Abstract

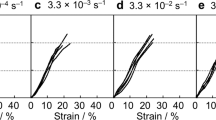

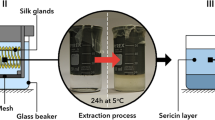

Typical spider dragline silk tends to outperform other natural fibres and most man-made filaments1. However, even small changes in spinning conditions can have large effects on the mechanical properties of a silk fibre2,3,4,5,6 as well as on its water uptake. Absorbed water leads to significant shrinkage in an unrestrained dragline fibre7,8 and reversibly converts the material into a rubber9. This process is known as supercontraction10 and may be a functional adaptation for the silk’s role in the spider’s web11. Supercontraction is thought to be controlled by specific motifs in the silk proteins12,13 and to be induced by the entropy-driven recoiling of molecular chains9,14. In analogy, in man-made fibres thermal shrinkage induces changes in mechanical properties15,16,17 attributable to the entropy-driven disorientation of ‘unfrozen’ molecular chains (as in polyethylene terephthalate)15,18 or the ‘broken’ intermolecular hydrogen bonds (as in nylons)17. Here we show for Nephila major-ampullate silk how in a biological fibre the spinning conditions affect the interplay between shrinkage and mechanical characteristics. This interaction reveals design principles linking the exceptional properties of silk to its molecular orientation.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Vollrath, F. & Knight, D. P. Liquid crystalline spinning of spider silk. Nature 410, 541–548 (2001).

Madsen, B., Shao, Z. & Vollrath, F. Variability in the mechanical properties of spider silks on three levels: interspecific, intraspecific and intraindividual. Int. J. Biol. Macromol. 24, 301–306 (1999).

Knight, D. P. & Vollrath, F. Liquid crystals and flow elongation in a spider’s silk production line. Proc. R. Soc. Lond. B 266, 519–523 (1999).

Knight, D. P., Knight, M. M. & Vollrath, F. Beta transition and stress-induced phase separation in the spinning of spider dragline silk. Int. J. Biol. Macromol. 27, 205–210 (2000).

Vollrath, F., Madsen, B. & Shao, Z. The effect of spinning conditions on the mechanics of a spider’s dragline silk. Proc. R. Soc. Lond. B 268, 2339–2346 (2001).

Liu, Y., Shao, Z. & Vollrath, F. Extended wet-spinning can modify spider silk properties. Chem. Commun. 19, 2489–2491 (2005).

Shao, Z. & Vollrath, F. The effect of solvents on the contraction and mechanical properties of spider silk. Polymer 40, 1799–1806 (1999).

Perez-Rigueiro, J., Elices, M. & Guinea, G. V. Controlled supercontraction tailors the tensile behaviour of spider silk. Polymer 44, 3733–3736 (2003).

Gosline, J. M., Denny, M. W. & Demont, M. E. Spider silk as rubber. Nature 309, 551–552 (1984).

Work, R. W. Dimensions, birefringences, and force-elongation behaviour of major and minor ampullate silk fibres from orb-web-spinning spiders-the effect of wetting on these properties. Text. Res. J. 47, 650–662 (1977).

Lewis, R. V. Spider silk: The unravelling of a mystery. Acc. Chem. Res. 25, 392–398 (1992).

Jelinski, L. W. et al. Orientation, structure, wet-spinning, and molecular basis for supercontraction of spider dragline silk. Int. J. Biol. Macromol. 24, 197–201 (1999).

Yang, Z. et al. Supercontraction and backbone dynamics in spider silk: C-13 and H-2 NMR studies. J. Am. Chem. Soc. 122, 9019–9025 (2000).

Shao, Z., Vollrath, F., Sirichaisit, J. & Young, R. J. Analysis of spider silk in native and supercontracted states using Raman spectroscopy. Polymer 40, 2493–2500 (1999).

Wilson, M. P. W. Shrinkage and chain folding in drawn poly(ethylene terephthalate) fibers. Polymer 15, 277–282 (1974).

Wu, G., Jiang, J. D., Tucker, P. A. & Cuculo, J. A. Oriented noncrystalline structure in PET fibers prepared with threadline modification process. J. Polym. Sci. B 34, 2035–2047 (1996).

Simal, A. L. & Martin, A. R. Structure of heat-treated Nylon 6 and 6.6 fibres. I. The shrinkage mechanism. J. Appl. Polym. Sci. 68, 441–452 (1998).

