Abstract

Black TiO2 nanobelts/g-C3N4 nanosheets laminated heterojunctions (b-TiO2/g-C3N4) as visible-light-driven photocatalysts are fabricated through a simple hydrothermal-calcination process and an in-situ solid-state chemical reduction approach, followed by the mild thermal treatment (350 °C) in argon atmosphere. The prepared samples are evidently investigated by X-ray diffraction, Fourier transform infrared spectroscopy, scanning electron microscopy, transmission electron microscopy, X-ray photoelectron spectroscopy, N2 adsorption, and UV-visible diffuse reflectance spectroscopy, respectively. The results show that special laminated heterojunctions are formed between black TiO2 nanobelts and g-C3N4 nanosheets, which favor the separation of photogenerated electron-hole pairs. Furthermore, the presence of Ti3+ and g-C3N4 greatly enhance the absorption of visible light. The resultant b-TiO2/g-C3N4 materials exhibit higher photocatalytic activity than that of g-C3N4, TiO2, b-TiO2 and TiO2/g-C3N4 for degradation of methyl orange (95%) and hydrogen evolution (555.8 μmol h−1g−1) under visible light irradiation. The apparent reaction rate constant (k) of b-TiO2/g-C3N4 is ~9 times higher than that of pristine TiO2. Therefore, the high-efficient laminated heterojunction composites will have potential applications in fields of environment and energy.

Similar content being viewed by others

Introduction

The utilization of semiconductor photocatalysts for the treatment of organic pollutants1,2 and hydrogen production from water splitting3 has been regarded as a promising method to solve environment issue4 and energy crisis5. Among various photocatalyst materials, titanium dioxide (TiO2) is the most famous photocatalysts owing to its low cost, high photocatalytic activity, good stability and nontoxicity6,7,8. Nevertheless, the wide band-gap (about 3.2 eV for anatase) and the rapid recombination of photoinduced electron-holes are major drawbacks in its poor photocatalytic activity9. To date, various methods were developed to improve the visible light absorption of TiO2, including metal and non-metal elements doping10, surface sensitization11, semiconductor heterojunction12, and so on. Among them, semiconductor coupling is an efficient method to reduce the recombination of photoinduced electron-hole pairs.

Recently, graphite-like carbon nitride (g-C3N4) has been reported to be a non-toxic, stable and facile metal-free visible light photocatalyst13,14,15. The band-gap of g-C3N4 is ~2.7 eV, indicating a strong absorption in visible light region16. g-C3N4 has displayed excellent properties in photodegradation of organic contaminant17 and H2 evolution18. However, the key issue with the high recombination of photoinduced electron-hole pairs is still limited the photocatalytic applications of g-C3N419. To resolve this problem, coupling g-C3N4 with other semiconductors has attracted much attention, which inhibits the recombination of photoinduced electron-hole pairs and thus improves catalytic performance20. There have been many studies on hybrids of g-C3N4 with TiO2. Recent studies on these composites have shown improved photocatalytic performance in dye degradation and H2 evolution under visible light irradiation21,22,23.

TiO2 nanobelts, have attracted great interest because of their large surface areas24, chemical stability25, and provide sufficient space for the new nucleation26. 2D semiconductor materials, such as g-C3N4 nanosheets, possess a unique layered structure and narrow band gap27, which could absorb visible light efficiently. Therefore, it is believed that 2D g-C3N4 nanosheets coupled with TiO2 nanobelts to form the 3D heterostructure will be a photocatalyst with superior photocatalytic activity. Moreover, the composites with high surface areas maybe produce more reaction active sites and exhibit improved photocatalytic efficiency.

To further expand the TiO2/g-C3N4 composite catalyst practical application, it is necessary to enhance the absorption of TiO2/g-C3N4 composite photocatalyst in the visible light region. During the past few decades, much effort has been devoted to make colorful TiO2 for better optical absorption28,29,30. Recently, Mao et al. presented black hydrogenated TiO2 with enhanced solar light absorption31. The black TiO2 displayed much higher photocatalytic performance over the pristine white TiO2, which was attributed to the higher photoinduced electron-hole pairs separation capability. The enhanced solar light absorption of the black TiO2 was attributed to the formed Ti3+ and oxygen vacancies32. Since then, different synthesis methods were proposed to prepare black TiO2, including high pressure hydrogenation, plasma assisted hydrogenation, chemical reduction, and high-temperature Al vapor reduction33,34,35. Therefore, the development of high photocatalytic activity based on black TiO2 is promising. To the best of our knowledge, up to now, few researchers report black TiO2 combining with g-C3N4 for pollutants degradation and hydrogen evolution under visible-light irradiation.

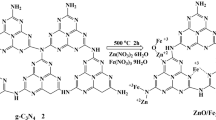

In this work, based on a hydrothermal-calcination method, black TiO2 nanobelts/g-C3N4 nanosheets laminated heterojunctions were prepared by mixing the melamine and the as-prepared TiO2 nanobelt, followed by an in-situ controllable solid-state reaction approach. The prepared b-TiO2/g-C3N4 photocatalyst with a narrow band gap exhibited excellent photocatalytic activity for methyl orange removal and hydrogen evolution under visible-light irradiation.

