Abstract

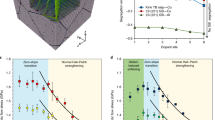

Forming alloys with impurity elements is a routine method for modifying the properties of metals. An alternative approach involves the incorporation of interfaces into the crystalline lattice to enhance the metal's properties without changing its chemical composition. The introduction of high-density interfaces in nanostructured materials results in greatly improved strength and hardness; however, interfaces at the nanoscale show low stability. In this Review, I discuss recent developments in the stabilization of nanostructured metals by modifying the architectures of their interfaces. The amount, structure and distribution of several types of interfaces, such as high- and low-angle grain boundaries and twin boundaries, are discussed. I survey several examples of materials with nanotwinned and nanolaminated structures, as well as with gradient nanostructures, describing the techniques used to produce such samples and tracing their exceptional performances back to the nanoscale architectures of their interfaces.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Pickering, F. P. in Materials Science Technology (eds Cahn, R. W., Haasen, P. & Kramer, E. J. ) (Wiley, 2005).

Allwood, J. M. & Cullen, J. M. Sustainable Materials: With Both Eyes Open (UIT Cambridge, 2012).

Gleiter, H. Nanostructured materials: basic concepts and microstructure. Acta Mater. 48, 1–29 (2000).

Gleiter, H. Nanocrystalline materials. Prog. Mater. Sci. 33, 223–315 (1989).

Meyers, M. A., Mishra, A. & Benson, D. J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427–556 (2006). A comprehensive review article on mechanical properties of nanocrystalline materials.

Liddicoat, P. V. et al. Nanostructural hierarchy increases the strength of aluminium alloys. Nat. Commun. 1, 63–79 (2010).

Koch, C. C., Morris, D. G., Lu, K. & Inoue, A. Ductility of nanostructured materials. MRS Bull. 24, 54–58 (1999).

Koch, C. C. Structural nanocrystalline materials: an overview. J. Mater. Sci. 42, 1403–1414 (2007).

Koch, C., Scattergood, R., Darling, K. & Semones, J. Stabilization of nanocrystalline grain sizes by solute additions. J. Mater. Sci. 43, 7264–7272 (2008). A comprehensive review article on thermal stability of nanocrystalline materials.

Lu, K., Lu, L. & Suresh, S. Strengthening materials by engineering coherent internal boundaries at the nanoscale. Science 324, 349–352 (2009). A concise review article on strengthening strategies using coherent internal boundaries at the nanoscale.

Lu, L., Shen, Y. F., Chen, X. H., Qian, L. H. & Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 304, 422–426 (2004). The first report on the nanotwinned materials and the nanotwin effect on strength and electrical conductivity.

Liu, X. C., Zhang, H. W. & Lu, K. Formation of nanolaminated structure in an interstitial-free steel. Scr. Mater. 95, 54–57 (2015).

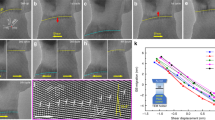

Liu, X. C., Zhang, H. W. & Lu, K. Strain-induced ultrahard and ultrastable nanolaminated structure in nickel. Science 342, 337–340 (2013). The first report on discovery of the nanolaminated structures in pure metals.

Hall, E. O. The deformation and ageing of mild steel: III. Discussion of results. Proc. Phys. Soc. B 64, 747–753 (1951).

Petch, N. J. The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25–28 (1953).

Erb, U. Electrodeposited nanocrystals: synthesis, properties and industrial applications. Nanostruct. Mater. 6, 533–538 (1995).

Schuh, C. A., Nieh, T. G. & Yamasaki, T. Hall–Petch breakdown manifested in abrasive wear resistance of nanocrystalline nickel. Scr. Mater. 46, 735–740 (2002).

Schuh, C. A., Nieh, T. G. & Iwasaki, H. The effect of solid solution W additions on the mechanical properties of nanocrystalline Ni. Acta Mater. 51, 431–443 (2003).

