Abstract

Producing electrolytes with high ionic conductivity has been a critical challenge in the progressive development of solid oxide fuel cells (SOFCs) for practical applications. The conventional methodology uses the ion doping method to develop electrolyte materials, e.g., samarium-doped ceria (SDC) and yttrium-stabilized zirconia (YSZ), but challenges remain. In the present work, we introduce a logical design of non-stoichiometric CeO2-δ based on non-doped ceria with a focus on the surface properties of the particles. The CeO2−δ reached an ionic conductivity of 0.1 S/cm and was used as the electrolyte in a fuel cell, resulting in a remarkable power output of 660 mW/cm2 at 550 °C. Scanning transmission electron microscopy (STEM) combined with electron energy-loss spectroscopy (EELS) clearly clarified that a surface buried layer on the order of a few nanometers was composed of Ce3+ on ceria particles to form a CeO2−δ@CeO2 core–shell heterostructure. The oxygen deficient layer on the surface provided ionic transport pathways. Simultaneously, band energy alignment is proposed to address the short circuiting issue. This work provides a simple and feasible methodology beyond common structural (bulk) doping to produce sufficient ionic conductivity. This work also demonstrates a new approach to progress from material fundamentals to an advanced low-temperature SOFC technology.

Similar content being viewed by others

Introduction

Surface/interface structures are found to play a vital role in producing exceptional material properties. For example, topological insulators with an insulating core and electron conducting surface1,2,3 displayed unique electrical conducting properties. The interface between two insulating oxides can produce superconductivity4,5. In addition, semiconductor/ion conductor heterointerfaces, such as YSZ/SrTiO36,8,10 and Ce0.8Gd0.2O2-δ–CoFe2O411 composites, can enhance the ionic conductivity through two material interfaces by several orders of magnitude6,7,8,9,10. These extraordinary properties on surfaces or at interfaces indicate a new strategy to develop material functionality. Thus, a new emerging approach for oxide interfaces was established12,13. By tuning the electronic states, oxygen ion conducting properties can be modified at interfaces14.

Ceria (CeO2) has attracted extensive interest and demonstrated multifunctionality in many fields, such as catalytic applications15,16,17, solar cells and photoelectrochemistry18,19,20, lithium batteries21,22, fuel cells23,24,25,26 and a variety of other energy-related applications25,26. The most important characteristic of ceria is the capacity to store and release oxygen via facile Ce4+/Ce3+ redox cycles, which largely depends on the concentration and types of oxygen vacancies in the lattice as well as surface structures and states. Unique physical properties are associated with Ce3+ ions and oxygen vacancies. Especially from the nanoscale perspective, non-stoichiometric oxygen atoms are present at the grain boundaries or surface, and these concomitant vacancies play an important role in determining the various chemical and physical properties of ceria. The surface state is fundamental27,28 and demonstrates significantly different physical and chemical properties when compared to those of the bulk matrix. The role of vacancy dynamics may be very important at interfaces and on surfaces because of the high mobility and redistribution of charged vacancies29. Ceria can be easily reduced from CeO2 to CeO2−δ through surface reduction at low oxygen partial pressures. The changes in surface oxygen vacancies often dramatically alter material physical and electrochemical properties, especially when the ceria particle size is less than 100 nm.

It is well known that CeO2 itself is an insulator. To improve the ionic conductivity of cerium-based oxides, aliovalent doping with rare earths and alkaline cations, such as Gd, Sm, Ca and La, introduces oxygen vacancies in the lattice as charge compensating defects and increases the ionic conductivity, where the highest level of oxide-ion conductivity was reported for Gd- and Sm-doped Ce1-xMxO2-δ (M = Gd and Sm)30,31. Although extensive efforts have been made to utilize doped ceria as an alternative electrolyte in solid oxide fuel cells (SOFCs), several critical challenges have hindered practical application of this material as reported extensively in the literature. (i) Ceria-based electrolytes under fuel cell conditions are reduced by H2, which can be accompanied by significant electronic conductivity to futher deteriorate the open-circuit voltage (OCV) and power output32. (ii) Once the ceria size is in nanometer scale, the electronic conduction is dominant; e.g., an enhancement of four orders of magnitude in the electronic conductivity was observed for CeO2 when the particle size transitioned from the micro- to nanoscale33. There were two approaches published in Nature in 2000 for high ionic conduction that were based on structural doping34 and surface mechanisms35. Doping to create bulk ionic conduction in a material is a central methodology in SOFC material research and development. However, alternative materials that can replace YSZ have not yet been successful; on the other hand, the surface approach has not been seriously developed in the current SOFC framework. This study highlights a new conceptual method to develop high electrical conductivity in CeO2 without doping based on characteristic surface defects (Ce3+, oxygen vacancies and superoxide radicals) combined with band energy alignment to avoid the formation of short circuits.

The CeO2 surface approach presented in this work addresses challenges based on recent scientific understanding and results achieved on this material. In our approach, we take advantage of the ceria electronic conduction and surface defects for the successful demonstration of new advanced SOFC materials and technologies. Through simple heat treatment processes, we created different surface defects and electrical properties to investigate the correlation between the conductivities and surface state of the CeO2. The presence of oxygen vacancies and defects on the CeO2 surface resulted in new electrical and band gap properties and successful SOFC application. Our study presents a new design concept for both materials and devices that will have a great impact on the next generation of advanced SOFCs.

