Abstract

Silver nanowires (AgNWs) networks are promising candidates for the replacement of indium tin oxide (ITO). However, the surface roughness of the AgNWs network is still too high for its application in optoelectronic devices. In this work, we have reduced the surface roughness of the AgNWs networks to 6.4 nm, compared to 33.9 nm of the as-deposited AgNWs network through the hot-pressing process, treatment with poly (3,4ethylenedioxythiophene)–poly (styrenesulfanate), and covered with graphene films. Using this method, we are able to produce AgNWs/PEDOT: PSS/SLG composite films with the transmittance and sheet resistance of 88.29% and 30 Ω/□, respectively. The OLEDs based on the AgNWs/PEDOT: PSS/SLG anodes are comparable to those based on ITO anodes.

Similar content being viewed by others

Introduction

Transparent conducting electrodes play an important role in large-area optoelectronic devices such as organic light-emitting diodes (OLED), solar cells and so on1,2,3,4,5. The prevailing material used in OLED electrodes is Tin-doped indium oxide (ITO) which has excellent photoelectric properties such as high optical transmittance and low sheet resistance6,7. However, ITO electrodes have some disadvantages such as high cost due to the shortage of indium and the diffusion of indium element into the light-emitting layer8. Therefore, it is necessary to explore new materials that can be applied in the transparent conductive anode in OLED. To replace ITO in transparent conducting electrodes, promising candidates include silver nanowires (AgNWs)9,10,11,12 and graphene13,14,15,16 which can provide both excellence electrical and optical performances, but they also have their own disadvantages. For example, the surface roughness of AgNWs network is relatively high due to the AgNWs junctions17, and it is well known that the resistance of single-layer graphene prepared by chemical vapor deposition (CVD) without doping is larger than 450 Ω/sq in general because of the existence of grain boundaries in polycrystalline graphene18,19. Q. Q Zhuo et al.20 reported that they used the direct production of graphene on substrates without transfer as the anode to fabricate OLEDs. Because the sheet resistance of N-doped graphene is still too high, it is difficult to obtain a good performance of the OLEDs only with graphene film as anode. In order to avoid these shortages, Saewon Kang et al.21 reported that they introduced a capillary printing technique to precisely control the nanowire alignment and the percolation behavior of the AgNWs network. The surface roughness (Rq) could be decreased from 33.9 nm to 15.6 nm. Moreover, they utilized the AgNWs/PEDOT: PSS composite transparent conductive film as OLED anodes to fabricate OLED devices with high luminous efficiency.

Although the nanowire entanglement issue for high-aspect-ratio AgNWs needs to be addressed, it shows great potential as the anodes of the OLEDs. Pei et al.22 recently reported that they used graphene oxide (GO) to wrap around and solder the AgNWs junctions to enhance the combination and reduce the square resistance. The composite membrane has excellent photoelectric properties, but the performance of the AgNWs/GO-based OLED devices is not satisfactory due to the high Rq of the composite film. In this work, we fabricated AgNWs/PEDOT: PSS/SLG (single-layer graphene) composite transparent conductive films with a low sheet resistance of 30 ± 5 Ω/sq and high optical transmittance above 87% in the visible spectrum. With the hot-press process, the surface roughness of the AgNWs network could be decreased from 33.9 nm to 9.5 nm, the surface wettability of AgNWs network was improve after the treatment of TiO2 sol coating. Furthermore, the surface roughness of the AgNWs network can be reduced to 6.4 nm with the cover of PEDOT: PSS. The AgNWs/PEDOT: PSS/Graphene composite transparent conductive films can be used as a great candidate to replace conventional ITO in large-area optoelectronic devices such as solar cells and touch panels.

Results and Discussion

The procedure used to prepare the AgNWs/PEDOT: PSS/SLG composite transparent conductive film is schematically illustrated in Fig. 1.

