Abstract

Rational design of high efficient and low cost electrocatalysts for oxygen evolution reaction (OER) plays an important role in water splitting. Herein, a general gelatin-assisted wet chemistry method is employed to fabricate well-defined iron oxy-hydroxides and transitional metal doped iron oxy-hydroxides nanomaterials, which show good catalytic performances for OER. Specifically, the Co-doped iron oxy-hydroxides (Co0.54Fe0.46OOH) show the excellent electrocatalytic performance for OER with an onset potential of 1.52 V, tafel slope of 47 mV/dec and outstanding stability. The ultrahigh oxygen evolution activity and strong durability, with superior performance in comparison to the pure iron oxy-hydroxide (FeOOH) catalysts, originate from the branch structure of Co0.54Fe0.46OOH on its surface so as to provide many active edge sites, enhanced mass/charge transport capability, easy release oxygen gas bubbles, and strong structural stability, which are advantageous for OER. Meanwhile, Co-doping in FeOOH nanostructures constitutes a desirable four-electron pathway for reversible oxygen evolution and reduction, which is potentially useful for rechargeable metal−air batteries, regenerative fuel cells, and other important clean energy devices. This work may provide a new insight into constructing the promising water oxidation catalysts for practical clean energy application.

Similar content being viewed by others

Introduction

Nowadays, the urgent demands of clean energy have been stirred up in the exploration of sustainable energy production with high efficiency, low cost, and environmental benignity1,2,3,4. Water splitting, which could develop energy storage and conversion devices, has been recognized as one of the key technological candidates to meet the ever-growing sustainable energy demands. However, the efficiency of economical water splitting is under restriction mostly due to the high overpotential interrelated to the occurrence of oxygen evolution reaction (OER). Despite of recent advances in the utilization of various nanostructured catalysts, such as commonly used noble metal Ru and Ir-based nanocatalysts, the exploration of novel catalysts with low cost and high activities to enhance the OER efficiency still remains a big challenge.

In the past few decades, many efforts have been made to solve this challenge by using transitional metals with low cost such as Fe, Co and Ni-based catalysts to substitute noble metal nanocatalysts to expedite OER efficiency5,6. Recently, as one of the most important transitional-metal-based nanocatalysts ion oxy-hydroxides (FeOOH) with open structure, low cost, natural abundance, and environmental friendliness of iron7 have been gradually acknowledged and further explored for OER application8,9. However, the poor electrical conductivity of the FeOOH (~10−5 S cm−1) remains a major challenge and limits its mass-transfer kinetics8. Thus, recently, some studies have tried to address this issue by forming hybrid FeOOH nanomaterials10,11,12. Among them, Co doping in FeOOH nanostructure had shown excellent OER performance, because the Co ions could improve electron transfer thus enhance the electrical conductivity13. However, in the above cases, fabricate of high-quality FeOOH and Co-doped FeOOH nanostructures with pure phase, monodisperse and well-defined morphology, have not been demonstrated, which stimulate the continuous and systematic exploration.

Gelatin as a water-soluble collagen, consisting of N-H functional groups, possesses many advantages to form inorganic-organic template for manipulating the growth of inorganic nanomaterials with diverse novel structures14,15,16. Particularly, the molecule of gelatin is composed of periodic repetitions of amino acid sequences, i.e. glycine-proline-hydroxyproline segments, where the constituent N-H functional groups trend to interact strongly with metal ions via multiple nitrogen coordination reactions17,18,19,20,21.

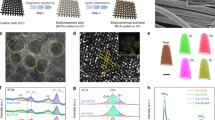

Owing to gelatin’s unique structural features and tunable properties, in the present work, we chose gelatin as the soft-template to synthesize high-quality FeOOH and Co-doped FeOOH nanostructures (CoxFe1−xOOH (x = 0.23, 0.54, 0.77)) (Fig. 1). The Co0.54Fe0.46OOH hybrid had lower onset potential of 1.52 V, lower overpotential of 390 mV at current density of 10 mA/cm2, smaller tafel slope of 47 mV/dec and fairly longer time stability of 25000 s than other contrast catalysts, which can be attributed to more active edge sites, enhanced mass/charge transport capability and strong structural stability of the Co0.54Fe0.46OOH hybrid.

