Abstract

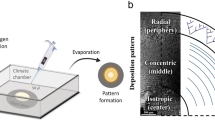

Our Patterning on Topography (PoT) printing technique enables fibronectin, laminin and other proteins to be applied to biomaterial surfaces in complex geometries that are inaccessible using traditional soft lithography techniques. Engineering combinatorial surfaces that integrate topographical and biochemical micropatterns enhances control of the biotic-abiotic interface. Here, we used this method to understand cardiomyocyte response to competing physical and chemical cues in the microenvironment.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Whitesides, G.M., Ostuni, E., Takayama, S., Jiang, X.Y. & Ingber, D.E. Annu. Rev. Biomed. Eng. 3, 335–373 (2001).

Bettinger, C.J., Langer, R. & Borenstein, J.T. Angew. Chem. Int. Ed. 48, 5406–5415 (2009).

Falconnet, D., Csucs, G., Michelle Grandin, H. & Textor, M. Biomaterials 27, 3044–3063 (2006).

Greene, A.C., Washburn, C.M., Bachand, G.D. & James, C.D. Biomaterials 32, 8860–8869 (2011).

Feinberg, A.W. et al. J. Biomed. Mater. Res. A 86A, 522–534 (2007).

Szymanski, J.M., Jallerat, Q. & Feinberg, A.W. J. Vis. Exp. 86, e51176 (2014).

Feinberg, A.W. & Parker, K.K. Nano Lett. 10, 2184–2191 (2010).

Chung, C.-Y. et al. FASEB J. 25, 851–862 (2011).

Feinberg, A.W. et al. Biomaterials 33, 5732–5741 (2012).

Feinberg, A.W. et al. Science 317, 1366–1370 (2007).

Palchesko, R.N., Zhang, L., Sun, Y. & Feinberg, A.W. PLoS ONE 7, 1–13 (2012).

Klotzsch, E. et al. Proc. Natl. Acad. Sci. USA 106, 18267–18272 (2009).

Bray, M.-A.P. et al. Biomaterials 31, 5143–5150 (2010).

Acknowledgements

We acknowledge financial support from China Scholarship Council (CSC) for State Scholarship Fund No. [2008]3027 (Y.S.), the Carnegie Mellon University Dowd-ICES Fellowship (Q.J.), the NIH Biomechanics in Regenerative Medicine T32 training grant (T32EB003392) and the Bertucci Graduate Fellowship (J.M.S.) and the NIH Director's New Innovator Award (DP2HL117750) (A.W.F.).

Author information

Authors and Affiliations

Contributions

A.W.F. conceived and supervised the project. A.W.F. and Y.S. designed the experiments. Y.S., Q.J. and J.M.S. performed the experiments. A.W.F., Q.J., J.M.S. and Y.S. analyzed the data and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

A.W.F. is a co-inventor on a filed patent application covering the surface-initiated assembly process that is part of the PoT technique described in the present study.

Integrated supplementary information

Supplementary Figure 1 The thickness of the PIPAAm layer was tuned by changing the concentration (w/v) of PIPAAm being spincoated.

The concentration of PIPAAm dissolved in butanol (w/v) was varied from 10% to 40% in order to tune the thickness of the resulting PIPAAm layer being spincoated. Representative AFM images of the spincoated PIPAAm layer on glass coverslips from (a) 10%, (b) 20%, (c) 30%, and (d) 40% PIPAAM solutions. (e-h) Cross sectional profiles of the red line drawn in the respective AFM images (a-d) demonstrated control of the PIPAAm thickness. (i) Quantification of the PIPAAm layer thickness showed that the PIPAAm layer increased from 0.73 ± 0.10 μm to 5.67 ± 1.18 μm. The red line is linear regression with R2 = 0.9934. Error bars are standard deviation of n=3 PIPAAm coated coverslips where the thickness of the layer was the mean of measurements taken at the center, right edge, and left edge.

Supplementary Figure 2 PoT printed FN lines conform to surfaces with a range of surface roughness.

These confocal images of FN rendered in 3D illustrate the ability of PoT to conformally follow the surface microtopography. (a) A PDMS replica of A4 size printer paper coated with FN (yellow) adsorbed from solution, μCP with 20 μm wide, 20 μm spaced FN lines or PoT printed with 20 μm wide, 20 μm spaced FN lines. (b) A PDMS replica of 220-grit sand paper PoT printed with 20 μm wide, 20 μm spaced FN lines (red). (c) A PDMS replica of 150-grit sand paper PoT printed with 20 μm wide, 20 μm spaced FN lines (red). These images are representative of n=3 separate experiments.

