefficients of more than 1.0 × 10−5 s/m, single-crystalline Fe1-xGax alloys grown on PMN-PT are promising materials34,35, as Fe1-xGax alloys are good magnetostrictive materials for strain sensors, actuators, and energy harvesters36,37. However, spin polarization at the Fermi level of Fe1-xGax alloys is less than that of spintronic materials36. Thus, high-performance spintronic materials, such as FM half-metals grown on PMN-PT, should be explored to realize magnetization switching with ultralow power consumption23,24,25. Here, we have chosen Co-based Heusler alloys, since they are expected to be half-metallic materials with high Curie temperatures38,39,40. In this work, we focus particularly on Co2FeSi as an FM material because the L21-ordered Co2FeSi has already shown a half-metallic nature40,41,42. We demonstrate giant ME coupling coefficients of more than 1.0 × 10−5 s/m by utilizing high-performance polycrystalline Co2FeSi films with the L21-ordered structure on PMN-PT(011). The findings in the present study have the potential to overcome the current bottleneck in spintronic devices.

Results

Polycrystalline Co2FeSi/PMN-PT(011) heterostructures

We use an FE rhombohedral PMN-PT pseudocubic substrate with a large piezoelectric constant43. Unlike in the previous report on PMN-PT(001)29, the PMN-PT(011) single crystal is chosen because there have been many studies on the electric-field control of the magnetization vector26,27,28. The detailed growth procedure of Co2FeSi films on PMN-PT(011) is described in the Materials and methods.

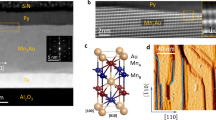

A schematic of the Co2FeSi/PMN-PT(011) heterostructure is shown in Fig. 1a, where a 0.3-nm-thick Fe layer is inserted between Co2FeSi (30 nm) and PMN-PT(011). This layer was added to improve the crystallinity of the Co2FeSi films, since films with poor structural quality are unlikely to have a substantial converse ME (CME) effect29. In Fig. 1b, we present a schematic of the atomic arrangements of a (011) plane for the PMN-PT pseudocubic single crystal. An evident difference in the atomic arrangement between PMN-PT[\(01\bar 1\)] and PMN-PT[100] crystallographic directions is expected. Prior to the growth of Co2FeSi films, we confirm that in situ reflection high-energy electron diffraction (RHEED) patterns indicate two different atomic arrangements of the PMN-PT[\(01\overline 1\)] and PMN-PT[100] directions, as shown at the bottom of Fig. 1c. During the growth of the Co2FeSi layers, we can also find a distinct difference in the RHEED patterns of the Co2FeSi surface between the PMN-PT[\(01\overline 1\)] and PMN-PT[100] azimuths in the top of Fig. 1c. The two different RHEED patterns indicate that the growth mode of the Co2FeSi layer on the (011) surface of PMN-PT is anisotropic.

a Schematic of the fabricated Co2FeSi/PMN-PT(011) heterostructure. b Atomic arrangements of the (011) plane for the PMN-PT pseudocubic single crystal. c RHEED patterns of the Co2FeSi layer during the growth (top) and the surface of PMN-PT(011) before growth (bottom) along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions under the observations. d HRTEM of the Co2FeSi/PMN-PT heterostructure near the interface (left) and digital diffractograms measured at region A and region B. e XRD pole figure of the L21-ordered structure for Co2FeSi on PMN-PT(011).

Figure 1d is a high-resolution transmission electron microscopy (HRTEM) image from a region at the interface that shows the PMN-PT substrate and the Co2FeSi film. The HRTEM clearly shows that between the substrate and film, an amorphous layer forms during growth, since the in situ RHEED from the substrate shows a well-ordered crystalline PMN-PT(011) surface. The EDX spectra from the amorphous interface layers (not shown here) showed that the amorphous layer in Fig. 1d is an oxide with little Co, Fe or Si. The grown film is polycrystalline with a grain width of 13 ± 4 nm. Co2FeSi grains are highly textured; hence, the RHEED patterns indicate epitaxial like film growth. The digital diffractograms from the labeled regions of the grains (Fig. 1d) show the grain orientations and the L21 structure of the Co2FeSi grains by observing the (111) ordering spots. We also performed nanodiffraction (see Figs. S1 and S2 of Supplementary information44) from individual grains that show the preferred grain growth along the [422] and [220] directions, and the results are further confirmed and discussed in the next paragraph.

The structural analysis from the X-ray diffraction (XRD) ω-2θ scan (out-of-plane) for the Co2FeSi/PMN-PT(011) heterostructure is shown in Fig. S3 of the Supplementary information44. Weak diffraction peaks from the (220) and (422) planes were observed in the out-of-plane XRD measurement (Fig. S3a), indicating that the grown Co2FeSi layer was not a highly oriented structure on PMN-PT(011), consistent with the data shown in Fig. 1d. On the other hand, from the pole figure measurement (2θ = 27.55 degrees) shown in Fig. 1e, we clearly observed {111} diffraction peaks, indicating the presence of the L21-ordered structure of Co2FeSi. These results are consistent with the results observed in the HRTEM image and diffractogram shown in Fig. 1d and the results presented in Figs. S1 and S2 of the Supplementary information44. From these structural characterizations, we conclude that the grown Co2FeSi layer is a textured polycrystalline film on PMN-PT(011), in which the polycrystalline Co2FeSi film includes the high spin polarization L21-ordered structure 40,41,42.

