Abstract

The purpose of this work was to study the ability of nineteen food-grade microorganisms as Pickering emulsion (PE) stabilizers. Medium-chain triacylglycerol (MCT) oil-in-water (50:50) PEs were fabricated by 10 wt% or 15 wt% of thermally-inactivated yeast, cocci, Bacillus spp. and lactobacilli cells. The characteristics of microorganisms related to “Pickering stabilization” including morphology, surface charge, interfacial tension, and “contact angle” were firstly studied. After that, the cells-stabilized PEs were characterized from both kinetic and thermodynamic viewpoints, microstructure and rheological properties. The interfacial tension and “contact angle” values of various microorganisms ranged from 16.33 to 38.31 mN/m, and from 15° to 106°, respectively. The mean droplet size of PEs ranged from 11.51 to 57.69 µm. Generally, the physical stability of cell-stabilized PEs followed this order: lactobacilli > Bacillus spp. > cocci > yeast. These variations were attributed to the morphology and cell wall composition. Increasing the microorganism concentration significantly increased the physical stability of PEs from a maximum of 12 days at 10 wt% to 35 days at 15 wt% as a result of better interface coverage. Shear-thinning and dominant elastic behaviors were observed in PEs. Physical stability was affected by the free energy of detachment. Therefore, food-grade microorganisms are suggested for stabilizing PEs.

Similar content being viewed by others

Introduction

Pickering emulsions (PEs) are a type of emulsions which are stabilized by the accumulation of insoluble solid particles at the interface1. The advantages of PEs over surfactant-stabilized emulsions include higher stability against coalescence and disproportionation, better taste characteristics, and the irreversible adsorption of solid particles to the interface2,3. The high physical stability of PEs against coalescence is rooted in strong anchoring energy, specific inter-particle interactions, and formation of densely packed particle layers at the interfaces4. The adsorption and desorption energy of particles at the interface is of the order of kBT (which is known as the thermal energy of Brownian motion)5 (Eq. 1)

where, E is the thermal energy (J); kB is the Boltzmann constant (J/K) and T is the absolute temperature (K). A dynamic balance of adsorption and desorption from the interface is observed for the surfactant molecules, however, for solid particles, the attachment at the interface is irreversible when the free energy of detachment (ΔGd) is much greater than kBT5. The adsorption might be a reversible process whenever ΔGd is lower than 10 × kBT6. For most PEs stabilized by particles with appropriate “contact angles” (θow) (i.e., not too close to 0° or 180°), ΔGd is several thousands of thermal energy and thus the attachment is almost irreversible5.

Many types of food-grade and non-food-grade particles are utilized as Pickering stabilizers. Among food-grade Pickering stabilizers, biopolymer-based (e.g., starch granules, and protein aggregates) and microorganism-based particles can be utilized for the formation of PEs6,7. Some biopolymer-based particles need further pretreatments (e.g., controlled aggregation of protein, and complex coacervation between protein and polysaccharide) for the formation, which can make their application in PE stabilization more challenging8. As potential Pickering particles, microorganisms do not require any specific step for their preparation (except for culturing that can be done in bioreactors)9. Due to safety concerns and also providing added values to final products, food-grade probiotic microorganisms are the solid particles of choice for the preparation of Pickering food emulsions. Considering the potential probiotic and prebiotic activity of live and inactive microorganisms, their utilization in food emulsion products can provide additional advantages to the consumers10. Similar to other Pickering particles, the size, shape, and surface characteristics of microorganisms are of importance for effective “Pickering stabilization”. Microorganisms have different geometric shapes (e.g., rod, cocci and ellipsoid) that can influence their adsorption at the interface, and thus the stability of emulsions11. A wide range of particle size can be utilized in emulsion stabilization. Higher physical stability is achieved when the size of particles is smaller than that of the oil droplets, possibly due to a higher packing density and homogeneity at the interface12. The size of microorganism also influences the desorption from the interface. Microorganisms have a higher motility and diffusivity than surfactant molecules. The motility is supported by an enhanced Brownian motion mechanism. Wettability, roughness, surface charge, and cell wall characteristics also affect the adsorption phenomenon13,14. Surface roughness enhances the accessible surface area. The surface charge of microorganisms is rooted in carboxyl, amino, and phosphate functional groups, which is an important factor on the adsorption to the interface. High electronegativity might decrease the bacterial adhesion to the interface, while, heterogeneity in surface charge considerably enhances the cell adhesion13,14. The cell wall of Gram-positive bacteria consists of thick peptidoglycan layer. The outer surface is covered by S-layer proteins, lipoteichoic acid, and polysaccharides, which help to reduce the interfacial tension (IFT) and improve PE stability13. The presence of negatively-charged extracellular polysaccharides (EPS) also increases the adsorption to the interface.

In addition to the Pickering particle type, there are other factors which affect the final physical and chemical stability of PE including the quantity and saturation degree of the oil phase. The volume fraction of dispersed phase (known as φ) determines the physical stability of emulsion through affecting the apparent viscosity (η) ratio of dispersed phase to continuous phase15. The medium-chain triacylglycerol (MCT) oil is a dietary oil, which can be used in the formulation of food emulsions. It is produced from some fractions of palm kernel and coconut oils16. The advantages of MCT oil over long-chain triacylglycerol (LCT) oil are rapid metabolism into ketone bodies and higher absorption17. The disadvantage of MCT oil is having a high percentage of saturated fatty acids. However, in an emulsion system, this can improve the oxidative stability of emulsion.

There are few reports dealing with the stabilization of PEs by food-grade microorganisms. Firoozmand and Rousseau (2016) studied the stabilization of O/W PEs by three types of microorganisms including Saccharomyces cerevisiae, Lactobacillus acidophilus, and Streptococcus thermophilus at various φ values and Pickering microorganisms’ concentrations11. They reported that some emulsions remained stable for more than four months. The physical stability of PEs followed this order: Saccharomyces cerevisiae > L. acidophilus > S. thermophilus. Moreover, Jiang et al. reported that the surface modification of L. acidophilus by octenyl succinic anhydride (OSA) led to improve the stability of PEs18. There are also some reported results regarding the utilization of non-food-grade microorganisms (e.g., Acinetobacter venetianus, Rhodococcus erythropolis, Pseudomonas fluorescens and Rhizomonas suberifaciens) in the stabilization of PEs. The highest and the lowest emulsion stability were observed in samples stabilized by A. venetianus (several months) and R. erythropolis (24 h), respectively. Also, P. fluorescens and R. suberifaciens were not able to stabilize the emulsions19. In another study, Wongkongkatep et al. studied the ability of cell/polymer networks fabricated by electrostatic attraction between positively charged chitosan and negatively charged Escherichia coli on the stabilization of PEs20.

Taking into account the large diversity of food-grade microorganisms and their differences even at the strain level, the potential application of these particles as novel candidates for stabilizing PEs should be determined. Therefore, the main objective of this work was to study the efficacy of nineteen food-grade microorganisms varying in genus, species, and strains on the stability of MCT O/W PEs. At the first stage, various characteristics of microorganisms related to “Pickering stabilization” including surface charge, IFT, θow, and morphology were studied. Following, PEs were produced using MCT oil as the lipid phase (at a constant φ of 0.5), and characterized in terms of physical stability, droplet size, zeta potential, microstructure, ΔGd, and rheological properties.

