Abstract

Creation, manipulation and detection of spin-polarized carriers are the key elements of spin-based electronics1,2. Most practical devices3,4,5 use a perpendicular geometry in which the spin currents are accompanied by charge currents. In recent years, new sources of pure spin currents (that is, transport of spin angular momentum without charge currents) have been demonstrated6,7,8,9 and applied10,11,12. Here we demonstrate a conceptually new source of pure spin current driven by the flow of heat across the interface between a ferromagnet and a non-magnetic metal. This spin current is generated because, in a ferromagnet, the Seebeck effect—which describes the generation of a voltage as a result of a temperature gradient—is spin dependent13,14. We studied this new source of spin currents experimentally in a non-local lateral geometry and developed a three-dimensional model that describes the heat, charge and spin transport in this geometry, enabling us to quantify this process15. We obtain a spin-dependent Seebeck coefficient for Permalloy of −3.8 μV K−1, suggesting that thermally driven spin injection is a feasible alternative for electrical spin injection in, for example, spin-transfer-torque experiments16.

Similar content being viewed by others

Main

The interplay of spin-dependent conductivity and thermoelectricity has been known since half a century ago, when it was used to describe the conventional Seebeck effect of ferromagnetic metals17. The discovery of the giant magnetoresistance effect3 sparked the interest of the community in spin-dependent conductivity and new spin electronics that still exists today4,5,8,18. Owing to experimental difficulties in controlling heat flows it was only very recently that thermoelectric spintronics was investigated19,20, leading to the new field of spin caloritronics13. A relevant example is given in ref. 9, which interprets its results in terms of the generation of a bulk spin accumulation due to an applied temperature gradient in a ferromagnetic film. In contrast, the effect we describe in this paper arises from a heat current flowing through a ferromagnetic/non-magnetic metal (FM/NM) junction, which creates a spin accumulation at the interface.

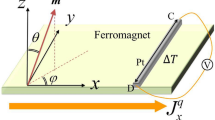

The concept of how we generate a heat current over an FM/NM junction and subsequently measure the spin accumulation is shown in Fig. 1. The scheme is essentially a lateral non-local spin-valve structure6 with the electrical injection replaced by thermal spin injection. We use this non-local scheme to separate spin injection from possible spurious effects6,11,12 and because the observed thermally generated non-spin-related voltage, to which we refer as the baseline resistance, enables us to extract the temperature distribution in the device by comparing this with modelling15.

A charge current I is sent through ferromagnet 1 (FM1) causing Joule heating owing to the large resistivity of FM1. The NM contacts (yellow) are highly thermally conductive, thereby providing heat sinks. The heat current Q through the centre FM1/NM interface injects a spin current into the NM depending on the magnetization direction M1. The generated spins diffuse towards the FM2/NM interface, where they generate a potential Δμ=P μs depending on the magnetization direction M2. As a consequence of Joule heating, the signal expected to arise from thermal spin injection scales with  . This potential is measured using the indicated voltage scheme by selectively switching the magnetization directions M1 and M2 by a magnetic field H.

. This potential is measured using the indicated voltage scheme by selectively switching the magnetization directions M1 and M2 by a magnetic field H.

We first formulate an appropriate diffusive-transport theory for thermally driven spin injection. The Seebeck coefficient indicates that an applied temperature gradient across a conductor generates an electric field21. In a ferromagnet, the transport processes for the majority and minority spins are different, leading to a spin-dependent conductivity σ↑,↓ and Seebeck coefficient S↑,↓ (refs 14, 17). The former is used to describe magnetoelectronics22 in FM/NM systems, where the latter is usually disregarded. To consider what happens when heat is sent through the system, we write the spin-dependent currents in both the bulk FM and NM regions:

here μ↑,↓ is the spin-dependent chemical potential and T is the temperature. When a heat current Q is sent through the bulk of a ferromagnet in the absence of a charge current, a spin current  flows driven by the spin-dependent Seebeck coefficient, which we define as Ss≡S↑−S↓ (Supplementary A). Here P is the conductivity polarization P=(σ↑−σ↓)/(σ↑+σ↓) of the ferromagnet and σF is the conductivity of the ferromagnet. We note that our definition of Ss should be distinguished from the spin Seebeck coefficient defined in ref. 9, where a so-called ‘entropy term’ was included23. We do not include this term in our analysis.

flows driven by the spin-dependent Seebeck coefficient, which we define as Ss≡S↑−S↓ (Supplementary A). Here P is the conductivity polarization P=(σ↑−σ↓)/(σ↑+σ↓) of the ferromagnet and σF is the conductivity of the ferromagnet. We note that our definition of Ss should be distinguished from the spin Seebeck coefficient defined in ref. 9, where a so-called ‘entropy term’ was included23. We do not include this term in our analysis.

