Abstract

In this manuscript, the scalability and recyclability of the catalytic transesterifications of polysaccharides with 1-ethyl-3-methylimidazolium acetate (EmimOAc) as both the solvent and the organocatalyst were evaluated. For the organocatalytic transesterifications of cellulose with EmimOAc, EmimOAc was recycled four times without an obvious decrease in its catalytic activity, and the recovery ratio of EmimOAc was sufficiently high (at least 96 wt%). To show the applicability of EmimOAc-catalyzed transesterifications, the EmimOAc-catalyzed cellulose modification was expanded to a gram-scale reaction with various polysaccharide sources, such as pulps, rayon, xylan, pullulan, and dextrin, which provides the corresponding polysaccharide esters with a practically perfect degree of substitution values.

Similar content being viewed by others

Introduction

During recent decades, metal-free catalysts, the so-called organocatalysts, have emerged in the chemical sciences.1, 2, 3, 4, 5, 6 With the rapid growth of organocatalysts in organic chemistry, these catalysts have gradually been integrated into polymer chemistry. For example, efficient organocatalysts have been utilized in a range of polymer syntheses, including the ring opening polymerizations of cyclic esters,7, 8, 9, 10, 11, 12, 13, 14 epoxides,15, 16, 17 and cyclic siloxane18; the group transfer polymerization of vinyl monomers;19, 20, 21, 22, 23, 24 step-growth polymerizations;7, 25, 26 and post-polymerization modification reactions,27 among others.28, 29

When considering that organocatalysts are free from organometallics and thus exhibit a ‘green nature’, the integration of organocatalysts into biorenewable resources provides new directions in biomass-related science and polymer chemistry. For example, organocatalysts have been utilized for the ring opening polymerization of bio-based cyclic esters,30 vinyl polymerization of bio-renewable monomers31, 32 and polymer analogous reactions of cellulose.33, 34, 35, 36, 37 Since polysaccharides, including cellulose, are one of the most important chemical sources, the utilization of cellulose as a starting material has been a long-lasting challenge in biomass-related chemistries.38 Owing to its strong inter- and intra-hydrogen bonding, cellulose is not soluble in aqueous to organic reaction media. In this context, imidazolium-based ionic liquids (Im-ILs) have been highlighted in biomass-related technologies since Im-ILs are known to dissolve cellulose under mild conditions without harming the cellulose’s chemical structure.39, 40 In addition to their excellent cellulose dissolving property, Im-ILs have become organocatalysts based on their molecular structure.41 Recently, we reported that Im-ILs may provide dual functions as an organocatalyst and a reaction solvent for cellulose modification reactions.35, 36 In particular, cellulose was subjected to transesterification reactions in 1-ethyl-3-methylimidazolium acetate (EmimOAc) with stable esters, such as isopropenyl acetate. EmimOAc behaved both as a reaction medium and an organocatalyst for the transesterification. Thus, our synthetic protocol has realized not only active but also instinctively green cellulose modification reactions, which potentially lead to materials science based on cellulose.

Despite the inherent green nature of the cellulose modification protocol, the practical aspect of the reaction system has remained a consideration. The cellulose modification reactions were conducted on a milligram scale starting from a single cellulose source. In this context, the use of a wide range of polysaccharides, including cellulose, needs to be addressed. Additionally, because Im-ILs are expensive compared with common organic solvents, their reusability should be verified. Since Im-ILs are both chemically stable and involatile even under high vacuum conditions, high vacuum distillation of the reaction system should easily recover the Im-ILs. However, these issues have not been addressed in detail in our latest studies. With the intrinsic green advantage of polysaccharides (including cellulose), an improvement in the practical applicability of organocatalytic transesterification will provide a practical and operationally easy synthetic strategy to both polymer chemists and materials scientists who wish to use polysaccharide derivatives.

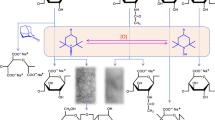

We now provide an insight into the practical applicability of our synthetic protocol (Scheme 1). This article represents: (1) scalability of the organocatalytic transesterification reactions for a range of polysaccharides, including cellulose, and (2) recyclability of EmimOAc for cellulose modification reactions.

