Abstract

Currently, optical or mechanical resonances are commonly used in microfluidic research. However, optomechanical oscillations by light pressure were not shown with liquids. This is because replacing the surrounding air with water inherently increases the acoustical impedance and hence, the associated acoustical radiation losses. Here, we bridge between microfluidics and optomechanics by fabricating a hollow-bubble resonator with liquid inside and optically exciting vibrations with 100 MHz rates using only mW optical-input power. This constitutes the first time that any microfluidic system is optomechanically actuated. We further prove the feasibility of microfluidic optomechanics on liquids by demonstrating vibrations on organic fluids with viscous dissipation higher than blood viscosity while measuring density changes in the liquid via the vibration frequency shift. Our device will enable using cavity optomechanics for studying non-solid phases of matter, while light is easily coupled from the outer dry side of the capillary and fluid is provided using a standard syringe pump.

Similar content being viewed by others

Introduction

A major application of optical resonators is in the field of sensing where microresonators were used to sense biomarkers in serum1 and to detect viruses and nanoparticles2,3,4 in an aqueous environment. With similar motivation and in a parallel effort, mechanical resonators were used to weigh biomolecules and cells.5,6 Just like we use more than one sense (e.g., eyes and ears) to detect hazards, optomechanics might suggest a bridge between the seemingly parallel optical and mechanical detection fields. The recent availability of liquid containing bubble shaped resonators,7,8 in combination with optomechanical vibrations at >GHz rate,9,10,11,12 might pave the way for ultrasound investigations on analytes in liquids. Nevertheless, cavity optomechanics on non-solid phases of material was never before demonstrated.

One of the major ‘show stoppers’ on the way to microfluidic optomechanics originates from the fact that water has acoustical impedance that is more than 4000 times larger than air. Hence, naively immersing optomechanical devices in water will accordingly increase the acoustical radiation losses. Liquid submerged optomechanical oscillators are therefore challenging, as sound will tend to escape from the cavity by radiating out rather than being confined to the resonator. Here, we confine the high-impedance water inside6,13 a silica-bubble resonator so that its acoustical quality factor is minimally affected. In this manner, when both mechanical and optical quality factors, Qm and QO, of microdevices are sufficiently leveraged, their optical and mechanical modes can be parametrically coupled, allowing the optical excitation of vibrations.14 In spherical shapes9 such as our bubble, excitation of mechanical breathe modes, at 100 MHz rates, is expected via the centrifugal pressure applied by a circulating optical whispering-gallery mode. It is interesting that we could also observe some 1 GHz and 11 GHz modes in the same microfluidic device that were excited via a different mechanism as explained in Refs. 11 and 15.

Bubbles along microcapillaries7,8,16,17 and on-chip18 devices can possess excellent optical transmission7,8,16,17 together with low mechanical dissipation while allowing liquid to be placed inside the device. Additionally, such glass bubbles can benefit from optically excited vibrations as no electrodes are needed. This is because optical excitation can be performed in a contactless manner with light coupled into the device from a nearby tapered fibre that does not dampen mechanical vibrations.19 This makes such silica-glass bubbles attractive as a new type of a microfluidic optomechanical device as we will show here.

Materials and methods

Fabrication

Following the similar method presented in Ref. 7, we stretch a silica capillary while softening the glass using amplitude modulated CO2 lasers, into a large diameter bubble in the middle of a microcapillary (Figure 1a–1c). We can fabricate devices with various bubble diameters upon request and with wall thickness below 600 nm.8

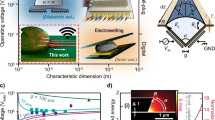

Fabrication and experimental set-up. (a) SEM image of a bubble-shaped capillary resonator together with its calculated first and third eigen mechanical modes (b, c) where colours stand for deformation. Corresponding experimentally measured oscilloscope and electric spectrum analyser signals are also shown underneath. Diameter and wall thickness of our device are 72 and 10 µm. (d, e) Experimental set-up: light (red) is evanescently coupled to an optical whispering-gallery mode of a bubble capillary where its centrifugal radiation pressure excites the bubble’s mechanical breathing mode (e, green arrows). This vibration modulates the transmitted light as detected with a photodiode on the other side of the coupler. Transmitted signal shows high modulation due to mechanical vibrations of the resonator. Water is inserted in the bubble through a microcapillary inlet, using a syringe pump. The optical wavelength that we used is 1.5 µm. SEM, scanning electron microscope.