Initial in-plane uniaxial anisotropy

Prior to the investigation of magnetic properties of the Co2FeSi/PMN-PT(011) heterostructure, we briefly present the well-known unpoled state of the PMN-PT(011) substrate21, as schematically shown in Fig. 2a. The spontaneous piezoelectric polarizations of (011) cut PMN-PT lie along the diagonals of the (011) plane and (\(01\overline 1\)) plane, as shown in the top section of the figure21. In this situation, the (011) plane of the PMN-PT pseudocubic single crystal has a rectangular shape with a long axis along the [\(01\overline 1\)] direction, as depicted at the bottom of the figure.

a Schematics of the correlation between spontaneous polarization vectors and crystal orientations of the (011)-oriented PMN-PT substrate. b Magnetization hysteresis curves measured at 300 K under H along PMN-PT[\(01\bar 1\)] (red) and PMN-PT[100] (blue). c A polar plot of the remanent magnetization (MR) normalized by the saturation magnetization (MS) at 300 K. In-plane magnetic anisotropy is observed near PMN-PT[\(01\bar 1\)].

We first measure general magnetic properties of the Co2FeSi/PMN-PT(011) heterostructure at room temperature. Magnetic-field (H)-dependent magnetization, measured along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] crystallographic directions in the film plane, is presented in Fig. 2b. An anisotropic feature of the magnetization curves is present along the two different crystal axes, where the two different RHEED patterns are observed during the growth in Fig. 1c. Because the value of the saturation magnetization (MS) (1090 ± 30 kA/m) is nearly the same as that in our previous works on Co2FeSi films29,42,45, we regard the relatively high MS value as a consequence of the formation of the L21-ordered structure. Figure 2c shows a polar plot of the squareness of the magnetization curves, where the remanent magnetization (MR) is normalized by MS in various H directions in the film plane. In the Co2FeSi/PMN-PT(011) heterostructure, an evident in-plane uniaxial magnetic anisotropy along the PMN-PT[\(01\bar 1\)] with a small off-axis orientation is induced. These features are reproduced for multiple samples. Since the observed uniaxial anisotropy is almost parallel to the long axis of the rectangular shape of the (011) plane of PMN-PT (the bottom of Fig. 2a), the in-plane uniaxial magnetic anisotropy can be understood by the anisotropic lattice distortion induced from the (011) plane of the PMN-PT substrate. This evidence shows that by utilizing our growth method, as illustrated in Fig. 1, moderate in-plane uniaxial magnetic anisotropy can be induced even in polycrystalline Co2FeSi/PMN-PT(011) heterostructures. Because the (011) surface of the pseudo-cubic PMN-PT unit cell is distorted with shear strain along the red polarization vectors46, we infer that the small deviation of the uniaxial easy axis from PMN-PT[\(01\bar 1\)] is an intrinsic property of this system.

Strain-induced converse magnetoelectric effect

To characterize the electric field (E) effect on magnetic properties for the Co2FeSi/PMN-PT(011) heterostructures, we perform magneto-optic Kerr ellipticity (η) measurements at room temperature by applying E, where H is applied to the crystallographic direction along PMN-PT[\(01\bar 1\)] or [100] while E is applied to the PMN-PT[011] direction. Here, as a reference, the reported polarization switching process of a PMN-PT(011) single crystal is described in Fig. S4 of the Supplementary information44. Figure 3a shows the plots of the Kerr-ellipticity magnitude in the remanent state (ηR) as a function of E at room temperature, in which each point is obtained by measuring H-dependent Kerr-ellipticity curves along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] direction, as shown in Fig. 3b. Because we can clearly observe the saturation behavior of the Kerr-ellipticity magnitude (ηS) in Fig. 3b, we can assume that the value of ηS {(611 ± 3) × 10−6 radian} corresponds to the value of MS (1090 ± 30 kA/m) measured in Fig. 2b. On the basis of the assumption, the MR values in the right axes in Fig. 3a are determined as MR = MS (ηR/ηS).

a E-dependent remanent magnetization measured along PMN-PT[\(01\bar 1\)] and PMN-PT[100] at room temperature. The blue and red plots are the up-sweep and down-sweep data, respectively, within an E of ±0.8 MV/m. b Room-temperature magnetization curves measured along PMN-PT[\(01\bar 1\)] and PMN-PT[100] for the two different states at E = 0. The blue and red curves were measured after E sweeping from −0.8 MV/m to 0 or from +0.8 MV/m to 0, respectively. c, d Lattice deformation of the (011) plane at E = 0 when E is changed from −0.8 MV/m to 0 and from +0.8 MV/m to 0, respectively, in the presence of the anisotropic piezostrain of the (011) plane.