Experimental Procedures

Materials

1-Ethyl-3-methylimidazolium acetate (EmimOAc; 95%), dichloromethane, methanol, chloroform, chloroform-d (CDCl3) and dimethylsulfoxide-d6 (DMSO-d6) were obtained from Kanto Chemical Co., Inc. (Tokyo, Japan), and used without further purification. Isopropenyl acetate (99%) and dimethyl sulfoxide (DMSO; anhydrous>99.9%) were obtained from the Sigma-Aldrich Chemicals Japan KK (Tokyo, Japan), and used as received. As the cellulose source, Avicel PH-101 was purchased from the Sigma-Aldrich Chemicals Japan KK. The apparent molecular weight of Avicel was determined using size exclusion chromatography measurements in tetrahydrofuran (THF) with polystyrene calibrations of the carbanilated cellulose sample (reacted with phenyl isocyanate). The carbanilation reaction was carried out according to a previously reported method.42 The apparent number of the average degree of polymerization of the original cellulose was calculated to be 105. The cellulose sources, pulps A, B and C, and rayon, were kindly supplied by DAICEL Chemical Industries, Ltd (Tokyo, Japan). Xylan, pullulan and benzoyl chloride were purchased from Tokyo Chemical Industry Co., Ltd (Tokyo, Japan). Dextrin was purchased from Nakalai Tesque, Inc (Kyoto, Japan). All other chemicals were commercially available and used without further purification unless otherwise stated.

Instruments

All 1H and 13C NMR spectra in solution were recorded using JEOL (Tokyo, Japan) 400 and 600 MHz FT-NMR spectrometers in deuterated solvents, and the chemical shifts (δ) were given in p.p.m. with either the solvent peak or TMS as the internal standard. Size exclusion chromatography measurements of the polysaccharides were performed in CHCl3 at 40 °C with the flow rate of 1.0 ml min−1 using a Shimadzu (Kyoto, Japan) Prominence gel permeation chromatography system (DGU-20A degassing unit, LC-20AD pump, SIL-20A HT auto sampler, CTO-20A column oven, and RID-20A refractive index detector) with two Shodex KF-806L columns (Showa Denko K.K., Tokyo, Japan). The number average molecular weight (Mn,SEC) and polydispersity (Mw/Mn) were determined by the RI based on polystyrene standards (polystyrenes with molecular weights of 0.5 K, 2.42 K, 5.97 K, 18.1 K, 37.9 K, 190 K, 427 K, 1090 K, 2110 K, 8420 K g mol−1).

Transesterification reaction of cellulose in EmimOAc/DMSO mixed solvents

A typical reaction based on the transesterification reaction of cellulose was conducted as follows: a solution of cellulose (120 mg, [monomeric unit]0=0.74 mmol) in EmimOAc (4.00 g, 23.5 mmol) was dried for 4 h under vacuum conditions at 80 °C. After the drying process was finished, DMSO (4.00 ml) and isopropenyl acetate (4.00 ml, 36.8 mmol) were added under an argon atmosphere. After the reaction mixture was stirred for 30 min, the reaction mixture was diluted with CH2Cl2 and poured into a large amount of methanol. The obtained polymer was purified by reprecipitation (CH2Cl2/methanol) to yield a pale yellowish powder. Yield: 192 mg.

Determination of degree of substitution values of cellulose acetates

The degree of substitution (DS) values of the obtained cellulose acetates were determined using 1H NMR measurements of the cellulose derivatives that were obtained via the reaction of cellulose acetate with an excess amount of benzoyl chloride. The typical procedure is as follows: a 4 ml CHCl3 solution of cellulose acetate (100 mg, 347 μmol), benzoyl chloride (440 mg, 3.1 mmol) and triethylamine (318 mg, 3.1 mmol) was stirred for 24 h at room temperature. The reaction mixture was then poured into a large quantity of methanol. The obtained precipitate was collected and dried under vacuum conditions. Yield: 90.1 mg.

The DS values were calculated using the following equation:

To avoid the potential overlap of the aromatic protons and solvent peak, NMR measurements were conducted in DMSO-d6. The DS determination for the polysaccharide derivatives was conducted in a similar manner to cellulose acetate.

Results and discussion

Recycling and reusing EmimOAc for cellulose modification reactions in EmimOAc/DMSO mixed solvent systems.