To quantify the thermal injection of spins we consider the FM/NM interface and solve the Valet–Fert equation24 in a fashion similar as in ref. 25 (Supplementary A). The result is depicted in Fig. 2. A spin accumulation μs=μ↑−μ↓ appears at the interface driven by the abrupt change of spin current going from the bulk FM to the bulk NM, thereby acting as an effective source of spins at the interface. The resulting spin accumulation has the following expression:

where Rmis=RN/(RN+RF/(1−P2)) is a conductivity mismatch26 factor in which RF=λF/σF and RN=λN/σN are the spin resistances determined by the relaxation lengths λF and λN and the conductivities σF and σN. For the metallic interfaces under consideration in this paper, this factor is very close to unity. The resulting spin accumulation induced by the heat flow  , where kFM is the thermal conductivity of and

, where kFM is the thermal conductivity of and  the thermal gradient in the ferromagnet, is determined solely by the spin-dependent Seebeck coefficient Ss and the ferromagnetic spin relaxation length λF. Its direction is determined by the sign of the spin-dependent Seebeck coefficient, which changes sign when the magnetization of the ferromagnet reverses.

the thermal gradient in the ferromagnet, is determined solely by the spin-dependent Seebeck coefficient Ss and the ferromagnetic spin relaxation length λF. Its direction is determined by the sign of the spin-dependent Seebeck coefficient, which changes sign when the magnetization of the ferromagnet reverses.

Schematic figure showing the resulting spin-dependent chemical potentials μ↑,↓ across an FM/NM interface when a heat current  crosses it. The heat current is taken to be continuous across the interface, leading to a discontinuity in

crosses it. The heat current is taken to be continuous across the interface, leading to a discontinuity in  . No currents are allowed to leave the FM; nevertheless, a spin current proportional to the spin-dependent Seebeck coefficient flows through the bulk FM, which needs to become unpolarized in the bulk NM. This creates a spin imbalance μ↑−μ↓ at the boundary, which relaxes in the FM and NM on the length scale of their respective spin-relaxation lengths λi. A thermoelectric interface potential Δμ=P μs also builds up. On the left side no spin current is allowed to leave, leading to a spin accumulation of opposite sign.

. No currents are allowed to leave the FM; nevertheless, a spin current proportional to the spin-dependent Seebeck coefficient flows through the bulk FM, which needs to become unpolarized in the bulk NM. This creates a spin imbalance μ↑−μ↓ at the boundary, which relaxes in the FM and NM on the length scale of their respective spin-relaxation lengths λi. A thermoelectric interface potential Δμ=P μs also builds up. On the left side no spin current is allowed to leave, leading to a spin accumulation of opposite sign.

The signal due to thermally driven spin injection in the geometry of Fig. 1 scales with Joule heating:  , where I is the charge current sent through the device. Therefore, we use a lock-in technique to determine the relevant parameters R1 (μV mA−1) and R2 (μV mA−2) from the observed voltage15:

, where I is the charge current sent through the device. Therefore, we use a lock-in technique to determine the relevant parameters R1 (μV mA−1) and R2 (μV mA−2) from the observed voltage15:

The baseline ‘resistance’, defined in terms of a parallel and an antiparallel contribution as (RiP+RiAP)/2=Rib, enables us to extract the magnitude of Joule and Peltier heating effects and possible conventional Ohmic potential drops15. Here R1b is determined by the Ohmic potential drop and Peltier heating/cooling measured by the FM2–NM thermocouple, whereas the baseline resistance R2b is determined by Joule heating measured by the same thermocouple. The spin-dependent contribution RiP−RiAP=Ris to R1 is due to a conventional spin-valve signal, whereas this contribution to R2 comes from thermal spin injection.

A dedicated device was fabricated to study this effect and is shown in Fig. 3. The heating of FM1 has been kept very localized to an area of 150 × 150 nm2 by using thick gold contacts. Moreover, the contacts are placed asymmetrically to minimize the possible current flowing in and out of the FM1/NM interface. An extra Contact 5 is present to be able to send a current directly through the FM1/NM interface. By comparing the obtained signal R1s with a model (see Methods), we can extract the spin injection/detection efficiency15, which has been made as high as possible by keeping the size of the FM/NM contacts small. All measurements are made at room temperature.