Experimental section

Synthesis of CeO2 powder

CeO2 powders were prepared using the wet chemical precipitation method. In a typical synthesis procedure, 5.43 g cerium nitrate hexahydrate (Ce (NO3)3·6H2O) and 1.98 g ammonium bicarbonate (NH4HCO3) were separately dissolved in 200 ml deionized water under magnetic stirring. Then, the NH4HCO3 solution was used as the deposition agent and poured slowly (10 ml min−1) into the Ce(NO3)3·6H2O solution, which was stirred for 2 h and statically aged for 12 h at room temperature. Following filtration, the material was washed with deionized water to remove any possible ionic remnants and then a pure CeO2 precursor was obtained. The CeO2 precursor was dried at 120 °C for 24 h and calcined in air at 900 °C for 4 h to obtain CeO2 powder.

Characterization

The X-ray diffraction (XRD) patterns of the as-prepared CeO2 samples were analyzed to determine the crystallographic phases via a Bruker D8 X-ray diffractometer (XRD, Germany, Bruker Corporation) operating at 45 kV and 40 mA with Cu Kα radiation (λ = 1.54060 Å). The morphology of the samples were investigated using a JSM7100F field emission scanning electron microscope (FESEM, Japan) operating at 15 kV. To further characterize the microstructures, scanning transmission electron microscope (STEM) was performed on a JEOL ARM-200CF field emission microscope with a probe corrector and Gatan imaging filter (GIF) electron energy-loss spectrometer (EELS) operating with an accelerating voltage of 200 kV. Collection semi angle of 57.1 mrad was used to record the EELS line scan. The high angle annular dark field (HAADF) image was simulated using a multislice method implemented in QSTEM image simulation software. Ultraviolet photoelectron spectroscopy (UPS) measurements were performed to obtain the valence band level. The UV-vis diffused reflection spectra of the materials were tested on a UV3600 spectrometer (MIOSTECHPTY Ltd.).

Cell construction and measurement

The devices used for measurements were constructed using 0.2 g CeO2 powder sandwiched between two thin layers of LiNi0.8Co0.15Al0.05O2 semiconductor pasted on nickel foam and pelletized at room temperature under a hydraulic press pressure of 200 MPa to obtain a simple symmetric configuration device of (Ni)NCAL/CeO2/NCAL(Ni). Two nickel foam acted as current collectors. The device was shaped as 13 mm in diameter, around 1.0 mm in thickness with an effective area of 0.64 cm2. Pure hydrogen and ambient air were supplied to each side of the cells as fuel and oxidant, respectively. The flow rates were controlled in the range of 80–120 ml min−1 for H2 and 150–200 ml min−1 for air under 1 atm. To analyze the cell performance, the voltage and current readings were collected using a programmable electronic load (IT8511, ITECH Electrical Co., Ltd.) to plot the I–V and I–P characteristics.

Electrochemical impedance spectroscopy (EIS) was carried out by using an electrochemical workstation (Gamry Reference 3000, USA) in both air and fuel cell operation atmospheres, and the frequency ranged from 0.1 Hz to 1 MHz with an amplitude of 10 mV.

Results and discussion

Figure 1 shows the XRD pattern of the CeO2 powder synthesized at 900 °C for 4 h compared with that of CeO2 reduced in H2 at 550 °C for 1 h (R-CeO2). The patterns exhibit the same fluorite structure. However, a shift towards lower angle is observed for R-CeO2 sample in the expanded XRD pattern, as shown in the inset. The lattice parameters for the CeO2 powder and R-CeO2 calculated by Scherrer equation were 5.403 Å and 5.452 Å, respectively, suggesting a slight CeO2 local lattice expansion. The XRD analysis indicates that i) the CeO2 obtained at 900 °C had a normal lattice structure that agreed with the standard lattice parameter of 0.5410 nm indicated in the JCPDS card; and ii) the hydrogen treatment led to a reduction of Ce4+ to Ce3+, thereby causing lattice structural changes, i.e., the lattice expanded significantly from 5.403 to 5.452 A. The large Ce3+ radius can bring about lattice expansion by forming non-stoichiometric CeO2-δ in the CeO2 fluorite structure within tolerance limitations. The effect is similar to that of large Sm3+ and Gd3+ rare earth ions doping into CeO2 and cause corresponding lattice expansion.

Along with the production of Ce3+, oxygen vacancies are also created in the CeO2 lattice. This process can be described by:

This is a fundamental way to improve CeO2 electrical properties. CeO2 has stoichiometry valence of Ce4+ which is located in the grain interior36. Hydrogen treatment leads to chemical defects on the CeO2 particle surfaces. This process can be deemed as a surface doping process due to the replacement of Ce4+ by Ce3+. The introduction of oxygen vacancies and accompanying large-sized Ce3+ ions leads to a distortion of the local symmetry and results in an increased lattice expansion, thus causing strain and surface stresses. This speculation can be directly observed in the high-resolution STEM images and is discussed in the next section. The hydrogen reduction process, e.g., during fuel cell operation or at a low oxygen partial pressure, starts from CeO2 particle surfaces and approaches to the bulk, it is reasonable to consider a different surface state from the bulk to be further characterized in the following sections. The production of Ce3+ in CeO2 can have the same effect as trivalent rare earth ions, e.g., replacing Ce4+ with Sm3+ or Gd3+, that are doped in CeO2 to cause CeO2 a lattice expansion. We noticed that Ce3+ ions have an ionic radius of 1.03 Å that is larger than the value of Ce4+ (0.92 Å), Gd3+ (1.05 Å) and Sm3+(1.08 Å), respectively. Therefore, producing Ce3+ in CeO2 may result in doping effects, similar to Sm3+ and Gd3+, and impact not only the lattice but also the ionic conductivity. However, it should be noted that Ce3+ is on the surface, while Sm3+ and Gd3+ are doped in the bulk37.

