Abstract

In the pursuit of magnesium (Mg) alloys with targeted mechanical properties, a multi-objective Bayesian optimisation workflow is presented to enable optimal Mg-alloy design. A probabilistic Gaussian process regressor model was trained through an active learning loop, while balancing the exploration and exploitation trade-off via an acquisition function of the upper confidence bound. New candidate alloys suggested by the optimiser within each iteration were appended to the training data, and the performance of this sequential strategy was validated via a regret analysis. Using the proposed approach, the dependency of the prediction error on the training data was overcome by considering both the predictions and their associated uncertainties. The method developed here, has been packaged into a web tool with a graphical user-interactive interface (GUI) that allows the proposed optimal Mg-alloy design strategy to be deployed.

Similar content being viewed by others

Introduction

Magnesium (Mg) alloys continue to garner attention due to their potential for enhancing energy efficiency in numerous applications1. The strength-to-weight ratio of Mg alloys makes them appealing for use in weight-sensitive applications such as the aerospace, automotive and electronic (3C) industries2,3,4. Despite such potential, the more extensive application of Mg alloys remains—in part—constrained by their balance of mechanical properties, including the attainment of strength with appropriate ductility1. Whilst researchers continue to address such issues by alloying and manufacturing processes1,2; the potentially (very) wide range of possible alloy compositions and processing parameters presents an empirical challenge in achieving the optimal design for specific applications.

One promising approach for expediting the discovery of metallic alloys with target mechanical properties is by using machine learning5,6,7,8. Machine learning (ML) accelerates new materials discovery by reducing the time and cost required for traditional trial-and-error approaches6,9,10, and utilising large datasets, advanced algorithms, and computational methods. This enables the acceleration of optimal alloy identification. In particular, so-called active machine learning approaches, which combine human expertise with iterative model refinement, have demonstrated great potential in reducing the experimental burden and maximising the search efficiency in materials design11,12,13,14. Bayesian optimisation and adaptive design are methods following an active ML strategy, which require goal-directed iterative feedback6,15,16.

Bayesian optimisation is an ML-based method for optimising computationally ‘expensive’ black-box functions; where the objective function is not explicitly known and must be evaluated through time-consuming processes such as experiments or simulations17. To date, Bayesian optimisation has been successful in a wide range of applications, including drug discovery, robotics, and materials science18,19,20,21,22,23,24,25. In the context of Mg alloys, for the first time, Bayesian optimisation is considered to identify the composition and processing conditions that lead to desired mechanical properties, such as strength and ductility. Bayesian optimisation can optimise multiple properties simultaneously, which is particularly useful in the design of metallic alloys, where different applications can have conflicting requirements. Specifically, in the case of Mg-alloys where increasing strength can often lead to a reduction in ductility, Bayesian optimisation can help identify the optimal trade-off between conflicting properties. The use of ML-based Bayesian optimisation in the design of metallic alloys remains a relatively new field with many challenges and opportunities for future research, despite Bayesian optimisation having been utilised quite heavily in other domains over the past decade. One challenge is the need for high-quality data, especially when experiments and simulations are expensive or time-consuming. Another challenge is the need for accurate models that can, in the context of alloys, capture complex relationships between composition, structure, processing conditions, and resultant mechanical properties.

The work herein proposes an active machine-learning approach for the optimal design of Mg alloys, utilising Bayesian optimisation. Whilst the approach employed in the present work is elaborated upon in the accompanying methods section, Bayesian optimisation is particularly relevant because the method employs probabilistic models to guide the search for a ‘best solution’ in a noisy parameter space of high dimensionality. By iteratively selecting the most informative experiments, Bayesian optimisation facilitates the exploration and exploitation of the Mg alloys design space, sampling more efficiently, and potentially leading to the discovery of promising alloy compositions with enhanced mechanical properties26. The objective of the present study is to develop an active learning framework that combines Bayesian optimisation with a comprehensive dataset of Mg alloys. The details of the data collection for Mg alloys have been provided in the previous work of the authors9. The framework leverages available data, expert knowledge, and accurate random forest (RF) models that have been trained with that Mg alloys data10. The proposed approach can enhance the efficiency of materials design by iteratively improving the model's predictive capabilities while simultaneously optimising the alloy's mechanical properties. Relying on the performance of those accurate and robust RF models within the proposed active learning loop can reduce the need for the expensive and time-consuming experiments.