Experimental set-up

We evanescently couple light from a tapered optical fibre19 (Figure 1d and 1e) into the glass bubble to excite its optical whispering-gallery mode. The inflating radiation pressure on the device walls is enhanced by the multiple optical recirculations and excites the vibrational breathe mode of the bubble in a self-sustained process.14 Vibration, in return, modulates the circulating light in a manner that can be observed by a photodetector. We optically measure mechanical vibrations by coupling part of the resonator light that was circulating in the vibrating cavity through the other side of fibre to a photodetector (Figure 1e).

Light experiences a high degree of modulation (Figure 1e) due to the mechanical vibrations, and since its power is at the mW scale, it is easily measurable with a low-noise photodetector (Figure 1e, Figure 2). To reiterate, the mechanical mode is both excited and interrogated by light via standard telecom-compatible optical fibres with no external feedback, control or modulation needed. As for the fluidic capability, liquids or gases are flown through the capillary by using a syringe pump.

Proof of feasibility: optomechanical vibration on non-solid phases of materials. (a) Experimentally measured opto-excited vibration while different fluids are inside the resonator. The inspected fluids are air and viscous water sugar solution with sugar concentration changing from 0 to 45% (w/w). (b) The experimental frequency drift is presented as a function of the fluid density together with its corresponding finite element numerical calculation and analytical estimation (Equation (1)). (c) Finite element calculation of the mechanical modes where wireframe represents the device at mechanical equilibrium. Colours and deformation of the wall represent the acoustical amplitude. Note that despite of its shape, the ‘with air’ mode is the first order mode as all of its sections are moving in phase.

Results and discussion

We start our experiment with a sugar water solution at 44% weight concentration, and measure a 28.6 MHz vibration (Figure 2a, green). We choose to use high-concentration aqueous sucrose solution because its viscous dissipation is ten times higher than water and three times higher than blood, showing that our microfluidic optomechanical device (µFOM) works even on liquids with relatively large mechanical loss. To prove the feasibility of monitoring changes in the inspected analyte, we measured the vibration frequency while reducing the concentration of sugar down to pure water and then replacing water with air. A frequency shift of more than 3 MHz was observed. This large shift is not surprising since the fluid occupies a large portion of our device. Similar to previous work,9 selective excitation of individual mechanical modes is possible by tuning the photon lifetime in the cavity until it is comparable with the acoustical cycle time of the mechanical mode that we are interested to excite. This is done here by changing the optical loss rate (=optical frequency/QO) in our cavity by means of controlling the coupler–resonator distance to increase loss and excite mechanical modes at higher vibrational rates. QOs in the order of 106 were required for the high-frequency mechanical modes, while QOs in the order of 107 were needed for the low-frequency vibrations. We will now theoretically explain this frequency shift. First, we fit the measured frequency shift (Figure 2a) to a simplified analytical model where the vibrational frequency f is related to the time it takes sound to cross from one side of the device to the other as given by

where vsio2 is the speed of sound in silica and vsw is the speed of sound in the water sugar solutions as measured in Ref. 20. Similarly, xsio2 and xsw represents the thickness of silica and liquid region. Optimizing xsio2 and xsw as free parameters resulted a fit that is shown in Figure 2b in green, next to the corresponding experimental measurements. For getting further details on the vibrational mode, we calculated a numerical finite element solution that is simultaneously involving different physical models for the solid and liquid region of our device as explained in Ref. 21. This multiphysics model provides the natural mechanical frequency and the corresponding deformation of the device (Figure 2). It is evident that adding liquid modifies the shape of the mechanical mode; again, this behavior is expected since liquid occupies most of the volume of our device and has density much higher than air.

Showing above that we can experimentally work with viscous liquid while measuring changes, we now go to the important question about the detection resolution. Practically, the detection resolution is affected by the oscillation linewidth (such as the ones in Figure 2) and by the frequency fluctuations. The oscillation full width at half maximum for a water-filled bubble is measured to be 9 kHz near oscillation threshold implying a ‘cold’ mechanical quality factor of 2172 at 19.75 MHz. When the optical input is increased over the oscillation threshold, the linewidth narrows to 35 Hz as shown in Figure 3d. The frequency shift of the oscillation is then measured in the form of a spectrogram (Figure 3a).