We adjusted the synthesis conditions and found that the sintering temperature can play a role in determining the microstructure and electrical properties of as-prepared ceria. The detailed work with regard to sintering temperature was added in supplementary information (SI) and can be described as follows. The XRD patterns of the CeO2 powder sintered at various temperatures are presented as Fig. S1 in the SI. The results can be summarized: i) different temperatures led to the same fluorite structure; ii) the CeO2 crystallinity was enhanced with the sintering temperature; iii) the lattice constant decreased as the sintering temperature increased, indicating a change in the Ce3+/Ce4+ ratio. Upon increasing the sintering temperature from 500 to 900 °C, the lattice parameters decreased correspondingly from 5.416 to 5.403 Å, which was deduced from the XRD patterns. This may be due to Ce ions not being fully oxidized at low sintering temperature, i.e., some Ce3+ coexisted with Ce4+. The large Ce3+ can expand the ceria lattice, while sintering at increased temperatures can fully oxidize the Ce ions, converting Ce3+ to Ce4+, and lead to a normal lattice constant that agrees with standard JCDPS data. Figure S2 shows the morphology evolution of the CeO2 powder with sintering temperature through SEM characterization. A clear trend is discernible indicating that the grain size increased with the sintering temperature from several nanometers (500 °C) to 200–300 nm (1000 °C), which is closely related to the electrical conductivity and activation energy of ceria. The particular sintering temperature resulted in the formation of nanoscale CeO2, and the size effect possibly extended the interfacial area accompanying with a reduced enthalpy of defect formation on the CeO2 crystallizes and caused a high oxygen deficiency on the ceria particle surfaces, significantly enhancing the electrochemical performance of the cells. While focusing on low-temperature (<600 °C) SOFC electrolyte applications, we carefully optimized the synthesis conditions and fixed the sintering temperature at a sufficiently high temperature of 900 °C for 4 h to address the material stability and produce excellent electrochemical performance.

Figures 2a, b display the morphological change of the CeO2 particles before and after fuel cell measurements. The original CeO2 particles displayed a spherical shape with a 20–200 nm size distribution, and some pores were observed in the electrolyte layer, but the pores were enclosed without penetrating through the CeO2-electrolyte membrane. After the FC measurements, the gaps between the particles were filled, and the CeO2 electrolyte layer presented a fair density and good gas-tightness, thus ensuring that the assembled cells possessed high OCVs (above 1 V) and excellent power outputs (see the cell performance section below) compared with conventional cells based on a dense doped ceria electrolyte.

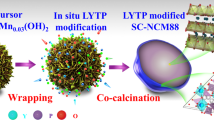

Figure 3a shows the HAADF-STEM image for individual CeO2 particles reduced by H2 for 2 h. The particle was an irregular sphere with a diameter of 190 nm. The energy dispersive X-ray spectrometer (EDXS) mapping of the main elements using O-k and Ce-L3,2 lines for the CeO2 particle is shown in Fig. 3b, c, and Fig. 3d is the survey image, which indicates an almost uniform element distribution throughout the entire particle. Figure 3e and f shows the atomically resolved HAADF-STEM image for the reduced CeO2 particles. A high-resolution image is displayed in Fig. 3d, showing the atomic arrangement. An atomic structure model of the cubic phase of the CeO2 along the [211] projection and a simulated HAADF image are superimposed on the HAADF image.

a HAADF-STEM image for individual CeO2 particles reduced by H2 for 2 h. EDXS mapping of the main elements extracted using b O-k and c Ce-L3,2 lines. e An atomically resolved HAADF image for CeO2 particle. f The enlarged image for the area in (e) marked by a blue rectangle. The inset shows the atomic model of CeO2 and the simulated HAADF image

To further investigate the surface state of the reduced CeO2 particles, the high spatial resolution of aberration-corrected STEM combined with EELS analysis were allowed to detected the valence variations of superficial Ce at the atomic scale. Figure 4a displays the particle area for EELS analysis and the blue arrow indicates the line scan direction. The plot of EELS scan signal from surface (point A) to grain interior (point B) was presented in Fiure 4b. The Ce M5/M4 ratio is sensitive to the chemical state of Ce; therefore, the oxidation state of Ce can be determined quantitatively from the M5/M4 ratio using the positive part of the second derivative of the experimental spectra. Figure 4c gives the Ce M5,4 edges extracted from particle surface and 20 nm away from the surface. The resultant intensity ratios are listed in the inserted table. It can be found that the M5/M4 ratio on the surface is higher than that of the interior grain. As reported, a small M5/M4 ratio corresponds to Ce4+ and a large ratio is associated with Ce3+. Therefore, Ce3+ was produced on the surface of the CeO2 particle, indicating the formation of a thin layer of oxygen-deficient CeO2-δ on the surface. EELS measurements confirmed the presence of oxygen vacancies on the particle surface. When a neutral oxygen vacancy is formed, two electrons are left behind. It is generally accepted that these electrons are localized in the f-state of the nearest Ce atoms38, which changes their valence state from + 4 to + 3. In other words, the presence of Ce3+ could be evidence of oxygen vacancy formation, which significantly improves ion conductivity on the surface. Therefore, the stoichiometric CeO2 in the interior grains is an insulator, and the oxygen-deficient CeO2-δ on the surface possesses promising electrical conducting properties. Therefore, a novel CeO2-δ@CeO2 structure with a topological configuration, i.e., an insulating core and high conducting shell, was formed as illustrated in Fig. 4d. This evidence clearly indicates that there is strong ionic conductivity for the reduced CeO2, which was reflected by the great power output of the fuel cells assembled from pure CeO2. In fact, it was reported that a surface layer of CeO1.5 is formed on the nano-CeO2 particles, and the CeO1.5 fraction presented a significant increase when the particle sizes were below 15 nm and reached up to 90% at 3 nm39.

