Abstract

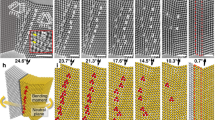

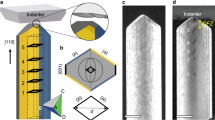

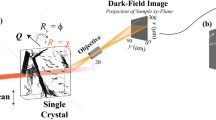

‘Smaller is stronger’ does not hold true only for nanocrystalline materials1 but also for single crystals2,3,4,5. It is argued that this effect is caused by geometrical constraints on the nucleation and motion of dislocations in submicrometre-sized crystals6,7. Here, we report the first in situ transmission electron microscopy tensile tests of a submicrometre aluminium single crystal that are capable of providing direct insight into source-controlled dislocation plasticity in a submicrometre crystal. Single-ended sources emit dislocations that escape the crystal before being able to multiply. As dislocation nucleation and loss rates are counterbalanced at about 0.2 events per second, the dislocation density remains statistically constant throughout the deformation at strain rates of about 10−4 s−1. However, a sudden increase in strain rate to 10−3 s−1 causes a noticeable surge in dislocation density as the nucleation rate outweighs the loss rate. This observation indicates that the deformation of submicrometre crystals is strain-rate sensitive.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kumar, K. S., Van Swygenhoven, H. & Suresh, S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 51, 5743–5774 (2003).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Greer, J. R., Oliver, W. C. & Nix, W. D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821–1830 (2005).

Volkert, C. A. & Lilleodden, E. T. Size effects in the deformation of sub-micron Au columns. Phil. Mag. 86, 5567–5579 (2006).

Kiener, D., Grosinger, W., Dehm, G. & Pippan, R. A further step towards an understanding of size-dependent crystal plasticity: In situ tension experiments of miniaturized single-crystal copper samples. Acta Mater. 56, 580–592 (2008).

Nix, W. D., Greer, J. R., Feng, G. & Lilleodden, E. T. Deformation at the nanometer and micrometer length scales: Effects of strain gradients and dislocation starvation. Thin Solid Films 515, 3152–3157 (2007).

Parthasarathy, T. A., Rao, S. I., Dimiduk, D. M., Uchic, M. D. & Trinkle, D. R. Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples. Scr. Mater. 56, 313–316 (2007).

Csikor, F. C., Motz, C., Weygand, D., Zaiser, M. & Zapperi, S. Dislocation avalanches, strain bursts, and the problem of plastic forming at the micrometer scale. Science 318, 251–254 (2007).

Benzerga, A. A. & Shaver, N. F. Scale dependence of mechanical properties of single crystals under uniform deformation. Scr. Mater. 54, 1937–1941 (2006).

Tang, H., Schwarz, K. W. & Espinosa, H. D. Dislocation escape-related size effects in single-crystal micropillars under uniaxial compression. Acta Mater. 55, 1607–1616 (2007).

Rao, S. I. et al. Athermal mechanism of size-dependent crystal flow gleaned from three-dimensional discrete dislocation simulations. Acta Mater. 56, 3245–3259 (2008).

Rao, S. I. et al. Estimating the strength of single-ended dislocation sources in micron-sized single crystals. Phil. Mag. 87, 4777–4794 (2007).

Norfleet, D. M., Dimiduk, D. M., Polasik, S. J., Uchic, M. D. & Mills, M. J. Dislocation structures and their relationship to strength in deformed nickel microcrystals. Acta Mater. 56, 2988–3001 (2008).

Ng, K. S. & Ngan, A. H. W. Stochastic nature of plasticity of aluminum micro-pillars. Acta Mater. 56, 1712–1720 (2008).

Kiener, D., Motz, C., Rester, M., Jenko, M. & Dehm, G. FIB damage of Cu and possible consequences for miniaturized mechanical tests. Mater. Sci. Eng. A 459, 262–272 (2007).

Shan, Z. W., Mishra, R. K., Syed Asif, S. A., Warren, O. L. & Minor, A. M. Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nature Mater. 7, 115–119 (2008).