Results

Morphologies of FeOOH nanostructures

The morphologies of FeOOH nanostructures were characterized by transmission electron microscopy (TEM) and high-angle annular dark field-scanning transmission electron microscopy (HAADF-STEM). Based on the TEM and HAADF-STEM results, three different morphologies of FeOOH nanostructures with high morphological yields were harvested22. Figure 2(a) and (b) show the TEM and HAADF-STEM images of urchin-like FeOOH (termed as FeOOH1) nanostructure. Numerous nanorods, with the average size of ~500 ± 100 nm in length and ~50 ± 10 nm in width, were integrated together to form such three dimensional (3D) hierarchical structures. A digital photo (inset of Fig. 2(b) demonstrates that the FeOOH1 nanostructures were readily dispersed and highly stable in absolute ethanol. Similarly, Fig. 2(c) and (d) exhibit the bowknot-like FeOOH (termed as FeOOH2) nanostructure with the average size of ~700 nm ± 100 nm in length and ~100 nm ± 50 nm in width at the knot position. Figure 2(e) and (f) depict the bamboo leaf-like FeOOH (termed as FeOOH3) nanostructure with the average size of ~500 nm ± 100 nm in length and ~50 nm ± 10 nm in width. Meanwhile, the insets of Fig. 2d and f show the digital photos of FeOOH2 and FeOOH3 nanostructures dispersed in absolute ethanol for more than 1 week, also demonstrating the high stability and dispersibility of FeOOH nanostructures.

XRD analysis of FeOOH nanostructures

The powder X-ray diffraction (XRD) patterns of FeOOH nanostructures are shown in Fig. 3(a). As indicated in Fig. 3(a), the XRD patterns of FeOOH nanostructures (FeOOH1, FeOOH2 and FeOOH3) were all indexed to a tetragonal phase of Akaganeite (JCPDS: 34–1266, space group: I4/m) with lattice constants: a = b = 10.54 Å, c = 3.03 Å, V = 336.29 Å3. Additionally, the broadening of the diffraction peaks suggested the samples were nanocrystalline nature. To study the chemical state of FeOOH nanostructures, the X-ray photoelectron spectroscopy (XPS) analysis is shown in Fig. 3(b) and Fig. S1 in the Supplementary Information. Figure 3(b) illustrates the Fe 2p XPS signals of FeOOH nanostructures, and the peaks located at 711.00 eV and 724.70 eV were ascribed to the core levels of Fe 2p3/2 and Fe 2p1/2 of FeOOH, respectively. Shakeup satellites located at 718.90 and 733.40 indicating the presence of trivalent Fe in FeOOH samples22. The above results suggested that the oxidation states of iron ions are mainly trivalent for the FeOOH nanostructures, which is also in accord with the result of XRD characterization.

Structure and composition of Co0.54Fe0.46OOH nanostructures

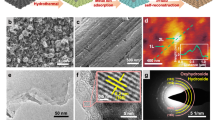

Specifically, metal oxy-hydroxide compound is an important semiconducting material with unique electrochemical properties23,24,25. As a proof of conception application, our FeOOH samples with diverse nanostructures were used for OER catalyst application (Fig. 1). Meanwhile, recent studies showed that the doping of transitional metals, such as Co doped into oxy-hydroxide based OER catalysts can improve electron transfer, reduce tafel slope, and increase electric conductivity, thus enhancing the OER performances26. Herein, we employed the gelatin-assisted wet chemistry method to obtain Co doped FeOOH nanocatalysts (CoxFe1−xOOH) and investigated their OER performances. Based on our study, the Co0.54Fe0.46OOH (x = 0.54) had the highest OER catalytic activity.

The XRD patterns of Co doped FeOOH nanomaterials are shown in Fig. 4(a) and Fig. S2 in the Supplementary Information. The main peaks of Co0.54Fe0.46OOH were similar to the pure FeOOH, suggesting that there were no phase transformation after Co doping. The elements species of Co0.54Fe0.46OOH nanostructure were tested by energy-dispersive X-ray spectrum (EDS conducted at three different areas of the sample), confirming Co element was present in the FeOOH nanostructure (Fig. 4(b) and Fig. S3 in the Supplementary Information), and the peaks of Cl element would originate from the Cl species located in the hollandite channels of the FeOOH27. The atomic ratios of metals in CoxFe1−xOOH (x = 0.23, 0.54, 0.77) nanostructures were determined by inductively coupled plasma atomic emission spectroscopy (ICP-AES) measurements (Table S1 in the Supplementary Information).

TEM and HAADF-STEM characterizations were employed to investigate the morphology and size of Co doped FeOOH nanomaterials (Fig. 5(a,b) and Fig. S4 in the Supplementary Information). As shown in Fig. 5(a) and (b), the rod-like Co0.54Fe0.46OOH nanostructures were of the average size of ~700 nm ± 100 nm in length and ~100 nm ± 50 nm in width. The SAED pattern (inset of Fig. 5(a)) revealed the Co0.54Fe0.46OOH nanostructures were of highly crystalline nature. The digital photo in inset of Fig. 5(b) depicts the Co0.54Fe0.46OOH nanostructures were readily dispersed and highly stable in absolute ethanol. The morphology difference between CoxFe1−xOOH and pure FeOOH nanostructures may be due to the presence of Co which could regulate the morphology of FeOOH nanostructures28.