Materials and methods

Materials

MCT oil was purchased from Nutricia Ltd. (Favona, Auckland, New Zealand). The fatty acids composition of MCT oil was caprylic (8:0, 53%), capric (10:0, 36–47%) and lower amounts of caproic (6:0) and lauric (12:0) acids. De man, Rogosa and Sharpe (MRS) broth, tryptic soy broth (TSB) and Sabouraud Dextrose Broth (SDB) were purchased from Merck Co. (Darmstadt, Germany). Chloramphenicol (purity > 99%) was purchased from Solarbio (Beijing, China). 100 μL of chloramphenicol ethanolic solution (0.1 g/1 mL EtOH) was added to 100 mL of SDB culture medium.

Preparation of microorganisms

More information about the genus, species, strains, culture medium, incubation temperature and incubation time of nineteen microorganisms is reported in Table 1. From different glycerol stocks, each microorganism was cultured on respective culture medium (agar plate) and incubated at appropriate temperature for 24 h to acquire a pure single colony. Active pure cultures were then obtained by taking a single colony from the culture medium followed by inoculation in 5 mL of culture medium broth in a shaking incubator. The incubation conditions were as follows: 150 rpm at 37 °C for lactobacilli, Bacillus spp., and cocci bacteria and 200 rpm at 28 °C for yeast cells. After that, an aliquot of 1 mL from the prepared subculture was inoculated into 10 mL of respective culture media and incubated in similar conditions. Then 10 mL of preculture was transferred into 100 mL of fresh medium and incubated until the optical density at 600 nm (OD600) reached 2. Finally, microorganisms were harvested by centrifugal force at 10,000×g for 5 min at 25 °C, washed twice times with sterile saline solution, and inactivated in a water bath at 85 °C for 30 min for lactobacilli and cocci bacteria and also yeast cells and at 121 °C for 15 min for Bacillus spp. The samples were then rapidly cooled to room temperature and subjected to centrifugation in similar conditions. After removing the supernatant, inactivated cells were washed five times with sterile saline solution and centrifuged. At the final stage, the inactivated microorganisms were washed with phosphate buffer solution (PBS 5 mM, pH 6.8). Uniform cells (non-lyophilized wet sediments) were obtained after centrifugation and then stored at 4° C for characterization. A fraction of wet sediments was lyophilized and then kept at room temperature for the preparation of PEs.

Microorganism characterization

Scanning electron microscopy

Prior to morphological evaluation by scanning electron microscopy (SEM, TESCAN-Vega 3, TESCAN Co., Czech Republic), air-dried non-lyophilized wet sediments were coated by a thin layer of gold (Desk Sputter Coater DSR1, Nanostructural Coating Co., Iran). The morphology of microorganisms was evaluated at an accelerating voltage of 20 kV and a magnification of 22.5 kx21.

After taking the micrographs, the sphericity was measured according to Eq. (2)22.

The volume of rod-shaped microorganisms (lactobacilli and Bacillus spp.) was calculated as πr2L, and the volume of cocci- and ellipsoid-shaped microorganisms (cocci, yeast) was calculated as (4/3)πr3.

Zeta potential

The non-lyophilized wet sediments were dispersed in double distilled water (DDW) to reach an OD600 of 0.7. The zeta potential of microorganisms was determined by dynamic light scattering (DLS, SZ100, Horiba, Japan) at 25 °C23.

Interfacial tension

Dispersion of non-lyophilized wet sediments was prepared in PBS so that to reach an OD600 of 0.7. Static and dynamic IFT were determined in MCT oil using the pendant drop method (Drop shape analyzer 100, KRÜSS GmbH, Hamburg, Germany). To determine static IFT, a drop of aqueous phase was formed at the tip of a needle in bulk MCT oil and IFT was measured exactly at the moment that the droplet detached from the needle. To determine dynamic IFT, a droplet of the aqueous phase with a constant volume of 10 µL was formed at the tip of needle, then the injection was stopped and dynamic IFT was measured by monitoring the changes in the shape of droplet through edge detection and fitting Laplace–Young Eq. 24. The dynamic IFT was only measured for four microorganisms. Actually, each selected microorganism represents a group of those studied in this work (E. faecium (cocci), L. delbrueckii (lactobacillus), B. licheniformis (bacillus) and S. boulardii (yeast)).

Contact angle

θow value of non-lyophilized wet sediments was measured by a drop shape analyzer. A flat layer of pellet was placed at the bottom of glass chamber and then carefully covered with the MCT oil. Then, water droplets (2 µL) were deposited on the pellet layer and photographed by a CCD camera. θow was determined by Image J software (ver. 1.53)20.

Free energy of detachment

The minimum energy required for the detachment of Pickering particles from the O/W interface is known as ΔGd. It is calculated by Eq. (3)1.

where, r is the particle radius; γow is the oil–water IFT; θow is the three-phase “contact angle” of particles.

Pickering emulsion preparation

The aqueous phase containing 10 wt% or 15 wt% of lyophilized microorganisms was firstly prepared in DDW. Then, the MCT oil phase (2.5 g) was added to the aqueous phase (2.5 g) and magnetically stirred (700 rpm for 2 min). Homogenization (16,000 rpm for 10 min) was carried out using a high speed homogenizer (Heidolph Silent Crusher, Schwabach, Germany) equipped with type 8F stainless steel probe.

Emulsion characterization

Emulsion type

The type of PEs was determined by the visual observation of dispersing an emulsion droplet into MCT oil or water phase25.

Emulsion activity index

PEs (1 mL) were diluted 100 times by DDW just after preparation. Then, 1 mL of diluted emulsion was mixed with 15 mL of 0.1% SDS solution. SDS was used to prevent the flocculation of emulsion droplets. Finally, the absorbance was measured at 500 nm (spec T92+, Pg instrument, United Kingdom). The emulsion activity index (EAI) was determined as follows26:

where, T (turbidity of PE) is 2.303; A is the absorbance; dilution factor is 1600; c is the weight of microorganism per unit volume (g/mL); φ is the volume fraction of MCT oil (0.5); and L is the width of the optical path (0.01 m).

Droplet size

The volume-weighted average droplet size (D43) and droplet size distribution (span) of PEs, which remained stable after 4 days, were measured by laser diffraction (Mastersizer 2000, Malvern, UK)25. The refractive indices of MCT oil and water were 1.45 and 1.33, respectively.

Zeta potential

The zeta potential of diluted PEs (1:50), which remained stable after 1 day, was determined as the method described in section "Zeta potential".

Rheological properties

Different rheological properties of PEs, which remained stable after 1 day, including steady shear, amplitude sweep and frequency sweep tests were determined at 25 °C using a rheometer (Anton Paar MCR 302, Graz, Austria) equipped with a cone and plate geometry (diameter: 25 mm, cone angle: 1°, gap: 0.052 mm).

Steady shear test was carried out at shear rate range of 0.1–100 s−1. The results were analyzed using various models including Power Law, Herschel–Bulkley, Bingham, and Casson (Eqs. 5–8, respectively)27. Moreover, the η of different PEs was also reported at the shear rate of 57.6 s−1.

where, γ is the shear rate (s−1); τ is the shear stress (Pa); τ0 is the yield stress (Pa); k is the consistency coefficient (in Pa sn for Herschel-Bulkley and Power Law and Pa s0.5 for Casson); n is the flow behavior index (dimensionless); and μ is the Bingham viscosity (Pa s).

Prior to performing frequency sweep test, the linear viscoelastic region (LVE) was determined using an amplitude (strain) sweep test at an angular frequency of 10 rad/s and strain range of 0.01–100%. The frequency sweep test was then performed at strain of 0.1% and angular frequency range of 0.1–100 rad/s.

