Abstract

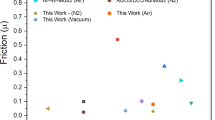

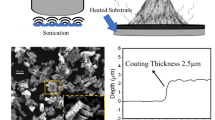

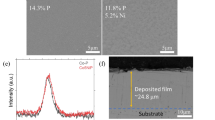

The tribological properties of solid lubricants such as graphite and the metal dichalcogenides MX2 (where M is molybdenum or tungsten and X is sulphur or selenium)1,2,3,4,5,6,7,8,9,10,11,12,13 are of technological interest for reducing wear in circumstances where liquid lubricants are impractical, such as in space technology, ultra-high vacuum or automotive transport. These materials are characterized by weak interatomic interactions (van der Waals forces) between their layered structures, allowing easy, low-strength shearing14,15. Although these materials exhibit excellent friction and wear resistance and extended lifetime in vacuum, their tribological properties remain poor in the presence of humidity or oxygen16,17,18,19, thereby limiting their technological applications in the Earth's atmosphere. But using MX2 in the form of isolated inorganic fullerene-like hollow nanoparticles similar to carbon fullerenes and nanotubes can improve its performance1. Here we show that thin films of hollow MoS2 nanoparticles, deposited by a localized high-pressure arc discharge method, exhibit ultra-low friction (an order of magnitude lower than for sputtered MoS2 thin films) and wear in nitrogen and 45% humidity. We attribute this ‘dry’ behaviour in humid environments to the presence of curved S–Mo–S planes that prevent oxidation and preserve the layered structure.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Rapoport, L. et al. Hollow nanoparticles of WS2 as potential solid-state lubricants. Nature 387, 791– 793 (1997).

Bell, M. E. & Findlay, J. H. Molydenite as a new lubricant. Phys. Rev. 59, 922–927 (1941).

Braithwaite, E. R. & Rowe, G. W. Principles and applications of lubrication with solids. Sci. Lubricat. 15, 92–96 (1957).

Winer, W. O. Molybdenum disulphide as a lubricant: A review of the fundamental knowledge. Wear 10, 422–452 (1967).

Spalvins, T. Lubrication with sputtered MoS2 films. ASLE Trans. 14, 267–271 (1972); Morphological and frictional behavior of sputtered MoS2 films. Thin Solid Films 96, 17– 24 (1982).

Holinski, R. & Gansheimer, J. A study of the lubricating mechanism of molybdenum disulphide. Wear 19, 329– 342 (1972).

Buck, V. Morphological properties of sputtered MoS2 films. Wear 91, 281–288 (1983).

Fleischauer, P. D. & Tolentino, L. U. Effects of crystallite orientation on the environmental stability and lubrication properties of sputtered MoS2 thin films. ASLE Trans. 27, 82–88 (1984).

Roberts, E. W. Thin solid lubricants in space. Tribol. Int. 23, 95–104 (1990).

Miyoshi, K. et al. A vacuum (10-9 Torr) friction apparatus for determining friction and endurance like that of MoSx films. Tribol. Trans. 36, 351–358 (1993).

Suzuki, M. Comparison of tribological characteristics of sputtered MoS2 films coated with different apparatus. Wear 218, 110–118 (1998).

Wang, D. Y., Chang, C. L., Chen, Z. Y. & Ho, W. Y. Microstructural characterization of MoS2-Ti composite solid lubricating films. Surf. Coat. Technol. 121, 629– 635 (1999).

Killeffer, D. H. & Linz, D. Molybdenum Compounds: Their Chemistry and Technology (Interscience, New York, 1952).

Dickinson, R. G. & Pauling, L. The crystal structure of molybdenite. J. Am. Chem. Soc. 45, 1466 –1471 (1923).

Bragg, W. The investigation of the properties of thin films by means of x-rays. Nature 115, 266–269 ( 1925).

Williams, J. A. Engineering Tribology 368–370 (Oxford Univ. Press, 1994).

Savage, R. H. Graphite lubrication. J. Appl. Phys. 19, 1–10 (1948).

Arnell, R. D., Davies, P. B., Halling, J. & Whomes, T. L. Tribology—Principles and Design Applications 105– 107 (Macmillan, London, 1991).

Matsumoto, K. & Suzuki, M. in Proc. Int. Tribology Conf. 1995 1165–1169 (JST, Tokyo, 1996).

Feldman, Y., Wasserman, E., Srolovitz, D. J. & Tenne, R. High-rate, gas-phase growth of MoS2 nested inorganic fullerenes and nanotubes. Science 267, 222– 225 (1995).

Jose-Yacaman, M. et al. Studies of MoS2 structures produced by electron irradiation. Appl. Phys. Lett. 69, 1065– 1067 (1996).

Amaratunga, G. A. J. et al. Hard elastic carbon thin films from linking of carbon nanoparticles. Nature 383, 321–323 (1996).

Chhowalla, M., Aharanov, R. A., Kiely, C. J., Alexandrou, I. A. & Amaratunga, G. A. J. Generation and deposition of fullerene- and nanotube-rich carbon thin films. Phil. Mag. Lett. 75, 329–335 ( 1997).

Srolovitz, D. J., Safran, S. A., Homyonfer, M. & Tenne, R. Morphology of nested fullerenes. Phys. Rev. Lett. 74 , 1779–1782 (1995).

Bilek, M. M. M., Martin, P. J. & McKenzie, D. R. Influence of gas pressure and cathode composition on ion energy distributions in filtered vacuum arcs. J. Appl. Phys. 83, 2965–2970 ( 1998).

Dunn, D. N., Seitzman, L. E. & Singer, I. L. The origin of anomalous low (0002) peak in x-ray diffraction spectra of MoS2 films grown by ion beam assisted deposition (IBAD). J. Mater. Res. 12, 1191– 1194 (1997).

Westergard, R. & Axén, N. Tribologia—Finn. J. Tribol. 17, 14–18 ( 1998).

Mattern, N., Hermann, H., Weise, G., Teresiak, A. & Bauer, H. D. Structure and properties of MoS2 films. Mater. Sci. Forum 235–238, 613– 618 (1997).

Dunn, D. N., Seitzman, L. E. & Singer, I. L. MoS2 deposited by ion beam assisted deposition: 2H or random layer structure? J. Mater. Res. 13, 3001–3007 (1998).

Fox, V. C., Renevier, N., Teer, D. G., Hampshire, J. & Rigato, V. The structure of tribologically improved MoS2-metal composite coatings and their industrial applications. Surf. Coat. Technol. 119, 492– 497 (1999).

Acknowledgements

We thank R. Aharonov for general assistance and advice, and J. A. Williams for discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chhowalla, M., Amaratunga, G. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 407, 164–167 (2000). https://doi.org/10.1038/35025020

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/35025020

This article is cited by

-

Influence of Different Neutral Gas Irradiation in Low Earth Orbit on the Structure and Tribological Performance of WS2 Films

Tribology Letters (2024)

-

Graphene-enhanced silver composites for electrical contacts: a review

Journal of Materials Science (2024)

-

Macro-superlubricity in sputtered MoS2-based films by decreasing edge pinning effect

Friction (2024)

-

Deposition of ultra-thin coatings by a nature-inspired Spray-on-Screen technology

Communications Engineering (2023)

-

Electrospun Flexible Nanofibres for Batteries: Design and Application

Electrochemical Energy Reviews (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.