OER electrocatalytic activity of Co0.54Fe0.46OOH nanostructures

To investigate the OER catalytic behavior of FeOOH nanostructures, the electrochemical activity of FeOOH1, FeOOH2, FeOOH3, Co0.54Fe0.46OOH nanomaterials were evaluated based on the above optimized conditions (rotation rate: 1600 rpm in O2 saturated 100 mM KOH solution) for the OER performances. For linear sweep voltammetry (LSV) and cyclic voltammograms (CV) curves of studied materials, the ohmic potential drop (iR)29 losses arising from the solution resistance were corrected (Fig. 6(a–f) and Fig. S5(a,b) in the Supplementary Information). LSV curves were shown in Fig. 6(a). In contrast, among the FeOOH nanomaterials, Co0.54Fe0.46OOH exhibited the excellent OER activity with an onset potential of 1.52 V and a sharp rise of the anodic current at the further positive potential, suggesting it’s highly electrocatalytic activity toward OER.

(a) Linear Sweep Voltammetry (LSV) of FeOOH1, FeOOH2, FeOOH3, Co0.54Fe0.66OOH electrode catalysts (The dotteikd lines as reference lines in the Fig. 6). The measurements were carried out with Rotating Disk Electrode (RDE) (loading ∼0.2 mg/cm2) at rotation rate of 1600 rpm in O2 saturated 100 mM KOH solution at pH = 13. (b) Tafel plots (log j-η) of FeOOH1, FeOOH2, FeOOH3, and Co0.54Fe0.46OOH electrodes. (c) Comparison of the Tafel slopes, onset potentials and over potentials required to reach a current density of 10 mA/cm2 for FeOOH1, FeOOH2, FeOOH3, and Co0.54Fe0.46OOH electrodes. (d) Chronoamperometric measurement for Co0.54Fe0.46OOH electrode at a fixed applied potential of 1.62 (vs. RHE) for 25000 s. Insets in Fig. 6d: (right) LSV for Co0.54Fe0.46OOH electrode before and after 1000 CV cycles between 1.16 V and 1.96 V at a scan rate of 250 mV/s; (left) an optical photograph of the Co0.54Fe0.46OOH on the GC electrode during the scans, indicating the production of many O2 bubbles on the electrode surface. (e) Ring current of Co0.54Fe0.46OOH on a Rotating Ring-Disk Electrode (RRDE) at a rotation rate of 1600 rpm in O2 saturated 100 mM KOH solution at pH = 13 (ring potential 1.50 V). (f) Ring current of Co0.54Fe0.46OOH on an RRDE at a rotation rate of 1600 rpm in O2 saturated 100 mM KOH solution at pH = 13 (ring potential 0.40 V).

In addition, we also learned about the catalyst properties for different ratio of Co doped nanomaterials under the same conditions (rotation rate: 1600 rpm in O2 saturated 100 mM KOH solution), where different ratio of Co doped nanomaterials showed different catalytic activities, among them, Co0.54Fe0.46OOH had the highest OER catalytic activities (Fig. S5(b) in the Supplementary Information). Importantly, the overpotential of Co0.54Fe0.46OOH was 390 mV (at a current density of 10 mA/cm2), which was lower than those of FeOOH1 (750 mV), FeOOH2 (530 mV), FeOOH3 (630 mV) electrodes. Notably, in comparison with the behavior of most metal oxy-hydroxide nanomaterials in alkaline electrolytes30,31,32,33, the overpotential was promising (listed in Supplementary Table S2).

Furthermore, the OER kinetics of the above catalysts was probed by corresponding Tafel plots (log j - η); where more favorable kinetics and superior catalytic activity were noticeable from the much lower Tafel slopes34 The Tafel plots in Fig. 6(b) suggested the kinetics of the electrochemical oxygen evolution on Co0.54Fe0.46OOH electrode was much faster than others. As shown in Fig. 6(b), the resulting Tafel slopes were found to be ~47, ~67, ~90 and ~102 mV/dec, for Co0.54Fe0.46OOH, FeOOH2, FeOOH3 and FeOOH1, respectively (Fig. 6(b,c) and Table 1). It should be noted that the Tafel slope of Co0.54Fe0.46OOH was much smaller than those of other FeOOH1, FeOOH2, FeOOH3, electrodes.

The catalyst stability is always an essential aspect for its property evaluation because durability is crucial for long term utilization35. Durability studies of Co0.54Fe0.46OOH nanomaterials with chronoampero metric measurements were conducted (Fig. 6(d)). After continuous CV scanning, a negligible difference was found between the curves measured at the initial cycle and after 1000 CV cycles (the right inset of Fig. 6(d)). When the potential was fixed at 1.62 V (vs. RHE), the catalytic activities remained stable for 25000 s, remaining at 89% of the maximum value. Meanwhile, there were no obvious changes of Co0.54Fe0.46OOH from the TEM and XPS results (Fig. S5(c) and (d) in the Supplementary Information) after the stability test, which proved the Co0.54Fe0.46OOH nanomaterials were stable for OER behavior.