Detor, A. J. & Schuh, C. A. Tailoring and patterning the grain size of nanocrystalline alloys. Acta Mater. 55, 371–379 (2007).

Trelewicz, J. R. & Schuh, C. A. The Hall–Petch breakdown in nanocrystalline metals: a crossover to glass-like deformation. Acta Mater. 55, 5948–5958 (2007).

Kumar, K. S., Van Swygenhoven, H. & Suresh, S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 51, 5743–5774 (2003).

Misra, A., Hirth, J. P. & Hoagland, R. G. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater. 53, 4817–4824 (2005).

Misra, A. & Thilly, L. Structural metals at extremes. MRS Bull. 35, 965–976 (2010).

Hughes, D. A. & Hansen, N. Exploring the limit of dislocation based plasticity in nanostructured metals. Phys. Rev. Lett. 112, 135504 (2014).

Wang, N., Wang, Z., Aust, K. T. & Erb, U. Room temperature creep behavior of nanocrystalline nickel produced by an electrodeposition technique. Mater. Sci. Eng. A 237, 150–158 (1997).

Schiotz, J., Di Tolla, F. D. & Jacobsen, K. W. Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561–563 (1998).

Chokshi, A. H., Rosen, A., Karch, J. & Gleiter, H. On the validity of the Hall–Petch Relationship in nanocrystalline materials. Scr. Metall. 23, 1679–1684 (1989).

Rupert, T. J., Gianola, D. S., Gan, Y. & Hemker, K. J. Experimental observations of stress-driven grain boundary migration. Science 326, 1686–1690 (2009).

Gianola, D. S. et al. Stress-assisted discontinuous grain growth and its effect on the deformation behavior of nanocrystalline aluminum thin films. Acta Mater. 54, 2253–2263 (2006).

Fang, T. H., Tao, N. R. & Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 331, 1587–1590 (2011). The first report on gradient nanograined metals with extraordinary mechanical properties.

Brandstetter, S., Zhang, K., Escuadro, A., Weertman, J. R. & Van Swygenhoven, H. Grain coarsening during compression of bulk nanocrystalline nickel and copper. Scr. Mater. 58, 61–64 (2008).

Zhang, K., Weertman, J. R. & Eastman, J. A. Rapid stress-driven grain coarsening in nanocrystalline Cu at ambient and cryogenic temperatures. Appl. Phys. Lett. 87, 061921 (2005).

Jin, M., Minor, A. M., Stach, E. A. & Morris, J. W. Jr Direct observation of deformation-induced grain growth during the nanoindentation of ultrafine-grained Al at room temperature. Acta Mater. 52, 5381–5387 (2004).

Hanlon, T., Kwon, Y. N. & Suresh, S. Grain size effects on the fatigue response of nanocrystalline metals. Scr. Mater. 49, 675–680 (2003).

Hasnaoui, A., Van Swygenhoven, H. & Derlet, P. M. Dimples on nanocrystalline fracture surfaces as evidence for shear plane formation. Science 300, 1550–1552 (2003).

Wang, Y. M., Ma, E. & Chen, M. W. Enhanced tensile ductility and toughness in nanostructured Cu. Appl. Phys. Lett. 80, 2395–2397 (2002).

Lu, L., Sui, M. L. & Lu, K. Superplastic extensibility of nanocrystalline copper at room temperature. Science 287, 1463–1466 (2000).

Pippan, R. et al. Saturation of fragmentation during severe plastic deformation. Annu. Rev. Mater. Res. 40, 319–343 (2010).

Darling, K. A. et al. Thermal stability of nanocrystalline nickel with yttrium additions. J. Mater. Res. 28, 1813–1819 (2013).

Weissmuller, J. Alloy effects in nanostructures. Nanostruct. Mater. 3, 261–272 (1993).

Kirchheim, R. Reducing grain boundary, dislocation line and vacancy formation energies by solute segregation. I. Theoretical background. Acta Mater. 55, 5129–5138 (2007).