Furthermore, the present study provides insights into the underlying relationships between alloy composition, processing parameters, and properties. By illuminating these complex interactions, the proposed active ML approach can accelerate the design of Mg alloys. Some fundamental concepts of ML and the principles of Bayesian optimisation are first introduced. Thereafter, the specific application of ML and Bayesian optimisation in the design of Mg alloys, including the prediction of mechanical properties, is elaborated upon. Critically, what is believed to be the first ‘user tool’ for digitally optimised Mg-alloy design is presented. The challenges and potential opportunities for future research in this field are also discussed.

Methods

Dataset

The alloy dataset utilised in this study includes three key categories, namely: thermomechanical processing conditions; chemical composition; and mechanical properties. The production routes and processing treatments for the alloys are comprised of a range of casting or thermomechanical processes (including heat treatments). To classify the alloys in a rational manner, these different production routes were encoded into one of six mutually exclusive categories by human experts. Furthermore, using the one-hot encoding method, the categorical processing data was encoded onto vectors of zeros and ones. The categories of processing designation that capture the alloys in the database are summarised in Table 1.

It is conceded that the shortform designations in Table 1 have truncated the many subvariants of processing which may have been carried out. This is a deliberate trade-off between having a rational number of processing conditions, and each processing condition being unique enough to disambiguate from alloys falling into two processing categories. The 916 unique Mg alloys in the original dataset incorporate at least one or more of 30 alloying elements. The elements in the alloy compositions including Mg, along with their range (wt%), mean, and standard deviation are summarised in Table 2.

The mechanical properties of alloys in the dataset have been restricted to the yield strength (YS), ultimate tensile strength (UTS), and elongation / ductility along with their lower and upper bounds, mean, and standard deviation are provided in Table 3.

The compiled and formatted database is publicly accessible through the following link: https://github.com/katrina-coder/Magnesium-alloys-database9.

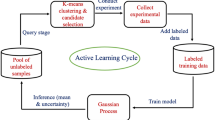

Bayesian optimisation

Bayesian optimisation is an ML-based technique that may be applied to solve an optimisation problem in which the objective function is continuous, expensive to evaluate, derivative-free and ‘black-box’27,28,29. In alloy design and discovery, iterative trial and error experiments make evaluating the alloy properties costly and time-consuming. The composition-process-property relationship of an alloy (or alloys) as a continuous objective function is unknown and often non-convex, non-linear, and high dimensional (and may be considered a black-box problem). In addition, the target property (f(x)) is being observed without its derivatives30,31. As a result, to discover new Mg alloys, a Bayesian optimiser was developed that consists of two main components. The first component was a surrogate function (probabilistic model) that estimates the mechanical property. In this case, a gaussian process regressor model (GPR) computed a posterior probability distribution based on Bayes’ rule32,33. The distribution included the function estimate and associated uncertainty around the estimation34,35,36. The second component of the optimiser was an acquisition function to specify the next candidate sample and evaluate its target property based on what was known (so far) from the posterior distribution. An acquisition function made this decision by balancing the exploration of the uncertain regions and exploitation of the regions with known higher target values24,37.

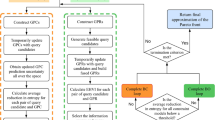

The probabilistic model was updated as new datapoints were acquired, and the acquisition function used the current state of the model to determine the next point to evaluate. The goal was to find an optimum of the function with the minimum number of evaluations. The suggested new alloy was added to the training data and the processes of modelling and querying the next sample were repeated. The optimiser learned dynamically (active learning) in that sense, and the optimal composition was expected to be found within a certain number of iterations (Fig. 1).

Schematic workflow of active learning over three iterations (iterations number 2–4). The dashed black lines show the objective function, and the solid black lines show the posterior mean of the Gaussian process (GP) approximation. The purple regions indicate the posterior uncertainty of the GP surrogate model’s prediction. The green areas represent the acquisition (utility) functions that balance the exploitation and exploration within the search space. Note that the acquisition function value is high where the prediction of the objective function by GP is high (exploitation) and where the prediction uncertainty is high (exploration) — areas with both attributes are sampled first24.