Both ηR − E curves shown in Fig. 3a indicate the presence of two magnetization states at E = 0. These features greatly differ from the conventional strain-induced magnetization vector switching processes that can be easily predicted from the polarization switching of PMN-PT(011), as shown in Fig. S421. The appearance of the two magnetization states at E = 0 is reproduced in multiple Co2FeSi/PMN-PT(011) heterostructures, as shown in Fig. S5a of the Supplementary information44. To consider the origin of the two magnetization states at E = 0, we first refer to the general behavior of the lattice deformation of the (011) plane21 after E is changed from 0 to ±0.8 MV/m and from ±0.8 MV/m to 0 in Fig. S4. When the large E of ±0.8 MV/m is applied (Fig. S4b, e), the long axis of the (011) rectangle plane is elongated along PMN-PT[\(01\bar 1\)], and the short axis along PMN-PT[100] is simultaneously contracted. In contrast, when E is increased from −0.8 MV/m to 0 (Fig. S4c), the long axis along PMN-PT[\(01\bar 1\)] is contracted, and the short axis along PMN-PT[100] is elongated. In this situation (E = 0), it is generally expected that the strain-induced magnetic easy axis of the Co2FeSi film is aligned toward the PMN-PT[100] direction. However, the data presented in blue in Fig. 3b indicate that the PMN-PT[100] and PMN-PT[\(01\bar 1\)] axes are magnetic hard and easy axes, respectively, in contrast to the simple expectation described above based on the reported polarization switching of the PMN-PT(011) substrate21. Thus, we next consider the presence of the anisotropic piezostrain at the PMN-PT(011) surface, as discussed in previous works on polycrystalline Ni/PMN-PT(011)16 and amorphous CoFeB/PMN-PT(011)28 systems.

In-plane piezostrain curves of the (011) surface of a representative PMN-PT(011) substrate are shown in Fig. S6 of the Supplementary information44. We clearly observed the anisotropic piezostrain of the (011) plane of the PMN-PT substrate between the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions, as described in a previous report28. Because there were two different piezostrain states in the (011) plane between the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions at E = 0 (Fig. S6c), we should consider the competition between the initial in-plane uniaxial magnetic anisotropy and the strain-induced magnetic anisotropy in the Co2FeSi film at the two states. The two different states of the lattice deformation of the (011) plane at E = 0 are schematically shown in Fig. 3c, d. When E is increased from −0.8 MV/m to 0, the tensile strain along PMN-PT[\(01\bar 1\)] is maintained at E = 0 (Fig. 3c). In this situation, the strain-induced uniaxial magnetic anisotropy of the Co2FeSi film along the PMN-PT[\(01\bar 1\)] direction is added to the initial uniaxial magnetic anisotropy along PMN-PT[\(01\bar 1\)] with a small off-axis orientation. As a result, the magnetization direction of the Co2FeSi film is maintained along a magnetic easy axis in the PMN-PT[\(01\bar 1\)] direction. On the other hand, when E is decreased from +0.8 MV/m to 0, compressive strain along PMN-PT[\(01\bar 1\)] is observed (Fig. 3d); this compressive strain decreases the magnitude of the uniaxial magnetic anisotropy of the Co2FeSi film along the PMN-PT[\(01\bar 1\)] direction. In this situation, the remanent magnetization direction of the Co2FeSi film can switch from near the PMN-PT[\(01\bar 1\)] to the PMN-PT[100] direction. Thus, we can qualitatively explain the origin of the two magnetization states at E = 0, shown in Fig. 3a, b, by considering the presence of the anisotropic piezostrain of the (011) surface of the PMN-PT substrate along the PMN-PT[\(01\bar 1\)] direction at E = 0. However, if the initial in-plane uniaxial anisotropy of the Co2FeSi film along the PMN-PT[\(01\bar 1\)] direction was weaker or stronger than that in the present study, the two magnetization states at E = 0 could have been unstable. To quantitatively understand its origin, we should further investigate the correlation among the magnitude of the initial in-plane uniaxial magnetic anisotropy, local domain structures, and the magnitude of the global piezostrain46,47 for many Co2FeSi/PMN-PT(011) heterostructures at E = 0.

As shown in Fig. 3b, the magnetization directions at two different states at E = 0 are nearly switched from the uniaxial hard axis to the uniaxial easy axis or the uniaxial easy axis to the uniaxial hard axis during the E sweeping process. Therefore, nearly 90° magnetization vector switching can occur in the remanent state (H = 0) after the application of positive or negative E values, as schematically shown in Fig. 4a. Figure 4b, c display nonvolatile switching of the remanent magnetization vector for the measurements along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions, respectively, and the sequence of the E application to PMN-PT[011] is also displayed in Fig. 4d. Evident variations in two different magnetic states with high/low MR can be repeatedly demonstrated for both measurements along the PMN-PT[\(01\bar 1\)] (b) and PMN-PT[100] (c) directions. Notably, the observed variation in MR was more than ~700 kA/m. The repeatable and nonvolatile magnetization vector switchings can be utilized as a part of the technology for voltage-induced magnetization switching in storage and/or memory devices having polycrystalline Co-based Heusler alloys.