Results

The samples are characterized by XRD to identify the phase composition of the samples. Figure 1 shows the XRD patterns of TiO2, b-TiO2, g-C3N4, TiO2/g-C3N4, b-TiO2/g-C3N4 composites. For pure TiO2, the peaks at around 25.3, 37.8, 47.9, 53.8, 55.1, 62.7, and 68.7° are ascribed to the (101), (004), (200), (105), (211), (204), and (116) crystal planes of anatase TiO226,36, respectively. Moreover, the b-TiO2 still keeps the pristine crystal phase after the process of treatment with NaBH4, indicating that the crystal phase can’t be influenced by NaBH4. However, the XRD pattern of b-TiO2 shows a slightly extending characteristic peak at 25.3°, which may be ascribed to the effect of oxygen vacancies (Ov), leading the disorder-induced lattice37. The component g-C3N4 is characterized by two diffraction peaks at around 13.1° and 27.4° are attributed to the (100) plane and (002) plane, which correspond to in-planar structural packing and inter-planar stacking peaks of the aromatic system38,39, respectively. For the TiO2/g-C3N4 and b-TiO2/g-C3N4 samples, the XRD patterns show the characteristic diffraction peaks of both anatase and g-C3N4, indicating that the composites consisted of both anatase TiO2 and g-C3N4. No other characteristic peaks are found, revealing the high purity of the as-prepared samples.

The FT-IR spectroscopy is applied to identify the composition of TiO2, b-TiO2, g-C3N4 and b-TiO2/g-C3N4 heterojunction photocatalysts, as shown in Fig. 2. For pure TiO2 and b-TiO2, the main peaks at appearing at 400–700 cm−1 is assigned to Ti-O-Ti and Ti-O stretching vibration modes40,41. The peaks at about 1650 and 3400–3500 cm−1 are corresponding to hydroxyl group and physically absorbed water on the surface of the TiO242, respectively. In the FT-IR spectrum of g-C3N4, the absorption band at 1640 cm−1 can be corresponded to the C-N heterocycle stretching vibration modes43, while the four at 1241, 1320, 1409, and 1567 cm−1 to aromatic C-N stretching vibration modes44,45. The peak at 808 cm−1 is associated with the breathing mode of triazine units46. For the b-TiO2/g-C3N4 composite, it can be clearly seen that all the main absorption peaks of g-C3N4 and TiO2 appeared in b-TiO2/g-C3N4 composite, suggesting the presence of TiO2 and g-C3N4 in the as-prepared composite.

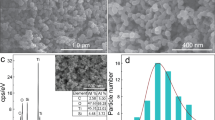

The morphology and microstructure of samples are studied by SEM and TEM. Figure S1 shows the SEM image of g-C3N4, which exhibits a wrinkled sheet structure. It could be found from Figure S2 that TiO2 nanobelt was about 2–3 μm long, 50–200 nm wide and appeared smooth surface. The SEM image of b-TiO2/g-C3N4 is presented in Fig. 3a. Apparently, when compared with the pure TiO2 nanobelt, the surface of the b-TiO2/g-C3N4 composite became coarse due to the introduction of g-C3N4 nanosheet, indicating that the g-C3N4 nanosheet has been coated on the surface of TiO2 nanobelt and formed the laminated structure. Figure 3b and c display the TEM images of the b-TiO2/g-C3N4 composite, the component g-C3N4 shows a sheet shape which is coated on the TiO2 nanobelt. Importantly, the close contact between g-C3N4 nanosheet and TiO2 nanobelt is necessary for superior catalytic performance. The high-resolution TEM (HRTEM) image of composite is depicted in Fig. 3d, the lattice fringe spacing of 0.35 nm and 0.33 nm corresponded to the (101) crystal plane of TiO2 and (002) crystal plane of g-C3N4, respectively. The result of the HRTEM image clearly indicates the formation of special laminated heterojunctions. All these results confirmed that g-C3N4 nanosheets were successfully combined with TiO2 nanobelts.