Regret analysis

Regret analysis is used to quantify the performance of an optimisation algorithm. It measures the difference between the value of the objective function at the ideal optimal point and the value of the objective function at the point obtained by the algorithm. The regret is usually expressed as a function of the number of evaluations or the computation time. Regret analysis is useful for comparing different optimisation algorithms and for determining the asymptotic behaviour of the algorithms. It provides a measure of the trade-off between exploration and exploitation in the optimisation process. In Bayesian optimisation, regret analysis is used to quantify the performance of the algorithm, and to determine the optimal number of function evaluations required to achieve a certain level of performance.

To validate the performance of the developed sequential optimiser for our Mg-alloy dataset, a regret analysis was implemented as defined in Eq. 1.

where \(f(x)\) was known from the value of the target property at the datapoint \(x\) which was suggested by the optimiser as the next candidate. While \(f{(x}^{*})\) was the optimal value of the target property at the datapoint \({x}^{*}\) that was expected to be found by the optimiser within the entire alloy data (\(x\in X\)) as defined in Eq. 2.

First, the gaussian model was trained with a random set of 20 initial datapoints and the next candidates were extracted from the remaining data through 100 iterations. Then, using the known maximum value of the target property within the entire dataset from Eq. 2, the regret value was calculated for each iteration. In can be summarised as defining the ideal value of the target properties \({f\left(x\right)}^{*}\) and regret value within each iteration as follows in Eqs. 3 and 4.

This regret value showed the difference between the real maximum target property value and the maximum target property value determined by the optimiser from the generated samples38.

Multi-objective Bayesian optimisation

Method evaluation based on “simulated results”

The validated Bayesian optimiser was used to simultaneously maximise the multiple mechanical properties of Mg alloys. To do this, a multi-objective optimisation problem was defined as follows:

where \({f}_{i}\left(x\right)\) represents the i-th objective function evaluated at input variables via successive queries of \(x\in X\)39,40,41.

First, a gaussian probabilistic model (GP) was trained as the surrogate function with the target properties of strength and ductility from Mg-alloy data. This can be expressed as follows:

where µ(x) is the mean and k(x,x') is the covariance that were computed based on the kernel function definition42,43,44,45.

Then, new alloys were "discovered" using an acquisition function based on the posterior distribution within iterations. In other words, at iteration t + 1, using the target property value of the previous sample of \({x}_{t}\), the posterior distribution was computed by Bayesian inference. Thus, to direct the so-called dynamic learning process, specifying the strength and ductility of the "discovered" alloy at each iteration is necessary, followed by updating the training set, re-fitting the model, and querying the next point. To obtain the actual target property values, lengthy and costly alloy-making and mechanical testing are usually required. As an alternative, the mechanical properties estimated by the RF model replaced the actual values. This method is referred to as evaluation based on simulated results.

Two different acquisition functions, namely upper confidence bound (UCB) and mutual information (MI), were evaluated to suggest new alloys. In UCB, the acquisition function (utility) is defined as:

where μ(x) is the exploitation term and σ(x) is the exploration term. K is the constant hyperparameter that controls the trade-off between exploration and exploitation46,47. The exploitation term estimates the expected reward at a given point based on the current model's predictions, and the exploration term quantifies the uncertainty or lack of knowledge about the true reward at that point. The exploration term encourages the algorithm to explore regions of the search space with high uncertainty, which may contain better solutions, while the exploitation term guides it towards regions with high predicted rewards based on existing knowledge.

