Abstract

The prevalence of tooth wear has increased significantly in recent decades. Whilst many treatment approaches are available, there is no consensus on the best materials or techniques. Advances in digital workflows have the potential to reduce the biological cost of treatment, improve treatment outcomes and reduce costs. This article describes modern CAD/CAM techniques which preserve tooth tissue and improve efficiency.

Similar content being viewed by others

Key points

-

Discusses the benefits that digital dentistry offers for the management of tooth wear.

-

Discusses how CAD/CAM techniques could reduce tooth preparation and improve efficiency.

-

Discusses the available materials for restoring tooth wear.

Introduction

Over the last decade, the United Kingdom has experienced a significant increase in the prevalence of tooth wear.1,2 Therefore, dentists must be well equipped to manage this condition. Prevention is key but restorative interventions, when indicated, can be complex.

In recent years, restorative techniques have altered towards more conservative treatment approaches. There is currently no consensus regarding the best technique or material for restoring the worn dentition. This is likely to be dependent on many different factors.3,4 For example, the presence of parafunction may contra-indicate the use of weaker materials, such as feldspathic porcelain. A lack of tooth tissue would favour conservative restoration designs with optimised bonding protocols in order to minimise tooth tissue reduction. Much of the current research is focused on finding the optimal techniques and materials for the management of tooth wear.

The digital age has revolutionised many aspects of our lives, ranging from entertainment to healthcare. One would hope that technological advances in dentistry will provide both dentists and patients with simpler and more affordable options. This paper aims to review the existing literature surrounding the use of modern CAD/CAM materials in the treatment of tooth wear. The clinical application of these materials is outlined, with several cases used to illustrate the techniques involved. There is a particular focus on how a digital workflow can be used to reduce the biological cost of restorations. We discuss design choices and specific milling/cementing techniques which preserve tooth tissue and improve efficiency.

Current approaches to the management of tooth wear

The role of direct composites

In the UK, direct composites are a popular method of restoring tooth wear.5,6 Their conservative, additive-only nature makes them an attractive option. In addition, they are repairable, relatively inexpensive and require minimal laboratory input.3

With that said, direct application is time consuming and tiring, particularly for generalised tooth wear cases where multiple prolonged visits are required. Manipulation of the composite can be technique sensitive and dependent on the operator's skill. Consequently, many general dental practitioners are not confident in providing this treatment. This has contributed to an ever-increasing number of referrals to secondary care centres.

In addition, direct composite build-ups require maintenance due to chipping, wearing and staining over time.4 It will be important to follow-up cases carefully to ensure that wear of the composite does not adversely alter guidance patterns. Despite this, high patient satisfaction has been reported with this treatment approach.7

Many still view composite build-ups as a medium-term solution, as there have been few long-term studies.3 Studies examining medium-term survival have reported survival rates between 50% and 95% up to 10 years.7,8,9,10 These studies are limited by small sample sizes and short follow-ups. A recent large scale prospective 8-year evaluation of 1,010 composites reported a survival of 93% over a mean follow-up of 33.8 months.9 The longest follow-up reported 50% survival of 283 composites at seven years.6 At ten years, 90% experienced a major or minor failure, illustrating the maintenance burden.

Ultimately, whilst direct composites are a suitable treatment option, there are many reasons to consider indirect restorations. Repeated failure, excessive maintenance burden and the skill level required are all factors which may influence the treatment plan. Regardless of the reason, the clinician then has to consider what the best material and preparation design is.

The role of indirect restorations in the management of tooth wear

There is a long history of using metal, metal ceramic and all ceramic restorations for the management of tooth wear. Whilst they may be durable, they have the potential to be highly destructive.11 Indirect composites are also a viable option. Short- and medium-term studies have been favourable, although there is a lack of data on long-term outcomes. Recent studies with follow-up periods between 2 to 5 years have reported survival rates of 87.2% to 97.4%.12,13,14,15,16 Longer term studies are required to clarify which approaches are most appropriate. To successfully manage the increasing prevalence of tooth wear, simplified solutions are required in order to overcome the limitations of traditional direct and indirect approaches.

The next paradigm shift - what can digital dentistry offer in the management of tooth wear?

Major advancements in digital dentistry and material science allow clinicians to develop novel treatment approaches. With the help of technology, time and cost can be decreased. Recently, a European agreement was published advocating an additive adhesive approach.4 CAD/CAM adhesive restorations satisfy this as they require minimal to no preparation and can be reliably bonded.