The device consists of two 15-nm-thick Permalloy (Ni80Fe20) ferromagnets, FM1 and FM2, of dimensions 1 μm × 300 nm and 150 × 40 nm2, separated from each other by 100 nm. They are connected by a 60-nm-thick copper funnel with small effective FM/NM contact areas of 40 × 40 nm2 and 30 × 40 nm2. 5/175-nm-thick Ti/Au Contacts 1 and 2 are placed asymmetrically on FM1 to Joule heat it, whereas Contacts 3 and 4 are used to measure Joule heating and thermal spin injection. An extra Contact 5 is present to measure a regular non-local spin-valve signal.

Figure 4 shows our principal results on thermal spin injection. Four distinct P–AP and AP–P switches are observed, up to 70 nV in magnitude, scaling with I2 on a large background originating from the Py2/Cu thermocouple.

a, Measurement scheme of the experiment. b, Second-harmonic measurement result R2sI2 (nV) of the observed thermal spin signal as a function of I2. The error bars represent the standard deviation in the average height of the four P–AP and AP–P switches. c, Measured second-harmonic signal at a root mean squared current of 1.5 mA, showing the four distinct switches resulting from the magnetization alignment of FM1 and FM2 illustrating thermal spin injection.

The interpretation of the obtained signals requires a detailed knowledge of the heat, charge and spin currents in the device. For this purpose a three-dimensional thermoelectric spin model was constructed, which extends the spin-dependent current model24 to include thermoelectricity as well as thermal spin injection by the spin-dependent Seebeck coefficient.

The calculated average contribution R2b is 2.4 μV mA−2 lower than the observed 7.69 μV mA−2. A difference between the observed and modelled values has been seen before in non-local spin-valve samples15. It can be explained by a reduction in the Permalloy thickness due to its oxidation, which effectively increases the Joule heating. In the following, we scale the overall Joule heating in our model to fit our measured result R2b. We then find that we are able to heat FM1 to a maximum of ≈40 K, at which  at the FM1/NM interface is ≈50 K μm−1. At this moment the current density is ≈8 × 1011 A m−2, close to the point where the device will fail owing to electromigration.

at the FM1/NM interface is ≈50 K μm−1. At this moment the current density is ≈8 × 1011 A m−2, close to the point where the device will fail owing to electromigration.

Electrical spin injection was also measured by sending the current directly through the Py1/Cu interface, and the result is shown in Fig. 5c. From the measured resistance RNLSV (Ω), we see that a relatively large 9 mΩ spin-valve signal is present on top of a 1.05 Ω background, which is only slightly different to the 7.8 mΩ and 640 mΩ calculated signals with the metallic spin parameters λCu=350 nm, λPy=5 nm and PPy=0.25 obtained from previously fabricated samples6,15. Here PPy is positive, as shown before27.

a, First-harmonic measurement R1 for the measurement set-up of Fig. 4. b, Calculated temperature distribution at a height of 10 nm with a current of 2 mA sent through FM1. This illustrates the localized Joule heating, Peltier cooling and heating of the two Au/Py current-injecting contacts and subsequent thermal conduction towards the three connected metallic contacts. c, Measured electrical spin-injection scheme and resulting spin valve. d, Calculated spin accumulation at a height of 10 nm. A small part of the current path is short-circuited by the Cu connection so that 4% still flows in and out of the Py1/Cu contact because of its large conductivity. This creates a large positive and negative spin accumulation. Owing to the asymmetry in spin injection and the asymmetrical placement at FM2, a small fraction of 3% is still predicted to give a small regular spin-valve signal R1s.

The observed thermal-spin-injection signal R2s=−15.6 nV mA−2 is determined from Fig. 4b. We obtain a spin-dependent Seebeck coefficient for Permalloy of −3.8 μV K−1, a fraction of the conventional Seebeck coefficient SF=−20 μV K−1 (ref. 9). This gives a polarization of the Seebeck coefficient of PS=Ss/SF=0.19, not too different from the spin polarization of the conductivity. At the maximum currents used, we extract a net spin accumulation of ≈1 μeV at the FM1/NM interface. The magnitude of the spin-dependent Seebeck coefficient is in good agreement with theoretical predictions14,16. The previously deduced spin Seebeck coefficient Ss=−2 nV K−1 and the spin-dependent Seebeck coefficient in this paper are similar by definition, but describe different physical processes (Supplementary A). The discrepancy between the two values arises from the modelling, which is different. We also do not exclude that the relevant physics itself in their experiment could be different, as alternative explanations have been reported28.