While the UCB is a common choice for managing this trade-off, an alternative approach using MI has emerged as a promising technique. Mutual Information is a measure of the dependence between two random variables and has gained attention in the context of Bayesian optimisation as an acquisition function for managing the exploration–exploitation trade-off. MI-based acquisition functions estimate the information gained by acquiring new data at a particular point in the search space. By maximizing the MI, the algorithm aims to explore regions that provide the most valuable information for reducing the uncertainty about the location of the global optimum. In the defined MI, the term that controls the exploration was updated over the iterations by information gained about f(x) by the query point xt as follows48,49:

in which, similar to Eq. 7, μ(x) was responsible for the exploitation ability of the function but the exploration term was controlled by Ø(x).

which is an increasing function of σ2(x) and empirically controlled by the amount of exploration that has already been done. The more the algorithm has gathered information on f, the more it focuses on the optimum48,50. The variable α is a constant hyperparameter and \(\widehat{\gamma }\) is defined as follows:

In both methods, the kernel function of the gaussian model was tuned and the "rat_quad" kernel was selected as the optimum kernel. The hyperparameters kappa and alpha were also tuned with 0.05 and 0.01, respectively.

Batch optimisation

Herein the goal was to find a batch of alloys in a single iteration without updating the model by estimated predictions or actual values of mechanical properties51. In sequential learning, predictions at each iteration were used due to limitations in assessing the actual values of UTS and ductility.

A penalised acquisition function was defined to collect a number of new compositions around the local maximum area of the function by excluding the previous local maximum. A schematic outline of this method for a batch size of 4 is shown in Fig. 2. The purple area shows the probability distribution estimated by the Gaussian regressor model. The first optimum point (red star) is discovered based on maximising the acquisition function (green area) in the first iteration. To obtain the second member of the batch points, the acquisition function is penalised in the second plot at the point around the previous optimum point (previous star, 0.6 < x < 1.5). This process is repeated in the third and fourth plots to discover the next two optimum points.

Schematic outline of batch optimisation with a batch size of 4. The figure illustrates the iterative process of selecting optimum points (indicated by red stars) based on the maximisation of the penalised acquisition function, shown as the light green area. The batch optimisation enabled simultaneous evaluation and selection of points in each iteration, achieved by penalising the acquisition function around the previous iteration's red star.

Results and discussion

Regret analysis

Figures 3 and 4 depict the mean (solid black line) and standard deviation (shaded purple area) of regret values over 10 repetitions of searches for the ultimate strength and ductility of Mg alloys, respectively. The results demonstrate that our optimiser successfully identifies the optimal composition for maximised UTS after 42 iterations (Fig. 3) and for maximised ductility after 59 iterations (Fig. 4), at which points that the regret values reach zero. In alignment with the goal of the regret analysis, the optimum is achieved when the regret value is zero, indicating that the optimiser has identified the points with the maximum target properties. The dashed green line represents the mean of the maximum target property across the 20 random initial datapoints, averaged over 10 repetitions. Since the optimiser started to learn from only 20 initial training datapoints, it can be claimed that its performance is efficient enough in real searches where training uses the whole dataset.

Calculated regret values for UTS optimisation of Mg alloys over 100 iterations by the Bayesian optimiser. The black line and purple area show the average and the standard deviation of regret values respectively, over 10 search trials. The dashed green line represents the mean of the maximum UTS across the 20 random initial datapoints, averaged over 10 repetitions.

Calculated regret values for ductility optimisation of Mg alloys over 100 iterations by the Bayesian optimiser. The black line and purple area show the average and the standard deviation of regret values respectively, over 10 search trials. The dashed green line represents the mean of the maximum ductility across the 20 random initial datapoints, averaged over 10 repetitions.

The performance of the trained Gaussian regressor models with the whole dataset along with the associated uncertainties are shown in Figs. S1 and S2 for the prediction of UTS and ductility. Both parity plots (actual value in the X-axis and Gaussian probabilistic model predicted value in the Y-axis) show that the model is efficient enough as a surrogate function within the Bayesian optimiser.

Multi-objective Bayesian optimisation based on “simulated results”

By iteratively selecting the point that maximises the acquisition function, the UCB or MI algorithms gradually balance exploration and exploitation, resulting in an efficient search process. Initially, the algorithms explore different regions of the search space, allowing the probabilistic model to learn and update its predictions based on the observed data. As the algorithms gather more information, the exploitation term becomes dominant, leading to a focus on promising regions and converging towards the global optimum. Predicted UTS and ductility of proposed alloys (orange dots) are shown in Figs. 5 and 6 for the UCB and MI methods respectively. Blue points show the values of mechanical properties for the existing Mg alloys.