Characterization of the AgNWs films

In order to explore the relationship between the sheet resistance and transmittance of the AgNWs network, we have prepared a series of films using AgNWs solution with different concentrations of 6, 4.5 and 3 mg/ml scraping coated onto quartz glass substrates. Figure 2 displays the SEM of the AgNWs network with different AgNWs densities, we can see that the transparency and sheet resistance increase with decreasing AgNWs density due to the overlapping lines. Lee et al. also reported the similar AgNWs network23. Considering the balance between high transparency and low sheet resistance, we chose the AgNWs network prepared with 3 mg/ml AgNWs solution for further processing.

Although the AgNWs network has excellence conductivity and transparency comparable to ITO, its high surface roughness cannot fulfill the application requirements of OLEDs anodes. Thus, we use the hot-press process to reduce the surface roughness. The surface morphology of the AgNWs networks on the quartz glass substrate was measured by SEM and AFM, as shown in Figs 3 and 4. After hot-pressed at 150 °C, the surface roughness of the AgNWs network on the glass is 33.9 nm, which is still too high to be suitable for OLEDs. The roughness of the AgNWs network decreased to 9.5 nm after the hot press process at 200 °C, the AgNWs at junctions change from overlap state to self-welding state, as shown in Fig. 3(b), which could be due to self-limited welding or via Rayleigh instability as suggested by Garnett et al.24. It has indicated that hot press at 200 °C can strongly enhanced surface smoothness of the AgNWs network, and a similar effect was observed by Sahin Coskun et al. for annealing treatment with AgNWs network25. Further increasing the hot press temperature to 250 °C, we found that fractures occurred at the junction of the AgNWs, as shown in Fig. 3(c), leading to a decrease of the number of junctions and current transport paths. It is well known that PEDOT: PSS with good photoelectric property and high work function (5.1 eV–5.2 eV) is usually used as a hole transporting layer in organic optoelectronic devices26. We used PEDOT: PSS to reduce the roughness of the composite films, and the surface roughness of the composite film was decreased to 6.4 nm, as shown in Fig. 4(c). Figure 4(d–f) show the 3D display corresponding to Fig. 4(a–c), and it can be more intuitive to see the change of the roughness. Song et al. reported that they improved the characteristics of the AgNWs network through a process of irradiating it with intense pulsed light (IPL)27. The surface roughness of the AgNWs/PEDOT: PSS composite film treated with IPL can reach 5.9 nm. However, it is similar with the AgNWs/PEDOT: PSS composite film treated with hot-press process.

Hydrophilic control of the AgNWs films

It is difficult to cover the PEDOT: PSS aqueous dispersion on the AgNWs surface after hot press with good uniformity due to the poor hydrophilicity of the AgNWs network. A sol–gel TiO2 solutions were spin-coated on the AgNWs network to improve the surface wettability of the AgNWs films. Figure 5(a) shows the contact angles of the AgNWs networks after the sol–gel TiO2 solutions treatment with different concentrations. With the increasing concentration of the sol–gel TiO2 solutions, the contact angle was decreased from 89.25° to 53.41°, which suggests an improved hydrophily of the AgNWs network for the further deposition of PEDOT: PSS on the surface.

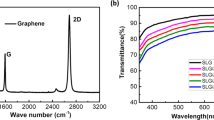

(a) Contact angles of the AgNWs network surfaces with different concentrations of the TiO2 sol treatment. (b) Raman spectrum and TEM image of a single-layer graphene. (c) Transmittance spectra of the ITO, single-layer graphene, AgNWs network, AgNWs/PEDOT: PSS, AgNWs/PEDOT: PSS/graphene and their sheet resistances.