To facilitate a greener and more practical cellulose modification protocol, we first focused on the recyclability and reusability of EmimOAc. Therefore, the initial purpose of this study was to test whether the employed EmimOAc could be recycled and reused for cellulose modification reactions in EmimOAc. Owing to the high viscosity and cost associated with the use of EmimOAc, the cellulose modification reaction was optimized in our latest study.35 In our study, the optimized reaction used DMSO as both a co-solvent and as an efficient accelerator for the organocatalytic ability of EmimOAc. Specifically, the cellulose modification reaction was conducted in the EmimOAc/DMSO mixed solvent with isopropenyl acetate as an ester donating reagent and EmimOAc as a cellulose solvent and an organocatalyst for the transesterification. The initial cellulose modification condition of [Cellulose]0/[EmimOAc]0/[DMSO]0/[IPA]0 was 120 mg/4.0 g/4.4 g/3.7 g with the cellulose concentration at 1.0 wt %. The transesterification reaction was conducted for 30 min under an Ar atmosphere at 80 °C. As previously reported, the cellulose transesterification reaction led to cellulose acetate featuring a high DS value of 2.95 (Figure 1). After the cellulose acetate was isolated via simple reprecipitation into methanol, the resultant methanol layer was evaporated and subsequently distilled under a high vacuum (Scheme 2). This provided the employed EmimOAc with a 99.2 wt % recovery ratio (run 1, Table 1). In the 1H NMR spectrum of the recovered EmimOAc that is depicted in Figure 2, a slight quantity of impurity was observed. Though a precise decomposition mechanism of EmimOAc has been unclear, this phenomenon can be correlated with the acidic C2 proton of the imidazolium ring. Since EmimOAc features a strongly basic acetate anion, the instinctive nucleophilic attack of the acetate anion on the C2 position would be inevitable and could lead to a decomposition reaction.43 Despite the confirmed impurity, which is likely due to decomposition during the reaction and/or purification steps, the recovered EmimOAc was used for the next cellulose modification reaction without any purification. In run 2 (Table 1), cellulose acetate was produced with a high DS value of 2.96 and good recyclability of EmimOAc (98.1%). This procedure was successfully iterated at least four times without any difficulties and a decrease in catalytic activities (runs 3~5, Table 1 and Figure 3). Thus, although unknown impurities have been generated in the employed EmimOAc through repeated reaction and purification steps, EmimOAc was revealed to be recyclable and reusable in the cellulose modification reaction at least four times.

1H NMR spectra in CDCl3 of the obtained cellulose acetates (Table 1, runs 1–5).

1H NMR spectra in CDCl3 of the fresh and recovered EmimOAc after the cellulose modification reactions (Table 1, runs 1–5). The symbol * refers to peaks due to impurities.

Scaling up and expanding the polysaccharide sources for organocatalytic transesterifications in EmimOAc/DMSO mixed solvent systems

As previously discussed, the facile recyclability and reusability of the employed EmimOAc were validated. Next, we focused on the practical aspect of the cellulose modification protocol. To provide a robust and reliable synthetic protocol, the scalability of the reaction system should be addressed because a large-scale synthesis might face difficulties due to a difference in the reaction scale itself. Along with the scalability of the reaction system, the polysaccharide source should be considered because polysaccharides are naturally occurring polymers and thus can be obtained from a range of natural sources. Apart from synthetic polymers, the source of naturally occurring polymers shows a significant effect on their material nature despite their identical monomeric structures. In cellulose, the cellulose source could lead to a clear difference in its molecular weight. In this context, we verified the tolerance of our synthetic protocol toward the abovementioned points. First, our previously reported protocol was scaled up with the standard cellulose, Avicel, as shown in run 6 (Table 2). The reaction scale of the cellulose modification reaction was increased by 20 times, which corresponds to a scale shift from 120 mg to 2.4 g without optimization or special precautions. As expected, the organocatalytic transesterification of cellulose was successfully achieved on a gram scale by simply scaling up the original reaction conditions, which demonstrates that the reported synthetic protocol is reliable and robust. Next, a range of cellulose sources was utilized for the cellulose modification reactions. In addition to Avicel, pulps and rayon were examined as cellulose sources (runs 7~10, Table 2), in which pulp-based cellulose shows a higher molecular weight than that of Avicel. Regardless of the employed cellulose source, the synthetic protocol realized the facile conversion of cellulose into cellulose acetates with high DS values (~2.9) (Supplementary Figures S1 and S2). Encouraged by the robustness of the organocatalytic transesterification, we aimed to expand our synthetic portfolio to polysaccharides, in addition to cellulose. For this, xylan, dextrin and pullulan were subject to organocatalytic transesterification, which essentially affords polysaccharide-based polymeric materials (Figure 4). Similar to the cellulose modification reaction, the organocatalytic transesterification reactions of xylan, dextrin and pullulan afforded the corresponding polysaccharide esters with essentially high DS values (runs 11~13, Table 2 and Supplementary Figure S3).