Chookajorn, T., Murdoch, H. A. & Schuh, C. A. Design of stable nanocrystalline alloys. Science 337, 951–954 (2012).

Babyak, W. J. & Rhines, F. N. The relationship between the boundary area and hardness of recrystallized cartridge brass. Trans. Mettall. Soc. AIME 218, 21–23 (1960).

Lu, L. & Lu, K. in Mechanical Properties of Nanocrystalline Materials (ed. Li, J. C. M. ) (Pan Stanford, 2011).

You, Z. et al. Plastic anisotropy and associated deformation mechanisms in nanotwinned metals. Acta Mater. 61, 217–227 (2013).

Zhu, T. & Gao, H. Plastic deformation mechanism in nanotwinned metals: an insight from molecular dynamics and mechanistic modeling. Scr. Mater. 66, 843–848 (2012).

Jin, Z. H. et al. The interaction mechanism of screw dislocations with coherent twin boundaries in different face-centred cubic metals. Scr. Mater. 54, 1163–1168 (2006).

Jin, Z. H. et al. Interactions between non-screw lattice dislocations and coherent twin boundaries in face-centered cubic metals. Acta Mater. 56, 1126–1135 (2008).

Zhu, T., Li, J., Samanta, A., Kim, H. G. & Suresh, S. Interfacial plasticity governs strain rate sensitivity and ductility in nanostructured metals. Proc. Natl Acad. Sci. USA 104, 3031–3036 (2007).

Zhou, H. F., Li, X. Y., Qu, S. X., Yang, W. & Gao, H. J. A. Jogged dislocation governed strengthening mechanism in nanotwinned metals. Nano Lett. 14, 5075–5080 (2014).

Zhou, H. F. & Gao, H. J. A plastic deformation mechanism by necklace dislocations near crack-like defects in nanotwinned metals. J. Appl. Mech. 82, 071015 (2015).

Chen, J., Lu, L. & Lu, K. Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 54, 1913–1918 (2006).

Shen, Y. F., Lu, L., Lu, Q. H., Jin, Z. H. & Lu, K. Tensile properties of copper with nano-scale twins. Scr. Mater. 52, 989–994 (2005).

Lu, L., Chen, X., Huang, X. & Lu, K. Revealing the maximum strength in nanotwinned copper. Science 323, 607–610 (2009).

Li, X., Wei, Y., Lu, L., Lu, K. & Gao, H. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 464, 877–880 (2010).

Lu, L. et al. Nano-sized twins induce high rate sensitivity of flow stress in pure copper. Acta Mater. 53, 2169–2179 (2005).

You, Z. S., Lu, L. & Lu, K. Tensile behavior of columnar grained Cu with preferentially oriented nanoscale twins. Acta Mater. 59, 6927–6937 (2011).

Pan, Q. S., Lu, Q. H. & Lu, L. Fatigue behavior of columnar-grained Cu with preferentially oriented nanoscale twins. Acta Mater. 61, 1383–1393 (2013).

Pan, Q. S. & Lu, L. Strain-controlled cyclic stability and properties of Cu with highly oriented nanoscale twins. Acta Mater. 81, 248–257 (2014).

Hodge, A. M. et al. Twin stability in highly nanotwinned Cu under compression, torsion and tension. Scr. Mater. 66, 872–877 (2012).

Zhang, X. & Misra, A. Superior thermal stability of coherent twin boundaries in nanotwinned metals. Scr. Mater. 66, 860–865 (2012).

Zhang, X. et al. Thermal stability of sputter-deposited 330 austenitic stainless-steel thin films with nanoscale growth twins. Appl. Phys. Lett. 87, 233116 (2005).

Anderoglu, O., Misra, A., Wang, H. & Zhang, X. Thermal stability of sputtered Cu films with nanoscale growth twins. J. Appl. Phys. 103, 094322 (2008).