Characterization of the AgNWs/PEDOT: PSS/SLG composite film

To further reduce the sheet resistance of the AgNWs/PEDOT: PSS films and improve the carrier mobility of the composite films, we use graphene films transferred to the surface of the composite film. Figure 5(b) shows the Raman spectrum of the graphene film to verify the number of the graphene layers. The sharp peaks at 1590 cm−1 and 2680 cm−1 are corresponding to the G band and 2D band of graphene, respectively28. From the TEM of the graphene film, we can see that it has only a single set of diffraction pattern for a regular hexagon. The intensity ratio of 2D band to G band is 1.9, and the weak peak (D band) at 1352 cm−1 shows a high crystalline quality of the single-layer graphene film29. Figure 5(c) shows the transmittance of the AgNWs network, SLG film, AgNWs/PEDOT: PSS film, AgNWs/PEDOT: PSS/SLG composite film and the reference ITO film as a function of wavelength in the range of 300–1100 nm. The transmittance of the AgNWs/PEDOT: PSS/SLG composite film and ITO at 550 nm is 88.29% and 85.56%, respectively. Particularly, the AgNWs/PEDOT: PSS/SLG composite film exhibits higher transmittance than that of the reference ITO in the range of 500–1100 nm. The sheet resistances of the AgNWs/PEDOT: PSS/SLG composite film and AgNWs/PEDOT: PSS composite film reach 30 Ω/□ and 40 Ω/□, slightly higher than that of ITO, which suggests that the AgNWs/PEDOT: PSS/SLG composite film is suitable for the application in OLEDs. The thicknesses of the AgNWs/PEDOT: PSS/SLG composite films and AgNWs/PEDOT: PSS composite films were in the range of 50–100 nm.

Characterization of the OLEDs

The OLEDs based on the AgNWs/PEDOT: PSS/SLG and AgNWs/PEDOT: PSS composite film anodes were fabricated. The OLEDs based on the ITO anodes were also fabricated for comparison. The OLEDs have the structure of anode/NPB (60 nm)/Alq3 (60 nm)/LiF (1 nm)/Al (80 nm). Figure 6(a,b) show the current density–voltage characteristics and the luminance–voltage characteristics of the devices respectively, in which the current density and luminance at each specific drive voltage of the AgNWs/PEDOT: PSS/SLG and AgNWs/PEDOT: PSS composite films based devices exhibit a little lower value than those of the ITO based device. These devices based on the AgNWs/PEDOT: PSS and AgNWs/PEDOT: PSS/SLG films show a higher turn-on voltage of 4.4 V than those of the ITO based device (3.8 V). Figure 6(c) shows that the device based on the AgNWs/PEDOT: PSS anode exhibit a current efficiency (CE) of 1.64 cd/A measured at 200 mA/cm2, which were comparable to the CE of 1.78 cd/A at 200 mA/cm2 of the device based on the AgNWs/PEDOT: PSS/SLG anode. But the CE of the two devices are lower than those of the ITO based device which shows the CE of 2.68 cd/A measured at 200 mA/cm2. It is due to the higher sheet resistances of the AgNWs/PEDOT: PSS/SLG (~30 Ω/□) and AgNWs/PEDOT: PSS (~40 Ω/□) composite films than ITO (~15 Ω/□). Figure 6(d) shows the electroluminescence (EL) spectrum of these OLED devices at 10 V. The OLEDs based on AgNWs/PEDOT: PSS, AgNWs/PEDOT: PSS/SLG and ITO anode exhibited typical green electroluminescence from Alq3 with the CIE (Commission Internationale de l’Eclairage) coordinates of (0.32, 0.53), (0.32, 0.53) and (0.32, 0.51). It is obviously that the emitting light colors tend to be consistent and the influence of the different transmittances of the diverse anodes can be ignored.

Conclusions

In conclusion, we have developed the AgNWs/PEDOT: PSS (~40 Ω/□, T550nm~91.04%) and AgNWs/PEDOT: PSS/SLG (~30 Ω/□, T550nm~88.29%) transparent conductive films with high transmittance, good conductivity and lower surface roughness. By a simple hot-pressing process, the roughness of the AgNWs network decreased from 33.9 nm to 9.5 nm. Further covered with PEDOT: PSS, which is readily used for the hole transport layer or hole injection layer in OLEDs, reduced the surface roughness to 6.4 nm. We have also demonstrated that the AgNWs network can be used as the transparent and conductive anodes in OLEDs. The performance of the device based on the AgNWs/PEDOT: PSS/SLG films is higher than the device based on the AgNWs/PEDOT: PSS films due to the contribution of graphene. These results suggest that the AgNWs/PEDOT: PSS/SLG film is a promising candidate as the transparent conductive electrode in optoelectronic devices.