Storage and freeze–thaw stability

PEs were kept at 25 °C and the storage stability (physical stability index) was evaluated over time using Eq. (9).

where, HT and HU are the total height of emulsion and upper layer, respectively.

Three emulsion samples (each from one group of microorganisms) were subjected to freeze–thaw cycling. The fresh samples were frozen at − 22 °C for 24 h and then thawed during 24 h at + 25 °C. After thawing, samples were centrifuged at 3000×g for 10 min and the released liquid was separated and the retentate was subjected to another freezing cycle. The freeze–thaw cycling was studied under four cycles and evaluated as the percentage of released liquid from the initial sample28.

Emulsion microstructure

The morphology of PEs was visualized using an Olympus CH2 optical microscope (Japan). The samples were photographed using a digital camera (Optikam PRO 5, OPTIKA Co., Italy) at 40 × magnification29.

Statistical Analysis

All tests were done at least in triplicate. The results were reported as mean values and standard deviations. Analysis of variance (ANOVA) was performed utilizing the SPSS software (ver. 22, IBM, New York). Duncan’s multiple ranges tests among the means were carried out at a significance level of 0.05. Also, analyzing the significant differences between Pickering cells concentrations was done based on paired-sample t-test.

Results and discussion

Characterization of microorganisms

Shape

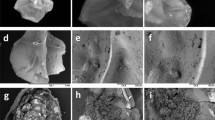

The shape of particles (e.g., microorganism cells) can affect the final stability of PEs. Figure 1 illustrates the morphology of different microorganisms applied in this study. The yeast cells were oval-shaped (ellipsoid) and significantly larger than the bacterial cells. While, the bacterial cells were spherical (coccus) or rod-shaped (Bacillus spp. and lactobacillus). The particle size of microorganisms is reported in Table S1.

Particles’ sphericity is a morphological property which affects the flow properties, heat/mass transfer22, as well as the wettability at the O/W interface. As shown in Table 2, the sphericity values of yeast and cocci cells were ≈ 1, while, those of lactobacilli and Bacillus spp. cells were in the range of 0.6–0.8. Bacillus spp. revealed some spherical structures along with the dominant rod-shaped structure, which might be attributed to the spore formation as a result of heat inactivation.

Zeta potential

The mobility of particles in an electric field (or electrophoretic mobility) is the consequence of three different forces including electric force, drag force, and retardation force (also known as relaxation effect)30. The zeta potential (determined from the electrophoretic mobility) of Pickering particles can influence the hydrophilic-lipophilic balance and thus their wettability at the interface. Moreover, higher zeta potential values result in a higher electrostatic repulsion among the oil droplets and thus a better physical stability. All microorganisms showed negative values of zeta potential with a considerable difference (p < 0.05) among different groups, species and even strains. As reported in Table 2, the zeta potential values ranged from − 9.00 ± 1.34 (S. cerevisiae (PTCC 5052)) to − 26.20 ± 1.83 mV (L. plantarum (Lp 299)). These differences were mainly attributed to the cell wall composition of microorganisms. The electric charge is derived from the ionization of functional (e.g., carboxyl, phosphate, and amino) groups under the effects of pH, ionic strength and growth media composition31,32. These functional groups are present along the backbone of peptidoglycan and various polyelectrolytes macromolecules such as teichuronic acid, lipoteichoic acid, lipopolysaccharides, lipoproteins, enzymes and mycolic acids33. Due to a greater concentration of negatively charged groups than positively charged ones, the net charge of microorganisms is negative. Several researchers reported negative zeta potential for Lactobacillus delbrueckii ssp. Bulgaricus31, Lactobacillus rhamnosus GG34, Lactobacillus acidophilus35, and Lactobacillus johnsonii36. In addition to the effect of cell wall composition on the zeta potential of microorganisms, this property is influenced by the shape characteristics (through affecting the relaxation effect)33, as well as the growth stage of microorganisms37. Particle shape might affect the zeta-potential values through affecting the specific surface area as well as the drag force during measurement38.

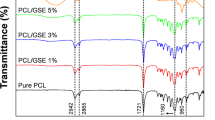

Interfacial tension

IFT reflects the tendency of particles for adsorption to the O/W interface39. A higher ability to reduce the IFT results in a greater interfacial adsorption40. As reported in Table 2, B. indicus (HU36) and L. reuteri (DSM 17939) led to the highest and the lowest static IFT values, which amounted to 40.08 and 16.33 mN/m, respectively. Microorganisms can decrease the static IFT by formation of extracellular and cell-bound biosurfactants41,42. The interfacial adsorption is also influenced by the surface chemistry and hydrophobicity of microorganisms43. The adsorption kinetics of microorganisms at the interface also depend on size and shape44. Smaller particles usually have faster adsorption at the interface. According to Binks et al., the rod-shaped particles generally reduce the IFT more than spherical-shaped particles due to more appropriate planar orientation and better interfacial coverage1. However, it seems that this conclusion cannot be readily extended to microorganisms with different morphologies. As can be seen from Table 2, the static IFT results of most cocci and lactobacilli cells were in a similar range. This means that the size and shape are not the only determinants of IFT reduction by microorganisms and other factors (such as surface smoothness and surface chemistry) might also have a contribution. For example, surface smoothness might lead to better wetting behavior as well as better spreading at the interface1. Despite the lower ability of some microorganisms (e.g., B. coagulans (MTCC 5856), L. delbrueckii (PTCC 1743) and L. gasseri (ATCC 33323)) as compared to the ability of L. reuteri (DSM 17939), L. plantarum (Lp 299), L. acidophilus (ATCC 4356), and B. licheniformis (ATCC 14580) to reduce static IFT, the respective PEs were almost stable during storage. Therefore, it can be concluded that, the IFT reduction is not the only factor in predicting “Pickering stabilization”, and other factors such as ΔGd and rheological properties can influence the final stability (discussed later). Some researchers reported the formation of stabilized PEs without any IFT reduction43,45. In addition to static IFT, the dynamic IFT was also measured for four microorganisms (including E. faecium (BH06), L. delbrueckii (PTCC 1743), B. licheniformis (ATCC 14580), and S. boulardii (ATCC MYA-797)). As shown in Fig. 2, a gradual dynamic IFT reduction was observed by E. faecium (BH06) from 24 to 17 mN/m, L. delbrueckii (PTCC 1743) from 27 to 21 mN/m and B. licheniformis (ATCC 14580) from 29 to 20 mN/m. However, the results showed that in the presence of S. boulardii (ATCC MYA-797), the droplet shape did not significantly change during the time and the dynamic IFT slightly decreased from 42 to 38 mN/m. As also verified by static IFT measurement (Table 2), the lower ability of yeasts to reduce IFT might be attributed to the larger size, ellipsoid shape and cell wall composition (polysaccharide and mannoprotein). In contrast, a gradual change (as stretching) in the shape of droplets was observed in the presence of lactobacilli, bacilli and cocci cells, confirming IFT reduction over time. The ability of bacteria to reduce IFT is arising from different surface proteins with different hydrophobicity43. The hydrophobicity of these three bacteria followed this order: L. delbrueckii (PTCC 1743) > E. faecium (BH06) > B. licheniformis (ATCC 14580). Hydrophobicity is rooted in the presence of proteins and lipoteichoic acids at the cell surface and hydrophilicity is due to the presence of polysaccharides46. A balance in the hydrophilic/hydrophobic properties at the cell wall determines the ability of microorganism to reduce IFT. The higher ability of rod-shaped bacteria than cocci bacteria to reduce IFT might also be related to the better interface coverage.