1H NMR spectra in DMSO-d6 of the obtained polysaccharide acetates (Table 2, runs 11–13).

Conclusions

As successfully demonstrated, the Im-IL-catalyzed transesterification showed not only a robustness on a gram-scale but also a sufficient green nature with a high recyclability. Additionally, the Im-IL-catalyzed transesterification was subjected to polysaccharides other than cellulose, including xylan, dextrin and pullulan, among others. The obtained results shed light on the synthetic utility of Im-ILs in the polymer sciences as both a green solvent and a recyclable organocatalyst.

Schematic representation of recyclable and scalable organocatalytic transesterification reactions of cellulose in the EmimOAc/DMSO mixed solvent system.

Recyclable reaction of cellulose in the EmimOAc/DMSO mixed solvent system.

References

Enders, D., Niemeier, O. & Henseler, A. Organocatalysis by N-heterocyclic carbenes. Chem. Rev. 107, 5606–5655 (2007).

James, T., van Gemmeren, M. & List, B. Development and applications of disulfonimides in enantioselective organocatalysis. Chem. Rev. 115, 9388–9409 (2015).

Bertelsen, S. & Jorgensen, K. A. Organocatalysis—after the gold rush. Chem. Soc. Rev. 38, 2178–2189 (2009).

Schreiner, P. R. Metal-free organocatalysis through explicit hydrogen bonding interactions. Chem. Soc. Rev. 32, 289–296 (2003).

Zhang, Z. & Schreiner, P. R. (Thio)urea organocatalysis—what can be learnt from anion recognition? Chem. Soc. Rev. 38, 1187–1198 (2009).

Hopkinson, M. N., Richter, C., Schedler, M. & Glorius, F. An overview of N-heterocyclic carbenes. Nature 510, 485–496 (2014).

Dove, A. P., Pratt, R. C., Lohmeijer, B. G. G., Culkin, D. A., Hagberg, E. C., Nyce, G. W., Waymouth, R. M. & Hedrick, J. L. N-Heterocyclic carbenes: Effective organic catalysts for living polymerization. Polymer 47, 4018–4025 (2006).

Dove, A. P., Pratt, R. C., Lohmeijer, B. G. G., Waymouth, R. M. & Hedrick, J. L. Thiourea-based bifunctional organocatalysis: supramolecular recognition for living polymerization. J. Am. Chem. Soc. 127, 13798–13799 (2005).

Nederberg, F., Connor, E. F., Möller, M., Glauser, T. & Hedrick, J. L. New paradigms for organic catalysts: the first organocatalytic living polymerization. Angew. Chem. Int. Ed. 40, 2712–2715 (2001).

Coulembier, O., Sanders, D. P., Nelson, A., Hollenbeck, A. N., Horn, H. W., Rice, J. E., Fujiwara, M., Dubois, P. & Hedrick, J. L. Hydrogen-bonding catalysts based on fluorinated alcohol derivatives for living polymerization. Angew. Chem. Int. Ed. 48, 5170–5173 (2009).

Sanda, F., Sanada, H., Shibasaki, Y. & Endo, T. Star polymer synthesis from ɛ-caprolactone utilizing polyol/protonic acid initiator. Macromolecules 35, 680–683 (2002).

Chuma, A., Horn, H. W., Swope, W. C., Pratt, R. C., Zhang, L., Lohmeijer, B. G. G., Wade, C. G., Waymouth, R. M., Hedrick, J. L. & Rice, J. E. The reaction mechanism for the organocatalytic ring-opening polymerization of l-lactide using a guanidine-based catalyst: hydrogen-bonded or covalently bound? J. Am. Chem. Soc. 130, 6749–6754 (2008).

Zhang, L., Nederberg, F., Pratt, R. C., Waymouth, R. M., Hedrick, J. L. & Wade, C. G. Phosphazene bases: a new category of organocatalysts for the living ring-opening polymerization of cyclic esters. Macromolecules 40, 4154–4158 (2007).