Digital scans can be obtained through direct intra-oral scanning or by scanning a conventional cast. Restorations can be designed using software or after scanning a diagnostic wax-up. Software can also accept digital (and analogue) facebows and facial scans. Models can be virtually articulated in both static and dynamic occlusion. More commercial labs are now adopting computer designed wax-ups due to their efficiency in terms of reduced design and fabrication time and reduced running costs. Indeed, it could be argued that the skillset of the modern dental technician is migrating away from traditional methods and towards CAD/CAM design. When compared to traditional indirect restorations, these improved efficiencies lend themselves to cost effective production, particularly in cases requiring multiple units. Automatic wax-up proposals are becoming increasingly accurate, reducing the time spent on digital design. Furthermore, as the use of intraoral scanners increases, the availability of, and need for, physical models will reduce. Finally, the manufacturing processes for CAD/CAM materials lead to reliable material properties such as lack of voids and a high degree of polymerisation. By contrast, traditional methods can introduce undesirable errors such as contamination within feldspathic porcelain, voids in wax patterns or casting defects. A meta-analysis of in-vitro studies reported superior marginal and internal fit of digitally manufactured restorations compared to conventional restorations.17

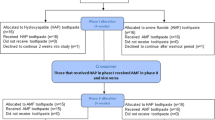

Several studies have reported good accuracy of intraoral scanners,18,19,20 although full-arch conventional impressions may still be more precise.21 Digital scans can be acquired in several ways. In the cases demonstrated in this paper, conventional impressions and casts were digitised to provide optimal precision over the full arch in line with current best evidence.21,22 The prostheses were milled, the advantages and disadvantages of which are discussed in Table 1.

Conservative CAD/CAM approaches to the management of tooth wear

In this paper, we describe a CAD/CAM based approach to conservatively manage tooth wear. The principles discussed are demonstrated by three clinical cases (Fig. 1, Fig. 2 and Fig. 3). We highlight specific design choices and cementation techniques. Finally, we discuss the reasoning behind how this approach can improve treatment efficiency whilst reducing the biological costs.

Case 1 - Description: With no preparation being carried out, conventional impressions were taken with Dcode silicone putty/wash impression material (Coltene Whaledent). D-code silicone has been formulated to have a matt surface when set, making it optimal for scanning. The impressions and casts were scanned along with a wax-up. These were used to create CAD designs (inLab, Dentsply Sirona) and restorations were milled from Crios blocks (Coltene Whaledent) in an MCXL machine (Denstply Sirona). The restorations were sandblasted on the fitting surfaces and cemented with One-coat 7 Universal and Duo-cem (Coltene Whaledent), following the manufacturer's instructions. The occlusion was re-organised with a slight posterior disclusion and posterior re-positioning of the mandible into the retruded arc of closure. The posterior teeth settled back into occlusion within a few weeks. (Case 1 by P. Nixon)

Case 2 - Description: Minimal preparation was used to create a finish line for each restoration. Conventional impressions were taken using D-code silicone impression material (putty and wash). The impressions and casts were scanned. A wax-up was carried out to increase the occlusal vertical dimension and restore normal dental contours. This was subsequently scanned. The specific CAD design allowed for undercuts in the preparations and overcontoured margins (to ensure correct milling). The final restorations were milled from high translucency Crios blocks (Coltene Whaledent). After polishing, the restorations were sandblasted on the fitting surfaces and cemented with One-coat 7 Universal and Everglow hybrid composite (Coltene Whaledent), following the manufacturer's instructions. A specific technique is required when cementing with composite to ensure correct seating. As illustrated by Figures 2j-n, the restoration is firmly seated for one minute to encourage the composite to flow out. The excess is then removed. The restorations need to be translucent enough for light to penetrate. With this cementation technique the 'cement' is a resin composite. As a result, any voids, undercuts or deficient margins are restored with conventional filling material, becoming a cohesive part of the restoration. The clinician then adjusts and polishes it into the desired shape and occlusal configuration. (Case by P. Nixon)

Case 3 - Description: Upper incisor and canine build-ups were planned to protect the teeth and restore form and function. Gross approximal undercuts were removed with minimal preparation (Fig. 3c: the central incisors had spacing pre-treatment). No labial or palatal reduction was performed. Silicone impressions were poured and scanned along with a scan of the wax-ups designed to increase the vertical dimension by 3 mm in the retruded arc of closure. CAD designs were heavily overcontoured labially to ensure a good mill and to strengthen the material during cementation (Figs 3d and 3e). Cerasmart (GC Europe) restorations were sandblasted on the fitting surfaces and cemented using Scotchbond Universal Adhesive and Rely-X Ultimate, following the manufacturer's instructions. Labial recontouring and polishing could subsequently take place (not shown). (Case by A. Keeling)

Tooth preparation and restoration design

Traditional all-ceramic and metal-ceramic crowns are associated with over 60% coronal tissue loss.11 Although the reduction required in the worn dentition would be less, notable preparation is often still needed. As illustrated by Figure 1, it is possible to use indirect milled composite restorations without tooth preparation. This is due to the specific milling design, material selection and cementation techniques chosen. We compensate for the lack of marginal preparation and tooth reduction during the restoration design and cementation.