Supplementary Figure 3 PoT printing on variable aspect ratio micro-ridges.

We engineered surfaces with 20 μm wide, 20 μm spaced micro-ridges at heights up to 48 μm and used confocal microscopy to analyze conformal patterning. PoT printed FN lines released onto the (a) 11.5 μm (b) 27 μm and (c) 37 μm high micro-ridges were found to achieve conformal patterning. This is a depth-to-width aspect ratio of 1.85 at the 37 μm ridge height and the FN pattern was continuous and conformal to the ridge tops, vertical sidewalls and trench bottoms. At higher ridge heights and aspect ratios >2.0 PoT was still able to pattern FN on the surfaces, however the FN started to become discontinuous in places, (d) as shown for the 48 μm high ridges at an aspect ratio of 2.4. Cross-section views of the (e) 11.5 μm (f) 27 μm and (g) 37 μm high micro-ridges confirmed the continuous and conformal FN patterning while the (h) 48 μm high micro-ridges showed distinct gaps in FN on the vertical sidewalls. Closer examination of PoT on the 48 μm high micro-ridges showed that (i) in 3D the gaps in FN transfer were observed only on the vertical sidewalls, and (j) in a top-down projection, the FN on the ridge tops appeared to be at higher density than the FN in the trench bottoms. The micro-ridges with aspect ratios >0.5 were PoT printed using the 40% (w/v) PIPAAm coating. Scale bars are 10 μm. Images are representative of at least 3 separate experiments. For each depth, the PDMS micro-ridges were prepared using the same master mold; therefore their depth remained constant for each experiment.

Supplementary Figure 4 PoT printing on variable size micro-ridges.

In addition to the 20 μm wide and 20 μm spaced PDMS micro-ridges, FN lines were also PoT printed across smaller and larger PDMS micro-ridges to demonstrate that the technique is applicable to a wide range of surface feature dimensions. Specifically, 20 μm wide FN lines were PoT printed across micro-ridges that were (a) 2 μm wide, 2 μm spaced, 2.5 μm deep with every fourth ridge missing, (b) 30 μm wide, 30 μm spaced, and 30 μm deep, (c) 50 μm wide, 50 μm spaced, and 32 μm deep, and (d) 200 μm wide, 200 μm spaced and 36 μm deep. Analysis of the cross-section of the (e) 2, (f) 30, (g) 50, and (h) 200 μm wide micro-ridges demonstrated that in all cases, the FN lines were able to fully conform to the topography. This confirms that PoT can pattern FN on micro-ridges spanning 2 orders-of-magnitude in X and Y dimensions and greater than 1 order-of-magnitude in the Z dimension. These results also suggest that smaller, nanometer scale features should be able to be patterned. Scale is in micrometers for (a-d). Scale bars are (e) 10 μm and (f-h) 20 μm. Images are representative for n=3 separate experiments.

Supplementary Figure 5 PoT printing can be performed using a range of ECM proteins.

Representative confocal images of 20 μm wide, 20 μm spaced, 5 μm tall micro-ridges in PDMS orthogonally PoT printed with 20 μm wide lines of (a) laminin (red) and (b) collagen type IV (violet). Note that the patterned ECM follows the contours of the micro-ridges, which run orthogonal to the direction of the ECM lines. (c) Confocal image of 20 μm wide, 20 μm spaced, 14.5 μm tall micro-ridges in PDMS PoT printed at a 45° angle with FN and laminin lines to create a bicomponent, orthogonal fibronectin/laminin mesh. The top view (d) shows the good pattern transfer fidelity over multiple PoT printings and the cross-section (e) demonstrates that both proteins are conformal to the vertical sidewalls. Scale bars are 20 μm. Images are representative for n=3 separate experiments.

Supplementary Figure 6 PoT printing of nanoscale FN lines.

Demonstration that ECM protein lines with nanometer widths can be successfully PoT printed on to micro-ridges. PDMS stamps consisting of 500 nm wide, 5 μm spaced lines were generated from a master mold fabricated using a Photonic Professional GT 3D printer (Nanoscribe Gmbh). AFM (a) height and (b) phase images of the FN nanolines microcontact printed onto the PIPAAm demonstrate that the FN lines vary in width from approximately 100-500 nm, with (c) heights of ~5 nm. These can be used to PoT print orthogonal FN nanolines onto 20 μm wide, 20 μm spaced, and 15 μm tall micro-ridges. (e) The maximum intensity projection shows that some shifting in the angle of the lines occurs, but the line-to-line spacing remains relatively constant. (f) Cross-sections and images of the ridge tops and trench bottoms confirm that patterning is conformal, including the vertical sidewalls. Scale bars are 10 μm. Images are representative for n=5 separate experiments.