Bourissou, D., Martin-Vaca, B., Dumitrescu, A., Graullier, M. & Lacombe, F. Controlled cationic polymerization of lactide. Macromolecules 38, 9993–9998 (2005).

Raynaud, J., Absalon, C., Gnanou, Y. & Taton, D. N-heterocyclic carbene-induced zwitterionic ring-opening polymerization of ethylene oxide and direct synthesis of α,ω-difunctionalized poly(ethylene oxide)s and poly(ethylene oxide)-b-poly(ɛ-caprolactone) block copolymers. J. Am. Chem. Soc. 131, 3201–3209 (2009).

Raynaud, J., Absalon, C., Gnanou, Y. & Taton, D. N-heterocyclic carbene-organocatalyzed ring-opening polymerization of ethylene oxide in the presence of alcohols or trimethylsilyl nucleophiles as chain moderators for the synthesis of α,ω-heterodifunctionalized poly(ethylene oxide)s. Macromolecules 43, 2814–2823 (2010).

Misaka, H., Sakai, R., Satoh, T. & Kakuchi, T. Synthesis of high molecular weight and end-functionalized poly(styrene oxide) by living ring-opening polymerization of styrene oxide using the alcohol/phosphazene base initiating system. Macromolecules 44, 9099–9107 (2011).

Lohmeijer, B. G. G., Dubois, G., Leibfarth, F., Pratt, R. C., Nederberg, F., Nelson, A., Waymouth, R. M., Wade, C. & Hedrick, J. L. Organocatalytic living ring-opening polymerization of cyclic carbosiloxanes. Org. Lett. 8, 4683–4686 (2006).

Fuchise, K., Chen, Y., Satoh, T. & Kakuchi, T. Recent progress in organocatalytic group transfer polymerization. Polym. Chem. 4, 4278–4291 (2013).

Fevre, M., Vignolle, J., Heroguez, V. & Taton, D. Tris(2,4,6-trimethoxyphenyl)phosphine (TTMPP) as potent organocatalyst for group transfer polymerization of alkyl (meth)acrylates. Macromolecules 45, 7711–7718 (2012).

Raynaud, J., Gnanou, Y. & Taton, D. Group transfer polymerization of (meth)acrylic monomers catalyzed by N-heterocyclic carbenes and synthesis of all acrylic block copolymers: evidence for an associative mechanism. Macromolecules 42, 5996–6005 (2009).

Raynaud, J., Liu, N., Gnanou, Y. & Taton, D. Expanding the Scope of group transfer polymerization using N-heterocyclic carbenes as catalysts: application to miscellaneous (meth)acrylic monomers and kinetic investigations. Macromolecules 43, 8853–8861 (2010).

Scholten, M. D., Hedrick, J. L. & Waymouth, R. M. Group transfer polymerization of acrylates catalyzed by N-heterocyclic carbenes. Macromolecules 41, 7399–7404 (2008).

Zhang, Y., Lay, F., García-García, P., List, B. & Chen, E. Y. X. High-speed living polymerization of polar vinyl monomers by self-healing silylium catalysts. Chem. Eur. J. 16, 10462–10473 (2010).

Pinaud, J., Vijayakrishna, K., Taton, D. & Gnanou, Y. Step-growth polymerization of terephthaldehyde catalyzed by N-heterocyclic carbenes. Macromolecules 42, 4932–4936 (2009).

Matsuoka, S.-i., Namera, S. & Suzuki, M. Oxa-Michael addition polymerization of acrylates catalyzed by N-heterocyclic carbenes. Polym. Chem. 6, 294–301 (2015).

Kakuchi, R., Wongsanoh, K., Hoven, V. P. & Theato, P. Activation of stable polymeric esters by using organo-activated acyl transfer reactions. J. Polym. Sci. Part A 52, 1353–1358 (2014).

Fevre, M., Pinaud, J., Gnanou, Y., Vignolle, J. & Taton, D. N-Heterocyclic carbenes (NHCs) as organocatalysts and structural components in metal-free polymer synthesis. Chem. Soc. Rev. 42, 2142–2172 (2013).

Mespouille, L., Coulembier, O., Kawalec, M., Dove, A. P. & Dubois, P. Implementation of metal-free ring-opening polymerization in the preparation of aliphatic polycarbonate materials. Prog.Polym. Sci. 39, 1144–1164 (2014).