Contact angle

As a thermodynamic property, the θow determines the wettability of colloidal particles by either aqueous phase or organic phase at the interface. It ranges from 0° to 180°. Lower values indicate a higher hydrophilicity and vice versa. Higher wetting by the aqueous phase (θow < 90°) favors the formation of O/W PE, whereas, preferential wetting by the oil phase (θow > 90°) generally results in the formation of W/O PE47,48. Very high hydrophilicity or hydrophobicity result in the formation of extremely unstable emulsions2. There are diverse parameters that affect the θow value such as the size of microorganism, layer thickness, moisture content, and the assay time49. Significant differences (p < 0.05) were observed among the θow values of different microorganisms (Table 2). The values ranged from 15° to 106° for S. boulardii (ATCC MYA-797) and L. delbrueckii (PTCC 1743), respectively. Some microorganisms including E. faecium (BH06), L. acidophilus (ATCC 4356), L. rhamnosus GG (ATCC 53103), L. reuteri (DSM 20016, ATCC 23272), and B. coagulans (MTCC 5856) had θow values around 90° and revealed very high emulsion stability (section "Droplet size and droplet charge"). According to Chevalier and Bolzinger (2013), a great emulsion stability is observed when the θow is around 90°, mainly due to the strong adsorption of particles to the interface as well as the balance between the wettability by both phases7. In this study, the yeast cells showed the lowest θow values (around 20°), which indicated the high hydrophilicity and inability to form stable PEs. Among different groups of microorganisms, the largest variation in θow values (17°–106°) were observed in lactobacilli group. These interspecies variations might be attributed to the differences in cell wall composition such as in hydrocarbon-like compounds and polysaccharide/protein ratio50. In this study, two species of lactobacilli microorganisms (L. delbrueckii (PTCC 1743) and L. gasseri (ATCC 33323)) had θow values more than 100°, however, the respective PEs were of O/W emulsion type. Van der Mei, Bos, and Busscher. (1998) similarly reported a high θow value (≈102°) for L. acidophilus RC1451.

Pickering emulsion characterization

Droplet size and droplet charge

D4,3 of oil droplets is reported in Table 3. In this work, PE samples which showed a physical stability index of 100% after 4 days were only analyzed. A decrease in D4,3 was observed by increasing the concentration of Pickering microorganisms, which could be explained by the fact that more microorganisms were available to effectively cover the O/W interfaces52. Smaller oil droplets have a higher specific surface area than the larger ones and thus need more amounts of Pickering particles for effective stabilization53. D4,3 of PEs stabilized by cocci, lactobacilli and Bacillus spp. groups were in the range of 19–57, 14–57, and 11–13 µm, respectively. At 10 wt% and 15 wt% concentration, the least and the highest values were observed in the PEs stabilized by B. licheniformis (ATCC 14580), and L. delbrueckii (PTCC 1743) as well as B. licheniformis (ATCC 14580), and P. acidilactici (M76), respectively.

The Span value (Table 3) of all emulsions was > 1, indicating a bimodal size distribution (Fig. S1). The larger population (lying in the range of 10–100 µm) indicates the oil droplets. The smaller population (centered at ≈ 1.5 μm) likely indicated the presence of free (un-adsorbed) microorganisms in the continuous phase.

The zeta potential of oil droplets stabilized by different microorganisms ranged from − 17 to – 76 mV (Table 3). Ly et al. reported the value of − 35 mV for the emulsions stabilized by Lactococcus lactis16. For same microorganisms, the absolute value of zeta potential generally decreased by increasing the cell concentration from 10 wt% to 15 wt%. This reduction was attributed to the higher viscosity of PEs at higher cell concentration (Table 3), that could influence the electrophoretic mobility of oil droplets in the electric field. The zeta potential of microorganism- stabilized oil droplets (Table 3) was larger than the zeta potential measured in the dispersion of microorganisms (Table 2). This increase was ascribed to the packing of Pickering cells at the interface. Generally, the dispersed droplets with zeta-potential values more negative than – 30 mV and more positive than + 30 mV are colloidally stable as a consequence of sufficient electrostatic repulsion among them54. Some microorganism-stabilized oil droplets (e.g., by L. delbrueckii (PTCC 1743) and L. acidophilus (ATCC 4356)) showed appropriate physical stability (7 days) with zeta potential values of about − 35 mV. However, some others (e.g., by B. subtilis (DE111), and L. plantarum (ATCC 8014)) revealed lower stability (1 day) despite more negative zeta potential values (≈ − 70 mV). This observation leads to a conclusion that the zeta potential is not the only factor determining the emulsion stability during storage and other parameters (e.g., Pickering particle size, IFT reduction, and θow which are collectively discussed in terms of ΔGd as well as rheological properties) also affect the emulsion stability.

Emulsion formation and physical stability

The ability of microorganisms to adsorb to the interface and subsequent stability of PEs are of paramount importance. Figure S2 shows the photographs of PEs stabilized by various microorganisms at 10 wt% and 15 wt% concentration during storage. The physical stability index is also reported in Table 4. At 10 wt% concentration, PEs stabilized by L. reuteri (DSM 20016, ATCC 23272) remained stable for 12 days and those stabilized by L. delbrueckii (PTCC 1743), L. acidophilus (ATCC 4356), B. coagulans (MTCC 5856), and B. licheniformis (ATCC 14580) remained physically stable for 7 days. Generally, the differences in physical stability can be attributed to microorganisms’ properties (e.g., surface charge, shape, size, functional groups at the cell wall, IFT reduction, wettability and etc.)11. A portion of observed stability can be rooted in the ability of microorganisms in the production of surface-bound biosurfactants prior to inactivation. High molecular weight biosurfactants are efficient at O/W emulsion stabilization, whereas, low molecular weight ones are useful in IFT reduction55. Increasing the Pickering cells concentration (i.e., 15 wt%) significantly increased the stability of PEs (to a maximum of 35 days by L. acidophilus (ATCC 4356)) mainly as the result of better interface coverage. PEs formulated by 15 wt% of B. licheniformis (ATCC 14580), E. faecium (BH06), L. acidophilus (ATCC 4356), L. reuteri (DSM 17939), L. reuteri (DSM 20016, ATCC 23272), L. delbrueckii (PTCC 1743), L. plantarum (Lp 299), L. rhamnosus GG (ATCC 53103), and L. gasseri (ATCC 33323) revealed physical stability index of 100% until the end of storage (10 days) and even more (Table 4). At lower concentration, the formation of larger oil droplets (Fig. 3) led to a higher physical instability in PEs. Moreover, increasing the microorganisms’ concentration could increase the physical stability by increasing the steric hindrance around the oil droplets, reducing the bulk aqueous phase volume, more IFT reduction and higher cells adsorption at the interface (i.e., by hydrophobic, Lewis acid–base and electrostatic interactions under the effects of chemical composition and conformation of proteins, polypeptides and polysaccharides at the cell wall)23,56,57. The ability of microorganisms to form PEs was also confirmed by measuring the EAI. As reported in Table 3, a significant (p < 0.05) increase in EAI was observed by increasing the cells concentration in emulsions.