The milled restorations can be intentionally overcontoured for several reasons. Firstly, this achieves an adequate thickness for the milling process. It also gives the restorations enough strength to withstand the cementation process. Finally, overcontouring allows us to ignore undercuts, thus preserving valuable tooth tissue. Inevitably, this may result in larger and poorer fitting restorations. Unlike with conventional crowns, this can be offset by the choice of cement material. Cementation with a composite resin fills any voids and forms a homogenous unit with the restoration. The restoration is then adjusted to remove any overhangs and create smooth margins.

A crucial component to this technique is cementation with a composite resin. Unlike with traditional crowns, where the cement is a weak point, in this technique the composite cement fills any voids that may be present. A key concept to appreciate is that the restoration and the cement form a homogenous unit. This is then easily adjustable, allowing the clinician to manage any overhangs, over contouring or occlusal issues by simply adjusting the restorations.

As illustrated by Figure 2, minimal preparation can be carried out to create a finish line for the restorations. This preparation makes it easier to define the edge of the restoration for the milling process.

Material choices

There are a plethora of materials that can be utilised in a CAD/CAM approach for the management of tooth wear. These include ceramics and composites, and relatively new materials such as resin-ceramics. Composite resins and resin-ceramics are the materials of choice for this technique for several key reasons.

Resin-ceramics were designed to combine the beneficial properties of ceramics and composites.23 Traditional ceramics have excellent chemical stability, aesthetics and generally superior mechanical properties. Compared to resins, their flexural modulus, flexural strength and hardness are greater.24,25 However, ceramics are brittle and repairing them is difficult. Conversely, composites wear faster, lose their polish quicker and generally have inferior mechanical properties.

To overcome the brittle nature of ceramics, hybridisation with a resin successfully increased the material's flexibility.26 Their elastic modulus is similar to that of both dentine and adhesive cements, allowing for a uniform stress distribution.26,27 This has resulted in superior fatigue resistance to ceramics.28,29,30 This is a particularly important property when managing cases of attrition, where an element of pathological bruxism may still be present. They have lower hardness values than ceramics, meaning they are less likely to cause pathological wear. It does however also mean that they wear faster than ceramics.31,32

Polishing resin-ceramics is simpler, requiring only regular composite polishing equipment. In contrast, ceramics require specialised equipment, and if left unpolished, are overly abrasive.33 Furthermore, the milling and polishing processes are simpler than ceramics, with no post-milling stages required except sprue removal and sandblasting (or acid etching).

Resin-ceramic materials can be milled thinner than ceramics, with less chipping of the fine edges. This is an important property for our technique, where the lack of preparation may leave the restoration with thin margins.34,35

They form a strong adhesive bond to composite, meaning it is easy to make adjustments and additions. This allows clinicians to characterise and repair restorations intra-orally.36,37 When compared to resins, resin-ceramics have shown a greater degree of resistance to degradation in stimulated oral environments.36,38

Cerasmart (GC Europe) is a resin-ceramic. It was the choice of material for the case illustrated in Figure 3 because the uniform nano-filler dispersal aids predictable milling in thin sections while maintaining strength. Cerasmart has outperformed several ceramics and resins during in-vitro flexural testing. It was also found to have the smoothest and most accurate post-milling margin. This is likely due to its less brittle nature.34

It should be emphasised that because of their relative novelty, there are currently limited data on the clinical performance of resin-ceramics. One would expect this to change as their use increases following the positive findings from in-vitro studies.

Advantages of the proposed technique

Key advantages of the proposed technique:

- 1.

More conservative. We propose accepting undercuts and minimising marginal reduction. This lowers the biological cost and makes the procedure technically simpler

- 2.

Less concern about margin precision and thickness. Careful cementation with a composite cement should fill voids and form a homogenous unit with the restoration. After cutting back and polishing, the restoration-tooth margin should be imperceptible

- 3.

Simpler chairside occlusal refinement. Accurate articulation of the models can be difficult to achieve, particularly in cases where the occlusal vertical dimension (OVD) is being altered. Despite the use of best practices, such as the facebow, some occlusal adjustment is likely to be required due to inherent operator variability and technique inaccuracies.39,40,41 Milled composite restorations can be easily adjusted post-cementation. This can save a significant amount of chairside time compared to conventional indirect restorations

- 4.