Giant CME coupling coefficient

We quantitatively evaluate the CME effect of the Co2FeSi/PMN-PT(011) heterostructures. To estimate the CME coupling coefficient (αE), we define the value of αE as follows: αE = \(\mu _0\frac{{dM_{{{\mathrm{R}}}}}}{{dE}}\), where μ0 is the vacuum permeability. Figure 5a displays the value of αE as a function of E, estimated from the data in Fig. 3a, for the Co2FeSi/PMN-PT(011) heterostructure in both measurements by applying H along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions. Very interestingly, the value of αE was over 1.0 × 10−5 s/m when E ~ −0.25 MV/m at room temperature, as shown in Fig. 5a. In the relevant fields, an αE of more than 1.0 × 10−5 s/m has thus far been reported in multiferroic heterostructures consisting of PMN-PT substrates and single-crystalline magnetostrictive materials such as FeRh22 and FeGa alloys34,35. On the other hand, we observe the giant αE of more than 1.0 × 10-5 s/m even in the polycrystalline Co2FeSi/PMN-PT(011) heterostructure, where Co2FeSi is one of the most representative spintronic Co-based Heusler alloys38,39. This evidence indicates that magnetostrictive materials and single-crystalline structures are not strict conditions for obtaining a giant αE of more than 1.0 × 10−5 s/m.

a Plots of the CME coupling coefficient (αE) versus E at room temperature for the polycrystalline Co2FeSi/PMN-PT(011) heterostructure along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions, where αE is estimated from the data in Fig. 3a, b αE versus E at room temperature for the polycrystalline Fe3Si/PMN-PT(011) heterostructure along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions.

To verify the importance of Co2FeSi, we also investigate the CME effect of the Fe3Si/PMN-PT(011) heterostructure, where Fe3Si is a binary Heusler alloy42, and the growth of the heterostructure, including its characterizations, is also shown in Fig. S7 of the Supplementary information44. Here, the Fe3Si/PMN-PT(011) heterostructure is also polycrystalline and shows an in-plane uniaxial magnetic anisotropy between the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions, similar to the case of the Co2FeSi/PMN-PT(011) heterostructures. Figure 5b shows the value of αE as a function of E for the polycrystalline Fe3Si/PMN-PT(011) heterostructure in both measurements along the PMN-PT[\(01\bar 1\)] and PMN-PT[100] directions. Although similar peaks and dips are observed at |E | ~ 0.20 MV/m, αE is relatively small compared to 1.0 × 10-5 s/m at room temperature. This feature is slightly different from that for the Co2FeSi/PMN-PT(011) heterostructures.

In Table 1, we summarize the reported values of the giant αE for various multiferroic heterostructures and compared them to those of this study. Apart from the Fe50Rh50/BaTiO3(001) system22, a giant CME effect was observed in various FM/PMN-PT systems28,34,35. As previously described, because ferroelectric PMN-PT has a piezoelectric constant43 that is relatively large compared to that of BaTiO3, a large piezostrain can be induced from PMN-PT to FM layers via multiferroic heterointerfaces26,27,28,29,34,35. For magnetostrictive materials such as Fe1-xGax, one has to achieve a metastable bcc (A2) phase with x ~ 30% as a single crystalline film on PMN-PT to obtain a giant αE of more than 1.0 × 10−5 s/m35. For spintronic materials such as Co40Fe40B2028 and Co2FeSi in this study, amorphous and polycrystalline films grown on PMN-PT have also shown giant values of αE. Although these spintronic materials did not have a large magnetostrictive constant, an induced uniaxial magnetic anisotropy (6 kJ/m3 for Co40Fe40B20 in ref. 28, 5.8 kJ/m3 for Co2FeSi in this work) can be largely and steeply modulated in the film plane by applying E. The above results show that electric-field control of the magnetization vector can be efficiently achieved by utilizing the strain-mediated magnetic anisotropy for high-performance spintronic materials with a giant αE.

Discussion

For the Co2FeSi/PMN-PT(011) multiferroic heterostructures, we should consider the strain-mediated variation in the magnetic anisotropy, which is an extrinsic mechanism. To discuss a substantial contributor to the CME effect in the Co2FeSi/PMN-PT(011) heterostructure, we focus on the correlation between the magnetocrystalline anisotropy energy for Co2FeSi and the extrinsic lattice strain in Co2FeSi in a simple model. Here, the extrinsic lattice strain is imposed through the in-plane lattice vectors a and b of the conventional 16-atom unit cell, as shown in the inset of Fig. 6a. Figure 6a shows the magnetocrystalline anisotropy energy (MAE) estimated by first-principles calculations for Co2FeSi, together with Fe3Si as a reference, as a function of b/a, where b/a is obtained by changing the lattice vector a while optimizing the b vector. The MAE of Co2FeSi changes linearly with b/a, where the tetragonal in-plane lattice distortion results in in-plane magnetization pointing to the elongated axis: the positive and negative MAEs for b/a > 1 and b/a < 1, respectively. In contrast, Fe3Si shows relatively small changes in the MAE with the opposite sign compared to Co2FeSi. This tendency supports that the value of αE for the Fe3Si/PMN-PT(011) heterostructure is smaller than that for the Co2FeSi/PMN-PT(011) heterostructure. From these results, we interpret that the modulation of the lattice strain induced by the application of E causes changes in the MAE in Co2FeSi and Fe3Si. Even though the result in Fig. 6a is obtained with the constraint of c = a for simplicity, the behavior of the in-plane anisotropy favoring the magnetization along the elongated axis remains unchanged for the case of full relaxation, as shown in Fig. 6b.

a MAE of the Co2FeSi and Fe3Si as a function of b/a. b MAE of the Co2FeSi as a function of the interfacial strain (Δa/a0 and Δb/b0). The dashed line represents the case of uniform in-plane deformation, where the MAE becomes exactly zero. c Projected DOS of Co 3d orbitals in Co2FeSi without the strain. Relevant states (t2g with up spins and eg with down spins) for the strain-induced magnetic anisotropy are drawn as front. d Projected DOS per d-orbital of the dominant Co 3d states for the magnetic anisotropy in Co2FeSi for Δa/a0 = 3.55% and Δb/b0= − 3.55%. The case without strain is also shown as shades. In a, the ratio b/a is controlled by changing a while optimizing b, where c is fixed as a for simplicity. In contrast, vectors a and b were changed independently by optimizing c as the full relaxation for given strain states for b, d.

