Abstract

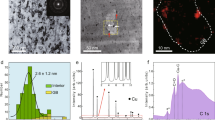

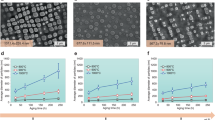

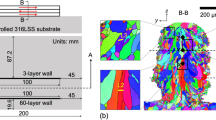

Oxide scale, which is essential to protect structural alloys from high-temperature degradation such as oxidation, carburization and metal dusting, is usually considered to consist simply of oxide phases. Here, we report on a nanobeam X-ray and magnetic force microscopy investigation that reveals that the oxide scale actually consists of a mixture of oxide materials and metal nanoparticles. The metal nanoparticles self-assemble into nanonetworks, forming continuous channels for carbon transport through the oxide scales. To avoid the formation of these metallic particles in the oxide scale, alloys must develop a scale without spinel phase. We have designed a novel alloy that has been tested in a high-carbon-activity environment. Our results show that the incubation time for carbon transport through the oxide scale of the new alloy is more than an order of magnitude longer compared with commercial alloys with similar chromium content.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ricker, R. E. Cost of corrosion. Science 252, 1232–1232 (1991).

Brindle, R. & Winkel, D. Energy impacts of corrosion, energy efficiency and renewable energy annual report and presentation (2005), <http://www1.eere.energy.gov/industry/imf/pdfs/7_corrosion.pdf>.

Zeng, Z. & Natesan, K. Relationship between the growth of carbon nanofilaments and metal dusting corrosion. Chem. Mater. 17, 3794–3801 (2005).

Young, D. J. Metal dusting reaction mechanisms. Mater. Sci. Forum. 522, 15–26 (2006).

Jakobi, D. & Gommans, R. Typical failures in pyrolysis coils for ethylene cracking. Mater. Corros. 54, 881–886 (2003).

Yamamoto, Y. et al. Creep-resistant, Al2O3-forming austenitic stainless steels. Science 316, 433–436 (2007).

Thurmer, K., Williams, E. & Reutt-Robey, J. Autocatalytic oxidation of lead crystallite surfaces. Science 297, 2033–2035 (2002).

Stierle, A. et al. X-ray diffraction study of the ultrathin Al2O3 layer on NiAl(110). Science 303, 1652–1656 (2004).

Wolf, I. & Grabke, H. J. A study on the solubility and distribution of carbon in oxides. Solid State Commun. 54, 5–10 (1985).

Hochman, R. F. in Proc. Symp. on Properties of High-Temperature Alloys with Emphasis on Environmental Effects (eds Foroulis, Z. A. & Pettit, F. S.) 715–732 (The Electrochemical Society, New Jersey, 1977).

Zeng, Z. & Natesan, K. Initiation of metal-dusting pits and a method to mitigate metal-dusting corrosion. Oxid. Met. 66, 1–20 (2006).

Baker, B. A., Hartmann, V. W., Shoemaker, L. E., McCoy, S. A. & Rajendran, S. A new nickel-base alloy for metal dusting resistance. Trans. Ind. Inst. Met. 56, 327–333 (2003).

Ackermann, H. et al. Metal dusting in low-NOx recirculation burners for fuel oil. Corros. Eng. Sci. Technol. 40, 233–238 (2005).

Korkhaus, J. Failure mechanisms and material degradation processes at high temperatures in ammonia synthesis. Corros. Eng. Sci. Technol. 40, 204–210 (2005).

Albertsen, J. Z., Grong, O., Mathiesen, R. H. & Schmid, B. Metallurgical investigation of metal dusting corrosion in plant-exposed nickel-based alloy 602CA. Corros. Eng. Sci. Technol. 40, 239–243 (2005).

Nishiyama, Y., Otsuka, N. & Kudo, T. Metal dusting behaviour of Cr–Ni steels and Ni-base alloys in a simulated syngas mixture. Corros. Sci. 48, 2064–2083 (2006).

Zhang, J., Cole, D. M. I. & Young, D. J. Alloying with copper to reduce metal dusting of nickel. Mater. Corros. 56, 756–764 (2005).