Greater clinician control. The final restoration's shape and occlusal surfaces are easily adjusted as desired. In the case of a chairside system, the clinician controls the full design

- 5.

Reduced costs. Reduced chairside time could lead to a cost saving. The blocks from which these restorations are milled typically cost around £15-20 and design software is improving in its usability (negating the need for physical wax-ups). A large upfront investment is required for a fully chairside system, but the techniques can equally be applied with no change to the chairside impression technique.

It should be noted that there are a lack of long-term data available to support this technique. Due to rapidly changing technology and materials, it can be challenging to conduct long-term clinical studies.

Conclusions

The technique described in this paper demonstrates good aesthetic and functional outcomes, whilst also preserving tooth tissue. Moreover, it has the potential to be much more time-efficient and cost-effective than traditional methods. The attractive features of this technique are its low biological cost and simplicity. As digital dentistry evolves and becomes more widely available, it has the potential to offer clinicians efficient and simplified treatment options for the management of tooth wear in general practice.

References

White D A, Tsakos G, Pitts N B et al. Adult Dental Health Survey 2009: common oral health conditions and their impact on the population. Br Dent J 2012; 213: 567.

Nunn J, Morris J, Pine C, Pitts N B, Bradnock G, Steele J. Adult dental health survey: The condition of teeth in the UK in 1998 and implications for the future. Br Dent J 2000; 189: 639.

Mesko M E, Sarkis-Onofre R, Cenci M S et al. Rehabilitation of severely worn teeth: A systematic review. J Dent 2016; 48: 9-15.

Loomans B, Opdam N, Attin T et al. Severe tooth wear: European consensus statement on management guidelines. J Adhes Dent 2017; 19: 111-119.

Darbar U R, Hemmings K W. Treatment of localized anterior tooth wear with composite restorations at an increased occlusal vertical dimension. Dent Update 1997; 24: 72-75.

Gulamali A B, Hemmings K W, Tredwin C J, Petrie A. Survival analysis of composite Dahl restorations provided to manage localised anterior tooth wear (ten year follow-up). Br Dent J 2011; 211: E9.

Aljawad A, Rees J S. Retrospective study of the survival and patient satisfaction with composite Dahl restorations in the management of localised anterior tooth wear. The Eur J Prosthodont Restor Dent 2016; 24:222-229.

Bartlett D, Varma S. A retrospective audit of the outcome of composites used to restore worn teeth. Br Dent J 2017; 223: 33.

Milosevic A, Burnside G. The survival of direct composite restorations in the management of severe tooth wear including attrition and erosion: A prospective 8year study. J Dent 2016; 44: 13-19.

Hemmings K W, Darbar U R, Vaughan S. Tooth wear treated with direct composite restorations at an increased vertical dimension: results at 30 months. J Prosthet Dent 2000; 83: 287-293.

Edelhoff D, Sorensen J A. Tooth structure removal associated with various preparation designs for anterior teeth. J Prosthet Dent 2002; 87: 503-509.

D'Arcangelo C, Zarow M, De Angelis F et al. Five-year retrospective clinical study of indirect composite restorations luted with a light-cured composite in posterior teeth. Clin Oral Investig 2014; 18: 615-624.

De Angelis F, D'arcangelo C, D'amario M, Zazzeroni S, Ciampoli C, Caputi S. The influence of luting systems on the microtensile bond strength of dentin to indirect resin-based composite and ceramic restorations. Oper Dent 2009; 34: 328-336.

Manhart J, Neuerer P, Scheibenbogen-Fuchsbrunner A, Hickel R. Three-year clinical evaluation of direct and indirect composite restorations in posterior teeth. J Prosthet Dent 2000; 84: 289-296.

Barone A, Derchi G, Rossi A, Marconcini S, Covani U. Longitudinal clinical evaluation of bonded composite inlays: A 3-year study. Quintessence Int 2008; 39: 65-71.

Gow A M, Hemmings K W. The treatment of localised anterior tooth wear with indirect Artglass restorations at an increased occlusal vertical dimension. Results after two years. The Eur J Prosthodont Restor Dent 2002; 10: 101-105.

Chochlidakis K M, Papaspyridakos P, Geminiani A, Chen C J, Feng I J, Ercoli C. Digital versus conventional impressions for fixed prosthodontics: A systematic review and meta-analysis. J Prosthet Dent 2016; 116: 184-190.

Patzelt S B, Emmanouilidi A, Stampf S, Strub J R, Att W. Accuracy of full-arch scans using intraoral scanners. Clin Oral Investig 2014; 18: 1687-1694.