To elucidate the origin of strain-induced MAE modulation, we evaluated the orbital-resolved MAE for Co2FeSi on the basis of perturbation theory (see Materials and methods). As we decompose the total MAE of Co2FeSi, it is found that the dominant contribution to the MAE comes from Co atoms relative to those from Fe and Si atoms. Figure 6c displays the projected density of states (DOS) of Co 3d orbitals in Co2FeSi. Here, the eg (t2g) states consist of degenerate \(d_{x^2 - y^2}\)and \(d_{3z^2 - r^2}\) (\(d_{xy}\), \(d_{xz}\), \(d_{yz}\)) states because the octahedral ligand field is valid due to the cubic structure. Even though the degeneracy is lifted by the interfacial strain, we also use this classification for the strain-perturbed states. With lateral strain, we find that the MAE is dominated by up spins in the occupied states and down spins in the unoccupied states, in particular, \(\langle t_{2g}, \uparrow {{{\mathrm{|}}}}H_{{{{\mathrm{SO}}}}}{{{\mathrm{|}}}}e_g, \downarrow\rangle\) couplings, where the bra (ket) in the matrix element corresponds to occupied (unoccupied) states. These dominant orbitals are shown in Fig. 6d for Δa/a0 = 3.55% and Δb/b0 = − 3.55%. Subtle changes are seen from the DOS that the unoccupied eg orbital with the down spins shifts toward the Fermi level (εF) by the in-plane deformation. The change in the electronic structures contributes to the negative MAE favoring the magnetization in the a direction. It should be noted that changes in the occupied down spins in Fig. 6d are irrelevant because the matrix element is small due to the very low density of states in unoccupied up-spin states. Therefore, the origin of the strain-induced MAE modulation in the Co2FeSi/PMN-PT(011) heterostructures is related to the modulation of the Co-3d orbitals occupied by up-spin states in Co2FeSi.

In the field of next-generation spintronic nonvolatile memories such as MRAMs1,2,3,4 and spintronic logic devices48,49, effective switching of the magnetization vector via spin transfer torque by using an electric current is one of the bottlenecks for low energy power consumption because of the heat dissipation process. In contrast, the CME effect in multiferroic heterostructures can provide a solution to overcome the heat dissipation of the magnetization switching at room temperature23,24,25. In this study, we have presented a giant CME effect in Co2FeSi/PMN-PT(011) multiferroic heterostructures with αE of more than 1.0 × 10−5 s/m at room temperature. The value of giant αE is the largest of the high-performance Heusler-based spintronic materials. We infer that the giant αE in the Co2FeSi/PMN-PT(011) heterostructures is strongly related to the strain-induced in-plane magnetic anisotropy derived from the Co 3d orbitals in Co2FeSi, in addition to a relatively large MS. Additionally, repeatable and nonvolatile magnetization vector switching without applying H has been demonstrated at room temperature. Thus, the present study provides a new solution for achieving magnetization switching with ultralow power consumption with hundreds of orders of magnitude of attoJoules in heat dissipation23,24,25.

Although the present study was performed by utilizing PMN-PT substrates, some technologies for PMN-PT films without the influence of substrate clamping, such as piezoelectric layers, have been demonstrated24,50. Furthermore, the giant CME effect based on the Co-based Heusler alloys/PMN-PT multiferroic heterostructures can be utilized for MTJs38,51 and current-perpendicular-to-plane giant magnetoresistance (CPP-GMR) devices with polycrystalline Co-based Heusler alloy electrodes52 and a new spintronic logic architecture, such as magnetoelectric spin-orbit devices23,53.

Materials and methods

Growth and characterization of Co2FeSi on PMN-PT(011)

The Co2FeSi/PMN-PT(011) multiferroic heterostructure was grown by molecular beam epitaxy (MBE). Prior to the growth of the Co2FeSi film, heat treatment was performed at 450 °C for 20 min to obtain a flat surface of the single-crystal PMN-PT(011) substrates with a size of 5.0 × 5.0 × 0.5 mm3. After cooling to a growth temperature of 300 °C, a 0.3-nm-thick Fe layer was grown on top of the cleaned PMN-PT(011) surface. When we did not use the 0.3-nm-thick Fe layer, the grown polycrystalline Co2FeSi film became completely nonoriented. To improve the crystallinity of the Co2FeSi film with an L21-ordered structure, the insertion of the 0.3-nm-thick Fe layer is essential. Thus, 30-nm-thick Co2FeSi film was grown by co-evaporation using Knudsen cells, where we set the supplied atomic composition ratio of Co:Fe:Si to 2.0:1.0:1.0 during the growth29,45. Here, the heat treatment temperature of 450 °C and the growth temperature of 300 °C were lower than those described in the literature, showing a very high αE of 1.5 − 4.5 × 10−5 s/m34. After growth, we characterized the Co2FeSi/PMN-PT(011) multiferroic heterostructure. First, the multiferroic heterostructure was evaluated by X-ray diffraction (XRD) (Rigaku SmartLab) for out-of-plane and in-plane analyses. High-resolution transmission electron microscopy (HRTEM) and bright-field transmission electron microscopy (BF-TEM) were performed using an aberration-corrected JEOL 2200FS TEM, and nanobeam diffraction was performed on a JEOL 2100+TEM. The specimen preparation for TEM analysis was performed using focused ion beam techniques.