The electron core level XPS spectra of the reduced and as-prepared CeO2 were obtained to peer the chemical composition and valance states of the elements. Figure 5a shows the Ce 3d spectra collected from the as-prepared CeO2. The spectrum is composed of two multiplets identified as V and U. These multiplets correspond to the spin-orbit split 3d 5/2 and 3d 3/2 core holes. The u″′ and v″′ peaks with a high binding energy indicate the final state of Ce 3d9 4f0 O2P6, and the peaks labeled as u, v, u″ and v″ with a low binding energy are attributed to the Ce 3d9 4f2 O2P4 and Ce 3d9 4f1 O2P5 final states. The six characteristic peaks can be indexed as the Ce 3d spectrum for Ce4+, which is consistent with previous reports40,41. Besides the six characteristic peaks of Ce4+, three extra peaks marked as u0, u′ and v′ appeared in the Ce 3d XPS of the R-CeO2 sample as Fig. 5b shown, demonstrating the existence of the Ce3+ oxidation state. The energy split between the v and v′ peaks is ~3.0 eV, which is close to the value observed for the Ce3+ compound42. Figure 5c, d presents the O1s XPS spectrum of the as-prepared and R-CeO2, which delivered an asymmetric feature that could be deconvoluted into different symmetrical signal. The spectrum for the as-prepared CeO2 sample is fitted by two peaks centered at 529.5 eV and 530.5 eV, which are attributed to the lattice oxygen (marked as OI) and surface adsorbed oxygen (marked as OII), respectively. For the R-CeO2 sample, the asymmetric O1s spectrum is deconvoluted into three peaks denoted as OI, OII and OIII. The new peak (OIII) with a higher binding energy is related to the presence of the oxygen vacancies, possibly due to the existence of Ce3+ produced by H2 reduction, which is crucial for ionic conduction and dominated the electrochemical performance of the assembled fuel cell.

This surface layer of the core–shell structure was further characterized to understand the boundaries and buried interface effects on the ionic conduction origin and enhancement. We carried out more careful characterization to identify and determine the tension of the grain boundaries with agglomerated CeO2-δ particles through STEM in combination with the EELS, as shown in Fig. 6. The HAADF images a and b show that the particle size was in the range of 10–200 nm. It is clear that all of the particles closely contacted each other, and the color of the interface region between the particles is different from the interior of the particles, indicating stress accumulation at the interface. As Fig. 6c shows, neither disordered nor amorphous structures are present at the grain boundaries, indicating that the boundaries are successfully joined at the atomic level.

a, b HAADF-STEM image for agglomerated CeO2-x particles. c The atomically resolved HAADF image for the grain boundary region, and the green rectangle marked where the EEL spectrum image was acquired. d Atomically resolved Ce valence state mapping obtained by multiple linear least squares fitting. e Ce valence state mapping deduced from Ce M5/M4 ratio

In Fig. 6, there are two direct pieces of evidence to support the interfacial conduction mechanism. (i) First, an analysis of the stress was carried out at the interfaces. As shown in Fig. 6a, b for the HAADF images, the contrast is bright at the interfaces, which indicates that there was an accumulation of stress. (ii) An emphasis is paid on analysis of the valency state at the interfaces. The Ce valence state changes were extracted using Ce-M5,4 edges in atomic resolution, as shown in Fig. 6e. Both the chemical shift and white-line ratio methods and analyses prove that there was an ~1.5 nm buried interface, where Ce was in the 3 + valence state and is highlighted in red in Fig. 6d. This implies that oxygen vacancies were created in the buried interfaces. Because accompanying with the Ce3+ formation, the oxygen vacancy generation process can be described by equation (1). The experimental evidence indicates that the surface and grain boundaries play a dominant role in ionic transport; it is well understood and reported in the literature43,44,45 that stress and tension generate vacancies at interfaces to promote ion transport.