Ryakhovskiy A N, Kostyukova V V. Comparative analysis of 3D data accuracy of single tooth and full dental arch captured by different intraoral and laboratory digital impression systems. Stomatologiia 2016; 95: 65-70.

Renne W, Ludlow M, Fryml J et al. Evaluation of the accuracy of 7 digital scanners: An in vitro analysis based on 3dimensional comparisons. J Prosthet Dent 2017; 118: 36-42.

Ender A, Attin T, Mehl A. In vivo precision of conventional and digital methods of obtaining complete-arch dental impressions. J Prosthet Dent 2016; 115: 313-320.

Ahlholm P, Sipilä K, Vallittu P, Jakonen M, Kotiranta U. Digital versus conventional impressions in fixed prosthodontics: a review. J Prosthodont 2016; 27: 35-41.

Horvath S D. Key parameters of hybrid materials for CAD/CAM-based restorative dentistry. Compend Contin Educ Dent 2016; 37: 638-643.

Quinn J B, Quinn G D. Material properties and fractography of an indirect dental resin composite. Dent Mater 2010; 26: 589-599.

Ferracane J L. Resin composite - state of the art. Dent Mater 2011; 27: 29-38.

Ausiello P, Rengo S, Davidson C L, Watts D C. Stress distributions in adhesively cemented ceramic and resin-composite Class II inlay restorations: a 3D-FEA study. Dent Mater 2004; 20: 862-872.

Coldea A, Swain M V, Thiel N. Mechanical properties of polymerinfiltratedceramicnetwork materials. Dent Mater 2013; 29: 419-426.

Schlichting L H, Maia H P, Baratieri L N, Magne P. Novel-design ultra-thin CAD/CAM composite resin and ceramic occlusal veneers for the treatment of severe dental erosion. J Prosthet Dent 2011; 105: 217-226.

Magne P, Knezevic A. Simulated fatigue resistance of composite resin versus porcelain CAD/CAM overlay restorations on endodontically treated molars. Quintessence Int 2009; 40: 125-133.

Johnson A C, Versluis A, Tantbirojn D, Ahuja S. Fracture strength of CAD/CAM composite and composite-ceramic occlusal veneers. J Prosthodont Res 2014; 58: 107-114.

Coldea A, Swain M V, Thiel N. In-vitro strength degradation of dental ceramics and novel PICN material by sharp indentation. J Mech Behavior Biomed Mater 2013; 26: 34-42.

Mörmann W H, Stawarczyk B, Ender A, Sener B, Attin T, Mehl A. Wear characteristics of current aesthetic dental restorative CAD/CAM materials: two-body wear, gloss retention, roughness and Martens hardness. J Mech Behavior Biomed Mater 2013; 20: 113-125.

Fasbinder D J, Neiva G F. Surface evaluation of polishing techniques for new resilient CAD/CAM restorative materials. J Esthet Restor Dent 2016; 28: 56-66.

Awada A, Nathanson D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J Prosthet Dent 2015; 114: 587-593.

Lebon N, Tapie L, Vennat E, Mawussi B. Influence of CAD/CAM tool and material on tool wear and roughness of dental prostheses after milling. J Prosthet Dent 2015; 114: 236-247.

Lauvahutanon S, Takahashi H, Shiozawa M et al. Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J 2014; 33: 705-710.

Koller M, Arnetzl G V, Holly L, Arnetzl G. Lava ultimate resin nano ceramic for CAD/CAM: customization case study. Int J Comput Dent 2012; 15: 159-164.

Thornton I, Ruse N D. Characterization of nanoceramic resin composite and lithium disilicate blocks. J Dent Res 2014; 93: 151.

Jesús G, Dib A, Espinosa I. Face bows in the development of Michigan occlusal splints. Rev Fac Odontol Univ Antioquia 2013; 25: 117-131.

Shodadai S, Türp J, Gerds T, Strub J. Is there a benefit of using an arbitrary facebow for the fabrication of a stabilization appliance? Int J Prosthodont 2001; 14: 517-522.

Choi D, Bowley J, Marx D, Lee S. Reliability of an ear-bow arbitrary face-bow transfer instrument. J Prosthet Dent 1999; 82: 150-156.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Antov, H., Jablonski, R., Keeling, A. et al. CAD/CAM techniques for the conservative and efficient management of tooth wear. Br Dent J 227, 791–796 (2019). https://doi.org/10.1038/s41415-019-0889-z

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41415-019-0889-z

This article is cited by

-

Let's CAD/CAM

British Dental Journal (2020)