To measure the conventional magnetic properties of the grown multiferroic heterostructures, we used a vibrating sample magnetometer (VSM) at room temperature, while magneto-optic Kerr ellipticity measurements using the LED with a wavelength of 670 nm were performed to examine the CME effect at room temperature. To apply an E to the PMN-PT substrate along the [011] direction, a Au(100 nm)/Ti(3 nm) electrode was deposited on the backside of the PMN-PT substrate, where the Co2FeSi film was also utilized as a top electrode. Prior to the evaluation of the CME effect, we first applied an E of −0.8 MV/m. Then, the amplitude of E was gradually changed from −0.8 MV/m to + 0.8 MV/m, then back to E = −0.8 MV/m. At each step, the Kerr-ellipticity magnitude was obtained by measuring the hysteresis loops as a function of H along the PMN-PT[\(01\bar 1\)] or [100] direction.

Computational details for first-principles calculations

We performed first-principles calculations on the basis of density functional theory by using the VASP code54, where the inner-core electrons were treated by the projector augmented-wave method55,56. The generalized gradient approximation parameterized by the Perdew-Burke-Ernzerhof functional was used for the exchange-correlation functional57. In addition, the DFT + U method with the effective Hubbard repulsion Ueff = 2.6 eV and Ueff = 2.5 eV was employed for the Co 3d and Fe 3d orbitals of Co2FeSi, respectively58. The cutoff kinetic energy for the plane-wave basis set was set to 520 eV, and k-point grids were set to 10 × 10× 10 and 15 × 15× 15 for ionic relaxation and static calculations, respectively. The in-plane strain was generated by changing the in-plane lattice parameters a and b. Here, the strain was approximated with Δa/a0 and Δb/b0, where Δa = a − a0, Δb = b − b0, and a0 (=b0) is the equilibrium lattice constant without strain.

The MAE was evaluated as the total-energy difference obtained from calculations including the spin-orbit coupling for magnetization along the [100] and [010] directions while fixing the electron density that was obtained by the self-consistent collinear calculation. For the orbital-decomposed MAE, contributions from each atomic site τ and couplings among atomic orbitals μ were derived from second-order perturbation theory59,60:

where i and j are indices of occupied and unoccupied eigenstates with eigenenergies εi and εj, respectively. Note that the indices i, j, and μ include the spin index. The spin-orbit coupling is approximated as HSO = ξl · s, where ξ is the coupling constant, l is the orbital-angular momentum quantum number, and s is the spin angular momentum quantum number. The values of ξ were compiled in a prior study61. In analyzing the MAE decomposition, electronic states obtained by the OpenMX code were used62. The x, y, and z directions in the MAE decomposition were defined as along the a, b, and c axes, respectively.

References

Brataas, A., Kent, A. D. & Ohno, H. Current-induced torques in magnetic materials. Nat. Mater. 11, 372 (2012).

Kent, A. D. & Worledge, D. C. A new spin on magnetic memories. Nat. Nanotechnol. 10, 187–191 (2015).

Bhatti, S. et al. Spintronics based random access memory: a review. Mater. Today 20, 530 (2017).

Yuasa, S., Hono, K., Hu, G. & Worledge, D. C. Materials for spin-transfer-torque magnetoresistive random-access memory. MRS Bull. 43, 352–357 (2018).

Matsukura, F., Tokura, Y. & Ohno, H. Control of magnetism by electric fields. Nat. Nanotechnol. 10, 209–220 (2015).

Chiba, D. et al. Magnetization vector manipulation by electric fields. Nature 455, 515–518 (2008).

Yamada, Y. et al. Electrically induced ferromagnetism at room temperature in cobalt-doped titanium dioxide. Science 332, 1065–1067 (2011).

Maruyama, T. et al. Large voltage-induced magnetic anisotropy change in a few atomic layers of iron. Nat. Nanotechnol. 4, 158–161 (2009).

Nozaki, T. et al. Highly efficient voltage control of spin and enhanced interfacial perpendicular magnetic anisotropy in iridium-doped Fe/MgO magnetic tunnel junctions. NPG Asia Mater. 9, e451 (2017).

Schmid, H. Multi-ferroic magnetoelectrics. Ferroelectrics 162, 317 (1994).

Kimura, T. et al. Magnetic control of ferroelectric polarization. Nature 426, 55–58 (2003).

Spaldin, N. A. & Fiebig, M. The Renaissance of Magnetoelectric Multiferroics. Science 309, 391–392 (2005).

Spaldin, N. A. & Ramesh, R. Advances in magnetoelectric multiferroics. Nat. Mater. 18, 203 (2019).

Duan, C. G., Jaswal, S. S. & Tsymbal, E. Y. Predicted magnetoelectric effect in Fe/BaTiO3 multilayers: Ferroelectric control of magnetism. Phys. Rev. Lett. 97, 047201 (2006).