In general, the yeast cells (likely due to the presence of too much fibrous polysaccharides in the cell wall) and some bacilli species showed low tendency to stabilize PEs. However, lactobacilli species showed high PE stability likely due to a better balance between the hydrophilic and hydrophobic characters of cell wall arising from peptidoglycans (up to 70 wt%), lipoteichoic acids bound to membrane, and glycoproteinaceous materials58,59,60. The higher emulsifying ability of lactobacilli cells than cocci cells can be ascribed to the presence of pili (protruded proteinaceous surface structures with a diameter of 1 to10 nm and length 1 μm) on the lactobacilli cells and pili’s effect on cell adhesion to the O/W interface. Pili also has a significant contribution on the formation of biofilms61. Regarding interspecies variations, S-layer proteins (40–200 kDa, 5–15 nm thickness with highly stable conformation) are the main surface proteins in many lactobacillus species such as L. acidophilus, L. casei, and L. rhamnosus, but not in L. gasseri60,62. They are composed of protein or glycoprotein subunits. These proteins are bound to the cell wall by non-covalent linkages and accumulate into the surface layers. S-layer proteins of lactobacilli have a large (≈ 30%) fraction of hydrophobic amino acid residues63. Unlike most other bacteria, the S-layer proteins in lactobacilli are highly basic and thus have high isoelectric point values. The yeasts’ cell walls are rigid and composed of mannose, chitin and glucan. S. cerevisiae reveals 99% genetic similarity to S. boulardii64. These are likely the reasons for the low stability of yeast-stabilized PEs as well as not significant differences in the PE stability between S. cerevisiae (PTCC 5052) and S. boulardii (ATCC 18824). Madivala et al. (2009) studied the effect of hematite particle shape (with aspect ratios ranging from 1 to 9) on the physical stability of emulsions against coalescence65. They found that, the shape characteristics of particles had a dominant effect on physical stability of O/W and W/O emulsions. The emulsions prepared by elongated (high-aspect ratio) particles were more stable than those prepared by spherical (low-aspect ratio) particles of similar wettability. In this study, L. rhamnosus GG (ATCC 53103) as a rod-shaped bacterium and E. faecium (BH06) as a spherical-shaped bacterium had similar θow values (75.16° ± 2.45 and 78.68° ± 0.31, respectively). However, the PEs stabilized by L. rhamnosus GG (ATCC 53103) particularly at lower microorganism concentration (10 wt%) was more stable than those stabilized by E. faecium (BH06), which were 4 and 2 days, respectively. Those behaviors were rotted in the interfacial shear rheology under the effect of surface coverage and shape-induced attractive capillary interactions. Due to a larger surface area, elongated particles have a better surface coverage at the O/W interface, which can contribute to the higher physical stability. As illustrated in Fig. S2, the overt sign of physical instability in PEs was the separation of aqueous phase at the bottom and in rare cases oiling off (e.g., B. subtilis (DE111), S. cerevisiae (PTCC 5052) and both strains of S. boulardii). Since the emulsion becomes cloudy after gentle stirring, creaming or flocculation are not considered as the important signs of emulsion instability, provided the oil droplets are not being subjected to coalescence7. Dorobantu et al., (2004) reported the formation of O/W and W/O PEs by hydrocarbon degrading bacteria. Partial hydrophobic character resulted in optimum emulsion stability19. In another study, Firoozmand and Rousseau reported that S. cerevisiae resulted in the highest emulsion stability, followed by L. acidophilus and S. thermophiles11. The long-term emulsion stability (4 months) reported by Firoozmand and Rousseau compared to that reported in the current study (maximum of 35 days) can be attributed to the strain-dependent characteristic of microorganisms and more importantly to the higher φ (0.8 vs. 0.5 in this study). Increasing φ increases the viscoelastic properties of emulsions and thus improves the storage stability.

The stability of food emulsions against syneresis can be considered by "freeze–thaw stability" assay. In this study, three PEs including those stabilized by 15 wt% E. faecium (BH06), 15 wt% L. delbrueckii (PTCC 1743), and 15 wt% B. licheniformis (ATCC 14580) were subjected to four cycles of freezing and thawing. From the third cycle, a limited syneresis (3.5%, 4.5%, and 4.8%, respectively) was observed in PEs. At fourth cycle, the syneresis significantly increased to 37.5%, 40.54%, and 45.45%, respectively. The increase in syneresis could be attributed to the structural breakdown mediated by centrifugal forces66.

The microstructure of PEs is shown in Fig. 3. Spherical or polyhedral oil droplets were observed in various PEs. For a same type of microorganism, smaller and more uniform oil droplets were observed by increasing the concentration of microorganism. This morphology led to a higher physical stability during storage. The adsorption of microorganisms to the interface (particularly for the yeast cells because of the larger size) was also seen in the optical micrographs.

Emulsion stability from a thermodynamic viewpoint

To develop stable emulsions, ΔGd should be greater than the thermal energy of particles67. As reported in Table 2, B. coagulans (MTCC 5856) and L. plantarum (ATCC 8014) had the highest (55 × 10−15 J) and the lowest (0.06 × 10−15 J) values of ΔGd, respectively. Large amount of ΔGd means that a high energy is required for the desorption of Pickering cells from the interface and therefore, the resultant PE has appropriate stability. Generally, the emulsifying capability of particulate structures depends on the particle size, IFT and θow. Smaller Pickering particles have usually fast kinetics of adsorption; however, the Pickering functionality is mostly influenced by the particle size (r2). For some microorganisms with low ability to reduce IFT, θow and particle size contributed to increase ΔGd. ΔGd tends to zero in the presence of highly hydrophilic (Cos 0° = 1) and hydrophobic (Cos 180° = − 1) particles. It is increased by increasing the θow to 90° (Cos 90° = 0). In other words, the highest amount of irreversible attachment is observed at θow values around 90°. According to Binks and Horozov (2006), ΔGd values of rod-shaped particles are more than the ΔGd values of spherical-shaped particles, mainly due to a favorable planar orientation of rodlike particles at the interface1. ΔGd reduction upon the interfacial attachment of rodlike particles is greater than that of spherical-shaped particles, which results in a higher thermodynamic stability. ΔGd determines the equilibrium in microorganism position at the interface and in the bulk. An activation energy is required for the detachment of particles from the interface. Larger particle size favors slower kinetics of adsorption and higher energy hurdles at the interface1. Therefore, the energy required for the detachment of particles from the interface rapidly decreases with decreasing particle size. As a result, the long-term physical stability of PEs stabilized by micron-sized particles is higher than that stabilized by nanoparticles68. The ΔGd of rod-shaped particles depends on the aspect ratio and θow. At a fixed particle volume, the parallel orientation results in the stronger adsorption of rod-shaped particles with rounded ends than spherical particles to the interface and thus larger ΔGd values68. As can be seen, the average ΔGd values of lactobacilli and Bacillus spp. cells were higher than those of cocci cells. Generally, most PEs with high ΔGd values showed high physical stability against coalescence during storage. However, in some PEs (e.g., those stabilized by L. reuteri (DSM 17939) and E. faecium (BH06)), despite the low amount of ΔGd, appropriate physical stability was observed over time, that could be arisen from the effect of rheological properties on the emulsion stability.