To further evaluate OER catalytic activities of electrodes, the mass activity and turnover frequency (TOF) of the above electrodes at η = 390 mV (η that needed to afford a current density of 10 mA/cm2 for Co0.54Fe0.46OOH electrode) were also presented (Table 1). The calculated mass activity for Co0.54Fe0.46OOH is 200 A/g, outperforming the other studied catalysts. The constructed Co0.54Fe0.46OOH electrode exhibited the highest TOF of 0.0225 s−1, implying that the metal atom on the crystal surface was catalytically active36.

To investigate the reaction mechanism, the rotating ring-disk electrode (RRDE) technique was employed with a Pt ring potential of 1.50 V to oxidize the peroxide intermediates formed on the Co0.54Fe0.46OOH surface during OER. As shown in Fig. 6(e), a very low ring current (μA scale) was detected, which was three orders of magnitude lower than that of the disk current (mA scale), suggesting a negligible hydrogen peroxide formation and therefore a desirable four-electron pathway for water oxidation: 4OH− → O2 + 2H2O + 4e− 37. Furthermore, to confirm that the observed current originated from water oxidation rather than other side reactions and to calculate the Faradaic efficiency, an RRDE with a ring potential of 0.40 V was applied to reduce the generated O2, rendering a continuous OER (disk electrode) → ORR (ring electrode) process (Fig. S6 in the Supplementary Information)37,38. With the disk current held constant at 200 μA, O2 molecules generated from the Co0.54Fe0.46OOH catalyst on the disk electrode swept across the surrounding Pt ring electrode that was held at an ORR potential and rapidly reduced. Consequently, a ring current of ~44.70 μA (collection efficiency 0.20) was detected (Fig. 6(f)), which could verify that the observed oxidation current catalyzed by Co0.54Fe0.46OOH can be fully attributed to OER with a high Faradaic efficiency of 97.30%39.

Two possible reasons were responsible for the excellent OER electrocatalytic performances of Co0.54Fe0.46OOH nanomaterials. The first one was the branch structure on the surface providing many active edge sites, enhanced mass/charge transport capability, easy release of oxygen gas bubbles, and strong structural stability, which are advantageous for OER40. The main reason was that the Co-doping in FeOOH nanostructures constituted a desirable four-electron pathway for reversible oxygen evolution and reduction, which is potentially useful for rechargeable metal−air batteries, regenerative fuel cells, and other important clean energy devices41. The charge transfer efficiency at the electrode interface was greatly improved after the Co doping into FeOOH nanostructure, which can be demonstrated by Nyquist plots for both catalysts (Fig. S7 in the Supplementary Information).

Extend the gelatin assisted method to synthesis other materials

Notably, we extend the gelatin assisted soft template method to fabricate lots of other metal oxides such as CoCO3 and Ni3(CO3)(OH)4 · 4H2O. TEM and HAADF-STEM images of the CoCO3 and Ni3(CO3)(OH)4 · 4H2O nanostructures are shown in Fig. S8 in the Supplementary Information. Fig. S8(a) and (b) in the Supplementary Information illustrate the belt-like CoCO3 nanostructures with the average size of ~700 nm ± 100 nm in length and ~100 nm ± 50 nm in width. Analogously, TEM and HAADF-STEM images of flake-like Ni3(CO3)(OH)4 · 4H2O nanostructures with the average size of ~200 nm ± 50 nm in length and ~50 nm ± 10 nm in width are shown in Fig. S8(c) and (d) in the Supplementary Information. The XRD patterns of CoCO3 nanostructures in Fig. S9(a) in the Supplementary Information is attributed to a rhombohedra phase of spherocobaltite (JCPDS: 11-0692, space group: R-3C (167) with lattice constants: a = 4.65 Å, b = 4.65 Å, c = 14.95 Å, V = 281.16 Å3. Figure S9(b) in the Supplementary Information shows the Co 2p XPS signals of CoCO3 nanostructures, and two discernible peaks at 780.90 eV and 796.40 eV were assigned to Co 2p3/2 and Co 2p1/2, respectively, demonstrating the presence of divalent Co in CoCO342. Meanwhile, the XRD patterns of Ni3(CO3)(OH)4 · 4H2O nanostructures (Fig. S9(c) in the Supplementary Information) could be ascribed to an orthorhombic phase of nickel oxide hydroxide (JCPDS: 16-0164). Furthermore, Fig. S9(d) in the Supplementary Information depicts the Ni 2p XPS signals of Ni3(CO3)(OH)4 · 4H2O nanostructures, and two peaks at 854.90 eV and 872.90 eV were attributed to the Ni 2p3/2 and Ni 2p1/2, respectively, suggesting the presence of divalent Ni in Ni3(CO3)(OH)4 · 4H2O42.