In addition to the thermal-spin-injection signal, a small regular spin-valve signal R1s=−20 μΩ is also present and is shown in Fig. 5a. The baseline resistance R1b of 90 μΩ is in line with the calculated 95 μΩ. This is caused by Peltier heating and cooling of the two current-injecting contacts15.

The negative regular spin-valve signal R1s can be understood as follows. Owing to the high conductivity of the copper, a fraction of the current flows into and out of the Py1/Cu interface electrically injecting spins. A small net spin accumulation at the detector interface remains, caused by the asymmetric placement of FM2. This is illustrated by the calculation of the spin accumulation at the Py1/Cu interface shown in Fig. 5d, which shows the high geometrical dependence of this effect. The observed R1s is somewhat smaller than the calculated −45 μΩ. We believe that the small 40 × 40 nm2 size of the copper contact makes sure copper grain size, lithographic precision and ballistic effects start dominating the magnitude of this effect.

A previous device showed a thermal-spin-injection signal of −5 nV mA−2 at an FM–FM distance of 400 nm, only visible at the highest current (Supplementary B). A similar calculation gives SsPy=−5 μV K−1, in agreement with the analysis for the sample presented. This measurement also rules out any influence of nonlinear behaviour of the process seen in the R1sI signal on the R1sI2 signal (Supplementary C).

Now that the parameters governing equation (2) are known, we may compare this to the electrical-spin-injection results for the transparent Py/Cu interface. We can calculate that  for thermal spin injection versus μS/J≈3 × 10−16 eV m2 A−1 for electrical spin injection through a transparent Cu/Py contact.

for thermal spin injection versus μS/J≈3 × 10−16 eV m2 A−1 for electrical spin injection through a transparent Cu/Py contact.

Owing to the lateral non-local geometry and Joule-heating method used in this paper, we are limited to a maximum temperature gradient of ≈50 K μm−1. However, in a typical perpendicular geometry switching by spin-transfer torque5 this does not have to be the case. To switch the magnetization by electrical spin-transfer torque5 we need a typical charge current density of ≈5 × 1011 A m−2. The same stack should be able to switch by applying a temperature difference of only a few tens of degrees as earlier theoretical14,16 and experimental29 studies have indicated. This simple example shows that, despite the weak signals observed in this paper, thermal spin injection can be a viable alternative, or even work alongside, electrical spin injection.

Methods

Fabrication.

The sample in this paper was fabricated by a one-step optical and five-step electron beam lithography process. In each step, metals are deposited using e-beam deposition. For the e-beam lithography process a PMMA 950 K resist is used of 70–400 nm thickness depending on the thickness of the deposited material and resilience to Ar ion milling. The first e-beam lithography process produces 5/30-nm-thick and 100-nm-wide Ti/Au markers, which using an automatic alignment procedure can be aligned to in the next e-beam deposition steps with high precision. In the next four steps, the 15 nm Py, 5/30 nm Ti/Au, 5/180 nm Ti/Au and 65 nm Cu layers are deposited. For the last three steps, Ar ion milling was used before deposition to remove any polymer residue and the Py oxide to obtain our highly ohmic contacts.

Measurements.

The measurements were made using an a.c. current source of a frequency <1 kHz far below the characteristic thermoelectric timescale of such sized systems of ≈1–100 ns. The obtained signal is sent to three lock-in systems measuring the first, second and third harmonic responses simultaneously. Care was taken in deriving R1 and R2 by scanning the current from 500 μA to 1.5 mA (root mean squared) to make sure that higher harmonics, as well as cross-talk, were negligible.

Modelling.