Keum, J. K. & Song, H. H. Thermal deformations of oriented noncrystalline poly (ethylene terephthalate) fibres in the presence of mesophase structure. Polymer 46, 939–945 (2005).

Riekel, C., Madsen, B., Knight, D. & Vollrath, F. X-ray diffraction on spider silk during controlled extrusion under a synchrotron radiation X-ray beam. Biomacromolecules 1, 622–626 (2000).

Eles, P. T. & Michal, C. A. A DECODER NMR study of backbone orientation in Nephila clavipes dragline silk under varying strain and draw rate. Biomacromolecules 5, 661–665 (2004).

Grubb, D. T. & Ji, G. D. Molecular chain orientation in supercontracted and re-extended spider silk. Int. J. Biol. Macromol. 24, 203–210 (1999).

Simmons, A. H., Michal, C. A. & Jelinski, L. W. Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk. Science 271, 84–87 (1996).

Beek, J. D. V., Hess, S., Vollrath, F. & Meier, B. H. The molecular structure of spider dragline silk: Folding and orientation of the protein backbone. Proc. Natl Acad. Sci. USA 99, 10266–10271 (2002).

Eles, P. T. & Michal, C. A. Strain dependent local phase transitions observed during controlled supercontraction reveal mechanisms in spider silk. Macromolecules 37, 1342–1345 (2004).

Fornes, R. E., Work, R. W. & Morosoff, N. Molecular-orientation of spider silks in the natural and supercontracted states. J. Polym. Sci. B 21, 1163–1172 (1983).

Grubb, D. T. & Jelinski, L. W. Fiber morphology of spider silk: the effects of tensile deformation. Macromolecules 30, 2860–2867 (1997).

Garrido, M. A., Elices, M., Viney, C. & Perez-Rigueiro, J. The variability and interdependence of spider drag line tensile properties. Polymer 43, 4495–4502 (2002).

Guinea, G. V., Elices, M., Real, J. I., Gutierrez, S. & Perez-Rigueiro, J. Reproducibility of the tensile properties of spider (Argiope trifasciata) silk obtained by forced silking. J. Exp. Zool. A 303, 37–44 (2005).

Termonia, Y. Molecular modelling of spider silk elasticity. Macromolecules 27, 7378–7381 (1994).

Shao, Z., Young, R. J. & Vollrath, F. The effect of solvents on spider silk studied by mechanical testing and single-fibre Raman spectroscopy. Int. J. Biol. Macromol. 24, 295–300 (1999).

Thiel, B. L. & Viney, C. A nonperiodic lattice model for crystals in Nephila clavipes major ampullate silk. Mater. Res. Soc. Bull. 20, 52–56 (1995).

Tsukada, M., Kato, H., Freddi, G., Kasai, N. & Ishikawa, H. Structural changes and dyeability of silk fibroin fibre following shrinkage in neutral salt solution. J. Appl. Polym. Sci. 51, 619–624 (1994).

Vollrath, F. Strength and structure of spiders’ silks. Rev. Mol. Biotechnol. 74, 67–83 (2000).

Oswald, H. J., Turi, E. A., Harget, P. J. & Khanna, Y. P. Development of a middle endotherm in DSC thermograms of thermally treated drawn pet yarns and its structural and mechanistic interpretation. J. Macromol. Sci.-Phys. B 13, 231–254 (1977).

Acknowledgements

For funding we thank the British EPSRC (grant GR/NO1538/01) as well as the European Commission (grant G5RD-CT-2002-00738), the National Natural Science Foundation of China (NSFC 20434010), the Science and Technology Development Foundation of Shanghai (grant 05JC14009) and the AFSOR of the United States of America (grant F49620-03-1-0111). We thank C. Holland and D. Porter for constructive criticism.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Liu, Y., Shao, Z. & Vollrath, F. Relationships between supercontraction and mechanical properties of spider silk. Nature Mater 4, 901–905 (2005). https://doi.org/10.1038/nmat1534

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat1534

This article is cited by

-

Production and secretion of recombinant spider silk in Bacillus megaterium

Microbial Cell Factories (2024)

-

Highly cross-linked carbon tube aerogels with enhanced elasticity and fatigue resistance

Nature Communications (2023)

-

Development of mechanically-consistent coarse-grained molecular dynamics model: case study of mechanics of spider silk

Scientific Reports (2023)

-

Protein fibers with self-recoverable mechanical properties via dynamic imine chemistry

Nature Communications (2023)

-

Water-responsive supercontractile polymer films for bioelectronic interfaces

Nature (2023)