(a) Measuring frequency stability of a water-filled resonator using a spectrogram. Standard deviation was measured as 112 Hz. (b) Allan deviation of oscillation peak frequencies. (c) Measuring mechanical quality factor of a water-filled resonator was obtained from the resonance linewidth at subthreshold. (d) In above threshold behaviour, linewidth narrowing down to 35 Hz was measured. FWHM, full width at half maximum.

Statistics of the oscillation spectrogram over a 36-s period provide a standard deviation of 112 Hz (Figure 3a). A more complete analysis for frequency stability is given by the Allan deviation22,23 (Figure 3b), which calculates deviation between two frequency measurements separated by a fixed time difference. Being conservative, we estimate our resolution limit as the 112 Hz standard deviation rather than the smaller Allan deviation. We believe that in the future, a differential detection scheme could cancel out drifts using a split mechanical mode similar to what is currently done in optical detection.4

The optical quality factor, QO, is measured using the resonance linewidth to be near 7×106. Moreover, this value of QO is not affected by introducing water inside the bubble resonator. Since water absorbs light for the wavelength used (1.5 µm), this result indicates that the optical mode did not extend to the liquid. We can therefore conclude that the mechanical mode can be optically excited even with optically opaque liquids inside the capillary.

The mechanical quality factor, Qm, with water inside, is measured from the subthreshold mechanical linewidth. We measure Qm=2172 at f=19.75 MHz (Figure 3c). This quality factor is six times smaller than what the dry device allows.

Measurement of the vibration threshold shows that oscillations typically start near 1 mW of optical power for the dry and wet capillaries and sustain as long as we keep our laser source on.

As the optical mode is phase modulated by the mechanical vibration, higher-order optical (Stokes) lines exist in the transmitted light.9 This is evident with more than 25 Harmonics of a 32 MHz vibration spanning up to 0.8 GHz as shown in Figure 4 (blue). These high harmonics indicate that the mechanical vibrations result in an optical frequency shift that is larger than the optical resonance width.9 The harmonics in Figure 4 might be useful in cases where frequency multiplication is needed without adding any hardware. Moreover, we were able to measure breathing mode vibrations up to 140 MHz rates (Figure 4, red) while relying on high-order mechanical modes.9 The harmonics of this signal extended above 1 GHz in frequency.

Conclusion

While in many optofluidic devices, the motion of fluids affects light,24,25 here, in contrast, radiation pressure allows light to create mechanical vibration in a device that contains a fluid. We show here sustainable optically excited vibrations in a µFOM bubble at 20 MHz to 140 MHz rates with different types of liquids inside the resonator. A variety of conditions can be easily maintained inside the bubble, including fluids more viscous than serum, while light is conveniently coupled from the outer dry side of the bubble. By doing this, our device technologically enables optomechanics on non-solid state phases of mater. In the future, microfludic optomechanics might evolve toward using superfluids to support low dissipation for experiments in quantum optomechanics.

References

Zhu H, Dale PS, Caldwell CW, Fan X . Rapid and label-free detection of breast cancer biomarker CA15-3 in clinical human serum samples with optofluidic ring resonator sensors. Anal Chem 2009; 81: 9858–9865.

Vollmer F, Arnold S . Whispering-gallery-mode biosensing: label-free detection down to single molecules. Nat Methods 2008; 5: 591–596.

Lu T, Lee H, Chen T, Herchak S, Kim J et al. High sensitivity nanoparticle detection using optical microcavities. Proc Natl Acad Sci USA 2011; 108: 5976–5979.

He LÖ zdemir SK, Zhu J, Kim W, Yang L . Detecting single viruses and nanoparticles using whispering gallery microlasers. Nat Nanotechnol 2011; 6: 428–432.

Ilic B, Czaplewski D, Zalalutdinov M, Craighead HG, Neuzil P et al. Single cell detection with micromechanical oscillators. J Vac Sci Technol B 2001; 19: 2825–2828.

Burg TP, Godin M, Knudsen SM, Shen W, Carlson G et al. Weighing of biomolecules, single cells and single nanoparticles in fluid. Nature 2007; 446: 1066–1069.

Sumetsky M, Dulashko Y, Windeler RS . Optical microbubble resonator. Opt Lett 2010; 35: 898–900.

Lee W, Sun Y, Hao L, Reddy K, Sumetsky M et al. A quasi-droplet optofluidic ring resonator laser using a micro-bubble. Appl Phys Lett 2011; 99: 091102 .