Supplementary Figure 7 Microcontact printing with low Young’s modulus PDMS stamps is unable to pattern conformal ECM protein on micro-ridges.

Representative confocal microscopy images of 20 μm wide, 20 μm spaced FN lines microcontact printed orthogonally onto 20 μm wide, 20 μm spaced micro-ridges using a low Young’s modulus PDMS stamp (E = 50 kPa), (a) At a 7 μm ridge height the FN lines reach the bottom of the trenches (b), but do not pattern the vertical side walls, leaving a distinct gap in protein transfer between the ridges tops and trench bottoms (c). Further, the pressure required to press the soft PDMS stamp onto the micro-ridges in order to pattern the trench bottoms causes loss of pattern fidelity on the ridge tops (a). Specifically, FN is also transferred in-between the 20 μm wide FN lines. (d) At a 14 μm ridge height, the FN lines do not reach the bottom of the trenches (e), and also do not pattern the vertical side walls (f). Further, as seen in (a), the pressure applied to the PDMS stamp in order to pattern the micro-ridges causes a loss of pattern fidelity with protein transfer in-between the FN lines. Scale bars are 10 μm. Images are representative for n=3 separate experiments.

Supplementary Figure 8 PoT printing on a rigid substrate.

FN lines 20 μm wide, 20 μm spaced were PoT printed orthogonally onto 20 μm wide, 20 μm spaced, 3 μm tall micro-ridges in SPR220 photoresist, demonstrating that surfaces besides PDMS can be patterned. Note that the photoresist is auto fluorescent, causing signal from the micro-ridges even though protein was not transferred in-between the FN lines. (b) Cross-sections and images of the ridge tops and trench bottoms show that the FN lines were conformal to the microtopography. Scale bars are 10 μm. Images are representative of n=3 separate experiments.

Supplementary Figure 9 CM alignment on high aspect ratio micro-ridges.

20 μm wide FN lines were PoT printed orthogonal to PDMS micro-ridges that were 20 μm wide, 20 μm wide and (a) 26 μm and (b) 33 μm tall. (c-d) Top view of the surfaces in (a-b) with CMs additionally stained for nuclei (blue). (e-f) Cross-sections of the areas highlighted by the dashed lines in (c-d). (g-h) Single ridges from the cross-sections in (e-f) show that the CMs are able to conform around the topographies. (i-j) Histograms of actin orientation angles of CMs on surfaces in (c-d). Scale bars are 20 μm. Images are representative of n=3 samples for each depth.

Supplementary Figure 10 Cardiomyocytes seeded on PoT printed high aspect ratio micro-ridges align to the FN pattern and conform their sarcomeric cytoskeletal structure to the microtopography.

Representative images of cardiomyocytes seeded onto 20 μm wide, 20 μm spaced micro-ridges with heights of (a) 15 μm and (b) 33 μm stained for FN (green) and actin (red). The cardiomyocytes generally align to the FN pattern. Close examination of the 3D shape of the cardiomyocytes on the (c) 15 μm and (d) 33 μm tall ridges with actin (red) and α-actinin (green) shows that the myofibrils conform to the topography and actually undergo a 90° bend while remaining continuous. (e) A higher magnification image of three cardiomyocytes coupled together across a trench in the micro-ridges. Note the ability of myofibrils to undergo a discrete change in direction, showing a flexibility of the contractile cytoskeleton that is not commonly observed. All sampled samples are stained for cell nuclei (blue) and scale bars are 20 μm. Images are representative for n=3 separate experiments.

Supplementary Figure 11 Cardiomyocytes align to FN lines PoT printed on PDMS replica of 220-grit sandpaper.

Confocal image of (a) cardiomyocytes cultured on 20 μm wide, 20 μm spaced FN lines PoT printed on a PDMS replica of 220-grit sandpaper stained for FN (green), actin (red) and nuclei (blue). (b) At higher magnification, it is clear that the cardiomyocytes adhere to and align along the PoT FN lines. (c) A 3D reconstruction of the image in (b) demonstrating that the cardiomyocytes were aligned along the FN lines despite undergoing large deviations in alignment in the z-axis as the cardiomyocytes followed the contours of the microtopography. (d) Analysis of cardiomyocyte actin alignment based on the maximum intensity projection in the XY plane (as seen in (a)) demonstrates that they were uniaxially organized in the direction of the PoT printed FN lines. Scale bars are (a) 100 μm and (b) 20 μm. Images are representative of n=3 separate experiments. The histogram in (d) is based on the actin alignment of the image in (b).