Rheological properties of PE

Apparent viscosity

Viscosity is influenced by the structural alterations due to the aggregation of emulsion droplets. Changes in the η of PEs as a function of shear rate (γ: 0.1–100 s−1) are shown in Fig. S3A–D. It was reduced by increasing the shear rate confirming shear-thinning or pseudoplastic behavior of emulsions. This behavior was ascribed to shear-induced deflocculation of oil droplets69,70. The η values of PEs stabilized by lactobacilli and Bacillus spp. microorganisms were greater than those stabilized by cocci and yeast cells. As reported in Table 3, the η of PEs at 57.6 s−1 ranged from 23.8 to 340.3 mPa s by 10 wt% of L. plantarum (ATCC 8014) and L. reuteri (DSM 20016, ATCC 23272), respectively, and from 43.3 to 1094.9 mPa.s by 15 wt% of S. boulardii (ATCC MYA-797) and L. reuteri (DSM 17939), respectively. Therefore, the viscosity of PEs can be adjusted by appropriate selection of microorganism and its concentration. The variations in the η might be attributed to the strength of interactions between cell-stabilized oil droplets, shape and size of microorganism, and also the presence of cell-bound exopolysaccharides in the continuous phase. A pseudoplastic behavior in PEs stabilized by microorganisms or other Pickering particles was similarly reported by Firoozmand and Rousseau and Boostani et al.11,70. Generally, the η of PEs was significantly increased by increasing the cells concentration likely owing to smaller oil droplet size (or larger specific surface area) and higher viscosity of continuous phase. In some cell-stabilized PEs (e.g., by L. reuteri (DSM 20016, ATCC 23272)), a decrease in η was observed by increasing the microorganism concentration. This reduction might be due to the higher concentration of free cells in the continuous phase that could reduce the friction via “ball-bearing” mechanism71. Particles with a spherical and smooth surface can highly reduce the friction as a result of considerable rolling.

The analysis results of four rheological models are reported in Table 5. Higher coefficient of determination (R2) and lower root mean square error (RMSE) values indicate a better fitting. Accordingly, Herschel-Bulkely model was better than Power Law, Casson and Bingham models to describe flow behavior of PEs. The flow behavior index values (n < 1) confirmed the pseudoplasticity. The values ranged from 0.79 to 0.26 for PEs stabilized by 10 wt% of L. plantarum (ATCC 8014) and L. reuteri (DSM 17939), respectively and from 0.83 to 0.49 for those stabilized by 15 wt% of P. acidilactici (M76) and L. reuteri (DSM 17939), respectively. For a same cell, an increase in the concentration generally increased the pseudoplasticity (i.e., lower n values) and consistency index (k or structuration degree) of PEs. The yield stress (τ0) of cell-stabilized PEs was dependent on microorganism type and concentration.

Dynamic rheological properties

The stability and application of PEs are determined by the viscoelastic properties72. Figure S4 illustrates the results of amplitude sweep test. The elastic modulus (G′) was greater than the viscous modulus (G″), indicating a higher degree of rigidity. The critical strain values were dependent on the microorganisms’ type and concentration. However, for most samples, the critical strain values were below 10% (Table S2). As can be seen, the strain value of 0.1% was within the LVE region of various PEs. Therefore, this value was selected for frequency sweep test. The results of frequency sweep test are shown in Fig. 4. Most PEs stabilized by different microorganisms showed dominant elastic properties (i.e., G' > G″) indicating the formation of 3D networks resulting in the high physical stability of emulsions during storage (section "Droplet size and droplet charge"). The dominant elastic properties could be related to the inter-droplet interactions of oil droplets as a result of cells’ packing at the interface25,73. Similar rheological properties were reported by Boostani et al. and Lu et al.3,70. The dependency of Gʹ and Gʺ to frequency was related to the type of Pickering microorganism. An increase in cell concentration increased the viscoelastic properties of PEs. The highest Gʹ values of PEs at the studied frequency range were measured in the samples stabilized by 10 wt% of B. coagulans (MTCC 5856), L. reuteri (DSM 20016, ATCC 23272), and L. delbrueckii (PTCC 1743) and 15 wt% of L. reuteri (DSM 20016, ATCC 23272), L. reuteri (DSM 17939), L. delbrueckii (PTCC 1743), and L. rhamnosus GG (ATCC 53103). The loss factor results (i.e., the ratio of G''/G' or tan δ) are reported in Fig. S5. The values < 1 and > 1 indicate dominant elastic and dominant viscous characters, respectively. For the most PE samples, no crossover (G'' = G') was observed over the studied range. For some samples stabilized by L. plantarum (Lp 299), L. gasseri (ATCC 33323), L. casei (ATCC 393), L. rhamnosus GG (ATCC 53103), L. plantarum (ATCC 8014), L. reuteri (DSM 17939), S. boulardii (ATCC MYA-797), B. subtilis (DE111), and B. indicus (HU36), a crossover was observed at higher frequency values indicating the change from a predominant elastic character to viscous character. Despite the dominant elastic behavior, PEs were not real gels (0.1 < tan δ)27. The η results were also confirmed by complex viscosity (η*) results (Fig. S6). The decrease in η* by increasing the frequency was attributed to droplet deflocculation, network disentanglement and breakdown of junction zones.

Frequency sweep test results of Pickering emulsions stabilized by (A) 10% of lactobacilli microorganisms, (B) 10% of spore-forming bacillus spp., cocci and yeast cells, (C) 15% of lactobacilli cells and (D) 15% of spore-forming bacillus spp. cocci and yeast cells; The samples which remained physically stable after 24 h were only analyzed.

Conclusion

This study showed that probiotic microorganisms such as lactobacillus, Bacillus spp. and coccus bacteria are able to stabilize PEs at 10 wt% and 15 wt% concentrations. Increasing the cells concentration resulted in a significant increase of physical stability against droplet coalescence and aqueous phase separation from a maximum of 12 days to 35 days. L. reuteri (DSM 20016, ATCC 23272), L. reuteri (DSM 17939), L. acidophilus (ATCC 4356), L. plantarum (Lp 299), E. faecium (BH06), and B. licheniformis (ATCC 14580) revealed a high emulsifying ability. Pickering functionality of probiotic microorganisms depended on the shape, size, and charge of cells, IFT reduction, θow and possibly cell wall composition. Pseudoplastic and predominant elastic behaviors were observed in PEs. Cell-stabilized PEs might have novel applications in food, drug and cosmetics industries. The stability of PEs under the formation of biopolymer/cell entangled networks, and the hydrophobic modification of cell wall is under research.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

Abbreviations

- ANOVA:

-

Analysis of variance

- D 4,3 :

-

Volume-weighted average droplet size

- DDW:

-

Double distilled water

- DLS:

-

Dynamic light scattering

- ΔG d :

-

The free energy of detachment

- EAI:

-

Emulsion activity index

- EPS:

-

Extracellular polysaccharides

- η :

-

Apparent viscosity

- η*:

-

Complex viscosity

- φ:

-

The volume fraction of dispersed phase

- G′:

-

Elastic modulus

- G″:

-

Viscous modulus

- IFT:

-

Interfacial tension

- LCT:

-

Long-chain triacylglycerol

- LVE:

-

Linear viscoelastic

- MCT:

-

Medium-chain triacylglycerol

- MRS:

-

De man, Rogosa and Sharpe

- OD:

-

Optical density

- PBS:

-

Phosphate buffer solution

- PE:

-

Pickering emulsion

- R 2 :

-

Coefficient of determination

- RMSE:

-

Root mean square error

- SDB:

-

Sabouraud dextrose broth

- SEM:

-

Scanning electron microscopy

- SPAN:

-

Droplet size distribution width

- tan δ :

-

Loss factor

- θ ow :

-

Three-phase contact angle

- TSB:

-

Tryptic soy broth

References

Binks, B. P. & Horozov, T. S. (eds) Colloidal Particles at Liquid Interfaces (Cambridge University Press, 2006).