Exploration–exploitation trade-off

Within the search for the global optimum, the optimiser balances the exploration of promising regions and the exploitation of known optimal regions. Upper confidence bound is one of the popular strategies employed to manage this exploration–exploitation trade-off. As defined in Eq. (7), the kappa coefficient controls this trade-off that refers to the delicate balance between exploring new regions of the search space to discover potentially better solutions and exploiting the information gained from previous observations to focus on promising areas. In the context of Bayesian optimisation, this trade-off is crucial as it enables efficient exploration of the search space while converging to the optimal solution. The UCB algorithm has demonstrated remarkable performance in various optimisation tasks, including hyperparameter tuning, experimental design, and materials discovery. Its ability to effectively manage the exploration–exploitation trade-off makes it a popular choice for Bayesian optimisation applications. However, the appropriate tuning of the exploration parameter is crucial to strike the right balance, as overly aggressive exploration can lead to excessive sampling in unproductive regions, while overly conservative exploration can result in premature convergence to suboptimal solutions. The optimiser’s suggestions with various kappa values in the UCB method are shown in Fig. 7. New families of Mg alloys suggested by the optimiser are Mg–Ca–Gd–Ga, Mg–Al–Gd–Ga, Mg–Gd–Ga, Mg–Y–Gd–Ni–Ga, Mg–Gd–Li–Ni–Ga, and Mg–Gd–Yb–Ni–Ga (with their chemical composition (wt%) and production route provided in Table S1). It is noted that in this work, to keep the focus on technical facets, the cost of elements addition in each iteration is not included in optimisation (which can be highly variable and a challenge to quantify in a manner that is consistent over a period of years).

The effect of the hyperparameter kappa in the trade-off between exploration and exploitation in the process of proposing new Mg alloys by Bayesian optimisation. Orange dots are the new suggestions via the optimisation, and blue dots are the original dataset of existing alloys. Maximising the mechanical properties of UTS and ductility as a multi-objective optimisation problem is defined in the UCB acquisition function.

MI-based acquisition functions typically leverage the predictive distribution obtained from a surrogate model, here a Gaussian process, to estimate the MI. This distribution captures the uncertainty in the model's predictions, allowing the acquisition function to balance exploration and exploitation effectively. High uncertainty regions, where the model lacks confidence, were explored to gain information about potentially better solutions, while regions with low uncertainty, where the model is confident about high rewards, were exploited to refine the search around promising solutions. Compared to the UCB algorithm, MI-based acquisition functions offer several advantages. MI can capture more complex relationships between input variables and the objective function, making it particularly useful in high-dimensional and non-linear optimisation problems. Additionally, MI-based acquisition functions tend to exhibit smoother acquisition landscapes, leading to improved convergence and reduced sensitivity to the exploration parameter. The optimiser’s suggestions with various alpha values in the MI method are shown in Fig. 8. New families of Mg alloys suggested by the optimiser are Mg–Gd–Ni–Ga, Mg–Zn–Gd–Ga, Mg–Gd–Ga, Mg–Gd–Yb–Ga, and Mg–Gd–Li–Ga (with their chemical composition (wt%) and production route provided in Table S1).

The effect of the hyperparameter alpha in the trade-off between exploration and exploitation in proposing new Mg alloys by Bayesian optimisation. Orange dots are the new suggestions by the optimisation and blue dots are the original dataset of existing alloys. Maximising mechanical properties of UTS and ductility as a multi-objective optimisation problem is defined in the MI acquisition function.

Multi-objective batch Bayesian optimisation

The outcomes of the batch method implemented in a single, are presented in Fig. 9. The optimiser was trained using the existing Mg-alloy data, employing a batch size of 5 over 10 repetitions of searches. Proposed new compositions as a batch of alloys allow us to pick several samples in a single run. To validate the results and repeat the search, the batch of alloys can be fabricated and tested in parallel. Actual mechanical properties of samples can be added to the original training data. New families of Mg alloys suggested by the batch optimiser are Mg–Ca–Nd–Ga, Mg–Gd–Ga, Mg–Gd–Yb–Sb–Ga, Mg–Gd–Li–Ni–Ga, Mg–Gd–Li–Mn–Ga, Mg–Gd–Si–Ga, Mg–Y–Zn–Nd–Sr–Ga, and Mg–Gd–Er–Pr–Ga (with their chemical composition (wt%) and production route provided in Table S1).