Szakalos, P., Pettersson, R. & Hertzman, S. An active corrosion mechanism for metal dusting on 304L stainless steel. Corros. Sci. 44, 2253–2270 (2002).

Schneider, A., Viefhaus, H., Inden, G., Grabke, H. J. & Mullerlorenz, E. M. Influence of H2S on metal dusting. Mater. Corros. 49, 336–339 (1998).

Di Gabriele, F., Stott, F. H. & Liu, Z. Effect of experimental conditions on the metal dusting phenomenon in several commercial nickel-base alloys. Mater. Corros. 58, 81–86 (2007).

Grabke, H. J. Mechanisms and prevention of corrosion in carbonaceous gases. Mater. Sci. Forum 369, 101–108 (2001).

Wagner, C. Theory of the tarnishing process. Z. Phys. Chem. B21, 25–41 (1933).

Maak, F. & Wagner, C. Mindestgehalte von Legierungsbestandteilen für die Bildung von Oxydschichten hoher Schutzwirkung gegen Oxydation bei höheren Temperaturen. Mater. Corros. 12, 273–277 (1961).

Bergner, D. Diffusion of C, N and O in metals, diffusion in metals and alloys. Proc. Int. Conf. 671, 223–240 (1983).

Quadakkers, W. J, Piron-Abellan, J., Shemet, V. & Singheiser, L. Metallic interconnectors for solid oxide fuel cells—a review. Mater. High Temp. 20, 115–127 (2003).

Renner, F. U. et al. Initial corrosion observed on the atomic scale. Nature 439, 707–710 (2006).

Schmutz, P. & Frankel, G. S. Corrosion study of AA2024-T3 by scanning Kelvin probe force microscopy and in situ atomic force microscopy scratching. J. Electrochem. Soc. 145, 2295–2306 (1998).

Buchanan, K. S., Zhu, X. B., Meldrum, A. & Freeman, M. R. Ultrafast dynamics of a ferromagnetic nanocomposite. Nano Lett. 5, 383–387 (2005).

Thayer, P. C. The Electrical Properties of Iron–Chromium Spinel, thesis for Degree of Doctor of Philosophy, Colorado State Univ., Fort Collins, Colorado (1972).

Natesan, K. & Zeng, Z. Argonne National Laboratory Report, ANL-07/30, 68–72, October, (2007).

Muller, F. & Kleppa, O. J. Thermodynamics of formation of chromite spinels. J. Inorg. Nucl. Chem. 35, 2673–2678 (1973).

Acknowledgements

We thank D. L. Rink for conducting the metal-dusting experiments, S. Cai for data analysis of the nanobeam XRD and J. Froitzheim for SEM analysis. This work is supported by the US Department of Energy, Office of Industrial Technologies. Use of the Advanced Photon Source, the Center for Nanoscale Materials and the Electron Microscopy Center for Materials Research were supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357.

Author information

Authors and Affiliations

Contributions

Z.Z. and K.N. planned the experiments and analysed the data, Z.C. carried out the APS nanobeam experiment and S.B.D. carried out MFM measurements and contributed to data analysis and interpretation.

Corresponding author

Rights and permissions

About this article

Cite this article

Zeng, Z., Natesan, K., Cai, Z. et al. The role of metal nanoparticles and nanonetworks in alloy degradation. Nature Mater 7, 641–646 (2008). https://doi.org/10.1038/nmat2227

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat2227

This article is cited by

-

Oxide scale microstructure and failure mechanism of alloy 601 under varying metal dusting conditions

Journal of Materials Science (2024)

-

An Expanded Model for the Pressure Effect in Metal Dusting of Mn-Containing Alloy 600 Based on Advanced Scale Characterization

High Temperature Corrosion of Materials (2023)

-

Effect of nano-grain carbide formation on electrochemical behavior of 316L stainless steel

Scientific Reports (2021)

-

Effect of nanograin–boundary networks generation on corrosion of carburized martensitic stainless steel

Scientific Reports (2018)

-

Corrosion Performance of Fe-Based Alloys in Simulated Oxy-Fuel Environment

Metallurgical and Materials Transactions B (2017)