Abstract

Since Li4Ti5O12 as a promising anode material in lithium-ion batteries (LIBs) has a poor rate performance due to low electronic conductivity, a doping of Li4Ti5O12 with heterogeneous atoms has been considered to overcome this problem. Herein, we report that there is an upper limit of doping level to maintain the zero strain characteristics of Li4Ti5O12 lattice during charge/discharge process. By using synchrotron studies, it was revealed that the Li+ diffusivity was maximized at a certain doping level for which the conductivity was markedly increased with maintaining the zero strain characteristics. However, with more doses of dopants over the upper limit, the lattice shrank and therefore the Li+ diffusivity decreased, although the electronic conductivity was further increased in comparison with the optimal doping level.

Similar content being viewed by others

Introduction

Lithium-ion batteries are a commercial success, but there are safety concerns about the carbon-based negative-electrode materials used in them1,2. Because their operating potential is relatively low and close to that of lithium metal, dendrites form on the surface of the carbon-based negative electrodes causing a short circuit, especially at high rates3,4. Cubic spinel Li4Ti5O12 has attracted much attention as a promising anode material for lithium-ion batteries because of its relatively high potential above 1.5 V (vs. Li), which imparts safety and stability to the battery. However, as an insulator, Li4Ti5O12 shows poor rate performance because of its low electronic and ionic conductivities5,6. To overcome this problem, doping a heterogeneous atom is an effective way to enhance the rate performance by changing the insulating characteristics7. Various transition metals such as Mg, Cr, Mn, Ta, Y, and Mo have been used as a dopant in Li4Ti5O12, enhancing its rate performance3,8,9,10,11,12,13,14,15. Some have attributed the enhanced rate performance to the increased electronic conductivity upon doping. However, others have reported that enhanced electronic conductivity does not guarantee enhanced rate performance, probably because of the decrease in Ti4+, which is the sole atom that participates in the redox reaction8,15. However, because only 40% of Ti4+ is reduced to Ti3+ in the charge process (Li4Ti5O12 → Li7Ti5O12), some other factor must affect the rate performance of Li4Ti5O12. Lithium-ion diffusivity and electronic conductivity are the main factors that play a role in high rate performance, and many researchers have tried to synthesize nanoscale particles into various shapes to shorten the lithium-ion pathways16,17,18.

Under doping of a heterogeneous atoms, changes in the lattice structures in Li4Ti5O12 can occur because bond lengths or bonding symmetry can change around the heterogeneous dopant. Those structural changes could affect the diffusion rate of lithium ions into the lattice. We studied how those structural changes affect the lithium-ion diffusivity and rate capability of Li4Ti5O12. Then, we found a lattice structure requirement needed for the zero-strain Li4Ti5O12.

Results and Discussion

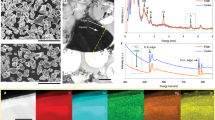

Cr3+ is the dopant most used in Li4Ti5O12, because its high octahedral site stabilization energy (OSSE) makes it possible to substitute it for 50% of the atoms positioned at 16d sites9,19. In a manner similar to that used in our previous studies, we prepared Li4−x/3Ti5−2x/3CrxO12 (x = 0, 1, 2, 3) by replacing one lithium ion and two titanium ions at the octahedral sites with three chromium ions (Li++ 2Ti4+ → 3Cr3+). Figure 1a presents the X-ray diffraction (XRD) patterns of the synthesized samples. All the patterns match well with the cubic spinel structure without any side peaks. When the amount of the dopant Cr3+ increased, a significant change in the lattice structure was observed using Rietveld refinement. Figure 1b presents the lattice parameter of Li4Ti5−2xCrxO12, which decreased linearly as the doping amount increased. This was expected because the average ionic radii at 16d octahedral sites decreased when one Li+ (0.76 Å) and two Ti4+ (0.61 Å) were replaced by three Cr3+ (0.62 Å). Figure 1b also shows the variation in the fractional coefficient of oxygen ions in the lattice. In general, the oxygen parameter decreased when near 0.25, which is the ideal value for oxygen ions. The results imply that distortion of the lattice structure decreased with an increase in the doping amount of Cr3+.