Supplementary Figure 12 PoT printed FN lines are stable under cell culture conditions, comparable to microcontact printed FN lines.

Representative confocal images of 20 μm wide, 20 μm spaced FN lines that were (a) microcontact printed or (b) PoT printed onto PDMS coated glass coverslips. These were incubated in cell culture conditions (growth media, 37°C, 10% CO2) without cells for two days and showed no discernable difference between the microcontact printed and PoT printed FN lines. C2C12 myoblasts seeded and cultured for 2 days on the (c) microcontact printed and (d) PoT printed FN lines showed similar cell morphology with alignment along the length of the FN lines. Imaging of the printed and cell-assembled FN on (e) microcontact printed and (f) PoT printed FN lines revealed comparable patterns of matrix assembly. Scale bars are 20 μm. Images are representative for n=3 separate μCP or PoT printed coverslips.

Supplementary Figure 13 Analysis of CM actin alignment in circular cardiac micro-tissue

(a) Analysis of the actin alignment throughout the thickness of the 100 μm diameter microtissue with cross-sections showing the alignment on CMs (i) in the micro-ridge area, (ii) just above the micro-ridge area, and (iii) well above the micro-ridge area. The grayscale images of each region contain an overlay of actin orientation vectors (red arrows). (b) Histograms of the CM actin alignment in each of the 3 regions. Scale bars are 20 μm. Images are representative of n=10 samples. Histograms in (b) are based on the actin alignment of the images in (a).

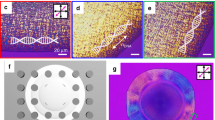

Supplementary Figure 14 PoT printing can be used to pattern adhesive ECM regions in combination with microtopography over a range of surface areas.

Examples of (a) 100, (c) 250 and (e) 500 μm diameter circles of FN patterned on top of 20 μm wide, 20 μm spaced, 5 μm tall micro-ridges in PDMS. The PoT printed FN is able to follow the contours of the micro-ridges. Cardiomyocytes cultured on the FN circles (b, d and f) align to the micro-ridges when in direct contact with the topography, but above the topography alignment depended on proximity to the edge of the FN circle. Scale bars are (a) and (b) 20 μm, (c) and (d) 50 μm and (e) and (f) 100 μm. Images are representative of greater than equal to n=10 per circle diameter.

Supplementary Figure 15 Cardiomyocytes cultured on large, circular areas of fibronectin on micro-ridges demonstrates the interplay between micropatterned topography and ECM proteins on cell alignment.

Fluorescent image of cardiomyocytes on the 500 μm diameter FN circles on 20 μm wide, 20 μm spaced, 5 μm tall micro-ridges stained for actin (false-colored). Two sub-regions show that the cardiomyocytes within the micro-ridges are well aligned, but above the micro-ridges follow the curvature of the FN pattern near the periphery or become primarily isotropic in the central region. Scale bars are 100 μm for the full image (left) and 20 μm for the zoomed regions (right). Image is representative of n=10 at the 500 μm circle diameter.

Supplementary information

Supplementary Text and Figures

Supplementary Figures 1–15 and Supplementary Note (PDF 2849 kb)

Rights and permissions

About this article

Cite this article

Sun, Y., Jallerat, Q., Szymanski, J. et al. Conformal nanopatterning of extracellular matrix proteins onto topographically complex surfaces. Nat Methods 12, 134–136 (2015). https://doi.org/10.1038/nmeth.3210

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmeth.3210

This article is cited by

-

Engineering aligned human cardiac muscle using developmentally inspired fibronectin micropatterns

Scientific Reports (2021)

-

Discretely-supported nanoimprint lithography for patterning the high-spatial-frequency stepped surface

Nano Research (2021)

-

Fibronectin-based nanomechanical biosensors to map 3D surface strains in live cells and tissue

Nature Communications (2020)

-

Measuring the Poisson’s Ratio of Fibronectin Using Engineered Nanofibers

Scientific Reports (2017)

-

Fabrication of highly modulable fibrous 3D extracellular microenvironments

Biomedical Microdevices (2017)