Chen, K.-C., Wu, W.-W., Liao, C.-N., Chen, L.-J. & Tu, K. N. Observation of atomic diffusion at twin-modified grain boundaries in copper. Science 321, 1066–1069 (2008).

Lu, K., Yan, F. K., Wang, H. T. & Tao, N. R. Strengthening austenitic steels by using nanotwinned austenitic grains. Scr. Mater. 66, 878–883 (2012).

Yan, F. K., Liu, G. Z., Tao, N. R. & Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 60, 1059–1071 (2012).

Yan, F. K. et al. Deformation mechanisms in an austenitic single-phase duplex microstructured steel with nanotwinned grains. Acta Mater. 81, 487–500 (2014).

Wang, H. T., Tao, N. R. & Lu, K. Strengthening an austenitic Fe–Mn steel using nanotwinned austenitic grains. Acta Mater. 60, 4027–4040 (2012).

Bouaziz, O., Barbier, D., Cugy, P. & Petigand, G. Effect of process parameters on a metallurgical route providing nano-structured single phase steel with high work-hardening. Adv. Eng. Mater. 14, 49–51 (2012).

Yuan, Y. et al. A novel strategy for the design of advanced engineering alloys-strengthening turbine disk superalloys via twinning structures. Adv. Eng. Mater. 13, 296–300 (2011).

Yuan, Y. et al. A new method to strengthen turbine disc superalloys at service temperatures. Scr. Mater. 66, 884–889 (2012).

Solozhenko, V. L., Kurakevych, O. O. & Le Godec, Y. Creation of nanostructures by extreme conditions: high-pressure synthesis of ultrahard nanocrystalline cubic boron nitride. Adv. Mater. 24, 1540–1544 (2012).

Irifune, T., Kurio, A., Sakamoto, S., Inoue, T. & Sumiya, H. Materials: ultrahard polycrystalline diamond from graphite. Nature 421, 599–600 (2003).

Tian, Y. et al. Ultrahard nanotwinned cubic boron nitride. Nature 493, 385–388 (2013).

Huang, Q. et al. Nanotwinned diamond with unprecedented hardness and stability. Nature 510, 250–253 (2014). The first report on nanotwinned diamond and its unique properties.

Hansen, N. New discoveries in deformed metals. Metall. Mater. Trans. A 32, 2917–2935 (2001).

Hughes, D. A. & Hansen, N. Microstructure and strength of nickel at large strains. Acta Mater. 48, 2985–3004 (2000).

Luo, Z. P., Zhang, H. W., Hansen, N. & Lu, K. Quantification of the microstructures of high purity nickel subjected to dynamic plastic deformation. Acta Mater. 60, 1322 (2012).

Ashby, M. F. The deformation of plastically non-homogeneous materials. Philos. Mag. 21, 399–424 (1970).

Zhang, D. L. & Cantor, B. Melting behaviour of In and Pb particles embedded in an Al matrix. Acta Metall. Mater. 39, 1595–1602 (1991).

Sheng, H. W., Ren, G., Peng, L. M., Hu, Z. Q. & Lu, K. Superheating and melting-point depression of Pb nanoparticles embedded in Al matrices. Phil. Mag. Lett. 73, 179–186 (1996).

Mei, Q. S. & Lu, K. Melting and superheating of crystalline solids: from bulk to nanocrystals. Prog. Mater. Sci. 52, 1175–1262 (2007).

Zhang, L., Jin, Z. H., Zhang, L. H., Sui, M. L. & Lu, K. Superheating of confined Pb thin films. Phys. Rev. Lett. 85, 1484–1487 (2000).

Zheng, S. et al. High-strength and thermally stable bulk nanolayered composites due to twin-induced interfaces. Nat. Commun. 4, 1696 (2013).

Beyerlein, I. J. et al. Emergence of stable interfaces under extreme plastic deformation. Proc. Natl Acad. Sci. USA 111, 4386–4390 (2014). A concise summary of formation of low-energy bimetal boundaries under extreme straining.