Experimental Procedures

Preparation of AgNWs/PEDOT: PSS/SLG composite films

First, a quartz glass substrate (23 × 23 mm2) was cleaned with de-ionized water, acetone, and isopropanol.

Preparation of the AgNWs network

The AgNWs (50 nm in diameter and 100–200 μm in length, XFNANO, China) dispersed in isopropyl alcohol with different concentrations was scraping coated onto the quartz glass substrate and annealed at 120 °C for 10 min before hot-pressing.

Hot-press process

The sample was placed on the bearing platform of the imprinting equipment (NC-AX1401, Nano Carve), which was covered with a PI film (25 μm). The pressure of 0.3–1 MPa was applied between the top substrate and the PI film in the imprinting chamber with different heating temperatures to achieve non-contact hot-pressing.

Hydrophilic treatment

The TiO2 solution was prepared by an ordinary method30. TiO2 sol–gel solution was spin-coated on the AgNWs network for 30 s at 6000 rpm to make it hydrophilic and annealed at 150 °C for 10 min. Then PEDOT: PSS (Clevios PH 1000, Heraeus) was spin-coated on the AgNWs network.

Graphene growth and transfer

The SLG films were synthesized by CVD on a 25 μm polishing copper foil (99.999%, Alpha). Before growth, the foils were annealed at 1000 °C in H2 atmosphere for 5 min. Then, the source gas CH4 was infused with a flow rate of 0.5–3 sccm while keeping the same temperature for 3–10 min. Finally, the copper foils were rapidly cooled to room temperature. The graphene films were transferred to the surface of the AgNWs/PEDOT: PSS film to form the AgNWs/PEDOT: PSS/SLG composite film by a typical method26.

Fabrication and measurement of OLEDs

The AgNWs/PEDOT: PSS/SLG composite film based anodes were patterned by photolithography technology and etching. OLED devices were fabricated with a structure of AgNWs/PEDOT: PSS/SLG/N, N ′- diphenyl - N, N′ - bis (1 - naphthyl) - (1, 1 ′- biphenyl) - 4, 4′ - diamin (NPB) (60 nm)/tris-(8-hydroxyquinoline) aluminium (Alq3) (60 nm)/LiF (1 nm)/Al (80 nm), where NPB was used as the hole-transporting material, Alq3 was used as both the host material and the electron-transporting material, and LiF (lithium fluoride) and Al were used as the electron-injecting material and the cathode material respectively.

To characterize the composite films, field-emission scanning electron microscope (SEM, FEI Quanta 600), transmission electron microscope, and atomic force microscope (NT-MDT) were used to examine the surface morphology. Raman measurements were performed using Thermo Scientific DXR Raman microscope spectrometer with a laser wavelength of 532 nm at room temperature. For sheet resistance measurements, we used a semiconductor analyzer (Agilent, B1500A) combined with a four-probe station (CASCADE, alessi REL-4800). The optical transmittance in the wavelength range of 300–1100 nm was obtained by a PV Measurements QEX10. The current–voltage (I–V) characteristics of the fabricated OLEDs were measured with an experimental set-up including a Keithley 2400 source meter. A spectroradiometer (PR750) was also employed to measure the electroluminescence spectrum of the 3 × 3 mm2 emitting area of the devices. The reference OLEDs with the same layer structures, except the AgNWs/PEDOT: PSS/SLG composite film was replaced by a conventional ITO layer (15 Ω/sq), were also fabricated for comparison.

Additional Information

How to cite this article: Xu, Y. et al. Silver Nanowires Modified with PEDOT: PSS and Graphene for Organic Light-Emitting Diodes Anode. Sci. Rep. 7, 45392; doi: 10.1038/srep45392 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Du, J., Pei, S., Ma, L. & Cheng, H. M. 25th anniversary article: carbon nanotube- and graphene-based transparent conductive films for optoelectronic devices. Advanced materials 26, 1958–1991, doi: 10.1002/adma.201304135 (2014).

Langley, D. et al. Flexible transparent conductive materials based on silver nanowire networks: a review. Nanotechnology 24, 452001, doi: 10.1088/0957-4484/24/45/452001 (2013).