Tavernier, I., Wijaya, W., Van der Meeren, P., Dewettinck, K. & Patel, A. R. Food-grade particles for emulsion stabilization. Trends Food Sci. Technol. 50, 159–174 (2016).

Lu, X., Zhang, H., Li, Y. & Huang, Q. Fabrication of milled cellulose particles-stabilized Pickering emulsions. Food Hydrocoll. 77, 427–435 (2018).

Leal-Calderon, F. & Schmitt, V. Solid-stabilized emulsions. Curr. Opin. Colloid Interf. Sci. 13, 217–227 (2008).

Rayner, M., Sjöö, M., Timgren, A. & Dejmek, P. Quinoa starch granules as stabilizing particles for production of Pickering emulsions. Faraday Discuss. 158, 139–155 (2012).

Dickinson, E. Use of nanoparticles and microparticles in the formation and stabilization of food emulsions. Trends Food Sci. Technol. 24, 4–12 (2012).

Chevalier, Y. & Bolzinger, M. A. Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf. A 439, 23–34 (2013).

Ribeiro, E. F., Morell, P., Nicoletti, V. R., Quiles, A. & Hernando, I. Protein-and polysaccharide-based particles used for Pickering emulsion stabilisation. Food Hydrocoll. 119, 106839 (2021).

Cheng, H. et al. Multi-functional magnetic bacteria as efficient and economical Pickering emulsifiers for encapsulation and removal of oil from water. J. Colloid Interface Sci. 560, 349–358 (2020).

Abd El-Salam, M. H. & El-Shibiny, S. Preparation and properties of milk proteins-based encapsulated probiotics: A review. Dairy Sci. Technol. 95, 393–412 (2015).

Firoozmand, H. & Rousseau, D. Microbial cells as colloidal particles: Pickering oil-in-water emulsions stabilized by bacteria and yeast. Food Res. Int. 81, 66–73 (2016).

Hunter, T. N., Pugh, R. J., Franks, G. V. & Jameson, G. J. The role of particles in stabilising foams and emulsions. Adv. Colloid Interface Sci. 137, 57–81 (2008).

Habimana, O., Semião, A. J. C. & Casey, E. The role of cell-surface interactions in bacterial initial adhesion and consequent biofilm formation on nanofiltration/reverse osmosis membranes. J. Membr. Sci. 454, 82–96 (2014).

Zheng, S. et al. Implication of surface properties, bacterial motility, and hydrodynamic conditions on bacterial surface sensing and their initial adhesion. Front. Bioeng. Biotechnol. 9, 643722 (2021).

McClements, D. J. Food Emulsions: Principles, Practices, and Techniques (CRC Press, 2004).

Ferguson, L. R. et al. Medium chain triglyceride oil: An intended placebo with unexpected adverse effects. Ann. Clin. Lab. Sci. 4, 3 (2016).

Paramita, V., Furuta, T. & Yoshii, H. High-oil-load encapsulation of medium-chain triglycerides and d-limonene mixture in modified starch by spray drying. J. Food Sci. 77, E38–E44 (2012).

Jiang, X. et al. Surface engineered bacteria as Pickering stabilizers for foams and emulsions. Food Hydrocoll. 89, 224–233 (2019).

Dorobantu, L. S., Yeung, A. K., Foght, J. M. & Gray, M. R. Stabilization of oil-water emulsions by hydrophobic bacteria. Appl. Environ. Microbiol. 70, 6333–6336 (2004).

Wongkongkatep, P. et al. Bacteria interface pickering emulsions stabilized by self-assembled bacteria–chitosan network. Langmuir 28, 5729–5736 (2012).

Kalab, M., Yang, A. F. & Chabot, D. Conventional scanning electron microscopy of bacteria. Infocus magazine 10, 42–61 (2008).

Sahin, S. & Sumnu, S. G. Size, shape, volume, and related physical attributes. In Physical Properties of Foods 1–37 (Springer, 2006).

Ly, M. H. et al. Importance of bacterial surface properties to control the stability of emulsions. Int. J. Food Microbiol. 112, 26–34 (2006).

Kazemzadeh, Y., Parsaei, R. & Riazi, M. Experimental study of asphaltene precipitation prediction during gas injection to oil reservoirs by interfacial tension measurement. Colloids Surf. A 466, 138–146 (2015).

Boostani, S. et al. The influence of emulsion parameters on physical stability and rheological properties of Pickering emulsions stabilized by hordein nanoparticles. Food Hydrocoll. 101, 105520 (2020).

Mu, L., Zhao, H., Zhao, M., Cui, C. & Liu, L. Physicochemical properties of soy protein isolates-acacia gum conjugates. Czech J. Food Sci. 29, 129–136 (2011).

Gahruie, H. H., Eskandari, M. H., Khalesi, M., Van der Meeren, P. & Hosseini, S. M. H. Rheological and interfacial properties of basil seed gum modified with octenyl succinic anhydride. Food Hydrocoll. 101, 105489 (2020).

Kaveh, Z., Azadmard-Damirchi, S., Yousefi, G. & Hosseini, S. M. H. A new approach in improving granular cold water swelling starch properties using xanthan gum and β-lactoglobulin/xanthan gum electrostatic coupled gel. Food Hydrocoll. 113, 106438 (2021).

Yan, H. et al. Synthesis of bacterial cellulose and bacterial cellulose nanocrystals for their applications in the stabilization of olive oil pickering emulsion. Food Hydrocoll. 72, 127–135 (2017).

Radko, S. P. & Chrambach, A. Separation and characterization of sub-μm-and μm-sized particles by capillary zone electrophoresis. Electrophoresis 23, 1957–1972 (2002).

Tymczyszyn, E. E. et al. Critical water activity for the preservation of Lactobacillus bulgaricus by vacuum drying. Int. J. Food Microbiol. 128, 342–347 (2008).

Cano-Sarmiento, C. T. D. I. et al. Zeta potential of food matrices. Food Eng. Rev. 10, 113–138 (2018).

Petr, J. & Maier, V. Analysis of microorganisms by capillary electrophoresis. TrAC Trends Anal. Chem. 31, 9–22 (2012).

Deepika, G., Rastall, R. A. & Charalampopoulos, D. Effect of food models and low-temperature storage on the adhesion of Lactobacillus rhamnosus GG to Caco-2 cells. J. Agric. Food Chem. 59, 8661–8666 (2011).

Schar-Zammaretti, P., Dillmann, M. L., D’Amico, N., Affolter, M. & Ubbink, J. Influence of fermentation medium composition on physicochemical surface properties of Lactobacillus acidophilus. Appl. Environ. Microbiol. 71, 8165–8173 (2005).

Dertli, E., Mayer, M. J. & Narbad, A. Impact of the exopolysaccharide layer on biofilms, adhesion and resistance to stress in Lactobacillus johnsonii FI9785. BMC Microbiol. 15, 1–9 (2015).

Halder, S. et al. Alteration of Zeta potential and membrane permeability in bacteria: A study with cationic agents. Springerplus 4, 1–14 (2015).

Salatin, S. & Yari Khosroushahi, A. Overviews on the cellular uptake mechanism of polysaccharide colloidal nanoparticles. J. Cell Mol. Med. 21, 1668–1686 (2017).

Duffus, L. J., Norton, J. E., Smith, P., Norton, I. T. & Spyropoulos, F. A. comparative study on the capacity of a range of food-grade particles to form stable O/W and W/O Pickering emulsions. J. Colloid Interface Sci. 473, 9–21 (2016).