Data availability for digital alloy design

A graphical user interface (GUI) was designed that connects to the above-mentioned optimisers, with a user interactive tool and display for the proposed alloys. Users may interact with the alloy design tool via the web-based GUI and enter their desired range of compositions to be explored, along with the exploration of any potential thermomechanical processing. An image of the GUI menu is shown in Fig. S3. In the left column, the lower and upper bounds in weight percentage (wt%) of the chemical composition in terms of various elements can be defined. Preferred thermomechanical processes can be selected from the upper right section called “Heat Treatment”. Sampling size, number of suggested alloy “discoveries” to display, the maximum number of alloying elements in each alloy, the maximum sum of the alloying elements to be explored (in wt%), and the mechanical properties that the user is interested to optimise, make up the main parameters of the “Bayesian Optimisation Setting” section. After running the optimiser, the results (presented as a composition and accompanying thermomechanical treatment) will be shown.

The GitHub code associated with the present study, has been linked with this Google Collaboratory notebook to develop a user-interactive web tool that is publicly accessible through the following hyperlink: https://colab.research.google.com/drive/1wR0bQnxdAVUurH879dQNZ5wVzc0jGeD1#scrollTo=B5qe8hjnEyxe.

Conclusions

The present study has provided the background, context, and tool development for digital alloy design and optimisation for Mg alloys. Specifically, optimisation is focused on the attainment of desirable mechanical properties including ultimate tensile strength and ductility. The Bayesian optimiser considers the data distribution via a probabilistic model that includes the function estimate and associated uncertainty around the estimation. New families of Mg alloys with maximised ultimate tensile strength (420–490 MPa) and ductility (12–30%) are capable of being generated en masse—based on a user interactive tool. In addition, the following conclusions may be drawn:

-

1.

Active learning within the prescriptive analysis is less dependent on the quality and volume of training data, compared with predictive analysis.

-

2.

The acquisition function can balance the exploration and exploitation, resulting in an efficient search process and optimal design.

-

3.

Regret analysis provided an estimate of the performance of the optimiser and a means to validate optimised suggestions.

-

4.

Bayesian optimisation was determined to be capable of optimising multiple properties simultaneously. The present study applies Bayesian optimisation to maximise either the Mg-alloy ductility, or ultimate tensile strength, or both the ductility and ultimate tensile strength simultaneously

-

5.

The process of batch optimisation provided a number of optimised Mg-alloy suggestions (for target properties) in a single application of the model available as a public open access web tool.

Data and Code availability

The codes developed in this study are openly available at the following site: https://colab.research.google.com/drive/1wR0bQnxdAVUurH879dQNZ5wVzc0jGeD1#scrollTo=B5qe8hjnEyxe. The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Trang, T. et al. Designing a magnesium alloy with high strength and high formability. Nat. Commun. 9(1), 2522 (2018).

Xu, T., Yang, Y., Peng, X., Song, J. & Pan, F. Overview of advancement and development trend on magnesium alloy. J. Magnes. Alloys 7(3), 536–544 (2019).

Zhang, J., Liu, S., Wu, R., Hou, L. & Zhang, M. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg–Gd and Mg–Y systems. J. Magnes. Alloys 6(3), 277–291 (2018).

Nie, J. F., Shin, K. S. & Zeng, Z. R. Microstructure, deformation, and property of wrought magnesium alloys. Metall. Mater. Trans. A 52, 6045 (2020).

Wei, J. et al. Machine learning in materials science. InfoMat 1(3), 338–358 (2019).

Tian, Y., Lookman, T. & Xue, D. Efficient sampling for decision making in materials discovery. Chin. Phys. B 30(5), 050705 (2021).

Juan, Y., Dai, Y., Yang, Y. & Zhang, J. Accelerating materials discovery using machine learning. J. Mater. Sci. Technol. 79, 178–190 (2021).

Zuo, Y. et al. Accelerating materials discovery with Bayesian optimization and graph deep learning. Mater. Today 51, 126–135 (2021).