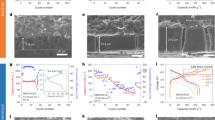

Electronic conductivity of the synthesized samples was measured using the van der Pauw method. A coin type pellet of active materials was fabricated by using the laboratory hydraulic press with the maximum pressure of 25 ton. Au paste was used to form the electrode at the position of cardinal points and Au wire was used to connect the measurement port of Hall effect measurement system. The electronic conductivity of bare Li4Ti5O12 could not be measured because it was extremely low (<10−13 S/cm) and out of measurement range. As seen in Fig. 2, the electronic conductivity of Li4Ti5O12 increased to about 10−7 S/cm under doping with Cr3+; this is six orders of magnitude greater than that of bare Li4Ti5O12. The electronic conductivity was markedly enhanced with the increase of doping level, because the carrier density was increased by the extra electrons donated by Cr3+ (Fig. 2).

In general, the enhanced electronic conductivity results in enhanced rate performance of Li4Ti5O12. To understand the effect of doping on electrochemical performance, we performed battery tests at various C-rates. Figure 3a shows representative charge–discharge curves for all samples at 0.5 C. The voltage difference between the charge and discharge curves decreased with Cr3+ doping, indicating that the voltage polarization decreased upon doping. However, the polarization increased with the Cr3+ doping level over x = 1. The specific capacity of each sample was inversely proportional to the voltage difference between the charge and discharge curves. Figure 3b shows the rate capability of all samples. The Li4−x/3Ti5−2x/3CrxO12 (x = 1) had the highest rate capability because it had the smallest voltage difference between the charge and discharge curves. Also, the Li4−x/3Ti5−2x/3CrxO12 (x = 1) exhibited good cycle performance at 1 C in Fig. S2. However, Fig. 3b and c show that the rate capability decreased with increasing the doping level of Cr3+ over x = 1 despite the increased electronic conductivity. Therefore, using the galvanostatic intermittent titration technique (GITT), we measured Li+ diffusivity, which is one of the main factors that affect the rate capability. Figure 3d shows the Li+ diffusivity of Li4−x/3Ti5−2x/3CrxO12 with increasing doping amount of Cr3+. While the electronic conductivity increased linearly in Fig. 2, the Li+ diffusivity showed a volcano-type variation, with a peak at x = 1 for Li4−x/3Ti5−2x/3CrxO12, and decreased linearly when the doping amount was greater than x = 1, which is similar to the variation of specific capacity at a high C-rate seen in Fig. 3c. This result implies that Li+ diffusivity more than electronic conductivity affects the rate capability with a linear increase. The highest Li+ diffusivity occurs when x = 1 because of the decrease in structural disorder caused by the swing of oxygen ions in the lattice. However, when the doping amount of Cr3+ was increased over x = 1, the Li+ diffusivity linearly decreased despite the increased structural order.

To understand the volcano-type variation of the Li+ diffusivity, the particle size of all synthesized samples was observed using scanning electron microscopy (SEM) (Fig. 1c). The particle size generally decreased when the doping amount increased, which did not seem to affect the volcano-type variation of Li+ diffusivity. Also, Cr ions in the powder were evenly distributed as shown in Fig. S1. Therefore, we carried out in situ XRD measurements of all samples to identify changes to the lattice structure when Li+ is inserted into the lattice. Figure 4b shows changes in the lattice dimension as a function of y in Li4−x/3+3yTi5−2x/3CrxO12 (the in situ XRD patterns of each sample are shown in Fig. 5). For samples of Li4−x/3Ti5−2x/3CrxO12 when x = 0 and x = 1, there was no significant change in the lattice dimension when Li+ was inserted, which is the zero-strain characteristic of the cubic spinel Li4Ti5O12. The lattice dimensions of the anode materials in lithium-ion batteries usually expand because of the change in ionic radii of the redox species in a solid matrix. However, during the lithiation of Li4Ti5O12, the oxygen ions in the lattice of Li4Ti5O12 swing to their ideal positions, leading to its rock salt structure without distortion from the distorted spinel structure as shown in Fig. 4a. That is why Li4Ti5O12 has zero strain although the Ti–O bond length increases during lithiation20. However, zero strain was not maintained when x = 2 and x = 3. Figure 4b shows the significant change in the lattice dimension for the two samples during lithiation. When the doping amount of Cr3+ increased, the lattice dimensions expanded as the lithium ions were inserted into the lattice. The lattice of the Li4−x/3Ti5−2x/3CrxO12 (x = 2) sample expanded from 8.329 to 8.339(1) Å, and the lattice of the Li4−x/3Ti5−2x/3CrxO12 (x = 3) sample expanded from 8.318 to 8.340(1) Å. Rapid changes in the lattice dimensions of the two samples were observed at the beginning of lithiation. These changes in lattice structure could have been caused by the decrease in lattice parameter that occurs with an increase in the doping amount of Cr3+. If the lattice parameter of the doped Li4Ti5O12 is less than about 8.34 Å, the lattice dimension will expand to about 8.34 Å during lithiation. Thus, the zero-strain characteristics of Li4Ti5O12 is retained when the lattice parameter is larger than a specific size, and if the doped Li4Ti5O12 loses the zero-strain characteristic because of a smaller lattice parameter, the Li+ diffusivity would decrease, resulting in the deterioration of electrochemical performance. Therefore, the changes in the lattice structure and the improvement in electronic conductivity upon doping should enhance the electrochemical performance of Li4Ti5O12.