The electrical behavior of the CeO2 pellets was examined by EIS analysis under air and H2/air FC environment at a device measuring temperature of 550 °C. The EIS results are shown in Fig. 7. To understand the EIS behavior in more detail, a simulation was carried out using the equivalent circuit models of Ro(R1-QPE1)(R2-QPE2) (Insets of Fig. 7), where R is the resistance and QPE represents the constant phase element. The high-frequency intercept on the Z’-axis, as shown in the enlarged inset, reflects the entire ohmic resistance of the device, including the resistance of CeO2 bulk, electrodes and connecting wires. Both EIS results were characterized as a semicircle followed by an inclined line, and the flat semicircle in the medium-frequency region could be superimposed by two standard semicircles. One is attributed to the grain boundary/surface effect in the middle-frequency range, and the other is due to the charge-transfer impedance on the electrode/CeO2 interface. In addition, the inclined line in the low-frequency region corresponds to the ion-diffusion process in the electrode process. These processes also commonly exist in fuel cells based on doped ceria electrolytes46. It can be seen clearly that the CeO2 based device under an air atmosphere exhibited a typical ion conducting nature and low conductivity, which are reflected by a large semicircle due to grain boundary and charge transfer processes. In the FC condition, the device immediately shows a mixed electron-ion conducting behavior and a rapid decrease in resistance of more than two orders of magnitude (see the inset of Fig. 7). The diameter of the semicircle in the medium-frequency region for the CeO2 under FC conditions is much smaller than that of the CeO2 device in air, indicating much lower grain boundary and charge-transfer resistances. The result suggests that the conductivity (both ions and electrons) of CeO2 under FC conditions was significantly enhanced in comparison with that under an air atmosphere. The fitting results show that the total electrical conductivity of the CeO2 in air was low, ~10−4 s/cm, as estimated from the EIS result in air; in contrast, a drastic change occurred to bring about a high conductivity state under FC conditions, and the conductivity exceeded 10−1 s/cm. In addition, the obtained capacitances displayed low values, revealing the rate-determining processes in the fuel cell. This result is consistent with the reduction of the Ce4+ to Ce3+ in the H2/air environment. This occurred because H2 can reduce CeO2 and form large oxygen vacancies, further resulting in significant enhancement of both oxygen ion and electronic conduction.

The oxygen deficient layer on the surface can function as an oxygen ion transport pathway and significantly dominate the charge conduction, especially the grain boundary conductivity, which was deduced from the EIS plot of the pellet. To further verify the surface conduction, we specifically separated the grain boundary resistance from the EIS results and converted the resistance to conductivity by using the pellet dimensions. Figure 8 shows the grain boundary conductivity (σgb) of CeO2 as a function of temperature obtained in air and H2/air atmospheres. The noteworthy point is that the σgb obtained in the H2/air atmosphere was significantly higher than that in the air, possibly due to the formation of an oxygen-deficient layer on the particle surface under the H2/air atmosphere, which provided a pathway for oxygen transport to significantly enhance σgb.

Based on the excellent electrical properties, the CeO2 samples were used as the electrolytes for fuel cells, and the cell performances are shown in Fig. 9. It can be seen clearly that high OCV values (1.0 to 1.12 V) and power outputs (140–660 mW/cm2) was achieved at operational temperatures of 400–550 °C. To verify the reproducibility of the performance, we fabricated 8 cells from non-doped CeO2 and evaluated their electrochemical performance. A box plot diagram was chosen to present the power maximum of the measured 8 cells at various testing temperatures, as shown in Fig. 10. The horizontal lines in the box denote the 25th, 50th and 75th percentile values. Obviously, the performance presented in Fig. 9 is close to the mean value; therefore, the value is representative. Although there was high electronic conduction, as discussed above, the CeO2 electrolyte exhibited no any electronic short-circuiting problem. These results obtained from non-doped CeO2 surface conduction demonstrated significant advantages over doped ceria electrolyte fuel cells from both the OCV and power output perspectives. For example, samarium-doped ceria (SDC) electrolyte fuel cell devices have demonstrated OCVs < 0.9 V and output powers < 100 mW/cm2 at 600 °C, while non-doped CeO2 achieved 660 mW/cm2 at 550 °C32. This indicates a very different ionic conduction mechanism and fuel cell principles between the doped bulk conducting SDC and non-doped surface conducting CeO2, which deserves further study.

It has been reported that nanoscale CeO2 shows strong or dominant electronic conductivity, giving nanosized CeO2 a mixed ionic and electronic conductivity (MIEC) state33. The grain boundary-enhanced electron concentration corresponding to depression in the positively charged ionic (oxygen vacancy) species is expected from space charge theory. It should be pointed out if the fuel cell electrolyte has significant electronic conductivity, i.e., a typical MIEC electrolyte, which will make significant device OCV and power losses. However, our case represents the opposite situation because excellent fuel cell performances were obtained for the OCV, which exceeded 1.0 V and even reached 1.12 V, and for the power output, which reached 660 mW/cm2 at 550 °C.

How can the MIEC type CeO2 be used as a fuel cell electrolyte and cause no additional losses in the OCV and power output? These conflict with conventional MIEC theory and SOFC devices for a doped ceria electrolyte fuel cell33. We propose a new scientific principle for a semiconductor junction combined with energy band alignment, which has been reported in other semiconductor-ionic membrane fuel cell systems47,48. In this case, the contacted CeO2 on the anode side was reduced by H2 to form Ce3+ and released free electrons. The surface conduction was formed, and the extra electrons simultaneously brought about n-type conduction for the CeO2 on the anode side. Martin and Duprez determined the oxygen and hydrogen surface diffusion on the oxide surfaces, and pointed out that both oxygen and hydrogen can transport rapidly on the CeO2 surface49,50. Lai et al. reported that a Sm-doped CeO2 thin film exhibited mixed ionic and electronic conductivity with a bulk ionic conductivity of 7mScm−1 and an electronic conductivity of 6mScm−1 under open-circuit conditions at 500 °C51. These data agree well with our fuel cell results, although we used the pure CeO2 phase, which possessed sufficient surface electron and ionic conductivities.