Carmon T, Vahala KJ . Modal spectroscopy of optoexcited vibrations of a micron-scale on-chip resonator at greater than 1 GHz frequency. Phys Rev Lett 2007; 98: 123901.

Eichenfield M, Camacho R, Chan J, Vahala KJ, Painter O . A picogram- and nanometre-scale photonic-crystal optomechanical cavity. Nature 2009; 459: 550–555.

Bahl G, Zehnpfennig J, Tomes M, Carmon T . Stimulated optomechanical excitation of surface acoustic waves in a microdevice. Nat Commun 2011; 2: 403.

Sun X, Fong KY, Xiong C, Pernice WH, Tang HX . GHz optomechanical resonators with high mechanical Q factor in air. Opt Express 2011; 19: 22316–22321.

Barton RA, Ilic B, Verbridge SS, Cipriany BR, Parpia JM et al. Fabrication of a nanomechanical mass sensor containing a nanofluidic channel. Nano Lett 2010; 10: 2058–2063.

Carmon T, Rokhsari H, Yang L, Kippenberg TJ, Vahala KJ . Temporal behavior of radiation-pressure-induced vibrations of an optical microcavity phonon mode. Phys Rev Lett 2005; 94: 223902.

Tomes M, Carmon T . Photonic micro-electromechanical systems vibrating at X-band (11-GHz) rates. Phys Rev Lett 2009; 102: 113601.

Watkins A, Ward J, Wu Y, Nic Chormaic S . Single-input spherical microbubble resonator. Opt Lett 2011; 36: 2113–2115.

Berneschi S, Farnesi D, Cosi F, Nunzi Conti G, Pelli S et al. High Q silica microbubble resonators fabricated by arc discharge. Opt Lett 2011; 36: 3521–3523.

Eklund EJ, Shkel AM . Glass blowing on a wafer level. J Microelectromech Syst 2007; 16: 232–239.

Cai M, Painter O, Vahala KJ . Observation of critical coupling in a fibre taper to a silica-microsphere whispering-gallery mode system. Phys Rev Lett 2000; 85: 74–77.

Rao MA, Rizvi SS, Datta AK . Engineering Properties of Foods. 3rd ed. New York: CRC Press, 2005.

El Baroudi A, Razafimahery F, Rakotomanana-Ravelonarivo L . Study of a spherical head model. Analytical and numerical solutions in fluid–structure interaction approach. Int J Eng Sci 2012; 51: 1–13.

Allan DW . Statistics of atomic frequency standards. Proc IEEE 1966; 54: 221–230.

Sullivan DB, Allan DW, Howe DA, Walls FL . Characterization of clocks and oscillators. NIST Tech. Note 1337, US Government Printing Office, Washington, DC, 1990.

Psaltis D, Quake SR, Yang C . Developing optofluidic technology through the fusion of microfluidics and optics. Nature 2006; 442: 381–386.

Stolyarov AM, Wei L, Shapira O, Sorin F, Chua SL et al. Microfluidic directional emission control of an azimuthally polarized radial fibre laser. Nat Photon 2012; 6: 229–233.

Acknowledgements

This research was supported by the Defense Advanced Research ProjectsAgency Optical Radiation Cooling and Heating in Integrated Devicesprogramme and by the Air Force Office of Scientific Research. We acknowledge communication with Prof. Jack Harris from Yale University, in particularly on his vision on quantum optomechancis with superfluids.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This work is licensed under the Creative Commons Attribution-NonCommercial-No Derivative Works 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Hyun Kim, K., Bahl, G., Lee, W. et al. Cavity optomechanics on a microfluidic resonator with water and viscous liquids. Light Sci Appl 2, e110 (2013). https://doi.org/10.1038/lsa.2013.66

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/lsa.2013.66

Keywords

This article is cited by

-

High spatiotemporal resolution optoacoustic sensing with photothermally induced acoustic vibrations in optical fibres

Nature Communications (2021)

-

Nonlinear dynamic analysis of a photonic crystal nanocavity resonator

Applied Mathematics and Mechanics (2019)

-

Single whispering-gallery mode lasing in polymer bottle microresonators via spatial pump engineering

Light: Science & Applications (2017)

-

Air-coupled ultrasound detection using capillary-based optical ring resonators

Scientific Reports (2017)

-

Dynamics and entanglement of a membrane-in-the-middle optomechanical system in the extremely-large-amplitude regime

Science China Physics, Mechanics & Astronomy (2016)