Liu, S., Ho, S. & So, F. Novel Patterning Method for Silver Nanowire Electrodes for Thermal-Evaporated Organic Light Emitting Diodes. ACS applied materials & interfaces 8, 9268–9274, doi: 10.1021/acsami.6b00719 (2016).

Zhu, Z. et al. Ultrahigh Aspect Ratio Copper-Nanowire-Based Hybrid Transparent Conductive Electrodes with PEDOT:PSS and Reduced Graphene Oxide Exhibiting Reduced Surface Roughness and Improved Stability. ACS applied materials & interfaces 7, 16223–16230, doi: 10.1021/acsami.5b01379 (2015).

Xu, L. H. et al. Microcavity-Free Broadband Light Outcoupling Enhancement in Flexible Organic Light-Emitting Diodes with Nanostructured Transparent Metal-Dielectric Composite Electrodes. ACS nano 10, 1625–1632, doi: 10.1021/acsnano.5b07302 (2016).

Yoo, J. H. et al. Silver Nanowire-Conducting Polymer-ITO Hybrids for Flexible and Transparent Conductive Electrodes with Excellent Durability. ACS applied materials & interfaces 7, 15928–15934, doi: 10.1021/acsami.5b03855 (2015).

Wang, Y., Tong, S. W., Xu, X. F., Ozyilmaz, B. & Loh, K. P. Interface engineering of layer-by-layer stacked graphene anodes for high-performance organic solar cells. Advanced materials 23, 1514–1518, doi: 10.1002/adma.201003673 (2011).

Hecht, D. S., Hu, L. & Irvin, G. Emerging transparent electrodes based on thin films of carbon nanotubes, graphene, and metallic nanostructures. Advanced materials 23, 1482–1513, doi: 10.1002/adma.201003188 (2011).

Cheong, H.-G., Song, D.-W. & Park, J.-W. Transparent film heaters with highly enhanced thermal efficiency using silver nanowires and metal/metal-oxide blankets. Microelectronic Engineering 146, 11–18, doi: 10.1016/j.mee.2015.02.029 (2015).

Shin, D., Kim, T., Ahn, B. T. & Han, S. M. Solution-Processed Ag Nanowires + PEDOT:PSS Hybrid Electrode for Cu(In,Ga)Ssf2) Thin-Film Solar Cells. ACS applied materials & interfaces 7, 13557–13563, doi: 10.1021/acsami.5b02989 (2015).

Jing, M.-X., Li, M., Chen, C.-Y., Wang, Z. & Shen, X.-Q . Highly bendable, transparent, and conductive AgNWs-PET films fabricated via transfer-printing and second pressing technique. Journal of Materials Science 50, 6437–6443, doi: 10.1007/s10853-015-9198-3 (2015).

Li, B., Ye, S., Stewart, I. E., Alvarez, S. & Wiley, B. J. Synthesis and Purification of Silver Nanowires To Make Conducting Films with a Transmittance of 99. Nano letters 15, 6722–6726, doi: 10.1021/acs.nanolett.5b02582 (2015).

Zhu, X.-Z. et al. The application of single-layer graphene modified with solution-processed TiOx and PEDOT:PSS as a transparent conductive anode in organic light-emitting diodes. Organic Electronics 14, 3348–3354, doi: 10.1016/j.orgel.2013.10.003 (2013).

Tsai, L. W. & Tai, N. H. Enhancing the electrical properties of a flexible transparent graphene-based field-effect transistor using electropolished copper foil for graphene growth. ACS applied materials & interfaces 6, 10489–10496, doi: 10.1021/am502020s (2014).

Park, H., Brown, P. R., Bulovic, V. & Kong, J. Graphene as transparent conducting electrodes in organic photovoltaics: studies in graphene morphology, hole transporting layers, and counter electrodes. Nano letters 12, 133–140, doi: 10.1021/nl2029859 (2012).

Miao, X. et al. High efficiency graphene solar cells by chemical doping. Nano letters 12, 2745–2750, doi: 10.1021/nl204414u (2012).