On the other hand, CeO2 on the air side showed hole conduction52, i.e., p-type conduction, while the CeO2 on the anode side reduced by H2 turns to electron (n-type) conduction. Naturally, a p-n junction was formed between two parts of the CeO2 electrolyte. In this case, we propose a double-layer electrolyte model for the fuel cell, as shown in Fig. 11f. Band energy alignment between the CeO2 and R-CeO2 is proposed to clarify the charge separation and barrier to block the electron passing through the CeO2 electrolyte, even though it is an MIEC-type electrolyte. An oxygen vacancy is associated with the formation of two Ce3+ ions and is a two-electron donor center, which can lead to significant electronic conduction. Concerning the formation of double-charged oxygen vacancies, electrons in the conduction band were composed of Ce 4 f energy states. The electrons formed during reduction were treated as being localized on the cerium, thereby converting Ce4+ to Ce3+ ions. To verify this assumption, the accurate band energy of the CeO2/R-CeO2 was determined by UPS combined with UV-vis diffused reflection. UPS of the CeO2 and R-CeO2 were carried out to determine their valence band. In the UPS spectra presented in Fig. 11b, the energy was calibrated with respect to He I photon energy (21.21 eV). As Fig. 11c, d shows, by defining the low-binding and high-energy cutoff, the valence band maximum below vacuum level was obtained to be −5.47 eV for CeO2 and −5.74 eV for the R-CeO2 sample. These band gaps were determined from the diffused reflection measurements (Fig. 11a) to be 3. 65 eV and 3.42 eV for CeO2 and R-CeO2, respectively. On the basis of these results, we can further deduce the corresponding conduction band (CB) levels to be 1.85 eV for CeO2 and 2.32 eV for R-CeO2. The final band alignment is sketched in Fig. 11e and clearly reveals that the CB position of CeO2 is higher than that of R-CeO2, the extra electrons produced by the reduction atmosphere should aggregate in the CB of the R-CeO2, further decreasing the CB position. The conduction band offset formed potential barriers to prevent the electrons generated on the anode side from passing through the interface between CeO2 and R-CeO2, thus avoiding a short-circuiting problem. In addition, the built-in field formed by the CeO2/R-CeO2 band energy alignment should promote oxygen ion transport.

a The diffused reflection spectra and b the UPS of as-prepared CeO2 and reduced CeO2. c UPS plots of CeO2 and R-CeO2 with magnified views of the low binding energy cutoff and d the high binding energy cutoff regions. e The energy alignment diagram and f the configuration schematic for the double-layer fuel cell using CeO2 as the electrolyte

In the present work, we discovered that CeO2 without doping can create much better electrical properties and fuel cell performance than those of conventional cation doped ceria, e.g., samarium-doped ceria (SDC) based on bulk ionic conduction. The possible underlying mechanism involves the formation of a surface oxygen-deficient layer and core–shell architecture for reduced CeO2 that is accompanied by band energy alignment to avoid shorting, which is a novel mechanism for ceria electrolyte materials and a novel fuel cell principle. On the other hand, the H2 supplied as fuel reduces the Ce4+ into Ce3+, which has the same doping effect as Sm3+ and improves the ionic conductivity, namely, “self-doping” occurs. However, cation doping and self-doping are different. For example, cation doping, such as with Sm3+ or Gd3+ takes place in the CeO2 particle bulk to create oxygen vacancies, further developing bulk conduction, while self-doping occurs at the particle surface accompanied by oxygen vacancies, leading to different surface conduction mechanisms. Surface conduction has unique advantages, including low activation energy and fast ionic mobility. Both of these advantages contribute to better ionic conductivity and fuel cell performance than conventional cation doped cerium-based electrolytes. For example, Shen et al. reported a Gd-doped ceria (GDC) electrolyte for SOFCs with mixed electronic conduction, resulting in an OCV < 0.9 V and power output < 100 mW/cm32. In other words, the surface conduction induced by fuel cell conditions is distinct from the ordinary O2− conduction mechanism in bulk doped ceria and appears to be a new methodology for the design of new functionalities for advanced technologies in the energy sector, especially for next generation SOFCs.

Conclusions

The occurrence of charged defects and the control of stoichiometry in fluorite CeO2 materials can be accomplished by a reduction treatment, which can strongly affect the CeO2 surface defects. Reducing and oxidizing conditions during cell operation produce CeO2 semiconducting (n-type at the anode and p-type at the cathode)-ionic properties and greatly enhance both the electronic and ionic conductivities. Ionic conductivity may play a dominant role in fuel cell processes and device performance accompanied by sufficient electron conduction. High ionic conductivities have been realized by creating surface defects, e.g., oxygen vacancies and surface pathways. The CeO2 should be reduced to non-stoichiometric CeO2-δ at the anode region and combined with CeO2 at the cathode side to form a double-layer device. The energy band alignment between CeO2-δ/CeO2 can produce efficient charge separation and avoid the device short circuiting problem, while charge separation is an enormous challenge for conventional SOFCs based on a doped ceria electrolyte, where OCV and power losses generally occur to some extent due to the existence of electronic conduction. The semiconducting and ionic properties take advantage of the semiconductor energy band to prevent the electrons from internally migrated simultaneously enhance the ionic transport. The synergistic effect to enhance the ionic conductivity is also observed above 0.1 S/cm at 550 °C. The non-doped CeO2 approach may instigate very interesting new fundamental understanding of the science and promote SOFC development.

References

Moore, J. E. The birth of topological insulators. Nature 464, 194–198 (2010).

Cava, R. J., Ji, H. W., Fuccillo, M. K., Gibson, Q. D. & Hor, Y. S. Crystal structure and chemistry of topological insulators. J. Mater. Chem. C. 1, 3176–3189 (2013).

Roche, F. O. S., Valenzuela, O. & Topological, S. Insulators Fundamentals and Perspectives. (Wiley, Hoboken, 2015).