Discussion

To conclude, high-quality FeOOH and Co-doped FeOOH have been synthesized through a gelatin-assisted soft-template wet chemistry process. Subsequently, Co0.54Fe0.46OOH exhibited higher OER activities, more favorable kinetics, and stronger durability in comparison to those of FeOOH nanostructures. The OER performance was the best among all of the previously reported FeOOH or metal doped FeOOH electrodes and was better than nonmetal OER catalysts, which can be attributed to the branch structure of the Co0.54Fe0.46OOH nanomaterial on the surface providing many active edge sites, enhanced mass/charge transport capability, easy release of oxygen gas bubbles, and strong structural stability. Meanwhile, a desirable four-electron pathway for reversible oxygen evolution and reduction was generated, which is potentially useful for rechargeable metal−air batteries, regenerative fuel cells, and other important clean energy devices. These Co-doped FeOOH nanostructures should serve as a promising noble-metal-free catalyst for efficient OER in alkaline media.

Methods

Chemicals and materials

Ferric chloride hydrates (FeCl3 · 6H2O, 99.50%, Tianjin Zhiyuan Chemical Company), Nickel chloride hydrates (NiCl2 · 6H2O, 99.50%, Tianjin Fetching Chemical Company), Cobalt chloride hydrates (CoCl2 · 6H2O, 99.50%, Tianjin Zhiyuan Chemical Company), Gelatin (C102H151N31O39, G7041-500G, 99.00%, Sigma-Aldrich), Urea (CO(NH2)2, 99.90%, Sigma-Aldrich), and Absolute ethanol (C2H6O, >99.70%, Guangdong Guanghua Scientific and Technical Corporation) were used as received without further purification.

Synthesis of FeOOH Nanostructures

In a typical procedure, 27.02 g (100 mmol) of FeCl3 · 6H2O, 1.00 g of gelatin and 6.06 g (100 mmol) of urea were added into a 100 mL teflon-lined stainless steel autoclave. After stirred for 1 h, the suspension solution in teflon-lined stainless steel autoclave was heated in an electric oven at 80 °C for 21 h. The autoclave was then cooled down to room temperature. The yellow precipitate was collected by centrifugation at 8000 rpm/min for 5 min, washed thoroughly with absolute ethanol, and dried at 65 °C overnight in a vacuum oven. FeOOH2 nanostructures synthetic procedure was similar to FeOOH1 except that urea was not included in the reaction system. FeOOH3 nanostructures synthetic procedure was similar to FeOOH1 except that the concentration of urea was increased to 300 mmol and the reaction time was extended to 46 h.

Synthesis of CoxFe1−xOOH Nanostructures

The synthetic procedure of CoxFe1−xOOH was similar to that of FeOOH nanostructures, except that CoCl2 · 6H2O and FeCl3 · 6H2O were used with different ratios as the precursors. Different materials, such as: Co0.23Fe0.77OOH, Co0.54Fe0.46OOH, Co0.77Fe0.23OOH were obtained, where Co0.54Fe0.46OOH exhibited the best OER activity.

Synthesis of CoCO3 Nanostructures

The synthetic procedure of CoCO3 was similar to that of FeOOH nanostructures except that CoCl2 · 6H2O was used as the precursor.

Synthesis of Ni3CO3(OH)4 · 4H2O Nanostructures

The synthetic procedure of Ni3CO3(OH)4 · 4H2O was similar to that of FeOOH nanostructures except that NiCl2 · 6H2O was used as the precursor.

Characterization

Powder X-ray diffraction (PXRD) patterns of the products were recorded on Rigaku D/MAX-RB (Japan) at a scanning rate of 5°/min from 10° to 70°, using Cu Ka radiation (λ = 1.5406 Å). Transmission electron microscope (TEM) analysis was performed with a Hitachi HT-7700 (Japan) transmission electron microscope operating at 100 kV. Selected area electron diffraction (SAED), high-angle annular dark field-scanning transmission electron microscopy (HAADF-STEM) and energy-dispersive x-ray spectrum (EDS) characterizations were performed with a FeiTecnat G2 F20S-Twin (USA) operated at 200 kV. X-ray photoelectron spectroscopy (XPS) was obtained using an Escalab 250 xi photoelectron spectrometer using Al K radiation (15 kV, 225 W, base pressure ≈5 × 10−10 Torr). The amount of atomic ratios of metals in the nanocrystals was determined on Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP-AES) measurements.