Ghorbani, M., Boley, M., Nakashima, P. & Birbilis, N. A machine learning approach for accelerated design of magnesium alloys. Part A: Alloy data and property space. J. Magnes. Alloys 11(10), 3620–3633 (2023).

Ghorbani, M., Boley, M., Nakashima, P. & Birbilis, N. A machine learning approach for accelerated design of magnesium alloys. Part B: Regression and property prediction. J. Magnes. Alloys 11(11), 4197–4205 (2023).

Mosqueira-Rey, E., Hernández-Pereira, E., Alonso-Ríos, D., Bobes-Bascarán, J. & Fernández-Leal, Á. Human-in-the-loop machine learning: A state of the art. Artif. Intell. Rev. 56(4), 3005–3054 (2023).

Kulik, H. et al. Roadmap on machine learning in electronic structure. Electron. Struct. 4(2), 023004 (2022).

Kusne, A. G. et al. On-the-fly closed-loop materials discovery via Bayesian active learning. Nat. Commun. 11(1), 5966 (2020).

Lookman, T., Balachandran, P. V., Xue, D. & Yuan, R. Active learning in materials science with emphasis on adaptive sampling using uncertainties for targeted design. npj Comput. Mater. 5(1), 21 (2019).

Schmidt, J., Marques, M. R. G., Botti, S. & Marques, M. A. L. Recent advances and applications of machine learning in solid-state materials science. npj Comput. Mater. 5(1), 83 (2019).

Shi, B. et al. Estimating the performance of a material in its service space via Bayesian active learning: A case study of the damping capacity of Mg alloys. J. Mater. Inf. 2, 8 (2022).

Pilania, G. Machine learning in materials science: From explainable predictions to autonomous design. Comput. Mater. Sci. 193, 110360 (2021).

Korb, K. B. & Nicholson, A. E. Bayesian Artificial Intelligence (CRC Press, 2010).

Imani, M., & Ghoreishi, S.F. Bayesian optimization objective-based experimental design. In 2020 American Control Conference (ACC). 2020. IEEE.

Terayama, K., Sumita, M., Tamura, R. & Tsuda, K. Black-box optimization for automated discovery. Acc. Chem. Res. 54(6), 1334–1346 (2021).

Pyzer-Knapp, E. O. Bayesian optimization for accelerated drug discovery. IBM J. Res. Dev. 62(6), 2:1-2:7 (2018).

Lei, B. et al. Bayesian optimization with adaptive surrogate models for automated experimental design. npj Comput. Mater. 7(1), 194 (2021).

Pyzer-Knapp, E. O. et al. Accelerating materials discovery using artificial intelligence, high performance computing and robotics. npj Comput. Mater. 8(1), 84 (2022).

Brochu, E., Cora, V.M., & De Freitas, N., A tutorial on Bayesian optimization of expensive cost functions, with application to active user modeling and hierarchical reinforcement learning. http://arxiv.org/abs/arXiv:1012.2599 (2010).

Wu, C. J. & Hamada, M. S. Experiments: Planning, Analysis, and Optimization (Wiley, 2011).

Xue, D. et al. Accelerated search for materials with targeted properties by adaptive design. Nat. Commun. 7(1), 11241 (2016).

Frazier, P.I., A tutorial on Bayesian optimization. http://arxiv.org/abs/arXiv:1807.02811 (2018).

Hart, G. L., Mueller, T., Toher, C. & Curtarolo, S. Machine learning for alloys. Nat. Rev. Mater. 6(8), 730–755 (2021).

Yu, J. et al. Machine learning-guided design and development of metallic structural materials. J. Mater. Info https://doi.org/10.20517/jmi.2021.08 (2021).

Frazier, P. I. & Wang, J. Bayesian optimization for materials design. In Information Science for Materials Discovery and Design (eds Lookman, T. et al.) 45–75 (Springer, 2016).

Zhang, Y., Apley, D. W. & Chen, W. Bayesian optimization for materials design with mixed quantitative and qualitative variables. Sci. Rep. 10(1), 1–13 (2020).

Rasmussen, C. E. Gaussian processes in machine learning. In Summer School on Machine Learning (eds Bousquet, O. et al.) (Springer, 2003).