We constructed a three-dimensional model of the fabricated sample using the finite-element program Comsol Multiphysics. The physics is defined in terms of a thermoelectric spin model where the spin-up, down and heat currents are given by:

where Π↑,↓ are the spin-dependent Peltier coefficients given by S↑,↓·T0. Here T0=300 K, which is the reference temperature of the device. We take these currents to be continuous across boundaries. At the end of all contacts we set the temperature to be T0. At Contact 1 in Fig. 3 we set J↑,↓=J/2 to inject a charge current, which is sent through the system by setting μ↑,↓=0 at Contact 2 or 5. At all other interfaces the currents are set to zero. We include Valet–Fert spin relaxation by assuming  in the bulk. Joule heating is included by assuming

in the bulk. Joule heating is included by assuming  , where a scaling factor ζ=3.2 is used to make the model correspond to the measured R2b. The system was meshed most accurately at the FM/NM interfaces where the mesh size was 1 nm to accurately calculate thermal spin injection. The dependencies R1(s) up to R4(s) were determined by calculating the results at ±1 and 2 mA for the parallel and antiparallel configurations. The measured resistivities σAu=2.2 × 107 S m−1, σCu=4.26 × 107 S m−1 and σPy=4.32 × 106 S m−1 were taken as inputs for the model. In this model, the substrate was also taken into account15. The Seebeck coefficients SAu=1.7 μV K−1, SCu=1.6 μV K−1 and SPy=−20 μV K−1 and thermal conductances kAu=300 W m−1 K−1, kCu=300 W m−1 K−1, kPy=30 W m−1 K−1 and ksubstrate=1 W m−1 K−1 were taken from various sources in the literature9,30.

, where a scaling factor ζ=3.2 is used to make the model correspond to the measured R2b. The system was meshed most accurately at the FM/NM interfaces where the mesh size was 1 nm to accurately calculate thermal spin injection. The dependencies R1(s) up to R4(s) were determined by calculating the results at ±1 and 2 mA for the parallel and antiparallel configurations. The measured resistivities σAu=2.2 × 107 S m−1, σCu=4.26 × 107 S m−1 and σPy=4.32 × 106 S m−1 were taken as inputs for the model. In this model, the substrate was also taken into account15. The Seebeck coefficients SAu=1.7 μV K−1, SCu=1.6 μV K−1 and SPy=−20 μV K−1 and thermal conductances kAu=300 W m−1 K−1, kCu=300 W m−1 K−1, kPy=30 W m−1 K−1 and ksubstrate=1 W m−1 K−1 were taken from various sources in the literature9,30.

References

Zutic, I., Fabian, J. & Das Sarma, S. Spintronics: Fundamentals and applications. Rev. Mod. Phys. 76, 323–410 (2004).

Chappert, C., Fert, A. & Nguyen van Dau, F. The emergence of spin electronics in data storage. Nature Mater. 6, 813–823 (2007).

Baibich, M. N. et al. Giant magnetoresistance of (001)Fe/(001)Cr magnetic superlattices. Phys. Rev. Lett. 61, 2472–2475 (1988).

Kiselev, S. I. et al. Microwave oscillations of a nanomagnet driven by a spin-polarized current. Nature 425, 380–383 (2003).

Albert, F. J., Katine, J. A., Buhrman, R. A. & Ralph, D. C. Spin-polarized current switching of a Co thin film nanomagnet. Appl. Phys. Lett. 77, 3809–3811 (2000).

Jedema, F. J., Filip, A. & van Wees, B. J. Electrical spin injection and accumulation at room temperature in an all-metal mesoscopic spin valve. Nature 410, 345–348 (2001).

Valenzuela, S. O. & Tinkham, M. Direct electronic measurement of the spin Hall effect. Nature 442, 176–179 (2006).

Costache, M. V., Sladkov, M., Watts, S. M., van der Wal, C. H. & van Wees, B. J. Electrical detection of spin pumping due to the precessing magnetization of a single ferromagnet. Phys. Rev. Lett. 97, 216603 (2006).

Uchida, K. et al. Observation of the spin Seebeck effect. Nature 455, 778–781 (2008).

Yang, T., Kimura, T. & Otani, Y. Giant spin-accumulation signal and pure spin-current-induced reversible magnetization switching. Nature Phys. 4, 851–854 (2008).

Lou, X. et al. Electrical detection of spin transport in lateral ferromagnet semiconductor devices. Nature Phys. 3, 197–202 (2007).

Dash, S. P., Sharma, S., Patel, R. S., de Jong, M. P. & Jansen, R. Electrical creation of spin polarization in silicon at room temperature. Nature 462, 491–494 (2009).

Bauer, G. E., MacDonald, A. H. & Maekawa, S. Spin caloritronics. Solid State Commun. 150, 459–460 (2010).

Tulapurkar, A. A. & Suzuki, Y. Contribution of electron–magnon scattering to the spin-dependent Seebeck effect in a ferromagnet. Solid State Commun. 150, 466–470 (2010).