Electrocatalytic Research

Electrochemical measurements were carried out at ambient temperature using a rotating disk electrode (RDE) made of glassy carbon (GC; RDE-3A, 3 mm diameter, 0.07 cm2) connected to CHI 760e Electrochemical Workstation (CHI Instruments, Shanghai Chenhua Instrument Corporation, China) in a conventional three-electrode system. The working electrodes were prepared according to the following methods. Typically, 3 mg of catalyst powder and 30 μL Nafion solution (5 wt.%, Sigma-Aldrich) were dispersed in 1.47 mL of DMF solution. Then the mixture solution was sonicated for 2 h to form a homogeneous ink. After that, 7 μL of the dispersion (containing 20 μg of catalyst) was loaded onto the RDE (loading ca. ~0.20 mg/cm2). Electrocatalytic performances were conducted in 100 mM KOH (purged with O2 for 0.50 h to ensure saturation of the electrolyte) using electrochemical cell setup, with saturated Ag/AgCl electrode (in saturated KCl solution) as the reference electrode and Pt net as the auxiliary electrode, and RDE as the working electrode with a rotation rate of 1600 rpm in O2 saturated 100 mM KOH solution (pH = 13). The potentials were reported versus the Ag/AgCl reference electrode, referenced to the RHE through RHE calibration36 ERHE = EAg/AgCl + 0.196 V + 0.0591 pH. Overpotentials (η) were calculated based on the formula η = EAg/AgCl + 0.196 V + 0.0591 pH - 1.23 V.

Calculation of Mass Activity and TOF from Gao and Co-workers

The mass activity (A/g) values were calculated from the catalyst loading m (0.20 mg/cm2) and the measured current density j (mA/cm2) at η = 390 mV

The TOF values were calculated by assuming that every metal atom is involved in the catalysis (lower TOF limits were calculated):

where j (mA/cm2) is the measured current density at η = 390 mV, S (0.07 cm2) is the surface area of the GC disk, the constant 4 means 4 electrons/mol of O2, F is Faraday’s constant (96485.30 C/mol), and n is the mole of coated metal atom on the electrode calculated from m, the molecular weight of the coated catalysts37.

Additional Information

How to cite this article: Zhang, X. et al. Effective Construction of High-quality Iron Oxy-hydroxides and Co-doped Iron Oxy-hydroxides Nanostructures: Towards the Promising Oxygen Evolution Reaction Application. Sci. Rep. 7, 43590; doi: 10.1038/srep43590 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Smith, R. D. L., Prevot, M. S., Fagan, R. D., Zhang, Z. & Sedach, P. A. et al. Photochemical route for accessing amorphous metal oxide materials for water oxidation catalysis. Science 340, 60–63 (2013).

Zhang, B., Zheng, X. L., Voznyy, O., Vojvodic, A. & Sargent, E. H. Homogeneously dispersed multimetal oxygen-evolving catalysts. Science. 352, 333–337 (2016).

Liang, Y., Li, Y., Wang, H., Zhou, J. & Dai, H. et al. Co3O4 nanocrystals on graphene as a synergistic catalyst for oxygen reduction reaction. Nat. Mater. 10, 780–786 (2011).

Turner, J. A. Sustainable hydrogen production. Science 305, 972–974 (2004).

Symes, M. D. & Cronin, L. Decoupling hydrogen and oxygen evolution during electrolytic water splitting using an electron-coupled-proton buffer. Nat. Chem. 5, 403–409 (2013).

Dresselhaus, M. S. & Thomas, I. L. Alternative energy technologies. Nature 414, 332–337 (2001).

Smith, R. D. L., PreÏvot, M. S., Fagan, R. D., Trudel, S. & Berlinguette, C. P. Water oxidation catalysis: electrocatalytic response to metal stoichiometry in amorphous metal oxide films containing iron, cobalt, and nickel. J. Am. Chem. Soc. 135, 11580–11586 (2013).

Chemelewski, W. D., Lee, H. C., Lin, J. F., Bard, A. J. & Mullins, C. B. Amorphous FeOOH oxygen evolution reaction catalyst for photoelectrochemical water splitting. J. Am. Chem. Soc. 136, 2843–2850 (2014).

Friebel, D., Louie, M. W., Bajdich, M., Sanwald, K. E. & Bell, A. T. et al. Identification of highly active Fe sites in (Ni, Fe)OOH for electrocatalytic water splitting. J. Am. Chem. Soc. 137, 1305–1313 (2015).

Li, Q., Wang, Z., Li, G., Guo, R. & Tong, Y. et al. Design and synthesis of MnO2/Mn/MnO2 sandwich-structured nanotube arrays with high supercapacitive performance for electrochemical energy storage. Nano Lett. 12, 3803–3807 (2012).

Lin, H., Weng, W., Ren, J., Qiu, L. & Peng, H. et al. Twisted aligned carbon nanotube/silicon composite fiber anode for flexible wire-shaped lithium-ion battery. Adv. Mater. 26, 1217–1222 (2014).