Li, Y. J. et al. Mechanisms of subgrain coarsening and its effect on the mechanical properties of carbon-supersaturated nanocrystalline hypereutectoid steel. Acta Mater. 84, 110–123 (2015).

Li, Y. et al. Segregation stabilizes nanocrystalline bulk steel with near theoretical strength. Phys. Rev. Lett. 113, 106104 (2014).

Lu, K. in Proc. 35th Riso Int. Symp. Mater. Sci. (eds Faster, S., Hansen, N., Juul Jensen, D., Ralph, B. & Sun, J. ) 80–102 (Roskilde, 2014). A comprehensive review article on gradient nanostructures in metals.

Lu, K. & Lu, J. Nanostructured surface layer on metallic materials induced by SMAT. Mater. Sci. Eng. A 375–377, 38–45 (2004).

Lu, K. & Lu, J. Surface nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach. J. Mater. Sci. Technol. 15, 193–197 (1999).

Huang, H. W., Wang, Z. B., Lu, J. & Lu, K. Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 87, 150–160 (2015).

Yang, L., Tao, N. R., Lu, K. & Lu, L. Enhanced fatigue resistance of Cu with a gradient nanograined surface layer. Scr. Mater. 68, 801–804 (2013).

Huang, H. W., Wang, Z. B., Yong, X. P. & Lu, K. Enhancing torsion fatigue behaviour of martensitic stainless steel by generating gradient nanograined layer via surface mechanical grinding treatment. Mater. Sci. Technol. 29, 1200–1205 (2012).

Wu, X., Jiang, P., Chen, L., Yuan, F. & Zhu, Y. T. Extraordinary strain hardening by gradient structure. Proc. Natl Acad. Sci. USA 111, 7197–7201 (2014).

Wei, Y. et al. Evading the strength–ductility trade-off dilemma in steel through gradient hierarchical nanotwins. Nat. Commun. 5, 3580 (2014).

Kou, H., Lu, J. & Li, Y. High-strength and high-ductility nanostructured and amorphous metallic materials. Adv. Mater. 26, 5518–5524 (2014).

Li, Y. S., Zhang, Y., Tao, N. R. & Lu, K. Effect of thermal annealing on mechanical properties of a nanostructured copper prepared by means of dynamic plastic deformation. Scr. Mater. 59, 475–478 (2008).

Lu, K. Making strong nanomaterials ductile with gradients. Science 345, 1455–1456 (2014).

Li, J. & Soh, A. K. Enhanced ductility of surface nano-crystallized materials by modulating grain size gradient. Model. Simul. Mater. Sci. 20, 085002 (2012).

Fang, T. H., Tao, N. R. & Lu, K. Tension-induced softening and hardening in gradient nanograined surface layer in copper. Scr. Mater. 77, 17–20 (2014).

Zhang, Y. S., Han, Z., Wang, K. & Lu, K. Friction and wear behaviors of nanocrystalline surface layer of pure copper. Wear 260, 942–948 (2006).

Fu, T. et al. Mechanical properties of DLC coating sputter deposited on surface nanocrystallized 304 stainless steel. Surf. Coat. Technol. 207, 555–564 (2012).

Howe, J. M. Interface in Materials (Wiley, 1997).

Hughes, G. D., Smith, S. D., Pande, C. S., Johnson, H. R. & Armstrong, R. W. Hall–Petch strengthening for the microhardness of twelve nanometer grain diameter electrodeposited nickel. Scr. Metall. 20, 93–97 (1986).

Zhang, H. W., Huang, X. & Hansen, N. Evolution of microstructural parameters and flow stresses toward limits in nickel deformed to ultra-high strains. Acta Mater. 56, 5451–5465 (2008).

Ebrahimi, F., Bourne, G. R., Kelly, M. S. & Matthews, T. E. Mechanical properties of nanocrystalline nickel produced by electrodeposition. Nanostruct. Mater. 11, 343–350 (1999).