Maaß, R., Petegem, S. V., Zimmermann, J., Borca, C. N. & Swygenhoven, H. V. On the initial microstructure of metallic micropillars. Scr. Mater. 59, 471–474 (2008).

Kiener, D., Motz, C. & Dehm, G. Dislocation-induced crystal rotations in micro-compressed single crystal copper columns. J. Mater. Sci. 43, 2503–2506 (2008).

Maaß, R. et al. Crystal rotation in Cu single crystal micropillars: In situ Laue and electron backscatter diffraction. Appl. Phys. Lett. 92, 071905 (2008).

Dehm, G., Legros, M. & Heiland, B. In-situ TEM straining experiments of Al films on polyimide using a novel FIB design for specimen preparation. J. Mater. Sci. 41, 4484–4489 (2006).

Gutkin, M. Yu. & Ovid’ko, I. A. Special mechanism for dislocation nucleation in nanomaterials. Appl. Phys. Lett. 88, 211901 (2006).

Li, J., Van Vliet, K. J., Zhu, T., Yip, S. & Suresh, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002).

Minor, A. M. Jr, Morris, J. W. & Stach, E. A. Quantitative in situ nanoindentation in an electron microscope. Appl. Phys. Lett. 79, 1625–1627 (2001).

Gilman, J. J. Micromechanics of Flow in Solids (McGraw-Hill, 1969).

Legros, M. et al. Microstructural evolution in passivated Al films on Si substrates during thermal cycling. Acta Mater. 50, 3435–3452 (2002).

Cao, A. & Ma, E. Sample shape and temperature strongly influence the yield strength of metallic nanopillars. Acta Mater. 56, 4816–4828 (2008).

Zhu, T., Li, J., Samanta, A., Leach, A. & Gall, K. Temperature and strain-rate dependence of surface dislocation nucleation. Phys. Rev. Lett. 100, 025502 (2008).

Acknowledgements

Part of this work was supported by the Austrian Academy of Sciences. S.H.O. gratefully acknowledges financial support by the Korea Basic Science Institute grant (N28078). Recurrent financial support from the Centre National de la Recherche Scientifique was used to complete the TEM experiments in the framework of the ESTEEM European program.

Author information

Authors and Affiliations

Contributions

S.H.O. and M.L. carried out the TEM experiments. S.H.O. and D.K. prepared the tensile testing sample using FIB. S.H.O. analysed the data, interpreted and discussed the results and wrote the paper. M.L., D.K. and D.L. revised the paper. M.L. double-checked the data analysis and refined the strain-rate calculation. G.D. conceived and designed the experiments.

Corresponding authors

Supplementary information

Supplementary Information

Supplementary Movie 1 (MOV 297 kb)

Supplementary Information

Supplementary Movie 2 (MOV 4337 kb)

Supplementary Information

Supplementary Movie 3 (MOV 5671 kb)

Supplementary Information

Supplementary Movie 4 (MOV 1544 kb)

Rights and permissions

About this article

Cite this article

Oh, S., Legros, M., Kiener, D. et al. In situ observation of dislocation nucleation and escape in a submicrometre aluminium single crystal. Nature Mater 8, 95–100 (2009). https://doi.org/10.1038/nmat2370

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat2370

This article is cited by

-

Dislocation-induced stop-and-go kinetics of interfacial transformations

Nature (2022)

-

Review of recent progress on in situ TEM shear deformation: a retrospective and perspective view

Journal of Materials Science (2022)

-

The Competition Between Deformation Twinning and Dislocation Slip in Deformed Face-Centered Cubic Metals

JOM (2022)

-

In-Situ Electron Channeling Contrast Imaging under Tensile Loading: Residual Stress, Dislocation Motion, and Slip Line Formation

Scientific Reports (2020)

-

Effect of Ion Irradiation Introduced by Focused Ion-Beam Milling on the Mechanical Behaviour of Sub-Micron-Sized Samples

Scientific Reports (2020)