Estrada-Fernández, A. G. et al. Stabilization of oil-in-water-in-oil (O1/W/O2) Pickering double emulsions by soluble and insoluble whey protein concentrate-gum Arabic complexes used as inner and outer interfaces. J. Food Eng. 221, 35–44 (2018).

Vilkova, N. G. & Nushtaeva, A. V. Influence of hydrophobized solid particles on the reduction of interfacial tension. Mendeleev Commun. 23, 155–156 (2013).

Naughton, P. J., Marchant, R., Naughton, V. & Banat, I. M. Microbial biosurfactants: Current trends and applications in agricultural and biomedical industries. J. Appl. Microbiol. 127, 12–28 (2019).

Ruhs, P. A., Böcker, L., Inglis, R. F. & Fischer, P. Studying bacterial hydrophobicity and biofilm formation at liquid–liquid interfaces through interfacial rheology and pendant drop tensiometry. Colloids Surf. B. 117, 174–184 (2014).

Lopez, D. & Lauga, E. Dynamics of swimming bacteria at complex interfaces. Phys. Fluids 26, 7255 (2014).

Mohebali, G., Ball, A., Kaytash, A. & Rasekh, B. Stabilization of water/gas oil emulsions by desulfurizing cells of Gordonia alkanivorans RIPI90A. Microbiology 153, 1573–1581 (2007).

Kirillova, A. V. et al. Assessment of resistance and bioremediation ability of Lactobacillus strains to lead and cadmium. Int. J. Microbiol. 2017, 1–7 (2017).

Zhu, W. et al. Magnetic molecularly imprinted microspheres via yeast stabilized Pickering emulsion polymerization for selective recognition of λ-cyhalothrin. Colloids Surf. A 453, 27–36 (2014).

Li, Y., Gong, H., Cheng, H., Wang, L. & Bao, M. Individually immobilized and surface-modified hydrocarbon-degrading bacteria for oil emulsification and biodegradation. Mar. Pollut. Bull. 125, 433–439 (2017).

Wan, J., Wilson, J. L. & Kieft, T. L. Influence of the gas-water interface on transport of microorganisms through unsaturated porous media. Appl. Environ. Microbiol. 60, 509–516 (1994).

Boonaert, C. J. & Rouxhet, P. G. Surface of lactic acid bacteria: Relationships between chemical composition and physicochemical properties. Appl. Environ. Microbiol. 66, 2548–2554 (2000).

Van der Mei, H. C., Bos, R. & Busscher, H. J. A reference guide to microbial cell surface hydrophobicity based on contact angles. Colloids Surf. B. 11, 213–221 (1998).

Rayner, M. et al. Biomass-based particles for the formulation of Pickering type emulsions in food and topical applications. Colloids Surf. A 458, 48–62 (2014).

Rousseau, D. Fat crystals and emulsion stability: A review. Food Res. Int. 33, 3–14 (2000).

McClements, D. J. & Rao, J. Food-grade nanoemulsions: Formulation, fabrication, properties, performance, biological fate, and potential toxicity. Crit. Rev. Food Sci. Nutr. 51, 285–330 (2011).

Calvo, C., Manzanera, M., Silva-Castro, G. A., Uad, I. & González-López, J. Application of bioemulsifiers in soil oil bioremediation processes. Future prospects. Sci. Total Environ. 407, 3634–3640 (2009).

Furtado, G. F., Picone, C. S., Cuellar, M. C. & Cunha, R. L. Breaking oil-in-water emulsions stabilized by yeast. Colloids Surf. B 128, 568–576 (2015).

Chapot-Chartier, M. P. & Kulakauskas, S. Cell wall structure and function in lactic acid bacteria. Microb. Cell Factories 13, 1–23 (2014).

Hu, S. et al. Heterologous protein display on the cell surface of lactic acid bacteria mediated by the s-layer protein. Microb. Cell Factories. 10, 1–13 (2011).

Mobili, P., Gerbino, E., Tymczyszyn, E. E. & Gómez-Zavaglia, A. S-layers in lactobacilli: Structural characteristics and putative role in surface and probiotic properties of whole bacteria. Curr. Res. Technol. Educ. Top. Appl. Microbiol. Microb. Biotechnol. 2010, 1224–1234 (2010).

Schar-Zammaretti, P. & Ubbink, J. The cell wall of lactic acid bacteria: Surface constituents and macromolecular conformations. Biophys. J. 85, 4076–4092 (2003).

Kankainen, M. et al. Comparative genomic analysis of Lactobacillus rhamnosus GG reveals pili containing a human-mucus binding protein. Proc. Natl. Acad. Sci. USA 106, 17193–17198 (2009).

Hynönen, U. & Palva, A. Lactobacillus surface layer proteins: Structure, function and applications. Appl. Microbiol. Biotechnol. 97, 5225–5243 (2013).

Åvall-Jääskeläinen, S. & Palva, A. Lactobacillus surface layers and their applications. FEMS Microbiol. Rev. 29, 511–529 (2005).

Chen, C., Wen, D. & Wang, J. Cellular surface characteristics of Saccharomyces cerevisiae before and after Ag (I) biosorption. Bioresour. Technol. 156, 380–383 (2014).

Madivala, B., Vandebril, S., Fransaer, J. & Vermant, J. Exploiting particle shape in solid stabilized emulsions. Soft Matter 5, 1717–1727 (2009).

Kalashnikova, I., Bizot, H., Cathala, B. & Capron, I. New Pickering emulsions stabilized by bacterial cellulose nanocrystals. Langmuir 27, 7471–7479 (2011).

De Folter, J. W., Van Ruijven, M. W. & Velikov, K. P. Oil-in-water Pickering emulsions stabilized by colloidal particles from the water-insoluble protein zein. Soft Matter 8, 6807–6815 (2012).

Gupta, R. Surface-active solid lipid nanoparticles for emulsion stabilization. Mol. Sci. (2011).

Ye, F. et al. Characterisations of oil-in-water Pickering emulsion stabilized hydrophobic phytoglycogen nanoparticles. Food Hydrocoll. 76, 78–87 (2018).

Boostani, S. et al. The stability of triphasic oil-in-water Pickering emulsions can be improved by physical modification of hordein-and secalin-based submicron particles. Food Hydrocoll. 89, 649–660 (2019).

Ji, L., Cornacchia, L., Sala, G. & Scholten, E. Lubrication properties of model dairy beverages: Effect of the characteristics of protein dispersions and emulsions. Food Res. Int. 157, 111209 (2022).

Xiao, J., Gonzalez, A. J. P. & Huang, Q. Kafirin nanoparticles-stabilized Pickering emulsions: Microstructure and rheological behavior. Food Hydrocoll. 54, 30–39 (2016).

Costa, A. L. R., Gomes, A. & Cunha, R. L. One-step ultrasound producing O/W emulsions stabilized by chitosan particles. Food Res. Int. 107, 717–725 (2018).

Acknowledgements

This research was supported by Shiraz University (Grant number 0GCB2M194065).

Author information

Authors and Affiliations

Contributions

M. Nejadmansouri: Formal analysis, Investigation, Writing Original draft, M.H. Eskandari: Validation, Resources, Review & Editing, G.H. Yousefi: Validation, M. Riazi: Writing Original draft, S.M.H. Hosseini: Conceptualization, Resources, Funding, Supervision, Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nejadmansouri, M., Eskandari, M.H., Yousefi, G.H. et al. Promising application of probiotic microorganisms as Pickering emulsions stabilizers. Sci Rep 13, 15915 (2023). https://doi.org/10.1038/s41598-023-43087-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-43087-w

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.