Dalla Torre, F., Van Swygenhoven, H. & Victoria, M. Nanocrystalline electrodeposited Ni: microstructure and tensile properties. Acta Mater. 50, 3957–3970 (2002).

Zhang, H. W., Lu, K., Pippan, R., Huang, X. & Hansen, N. Enhancement of strength and stability of nanostructured Ni by small amounts of solutes. Scr. Mater. 65, 481–484 (2011).

Dalla Torre, F., Spä tig, P., Schä ublin, R. & Victoria, M. Deformation behaviour and microstructure of nanocrystalline electrodeposited and high pressure torsioned nickel. Acta Mater. 53, 2337–2349 (2005).

Sanders, P. G., Eastman, J. A. & Weertman, J. R. Elastic and tensile behavior of nanocrystalline copper and palladium. Acta Mater. 45, 4019–4025 (1997).

Wang, Y. M. et al. Microsample tensile testing of nanocrystalline copper. Scr. Mater. 48, 1581–1586 (2003).

Cheng, S. et al. Tensile properties of in situ consolidated nanocrystalline Cu. Acta Mater. 53, 1521–1533 (2005).

Zhao, Y. H., Bingert, J. E., Liao, X. Z. & Cui, B. Simultaneously increasing the ductility and strength of ultra-fine-grained pure copper. Adv. Mater. 18, 2949–2953 (2006).

Ebrahimi, F., Zhai, Q. & Kong, D. Deformation and fracture of electrodeposited copper. Scr. Mater. 39, 315–321 (1998).

Tsuji, N., Ito, Y., Saito, Y. & Minamino, Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 47, 893–899 (2002).

Kamikawa, N., Huang, X., Tsuji, N. & Hansen, N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater. 57, 4198–4208 (2009).

Islamgaliev, R. K., Clmelik, F. & Kuzel, R. Thermal stability of submicron grained copper and nickel. Mater. Sci. Eng. A 237, 43–51 (1997).

Sitarama Raju, K. et al. Microstructure evolution and hardness variation during annealing of equal channel angular pressed ultra-fine grained nickel subjected to 12 passes. J. Mater. Sci. 46, 2662–2671 (2011).

Zhilyaev, A., Nurislamova, G., Valiev, R., Baro, M. & Langdon, T. Thermal stability and microstructural evolution in ultrafine-grained nickel after equal-channel angular pressing (ECAP). Metall. Mater. Trans. A 33, 1865–1868 (2002).

Schafler, E. & Pippan, R. Effect of thermal treatment on microstructure in high pressure torsion (HPT) deformed nickel. Mater. Sci. Eng. A 387–389, 799–804 (2004).

Zhang, H. W., Huang, X., Pippan, R. & Hansen, N. Thermal behavior of Ni (99.967% and 99.5% purity) deformed to an ultra-high strain by high pressure torsion. Acta Mater. 58, 1698–1707 (2010).

Oh-ishi, K., Horita, Z. & Smith, D. J. Fabrication and thermal stability of a nanocrystalline Ni. J. Mater. Res. 14, 4200–4207 (1999).

Saldana, C., King, A. H. & Chandrasekar, S. Thermal stability and strength of deformation microstructures in pure copper. Acta Mater. 60, 4107–4116 (2012).

Zhang, Y., Wang, J. T., Cheng, C. & Liu, J. Stored energy and recrystallization temperature in high purity copper after equal channel angular pressing. J. Mater. Sci. 43, 7326–7330 (2008).

Molodova, X., Gottstein, G., Winning, M. & Hellmig, R. J. Thermal stability of ECAP processed pure copper. Mater. Sci. Eng. A 460, 204–213 (2007).

Wang, Y. L., Lapovok, R., Wang, J. T., Qi, Y. S. & Estrin, Y. Thermal behavior of copper processed by ECAP with and without back pressure. Mater. Sci. Eng. A 628, 21–29 (2015).