Reyren, N. et al. Superconducting Interfaces Between Insulating Oxides. Science 317, 1196–1199 (2007).

Ben Shalom, M., Sachs, M., Rakhmilevitch, D., Palevski, A. & Dagan, Y. Tuning spin-orbit coupling and superconductivity at the SrTiO3/LaAlO3 interface: a magnetotransport study. Phys. Rev. Lett. 104, 126802 (2010).

Garcia-Barriocanal, J. et al. Colossal ionic conductivity at interfaces of epitaxial ZrO2:Y2O3/SrTiO3 heterostructures. Science 321, 676–680 (2008).

Kilner, J. A. Ionic conductors: feel the strain. Nat. Mater. 7, 838–839 (2008).

Lee, S. et al. Ionic conductivity increased by two orders of magnitude in micrometer-thick vertical yttria-stabilized ZrO2 nanocomposite films. Nano Lett. 15, 7362–7369 (2015).

Yang, S. M. et al. Strongly enhanced oxygen ion transport through samarium-doped CeO2 nanopillars in nanocomposite films. Nat. Commun. 6, 8588 (2015).

O’Sullivan, M. et al. Interface control by chemical and dimensional matching in an oxide heterostructure. Nat. Chem. 8, 347–353 (2016).

Lin, Y., Fang, S., Su, D., Brinkman, K. S. & Chen, F. Enhancing grain boundary ionic conductivity in mixed ionic–electronic conductors. Nat. Commun. 6, 6824 (2015).

Hwang, H. Y. et al. Emergent phenomena at oxide interfaces. Nat. Mater. 11, 103–113 (2012).

Mannhart, J. & Schlom, D. G. Oxide interfaces—an opportunity for electronics. Science 327, 1607–1611 (2010).

Leon, C., Santamaria, J. & A.Boukamp, B. Oxide interfaces with enhanced ion conductivity. MRS Bull. 38, 1056–1063 (2013).

Fu, Q., Saltsburg, H. & Flytzani-Stephanopoulos, M. Active nonmetallic Au and Pt species on ceria-based water-gas shift catalysts. Science 301, 935–983 (2003).

Deluga, G. A., Salge, J. R., Schmidt, L. D. & Verykios, X. E. Renewable hydrogen from ethanol by autothermal reforming. Science 303, 993–997 (2004).

Alessandro, T., Carla, de, L., Marta, B. & Giuliano, D. The utilization of ceria in industrial catalysis. Catal. Today 50, 353–367 (1999).

Cormai, A., Atienzari, P., Garciai, H. & Chane-Ching, J.-Y. Hierarchically mesostructured doped CeO2 with potential for solar-cell use. Nat. Mater. 3, 394–397 (2004).

Carvalho, L. G. A. et al. Color tunability in green, red and infra-red upconversion emission in Tm3+/Yb3+/Ho3+ co-doped CeO2 with potential application for improvement of efficiency in solar cells. J. Lumin. 159, 223–228 (2015).

Lu, X. H. et al. Facile synthesis of free-standing CeO2 nanorods for photoelectrochemical applications. Chem. Commun. 46, 7721–7723 (2010).

Hua, C. X. et al. Q. Lithium storage mechanism and catalytic behavior of CeO2. Electrochem. Commun. 25, 66–69 (2012).

Wang, G., Bai, J. T., Wang, Y. H., Ren., Z. Y. & Bai, J. B. Prepartion and electrochemical performance of a cerium oxide–graphene nanocomposite as the anode material of a lithium ion battery. Scr. Mater. 65, 339–342 (2011).

Steele, B. C. H. & Heinzel, A. Materials for fuel-cell technologies. Nature 414, 345–352 (2001).

Park, S. D., Vohs, J. M. & Gorte, R. J. Direct oxidation of hydrocarbons in a solid-oxide fuel cell. Nature 404, 265–267 (2000).

Melchionna, M. & Fornasiero, P. The role of ceria-based nanostructured materials in energy applications. Mater. Today 17, 349–357 (2014).

Sun, C. W., Li, H. & Chen, L. Q. Nanostructured ceria-based materials: synthesis, properties, and applications. Energy Environ. Sci. 5, 8475–8505 (2012).

Campbell, C. T. & Peden, C. H. F. Oxygen vacancies and catalysis on ceria surfaces. Science 309, 713–714 (2005).

Knoblauch, N., Dörrer, L., Fielitz, P., Schmücker, M. & Borchardt, G. Surface controlled reduction kinetics of nominally undoped polycrystalline CeO2. Phys. Chem. Chem. Phys. 17, 5849–5860 (2015).

Chen, X. Y., Yu, J. S. & Adler, S. B. Thermal and chemical expansion of Sr-doped lanthanum cobalt oxide (La1−xSrxCoO3−δ). Chem. Mater. 17, 4537–4546 (2005).

Hong, T., Zhang, Y. X. & Brinkman, K. Enhanced oxygen electrocatalysis in heterostructured ceria electrolytes for intermediate-temperature solid oxide fuel cells. ACS Omega 3, 13559–13566 (2018).

Zhang, T. S., Peter, H., Huang, H. T. & Kilner, J. Ionic conductivity in the CeO2–Gd2O3 system (0.05≤Gd/Ce≤0.4) prepared by oxalate coprecipitation. Solid State Ion. 148, 567–573 (2002).