Bakker, F. L., Slachter, A., Adam, J-P. & van Wees, B. J. Interplay of Peltier and Seebeck effects in nanoscale nonlocal spin valves. Phys. Rev. Lett. (in the press); preprint at http://arxiv.org/abs/1004.0118v1.

Hatami, M., Bauer, G. E. W., Zhang, Q. & Kelly, P. J. Thermal spin-transfer torque in magnetoelectronic devices. Phys. Rev. Lett. 99, 066603 (2007).

Barnard, R. D. Thermoelectricity in Metals and Alloys (Taylor and Francis Ltd, 1972).

Tserkovnyak, Y., Brataas, A., Bauer, G. E. W. & Halperin, B. I. Nonlocal magnetization dynamics in ferromagnetic heterostructures. Rev. Mod. Phys. 77, 1375–1421 (2005).

Gravier, L., Serrano-Guisan, S., Reuse, F. & Ansermet, J. P. Thermodynamic description of heat and spin transport in magnetic nanostructures. Phys. Rev. B 73, 024419 (2006).

Dubi, Y. & Di Ventra, M. Thermospin effects in a quantum dot connected to ferromagnetic leads. Phys. Rev. B 79, 081302 (2009).

Mott, N. F. & Jones, H. The Theory of the Properties of Metals and Alloys (Oxford Univ. Press, 1936).

Brataas, A., Bauer, G. E. W. & Kelly, P. J. Non-collinear magnetoelectronics. Phys. Rep. 427, 157–255 (2006).

Uchida, K. et al. Phenomenological analysis for spin-Seebeck effect in metallic magnets. J. Appl. Phys. 105, 07C908 (2009).

Valet, T. & Fert, A. Theory of the perpendicular magnetoresistance in magnetic multilayers. Phys. Rev. B 48, 7099–7113 (1993).

van Son, P. C., van Kempen, H. & Wyder, P. Boundary resistance of the ferromagnetic–nonferromagnetic metal interface. Phys. Rev. Lett. 58, 2271–2273 (1987).

Schmidt, G., Ferrand, D., Molenkamp, L. W., Filip, A. T. & van Wees, B. J. Fundamental obstacle for electrical spin injection from a ferromagnetic metal into a diffusive semiconductor. Phys. Rev. B 62, R4790–R4793 (2000).

Vlaminck, V. & Bailleul, M. Current-induced spin-wave Doppler shift. Science 322, 410–413 (2008).

Xiao, J., Bauer, G. E. W., Uchida, K., Saitoh, E. & Maekawa, M. Theory of magnon-driven spin Seebeck effect. Phys. Rev. B 81, 214418 (2010).

Yu, H., Granville, S., Yu, D. P. & Ansermet, J-Ph. Evidence for thermal spin transfer torque. Phys. Rev. Lett. 105, 146601 (2010).

Kittel, C. Introduction to Solid State Physics (John Wiley, 1996).

Acknowledgements

We would like to acknowledge J. G. Holstein, B. Wolfs and S. Bakker for technical assistance and T. Banarjee, I. J. Vera Marun, P. J. Zomer and S. Denega for critically reading the manuscript. This work was financed by the European EC Contracts IST-033749 ‘DynaMax’, the ‘Stichting voor Fundamenteel Onderzoek der Materie’ (FOM) and NanoNed.

Author information

Authors and Affiliations

Contributions

A.S. and B.J.v.W. conceived and designed the experiments. A.S. and F.L.B. carried out the main experiments and J-P.A. carried out some check-up experiments. All authors were involved in the analysis. A.S. wrote the paper, with the help of the co-authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 301 kb)

Rights and permissions

About this article

Cite this article

Slachter, A., Bakker, F., Adam, JP. et al. Thermally driven spin injection from a ferromagnet into a non-magnetic metal. Nature Phys 6, 879–882 (2010). https://doi.org/10.1038/nphys1767

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nphys1767

This article is cited by

-

Spin current driven by ultrafast magnetization of FeRh

Nature Communications (2023)

-

Chiral-phonon-activated spin Seebeck effect

Nature Materials (2023)

-

The role of spin in thermoelectricity

Nature Reviews Physics (2023)

-

Influence of heat flow control on dynamical spin injection in CoFeB/Pt/CoFeB trilayer

Scientific Reports (2022)

-

Electrical switching of spin-polarized current in multiferroic tunneling junctions

npj Computational Materials (2022)