In conclusion, we studied how the changes in the lattice structure of Li4Ti5O12 upon doping a heterogeneous atom affect its electrochemical properties. Unless the lattice parameter is larger than a specific size after doping, Li4Ti5O12 would lose its zero-strain characteristic because the lattice dimensions would expand during lithiation. Those structural changes cause the deterioration of the diffusion of lithium ions into the lattice, which results in the deterioration of rate capability. Therefore, to design Li4Ti5O12 with a high rate capability by doping a heterogeneous atom, the kind of dopant and the amount of doping should be controlled keeping in mind the changes in the lattice structure that occur.

Methods

Synthesis

Li4−x/3Ti5−2x/3CrxO12 (x = 0, 1, 2, 3) was synthesized by dissolving LiOH∙H2O in water and adding TiO2 and Cr(NO3)3∙9H2O to the solution with the appropriate molar ratios. After ball-milling for 2 h at 50 Hz, the solution was evaporated and dried in a vacuum oven at 80 °C for 24 h. Then, the ground powder was annealed at 800 °C for 12 h in air at a heating rate of 5 °C/min.

Characterization

Electrochemical tests were performed using 2032 coin cells assembled with working electrodes coated on Cu foil at a mass ratio of active material:acetylene black:PVDF of 80:10:10 and reference/counter electrodes made of Li metal on a Cu mesh. The mass loading of active material was about 0.06 ~ 0.062 mg/mm2. LiPF6 (1 M) in ethylene carbonate and dimethyl carbonate (DMC) (1:1 v/v) were used as the electrolyte. A polypropylene membrane was used as a separator. The coin cells were assembled in a glove box filled with Ar gas, and all electrochemical tests were carried out using a battery cycler (WC3000S, WonATech) at different C-rates in the voltage range of 1.0–3.0 V (vs. Li). The diffusion coefficients of the Li ions in all samples were measured using GITT with current application of 30 s21. High-resolution powder diffraction and in situ XRD patterns of the synthesized powders were measured with the 9B HRPD and 3D X-ray scattering (XRS) beamlines at the Pohang Light Source (PLS) with a wavelength of 1.5495 and 1.24 Å, respectively.

Additional Information

How to cite this article: Song, H. et al. An upper limit of Cr-doping level to Retain Zero-strain Characteristics of Li4Ti5O12 Anode Material for Li-ion Batteries. Sci. Rep. 7, 43335; doi: 10.1038/srep43335 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Arico, A. S., Bruce, P., Scrosati, B., Tarascon, J.-M. & van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 4, 366–377 (2005).

Mahmoud, A., Amarilla, J. M., Lasri, K. & Saadoune, I. Influence of the synthesis method on the electrochemical properties of the li4ti5o12 spinel in li-half and li-ion full-cells. A systematic comparison. Electrochim. Acta 93, 163–172 (2013).

Guo, M., Wang, S., Ding, L.-X., Huang, C. & Wang, H. Tantalum-doped lithium titanate with enhanced performance for lithium-ion batteries. J. Power Sources 283, 372–380 (2015).

Ding, Y., Li, G. R., Xiao, C. W. & Gao, X. P. Insight into effects of graphene in li4ti5o12/carbon composite with high rate capability as anode materials for lithium ion batteries. Electrochim. Acta 102, 282–289 (2013).

Li, N., Liang, J., Wei, D., Zhu, Y. & Qian, Y. Solvothermal synthesis of micro-/nanoscale cu/li4ti5o12 composites for high rate li-ion batteries. Electrochim. Acta 123, 346–352 (2014).

Zhao, Z., Xu, Y., Ji, M. & Zhang, H. Synthesis and electrochemical performance of f-doped li4ti5o12 for lithium-ion batteries. Electrochim. Acta 109, 645–650 (2013).

Song, H. & Kim, Y.-T. A mo-doped tinb2o7 anode for lithium-ion batteries with high rate capability due to charge redistribution. Chem. Commun. 51, 9849–9852 (2015).