Sun, H., Yang, Z., Chen, X., Qiu, L. & Peng, H. et al. Photovoltaic wire with high efficiency attached onto and detached from a substrate using a magnetic field. Angew. Chem. Int. Ed. 52, 8276–8280 (2013).

Feng, J. X., Xu, H., Dong, Y. T., Ye, S. H. & Li, G. R. et al. FeOOH/Co/FeOOH hybrid nanotube arrays as high-performance electrocatalysts for the oxygen evolution reaction. Angew. Chem Int. Ed. 128, 3758–3762 (2016).

Miller, D. D., Lenhart, W., Antalek, B. J., Williams, A. J. & Hewitt, J. M. The use of NMR to study sodium dodecyl sulfate-gelatin interactions. Langmuir 10, 68–71 (1994).

Kisailus, D., Choi, J. H., Weaver, J. C., Yang, W. & Morse, D. E. Enzymatic synthesis and nanostructural control of gallium oxide at low temperature. Adv. Mater. 17, 314–318 (2005).

Leveque, I., Cusack, M., Davis, S. A. & Mann, S. Promotion of fluorapatite crystallization by soluble-matrix proteins from lingula anatina shells. Angew. Chem. Int. Ed. 43, 885–888 (2004).

Wang, H. Y., Sun, K. N., Li, A. M., Wang, W. L. & Chui, P. F. Size-controlled synthesis and characterization of fluorapatite nanocrystals in the presence of gelatin. Powder Technol. 209, 9–14 (2011).

Li, X. Q., Feng, Z. W., Xia, Y. Y. & Zeng, H. C. Protein-assisted synthesis of double-shelled CaCO3 microcapsules and their mineralization with heavy metal ions. Chem. Eur. J. 18, 1945–1952 (2012).

Fang, K. M., Wang, Z. Z., Zhang, M., Wang, A. J. & Feng, J. J. et al. Gelatin-assisted hydrothermal synthesis of single crystalline zinc oxide nanostars and their photocatalytic properties. J. Colloid Interf. Sci. 402, 68–74 (2013).

Yang, X., Liao, S. J., Liang, Z. X., Li, Y. X. & Du, L. Gelatin-assisted templating route to synthesize sponge-like mesoporous silica with bimodal porosity and lysozyme adsorption behavior. Microporous Mesoporous Mater. 143, 263–269 (2011).

Liu, B., Xiao, J. Z., Xu, L., Yao, Y. J. & Gil, J. M. et al. Gelatin-assisted sol–gel derived TiO2 microspheres for hydrogen storage. Int. J. Hydrogen Energ. 40, 4945–4950 (2015).

Zhang, X. Y., Ge, J., Lei, B., Xue, Y. M. & Du, Y. P. High quality β-FeOOH nanostructures constructed by a biomolecule-assisted hydrothermal approach and their pH-responsive drug delivery behaviors. CrystEngComm. 17, 4064–4069 (2015).

Gao, M., Sheng, W., Zhuang, Z., Fang, Q. & Yan, Y. et al. Efficient water oxidation using nanostructured α-Nickel-Hydroxide as an electrocatalyst. J. Am. Chem. Soc. 136, 7077–7084 (2014).

Weng, L. P., Riemsdijk, W. H. V. & Hiemstra, T. Effects of fulvic and humic acids on arsenate adsorption to goethite: experiments and modeling. Environ. Sci. Technol. 43, 7198–7204 (2009).

Cai, R., Chen, J., Yang, D., Zhang, Z. Y. & Yan, Q. Y. et al. ACS Appl. Mater. Interfaces. 5, 10389–10394 (2013).

Liu, Y. C., Koza, J. A. & Switzer, J. A. Conversion of electrodeposited Co(OH)2 to CoOOH and Co3O4, and comparison of their catalytic activity for the oxygen evolution reaction. Electrochim. Acta. 140, 359–365 (2014).

Song, X. W. & Boily, J. F. Variable hydrogen bond strength in akaganéite. J. Phys. Chem. C. 116, 2303–2312 (2012).

Li, S. W., Wang, Y. C., Peng, S. J., Zhang, L. J. & Zheng, G. F. et al. Electrocatalysts: Co-Ni-Based nanotubes/nanosheets as efficient water splitting electrocatalysts. Adv. Energy Mater. 6, 1501661–1501667 (2016).

Wang, L., Lin, C., Huang, D. K., Zhang, F. X. & Jin, J. et al. A comparative study of composition and morphology effect of NixCo1–x(OH)2 on oxygen evolution/reduction reaction. ACS Appl. Mater. Interfaces. 6, 10172–10180 (2014).