Cui, H.-F., Zhang, Y.-F. & Li, C.-N. Flexible organic light-emitting devices with a smooth and transparent silver nanowire electrode. Optical Engineering 53, 077102, doi: 10.1117/1.oe.53.7.077102 (2014).

Kumar, Akshay et al. The race to replace tin-doped indium oxide: which material will win. ACS nano 4, 11–14 (2010).

Han, Y. et al. Clean surface transfer of graphene films via an effective sandwich method for organic light-emitting diode applications. J. Mater. Chem. C 2, 201–207, doi: 10.1039/c3tc31722f (2014).

Liang, J.-J. et al. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS nano 8, 1590–1600 (2014).

Kang, S. et al. Capillary Printing of Highly Aligned Silver Nanowire Transparent Electrodes for High-Performance Optoelectronic Devices. Nano letters 15, 7933–7942, doi: 10.1021/acs.nanolett.5b03019 (2015).

Liang, J.-J. et al. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS nano 8, 1590–1600 (2014).

Lee, H. et al. Highly efficient and low voltage silver nanowire-based OLEDs employing a n-type hole injection layer. Nanoscale 6, 8565–8570, doi: 10.1039/c4nr01768d (2014).

Garnett, E. C. et al. Self-limited plasmonic welding of silver nanowire junctions. Nature materials 11, 241–249, doi: 10.1038/nmat3238 (2012).

Coskun, S., Selen Ates, E. & Unalan, H. E. Optimization of silver nanowire networks for polymer light emitting diode electrodes. Nanotechnology 24, 125202, doi: 10.1088/0957-4484/24/12/125202 (2013).

Liu, Y.-F. et al. Improved efficiency of indium-tin-oxide-free organic light-emitting devices using PEDOT:PSS/graphene oxide composite anode. Organic Electronics 26, 81–85, doi: 10.1016/j.orgel.2015.06.031 (2015).

Song, C.-H. et al. Intense-pulsed-light irradiation of Ag nanowire-based transparent electrodes for use in flexible organic light emitting diodes. Organic Electronics 17, 208–215, doi: 10.1016/j.orgel.2014.12.015 (2015).

Deng, B. et al. Roll-to-Roll Encapsulation of Metal Nanowires between Graphene and Plastic Substrate for High-Performance Flexible Transparent Electrodes. Nano letters 15, 4206–4213, doi: 10.1021/acs.nanolett.5b01531 (2015).

Xie, C. et al. Schottky solar cells based on graphene nanoribbon/multiple silicon nanowires junctions. Applied Physics Letters 100, 193103, doi: 10.1063/1.4711205 (2012).

Wang, J. et al. Pseudocapacitive contributions to electrochemical energy storage in TiO2(anatase). J. Phys. Chem. C. 111, 14925–14931 (2007).

Acknowledgements

This research was supported by Science & Technology Commission of Shanghai Municipality (13DZ1106000), Shanghai Sai-ling Program (15YF1413200), and the CAS/SAFEA International Partnership Program for Creative Research Teams.

Author information

Authors and Affiliations

Contributions

Yilin Xu and Xiaohong Fang designed the experiments and analyzed the data. Yilin Xu and Cong Wang prepared the manuscript. Xiang Wei and Jin Cao prepared the fabrication of the OLEDs. Yigang Chen, Zhongquan Ma and Xiaoyuan Chen supervised the project and led the overall effort. Yilin Xu, Ying You and Jixiang Wan prepared the samples and carried out the characterization of AgNWs/PEDOT: PSS/SLG composites film. All authors discussed the experimental results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Xu, Y., Wei, X., Wang, C. et al. Silver Nanowires Modified with PEDOT: PSS and Graphene for Organic Light-Emitting Diodes Anode. Sci Rep 7, 45392 (2017). https://doi.org/10.1038/srep45392

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep45392

This article is cited by

-

Flexible, transparent patterned electrodes based on graphene oxide/silver nanowire nanocomposites fabricated utilizing an accelerated ultraviolet/ozone process to control silver nanowire degradation

Scientific Reports (2019)

-

Functional Printing of Conductive Silver-Nanowire Photopolymer Composites

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.