Chen, C. H. et al. Studies of mg-substituted li4−xmgxti5o12 spinel electrodes (0 ≤ x ≤ 1) for lithium batteries. J. Electrochem. Soc. 148, A102–A104 (2001).

Ohzuku, T., Tatsumi, K., Matoba, N. & Sawai, K. Electrochemistry and structural chemistry of li[crti]o4 (fd-3m) in nonaqueous lithium cells. J. Electrochem. Soc. 147, 3592–3597 (2000).

Capsoni, D. et al. Cr and ni doping of li4ti5o12: Cation distribution and functional properties. J. Phys. Chem. C 113, 19664–19671 (2009).

Sun, Y.-K., Jung, D.-J., Lee, Y. S. & Nahm, K. S. Synthesis and electrochemical characterization of spinel li[li(1−x)/3crxti(5−2x)/3]o4 anode materials. J. Power Sources 125, 242–245 (2004).

Song, H. et al. Anomalous decrease in structural disorder due to charge redistribution in cr-doped li4ti5o12 negative-electrode materials for high-rate li-ion batteries. Energy Environ. Sci. 5, 9903–9913 (2012).

Song, H. et al. Stabilization of oxygen-deficient structure for conducting li4ti5o12−d by molybdenum doping in a reducing atmosphere. Sci. Rep. 4, 4350–4357 (2014).

Capsoni, D. et al. Cations distribution and valence states in mn-substituted li4ti5o12 structure. Chem. Mater. 20, 4291–4298 (2008).

Bai, Y.-J., Gong, C., Lun, N. & Qi, Y.-X. Yttrium-modified li4ti5o12 as an effective anode material for lithium ion batteries with outstanding long-term cyclability and rate capabilities. J. Mater. Chem. A 1, 89–96 (2013).

Lee, S. C. et al. Spinel li4ti5o12 nanotubes for energy storage materials. J. Phys. Chem. C 113, 18420–18423 (2009).

Wang, Y. et al. Synthesis and electrochemical performance of nano-sized li4ti5o12 with double surface modification of ti (iii) and carbon. J. Mater. Chem. 19, 6789–6795 (2009).

Yu, S.-H. et al. Surfactant-free nonaqueous synthesis of lithium titanium oxide (lto) nanostructures for lithium ion battery applications. J. Mater. Chem. 21, 806–810 (2011).

Ganesan, M. Li4ti2.5cr2.5o12 as anode material for lithium battery. Ionics 14, 395–401 (2008).

Ariyoshi, K., Yamato, R. & Ohzuku, T. Zero-strain insertion mechanism of li[li1/3ti5/3]o4 for advanced lithium-ion (shuttlecock) batteries. Electrochim. Acta 51, 1125–1129 (2005).

Weppner, W. & Huggins, R. A. Determination of the kinetic parameters of mixed-conducting electrodes and application to the system li3sb. J. Electrochem. Soc. 124, 1569–1578 (1977).

Acknowledgements

This work was supported by the National Research Foundation (NRF) of Korea grant (2015R1A2A1A10056156, GCRC-SOP), Nano-Convergence Foundation (R201500910), and Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant (20153010041750).

Author information

Authors and Affiliations

Contributions

H.S. and Y.-T.K. proposed the concept and H.S. performed the experiment. T.-G. Jeong, S.-W.Y., E.-K.L. and S.-A.P. participated in acquiring the data. H.S. and Y.-T.K. wrote the paper. All authors commented on the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Song, H., Jeong, TG., Yun, SW. et al. An upper limit of Cr-doping level to Retain Zero-strain Characteristics of Li4Ti5O12 Anode Material for Li-ion Batteries. Sci Rep 7, 43335 (2017). https://doi.org/10.1038/srep43335

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep43335

This article is cited by

-

Development of design strategies for conjugated polymer binders in lithium-ion batteries

Polymer Journal (2023)

-

Physicochemical Properties of Oriented Crystalline Assembled Polyaniline/Metal Doped Li4Ti5O12 Composites for Li-ion Storage

Journal of Inorganic and Organometallic Polymers and Materials (2023)

-

Li4Ti5O12 prepared by Sr-doped for Li-ion batteries with enhanced electrochemical performance

Journal of Materials Science: Materials in Electronics (2023)

-

Ultrahigh lithiation dynamics of Li4Ti5O12 as an anode material with open diffusion channels induced by chemical presodiation

Rare Metals (2023)

-

pH effect upon sol–gel processing of titanium butoxide and lithium acetate precursors on the characteristics of Li4Ti5O12 as an anode for lithium-ion batteries

Bulletin of Materials Science (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.