Sahoo, S. et al. Ferroelectric control of magnetism in BaTiO3/Fe heterostructures via interface strain coupling. Phys. Rev. B 76, 092108 (2007).

Wu, T. et al. Electrical control of reversible and permanent magnetization reorientation for magnetoelectric memory devices. Appl. Phys. Lett. 98, 262504 (2011).

Venkataiah, G., Shirahata, Y., Itoh, M. & Taniyama, T. Manipulation of magnetic coercivity of Fe film in Fe/BaTiO3 heterostructure by electric field. Appl. Phys. Lett. 99, 102506 (2011).

Venkataiah, G., Wada, E., Taniguchi, H., Itoh, M. & Taniyama, T. Electric-voltage control of magnetism in Fe/BaTiO3 heterostructured multiferroics. J. Appl. Phys. 113, 17C701 (2013).

Radaelli, G. et al. Electric control of magnetism at the Fe/BaTiO3 interface. Nat. Commun. 5, 3404 (2014).

Shirahata, Y. et al. Electric-field switching of perpendicularly magnetized multilayers. NPG Asia Mater. 7, e198 (2015).

Zhang, S. et al. Giant electrical modulation of magnetization in Co40Fe40B20/Pb(Mg1/3Nb2/3)0.7Ti0.3O3(011) heterostructure. Sci. Rep. 4, 3727 (2014).

Cherifi, R. O. et al. Electric-field control of magnetic order above room temperature. Nat. Mater. 13, 345–351 (2014).

Manipatruni, S. et al. Scalable energy-efficient magnetoelectric spin-orbit logic. Nature 565, 35 (2019).

Hu, J.-M. & Nan, C.-W. Opportunities and challenges for magnetoelectric devices. APL Mater. 7, 080905 (2019).

Hu, J.-M., Li, Z., Chen, L.-Q. & Nan, C.-W. High-density magnetoresistive random access memory operating at ultralow voltage at room temperature. Nat. Commun. 2, 553 (2011).

Zhang, S. et al. Electric-field control of nonvolatile magnetization in Co40Fe40B20/Pb(Mg1/3Nb2/3)0.7Ti0.3O3 structure at room temperature. Phys. Rev. Lett. 108, 137203 (2012).

Zhang, S. et al. Strain-Mediated Coexistence of Volatile and Nonvolatile Converse Magnetoelectric Effects in Fe/Pb(Mg1/3Nb2/3)0.7Ti0.3O3 Heterostructure. ACS Appl. Mater. Interfaces 9, 20637–20647 (2017).

Wang, J. et al. Giant non-volatile magnetoelectric effects via growth anisotropy in Co40Fe40B20 films on PMN-PT substrates. Appl. Phys. Lett. 114, 092401 (2019).

Usami, T. et al. Giant magnetoelectric effect in an L21-ordered Co2FeSi/Pb(Mg1/3Nb2/3)O3-PbTiO3 multiferroic heterostructure. Appl. Phys. Lett. 118, 142402 (2021).

Liu, M. et al. Nonvolatile voltage-controlled magnetization reversal in a spin-valve multiferroic heterostructure. NPG Asia Mater. 13, 64 (2021).

Chen, A. et al. Giant nonvolatile manipulation of magnetoresistance in magnetic tunnel junctions by electric fields via magnetoelectric coupling. Nat. Commun. 10, 243 (2019).

Chen, A. et al. Full voltage manipulation of the resistance of a magnetic tunnel junction. Sci. Adv. 5, eaay5141 (2019).

Biswas, A. K., Ahmad, H., Atulasimha, J. & Bandyopadhyay, S. Experimental Demonstration of Complete 180° Reversal of Magnetization in Isolated Co Nanomagnets on a PMN-PT Substrate with Voltage Generated Strain. Nano Lett. 17, 3478–3484 (2017).

Begué, A. & Ciria, M. Strain-Mediated Giant Magnetoelectric Coupling in a Crystalline Multiferroic Heterostructure. ACS Appl. Mater. Interfaces 13, 6778–6784 (2021).

Meisenheimer, P. B. et al. Engineering new limits to magnetostriction through metastability in iron-gallium alloys. Nat. Commun. 12, 2757 (2021).

Wang, H. et al. Understanding strong magnetostriction in Fe100−xGax alloys. Sci. Rep. 3, 3521 (2013).

Yang, Z. et al. Scalable Nernst thermoelectric power using a coiled galfenol wire. AIP Adv. 7, 095017 (2017).

Sakuraba, Y. et al. Giant tunneling magnetoresistance in Co2MnSi/Al-O/Co2MnSi magnetic tunnel junctions. Appl. Phys. Lett. 88, 192508 (2006).

Felser, C., Fecher, G. H. & Balke, B. Spintronics: A challenge for materials science and solid-state chemistry. Angew. Chem. Int. Ed. 46, 668 (2007).

Bombor, D. et al. Half-Metallic Ferromagnetism with Unexpectedly Small Spin Splitting in the Heusler Compound Co2FeSi. Phys. Rev. Lett. 110, 066601 (2013).

Kimura, T., Hashimoto, N., Yamada, S., Miyao, M. & Hamaya, K. Room-temperature generation of giant pure spin currents using epitaxial Co2FeSi spin injectors. NPG Asia Mater. 4, e9 (2012).