Shen, S. L., Yang, Y. P., Guo, L. J. & Liu, H. T. A polarization model for a solid oxide fuel cell with a mixed ionic and electronic conductor as electrolyte. J. Power Sources 256, 43–51 (2014).

Tschöpe, A. & Birringer, R. Grain size dependence of electrical conductivity in polycrystalline cerium oxide. J. Electroceram. 7, 169–177 (2001).

Goodenough, J. B. Oxide-ion conductors by design. Nature 404, 821–823 (2000).

Chadwick, A. V. Solid progress in ion conduction. Nature 408, 925–926 (2000).

Feng, B. et al. Atomic structures and oxygen dynamics of CeO2 grain boundaries. Sci. Rep. 6, 20288 (2015).

Fu, Y.-P., Chen, S.-H. & Huang, J.-J. Preparation and characterization of Ce0.8M0.2O2−δ (M = Y, Gd, Sm, Nd, La) solid electrolyte materials for solid oxide fuel cells. Int. J. Hydrog. Energy 35, 745–752 (2010).

Skorodumova, N. V., Simak, S. I., Lundqvist, B. I., Abrikosov, I. A. & Johansson, B. Quantum origin of the oxygen storage capability of ceria. Phys. Rev. Lett. 89, 166601 (2002).

Wu, L. J. et al. Oxidation state and lattice expansion of CeO2−x nanoparticles as a function of particle size. Phys. Rev. B 69, 125415 (2004).

Ho, C. M. et al. Morphology-controllable synthesis of mesoporous CeO2 nano- and microstructures. Chem. Mater. 17, 4514–4522 (2005).

Zhou, Y. H., M. Perket, J. & Zhou, J. Growth of Pt nanoparticles on reducible CeO2 (111) thin films: effect of nanostructures and redox properties of ceria. J. Phys. Chem. C. 114, 11853–11860 (2010).

Bêche, E. et al. Ce 3d XPS investigation of cerium oxides and mixed cerium oxide (CexTiyOz). Surf. Interface Anal. 40, 264–267 (2008).

Gázquez, J. et al. Applications of STEM-EELS to complex oxides. Mat. Sci. Semicon. Proc. 65, 49–63 (2017).

Hojo, H. et al. Atomic structure of a CeO2 grain boundary: the role of oxygen vacancies. Nano Lett. 10, 4668–4672 (2010).

Song, K. P. et al. Cerium reduction at the interface between ceria and yttria-stabilised zirconia and implications for interfacial oxygen non-stoichiometry. APL Mater. 2, 032104 (2014).

Yan, D. T. et al. Electrical properties of grain boundaries and size effects in samarium-doped ceria. J. Power Sources 195, 6486–6490 (2010).

Zhu, B. et al. Novel fuel cell with nanocomposite functional layer designed by perovskite solar cell principle. Nano Energy 19, 156–164 (2016).

Zhu, B. et al. Charge separation and transport in La0.6Sr0.4Co0.2Fe0.8O3-δ and ion-doping ceria heterostructure material for new generation fuel cell. Nano Energy 37, 195–202 (2017).

Martin, D. & Duprez, D. Mobility of surface species on oxides. 1. Isotopic Exchange of 18O2 with 16O of SiO2, Al2O3, ZrO2, MgO, CeO2, and CeO2-Al2O3. Activation by noble metals. Correlation with oxide basicity. J. Phys. Chem. C. 100, 9429–9438 (1996).

Martin, D. & Duprez, D. Mobility of surface species on oxides. 2. Isotopic exchange of D2 with H of SiO2, Al2O3, ZrO2, MgO, and CeO2: Activation by rhodium and effect of chlorine. J. Phys. Chem. B 101, 4428–4436 (1997).

Lai, W. & Haile, S. M. Impedance spectroscopy as a tool for chemical and electrochemical analysis of mixed conductors: a case study of ceria. J. Am. Ceram. Soc. 88, 2979–2997 (2005).

Yokokawa et al. Thermodynamic reconsiderations on electronic properties of pure- and doped-ceria. ECS Trans. 28, 165–172 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC, Grant Nos. 51872080, 51772080 and 51502084), the Scientific Research Foundation for Returned Scholars, Ministry of Education of China (No. 2013032017), the Swedish Research Council (Grant No. 621-2011-4983), the European Commission FP7 TriSOFC-project (Grant No. 303454), and the Swedish Agency for Innovation Systems (VINNOVA).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, B., Zhu, B., Yun, S. et al. Fast ionic conduction in semiconductor CeO2-δ electrolyte fuel cells. NPG Asia Mater 11, 51 (2019). https://doi.org/10.1038/s41427-019-0152-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41427-019-0152-8

This article is cited by

-

Binder-Free Electrospun Nickel Cerium Selenide Nanofiber Electrodes Based on Voltage-Stimulated Diameter Refinement for Solar-Charged Quasi-solid-State Wearable Supercapacitors

Advanced Fiber Materials (2024)

-

Synthesis and characterization of nanocrystalline Ce0.9Gd0.1O2-δ powders with ameliorated ionic conductivity by citrate combustion route

Journal of Materials Science: Materials in Electronics (2023)

-

Fast ionic conduction and boosted cathode reaction enabled by BSCF–YSZ for LT-SOFC application

Journal of Materials Science: Materials in Electronics (2023)

-

Synthesis and characterization of (La, Cu) co-doped CeO2 nanomaterials used as electrolyte material in SOFC applications

Applied Physics A (2023)

-

Electrical Characteristics of Bismuth-Containing Cerium Oxide

Glass and Ceramics (2023)