Lugo, N., Llorca, N., Suñol, J. J. & Cabrera, J. M. Thermal stability of ultrafine grains size of pure copper obtained by equal-channel angular pressing. J. Mater. Sci. 45, 2264–2273 (2010).

Hasegawa, H. et al. Thermal stability of ultrafine-grained aluminum in the presence of Mg and Zr additions. Mater. Sci. Eng. A 265, 188–196 (1999).

Mishra, A., Kad, B. K., Gregori, F. & Meyers, M. A. Microstructural evolution in copper subjected to severe plastic deformation: experiments and analysis. Acta Mater. 55, 13–28 (2007).

Hebesberger, T., Stuwe, H. P., Vorhauer, A., Wetscher, F. & Pippan, R. Structure of Cu deformed by high pressure torsion. Acta Mater. 53, 393–402 (2005).

Li, Y. S., Tao, N. R. & Lu, K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 56, 230–241 (2008).

Zhilyaev, A. P. et al. Experimental parameters influencing grain refinement and microstructural evolution during high-pressure torsion. Acta Mater. 51, 753–765 (2003).

Liu, X. C., Zhang, H. W. & Lu, K. Formation of nano-laminated structure in nickel by means of surface mechanical grinding treatment. Acta Mater. 96, 24–36 (2015).

Sus´-Ryszkowska, M., Wejrzanowski, T., Pakieła, Z. & Kurzydłowski, K. J. Microstructure of ECAP severely deformed iron and its mechanical properties. Mater. Sci. Eng. A 369, 151–156 (2004).

Ivanisenko, Y., Valiev, R. Z. & Fecht, H. J. Grain boundary statistics in nano-structured iron produced by high pressure torsion. Mater. Sci. Eng. A 390, 159–165 (2005).

Iwahashi, Y., Horita, Z. & Nemoto, M. The process of grain refinement in equal-channel angular pressing. Acta Mater. 46, 3317–3331 (1998).

Xu, C., Horita, Z. & Langdon, T. G. The evolution of homogeneity in processing by high-pressure torsion. Acta Mater. 55, 203–212 (2007).

Zhang, Y., Tao, N. R. & Lu, K. Effect of stacking-fault energy on deformation twin thickness in Cu–Al alloys. Scr. Mater. 60, 211–213 (2009).

Xiao, G. H., Tao, N. R. & Lu, K. Effects of strain, strain rate and temperature on deformation twinning in a Cu–Zn alloy. Scr. Mater. 59, 975–978 (2008).

Acknowledgements

The author thanks the Ministry of Science and Technology of China (Grant 2012CB932201), the National Natural Science Foundation of China (Grants 51231006), the Danish-Chinese Center for Nanometals (Grants 51261130091 and DNRF86-5) and the Key Research Program of Chinese Academy of Sciences (Grant KGZD-EW-T06) for financial support, and X. C. Liu, X. Y. Li and L. Lu for discussions and assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The author declares no competing interests.

Rights and permissions

About this article

Cite this article

Lu, K. Stabilizing nanostructures in metals using grain and twin boundary architectures. Nat Rev Mater 1, 16019 (2016). https://doi.org/10.1038/natrevmats.2016.19

Published:

DOI: https://doi.org/10.1038/natrevmats.2016.19

This article is cited by

-

Nanovoid formation mechanism in nanotwinned Cu

Discover Nano (2024)

-

Quasi-instantaneous materials processing technology via high-intensity electrical nano pulsing

Scientific Reports (2024)

-

An extended substrate screening strategy enabling a low lattice mismatch for highly reversible zinc anodes

Nature Communications (2024)

-

Interface Design Strategy for GNS/AZ91 Composites with Semi-Coherent Structure

Acta Metallurgica Sinica (English Letters) (2024)

-

A Review of Mechanical Properties and Improvement Methods of Medium Entropy Alloys at High Temperature

JOM (2024)