Hamaya, K. et al. Estimation of the spin polarization for Heusler-compound thin films by means of nonlocal spin-valve measurements: Comparison of Co2FeSi and Fe3Si. Phys. Rev. B 85, 100404(R) (2012).

Guo, Y. et al. The phase transition sequence and the location of the morphotropic phase boundary region in (1-x)[Pb(Mg1/3Nb2/3)O3]- xPbTiO3 single crystal. J. Phys. Condens. Matter 15, L77 (2003).

See Supplementary information at [URL inserted by publisher] for XRD measurements for Co2FeSi/Fe/PMN-PT(011) heterostructures, polarization switching process of PMN-PT(011), reproducibility of the giant CME effect, anisotropic piezoelectric response in the PMN-PT(011), and characterization of a Fe3Si/PMN-PT(011) heterostructure.

Yamada, S. et al. Electric field tunable anisotropic magnetoresistance effect in an epitaxial Co2FeSi/BaTiO3 interfacial multiferroic system. Phys. Rev. Mater. 5, 014412 (2021).

Ghidini, M. et al. Shear strain-mediated magnetoelectric effects revealed by imaging. Nat. Mater. 18, 840–845 (2019).

Conte, R. L. et al. Influence of Nonuniform Micron-Scale Strain Distributions on the Electrical Reorientation of Magnetic Microstructures in a Composite Multiferroic Heterostructure. Nano Lett. 18, 1952–1961 (2018).

Dery, H., Dalal, P., Cywiński, Ł. & Sham, L. J. Spin-based logic in semiconductors for reconfigurable large-scale circuits. Nature 447, 573–576 (2007).

Behin-Aein, B., Datta, D., Salahuddin, S. & Datta, S. Proposal for an all-spin logic device with built-in memory. Nat. Nanotechnol. 5, 266–270 (2010).

Irwin, J. et al. Magnetoelectric Coupling by Piezoelectric tensor Design. Sci. Rep. 9, 19158 (2019).

Lim, W. C., Choi, G. M., Lee, T. D. & Seo, S. A. Fabrication of Magnetic Tunnel Junctions with Co2FeSi Heusler Alloy and MgO Crystalline Barrier. IEEE Trans. Magn. 44, 2595 (2008).

Nakatani, T., Li, S., Sakuraba, Y., Furubayashi, T. & Hono, K. Advanced CPP-GMR Spin-Valve Sensors for Narrow Reader Applications. IEEE Trans. Magn. 54, 3300211 (2018).

Manipatruni, S., Nikonov, D. E. & Young, I. A. Beyond CMOS computing with spin and polarization. Nat. Phys. 14, 338–343 (2018).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmentedwave method. Phys. Rev. B 59, 1758 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865 (1996).

Chen, J., Lin, C., Yang, Y., Hu, L. & Cheng, W. Ab initio study of the magnetoelectric effect and critical thickness for ferroelectricity in Co2FeSi/BaTiO3 multiferroic tunnel junctions. Model. Simul. Mater. Sci. Eng. 22, 015008 (2014).

Nakamura, S. & Gohda, Y. Prediction of ferromagnetism in MnB and MnC on nonmagnetic transition-metal surfaces studied by first-principles calculations. Phys. Rev. B 96, 245416 (2017).

Torbatian, Z., Ozaki, T., Tsuneyuki, S. & Gohda, Y. Strain effects on the magnetic anisotropy of Y2Fe14B examined by first-principles calculations”. Appl. Phys. Lett. 104, 242403 (2014).

Yanase, Y. & Harima, H. Lecture on fundamental solid state physics: Spin-orbit interactions and electronic states in crystals (part 1). Solid State Phys. 46, 229 (2011). [in Japanese].

Ozaki, T. Variationally optimized atomic orbitals for large-scale electronic structures. Phys. Rev. B 67, 155108 (2003).

Acknowledgements

The authors appreciate Dr. Irene Azaceta of University of York for sample preparation related to TEM observations. This work was partly supported by JST CREST, Grant Number JPMJCR18J1, JSPS KAKENHI Grant Numbers 19H05616, 20K21002, 21K14196, and the Spintronics Research Network of Japan (Spin-RNJ). Some of the calculations were carried out on supercomputers at ISSP, The University of Tokyo, and TSUBAME, Tokyo Institute of Technology.

Author information

Authors and Affiliations

Contributions

K.H. proposed and supervised this study. The growth of the ferromagnetic films was conducted by S.F., T.U., S.Y., and K.H. The XRD and HRTEM measurements were performed by S.F. and T.U. and by A.K. and V.L., respectively. The magnetic properties and the CME effect were characterized by S.F., T.U., Y.S., R.N., and K.H. The strain was measured by T.K. The theoretical calculations were carried out by A.Y. and Y.G., and the data analyses were performed by A.Y., Y.G., T.O. All authors contributed to the discussion and interpretation of the results and preparation of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fujii, S., Usami, T., Shiratsuchi, Y. et al. Giant converse magnetoelectric effect in a multiferroic heterostructure with polycrystalline Co2FeSi. NPG Asia Mater 14, 43 (2022). https://doi.org/10.1038/s41427-022-00389-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-022-00389-1

This article is cited by

-

Strain-induced specific orbital control in a Heusler alloy-based interfacial multiferroics

NPG Asia Materials (2024)