El-Deab, M. S., Awad, M. I., Mohammad, A. M. & Ohsaka, T. Enhanced water electrolysis: electrocatalytic generation of oxygen gas at manganese oxide nanorods modified electrodes. Electrochem. Commun. 9, 2082–2087 (2007).

Swierk, J. R., Klaus, S., Trotochaud, L., Bell, A. T. & Tilley, T. D. Electrochemical study of the energetics of the oxygen evolution reaction at nickel iron (oxy)hydroxide catalysts. J. Phys. Chem. C. 119, 19022–19029 (2015).

Huang, J. H., Chen, J. T., Yao, T., He, J. F. & Wei, S. Q. et al. CoOOH nanosheets with high mass activity for water oxidation. Angew. Chem. Int. Ed. 127, 8846–8851 (2015).

Lu, B., Wang, C. Q., Chen, S. L., Yin, J. L. & Cao, D. X. et al. A novel composite electrode for oxygen evolution reaction. J. Solid. State. Electrochem. 17, 2277–2282 (2013).

Merki, D. & Hu, X. Recent developments of molybdenum and tungsten sulfides as hydrogen evolution catalysts. Energy Environ. Sci. 4, 3878–3888 (2011).

An, L., Zhou, P. P., Yin, J., Liu, H. & Xi, P. X. et al. Phase transformation fabrication of a Cu2S nanoplate as an efficient catalyst for water oxidation with glycine. Inorg. Chem. 54, 3281–3289 (2015).

Gao, M. R., Cao, X., Gao, Q., Jiang, J. & Yu, S. H. et al. Nitrogen-doped graphene supported CoSe2 nanobelt composite catalyst for efficient water oxidation. ACS Nano. 8, 3970–3978 (2014).

Ma, T. Y., Dai, S., Jaroniec, M. & Qiao, S. Z. Metal–organic framework derived hybrid Co3O4-Carbon porous nanowire arrays as reversible oxygen evolution electrodes. J. Am. Chem. Soc. 136, 13925–13931 (2014).

Nakagawa, T., Bjorge, N. S. & Murray, R. W. Electrogenerated IrOx nanoparticles as dissolved redox catalysts for water oxidation. J. Am. Chem. Soc. 131, 15578–15579 (2009).

McCrory, C. L. C., Jung, S., Peters, J. C. & Jaramillo, T. F. Benchmarking heterogeneous electrocatalysts for the oxygen evolution reaction. J. Am. Chem. Soc. 135, 16977–16987 (2013).

Wang, X., Sumboja, A., Khoo, E., Yan, C. Y. & Lee, P. S. Cryogel synthesis of hierarchical interconnected macro-/mesoporous Co3O4 with superb electrochemical energy storage. J. Phys. Chem. C. 116, 4930–4935 (2012).

Zhan, Y., Du, G. J., Yang, S. L., Xu, C. H. & Lee, J. Y. et al. Development of cobalt hydroxide as a bifunctional catalyst for oxygen electrocatalysis in alkaline solution. ACS Appl. Mater. Interfaces. 7, 12930–12936 (2015).

Biesinge, M. C., Payne, B. P., Grosvenor, A. P., Laua, L. W. M. & Smart, R. S. C. et al. Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl. Surf. Sci. 257, 2717–2730 (2011).

Acknowledgements

We gratefully acknowledge the financial aid from the start-up funding from Xi’an Jiaotong University, the Fundamental Research Funds for the Central Universities (2015qngz12), the China National Funds for Excellent Young Scientists (grant no. 21522106) and NSFC (grant no. 21371140, 21571089). We also thank Dr. Xinghua Li from Northwest University (China) for the HAADF-STEM characterization.

Author information

Authors and Affiliations

Contributions

X.Z. carried out the electric storage analysis, wrote the paper. J.Y. checked the electric storage analysis and the paper, and L.A. assisted with the electric measurements. P.X., Z.Z. and Y.D. wrote the paper and supervised all of the work. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhang, X., An, L., Yin, J. et al. Effective Construction of High-quality Iron Oxy-hydroxides and Co-doped Iron Oxy-hydroxides Nanostructures: Towards the Promising Oxygen Evolution Reaction Application. Sci Rep 7, 43590 (2017). https://doi.org/10.1038/srep43590

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep43590

This article is cited by

-

Tetraether bridged benzylideneamino mercaptopropanoic acid substituted Cobalt phthalocyanine/rGO as a catalyst for oxygen evolution reaction in an alkaline medium

Chemical Papers (2024)

-

Promotion of Oxygen Evolution Activity of Co-Based Nanocomposites by Introducing Fe3+ Ions

Topics in Catalysis (2021)

-

A general ligand-assisted self-assembly approach to crystalline mesoporous metal oxides

NPG Asia Materials (2018)

-

MOF-derived, CeO x -modified CoP/carbon composites for oxygen evolution and hydrogen evolution reactions

Journal of Materials Science (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.