Martín, L.A. & Garrido-Merchán, E.C., Many Objective Bayesian Optimization. http://arxiv.org/abs/arXiv:2107.04126 (2021).

Schulz, E., Speekenbrink, M. & Krause, A. A tutorial on Gaussian process regression: Modelling, exploring, and exploiting functions. J. Math. Psychol. 85, 1–16 (2018).

Rasmussen, C.E. & Williams, C.K., Gaussian processes for machine learning. ISBN 026218253x. (2006), The MIT Press, Massachusetts Institute of Technology.

Solomou, A. et al. Multi-objective Bayesian materials discovery: Application on the discovery of precipitation strengthened NiTi shape memory alloys through micromechanical modeling. Mater. Des. 160, 810–827 (2018).

Williams, C. K. & Rasmussen, C. E. Gaussian Processes for Machine Learning Vol. 2 (MIT Press, 2006).

Kandasamy, K., Schneider, J., & Póczos, B. High dimensional Bayesian optimisation and bandits via additive models. In International Conference on Machine Learning (2015). PMLR

Galuzio, P. P., de Vasconcelos Segundo, E. H., dos Santos Coelho, L. & Mariani, V. C. MOBOpt—Multi-objective Bayesian optimization. SoftwareX 12, 100520 (2020).

Daulton, S., Eriksson, D., Balandat, M., & Bakshy, E. Multi-objective bayesian optimization over high-dimensional search spaces. In Uncertainty in Artificial Intelligence. (2022). PMLR.

Wada, T. and Hino, H., Bayesian optimization for multi-objective optimization and multi-point search. http://arxiv.org/abs/arXiv:1905.02370 (2019).

Park, S., Na, J., Kim, M. & Lee, J. M. Multi-objective Bayesian optimization of chemical reactor design using computational fluid dynamics. Comput. Chem. Eng. 119, 25–37 (2018).

Khan, N., Goldberg, D.E., & Pelikan, M. Multi-objective Bayesian optimization algorithm. In Proceedings of the 4th Annual Conference on Genetic and Evolutionary Computation (2002).

Shu, L., Jiang, P., Shao, X. & Wang, Y. A new multi-objective Bayesian optimization formulation with the acquisition function for convergence and diversity. J. Mech. Des. 142(9), 091703 (2020).

Swersky, K., Snoek, J., & Adams, R.P., Multi-task Bayesian optimization. Adv. Neural Inf. Process. Syst. 26 (2013).

Oliveira, R., Ott, L., & Ramos, F., Bayesian optimisation under uncertain inputs. In Proceedings of the Twenty-Second International Conference on Artificial Intelligence and Statistics, (eds Kamalika, C., & Masashi, S.) 1177--1184. PMLR: Proceedings of Machine Learning Research (2019).

Berk, J., Gupta, S., Rana, S., & Venkatesh, S., Randomised gaussian process upper confidence bound for bayesian optimisation. http://arxiv.org/abs/arXiv:2006.04296 (2020).

Contal, E., Perchet, V., & Vayatis, N. Gaussian process optimization with mutual information. In International Conference on Machine Learning. PMLR (2014).

Thomas, M. & Joy, A. T. Elements of Information Theory (Wiley-Interscience, 2006).

Suzuki, S., Takeno, S., Tamura, T., Shitara, K., & Karasuyama, M. Multi-objective Bayesian optimization using pareto-frontier entropy. In International Conference on Machine Learning. PMLR (2020).

González, J., Dai, Z., Hennig, P., & Lawrence, N. Batch Bayesian optimization via local penalization. In Artificial Intelligence and Statistics. PMLR (2016).

Acknowledgements

We acknowledge the support of a Monash-IITB Academy Scholarship. We also thank the Australian Research Council for support via DP190103592.

Author information

Authors and Affiliations

Contributions

MG performed the coding and development of the models. NB, MG, MB and PNHN contributed in the study design and preparation of the manuscript. NB supervised the study.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghorbani, M., Boley, M., Nakashima, P.N.H. et al. An active machine learning approach for optimal design of magnesium alloys using Bayesian optimisation. Sci Rep 14, 8299 (2024). https://doi.org/10.1038/s41598-024-59100-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-59100-9

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.