Hong, M. & Chen, E. Y. Towards truly sustainable polymers: a metal-free recyclable polyester from biorenewable non-strained gamma-butyrolactone. Angew. Chem. Int. Ed. 55, 4188–4193 (2016).

Gowda, R. R. & Chen, E. Y. X. Organocatalytic and chemoselective polymerization of multivinyl-functionalized γ-butyrolactones. ACS Macro Lett. 5, 772–776 (2016).

Zhang, Y., Schmitt, M., Falivene, L., Caporaso, L., Cavallo, L. & Chen, E. Y. Organocatalytic conjugate-addition polymerization of linear and cyclic acrylic monomers by N-heterocyclic carbenes: mechanisms of chain initiation propagation and termination. J. Am. Chem. Soc. 135, 17925–17942 (2013).

Schenzel, A., Hufendiek, A., Barner-Kowollik, C. & Meier, M. A. R. Catalytic transesterification of cellulose in ionic liquids: sustainable access to cellulose esters. Green Chem. 16, 3266–3271 (2014).

Chen, C. Y., Chen, M. J., Zhang, X. Q., Liu, C. F. & Sun, R. C. Per-O-acetylation of cellulose in dimethyl sulfoxide with catalyzed transesterification. J. Agric. Food. Chem. 62, 3446–3452 (2014).

Kakuchi, R., Ito, R., Nomura, S., Abroshan, H., Ninomiya, K., Ikai, T., Maeda, K., Kim, H. J. & Takahashi, K. A mechanistic insight into the organocatalytic properties of imidazolium-based ionic liquids and a positive co-solvent effect on cellulose modification reactions in an ionic liquid. RSC Adv. 7, 9423–9430 (2017).

Kakuchi, R., Yamaguchi, M., Endo, T., Shibata, Y., Ninomiya, K., Ikai, T., Maeda, K. & Takahashi, K. Efficient and rapid direct transesterification reactions of cellulose with isopropenyl acetate in ionic liquids. RSC Adv. 5, 72071–72074 (2015).

Hinner, L. P., Wissner, J. L., Beurer, A., Nebel, B. A. & Hauer, B. Homogeneous vinyl ester-based synthesis of different cellulose derivatives in 1-ethyl-3-methyl-imidazolium acetate. Green Chem. 18, 6099–6107 (2016).

Klemm, D., Heublein, B., Fink, H.-P. & Bohn, A. Cellulose: fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 44, 3358–3393 (2005).

Swatloski, R. P., Spear, S. K., Holbrey, J. D. & Rogers, R. D. Dissolution of cellose with ionic liquids. J. Am. Chem. Soc. 124, 4974–4975 (2002).

Gericke, M., Fardim, P. & Heinze, T. Ionic liquids–promising but challenging solvents for homogeneous derivatization of cellulose. Molecules 17, 7458–7502 (2012).

Kelemen, Z., Holloczki, O., Nagy, J. & Nyulaszi, L. An organocatalytic ionic liquid. Org. Biomol. Chem. 9, 5362–5364 (2011).

Schlufter, K., Schmauder, H.-P., Dorn, S. & Heinze, T. Efficient homogeneous chemical modification of bacterial cellulose in the ionic liquid 1-N-butyl-3-methylimidazolium chloride. Macromol. Rapid Commun. 27, 1670–1676 (2006).

Lin, B., Dong, H., Li, Y., Si, Z., Gu, F. & Yan, F. Alkaline stable C2-substituted imidazolium-based anion-exchange membranes. Chem. Mater. 25, 1858–1867 (2013).

Acknowledgements

This research was promoted by the COI program ‘Construction of next-generation infrastructure using innovative materials—Realization of a safe and secure society that can coexist with the Earth for centuries’—supported by MEXT and JST. This study was also supported in part by the Advanced Low Carbon Technology Research and Development Program (ALCA) of the JST and the Cross-ministerial Strategic Innovation Promotion Program (SIP) from the JST.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Rights and permissions

About this article

Cite this article

Van Nguyen, Q., Nomura, S., Hoshino, R. et al. Recyclable and scalable organocatalytic transesterification of polysaccharides in a mixed solvent of 1-ethyl-3-methylimidazolium acetate and dimethyl sulfoxide. Polym J 49, 783–787 (2017). https://doi.org/10.1038/pj.2017.49

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.49