In order to examine the surface chemical composition and chemical states of elements in the as-prepared g-C3N4 and b-TiO2/g-C3N4 sample, XPS measurements are performed. The survey XPS spectra of g-C3N4 and b-TiO2/g-C3N4 sample (Figure S3) reveal the presence of Ti, O, N and C elements. The results of the high-resolution XPS spectra of Ti 2p, O 1s, N 1s and C 1s of the sample are shown in Fig. 4. Figure 4a shows the Ti 2p XPS spectra of the b-TiO2/g-C3N4 sample, the peak located at 464.1, 463.5, 458.3 and 457.8 eV are assigned to Ti4+ 2p1/2, Ti3+ 2p1/2, Ti4+ 2p3/2 and Ti3+ 2p3/2, respectively. The Ti3+ species are created due to the Ti4+ reduction of TiO2 by the treatment with NaBH447. The O 1s spectra in Fig. 4b can be fitted into two peaks, corresponding to the Ti-O bond (529.8 eV) and the -OH group (532.1 eV) on the surface of the b-TiO2/g-C3N4 sample4. Four peaks are observed in the high-resolution XPS spectrum of N 1s for g-C3N4 (Fig. 4c). The peak at 398.2 eV is assigned to sp2-hybridized aromatic N bound to C atoms (C = N-C), while the signal at the binding energy of 399.3 eV indicates tertiary nitrogen N-(C)3. The peaks at 400.9 and 404.2 eV are assigned to C-N-H groups and charging effects6. In N 1s XPS spectrum, compared with the g-C3N4, the peaks of g-C3N4/b-TiO2 shifted 0.5 eV towards higher binding energy can be attributed to the chemical environment change arising from the close interaction between g-C3N4 and TiO242. The intensity of peaks in g-C3N4/b-TiO2 is higher than in pure g-C3N4 due to the existence of N defects in g-C3N4 after treatment by NaBH4. Figure 4d shows the XPS of g-C3N4 and b-TiO2/g-C3N4 in the C 1s binding energy regions. Peaks at 284.8 and 287.9 eV can be assigned to the adventitious carbon C-C and N-C = N48. Correspondingly, in the C 1s spectrum of the b-TiO2/g-C3N4 sample, the peak of N-C = N shifted 0.5 eV towards higher binding energy. The shifts of the N 1s and C 1s peaks of b-TiO2/g-C3N4 may be attributed to the tight contact at the interface between g-C3N4 and TiO2.

The nitrogen adsorption-desorption isotherms and the pore size distributions curves of pure g-C3N4, TiO2 and b-TiO2/g-C3N4 heterojunction photocatalyst are shown in Fig. 5a and b. It can be seen from Fig. 5a that pure TiO2 (36.5 m2/g) has a larger surface area than that of g-C3N4 (26.5 m2/g). Notably, the BET surface area of the b-TiO2/g-C3N4 composite (29.3 m2/g) is decreased after coupling with TiO2 due to the relatively low surface area of g-C3N4. Figure 5b shows the peak at 21.6 nm of b-TiO2/g-C3N4 is larger than the pure g-C3N4 which is the sharp peak at 3.5 nm, indicating that g-C3N4 nanosheet coated on the surface of TiO2 nanobelt.

To study the light absorption ability of as-prepared samples, the UV-vis DRS analysis was performed, as shown in Fig. 6a. The absorption wavelength of g-C3N4 is up to 450 nm39. However, the TiO2 is under 390 nm which means pure TiO2 can only have a response to UV light49. After coupling with g-C3N4, the TiO2/g-C3N4 composite exhibits the broader absorption edge and extends to visible light region. For the b-TiO2, the absorption shows distinctly enhanced in the visible light region, which can be attributed to the introduction of Ti3+ and oxygen vacancies32. As can be seen clearly, the b-TiO2/g-C3N4 composite exhibits obvious absorption in the visible light range, due to the synergistic effect between TiO2, g-C3N4 and the Ti3+. It has been reported that Ti3+ and oxygen vacancies could break the selection rule for indirect transitions of TiO2 and improve absorption for photon energy50. Figure 6b shows the band gap energies of all the samples. The band gap of TiO2, g-C3N4, TiO2/g-C3N4 b-TiO2 and b-TiO2/g-C3N4 are 3.15, 2.62, 2.88, 2.58 and 2.32 eV, respectively. The narrow band gap is beneficial to improve the visible light absorption properties, so the b-TiO2/g-C3N4 can show an enhanced photocatalytic performance.

Figure 7a shows the photocatalytic degradation of MO for different photocatalysts. The blank test demonstrates that MO could not be degraded under visible light irradiation without catalysts, and thus it can be considered that MO is stable. For pure TiO2 and g-C3N4, the concentration of MO is only reduced by about 17.1% and 24.6% under visible light irradiation for 120 min. The TiO2/g-C3N4 and b-TiO2 show higher photocatalytic activity, which the removal of MO is about 45.6% and 64.7%. As expected, the b-TiO2/g-C3N4 photocatalyst exhibits higher photocatalytic activity than other samples under visible light irradiation. The concentration of MO is reduced by about 95.1%. From Fig. 7b, the apparent reaction rate constant (k) values of TiO2, g-C3N4, TiO2/g-C3N4, b-TiO2 and b-TiO2/g-C3N4 are 0.0016, 0.0025, 0.0052, 0.0074 and 0.0153 min−1, respectively. Moreover, the k value of b-g-C3N4/TiO2 is also higher than others, which is about ~9 times higher than that of pure TiO2. This result suggests that introducing Ti3+ of black TiO2 and a better heterostructured combination between g-C3N4 and black TiO2 could promote the separation of photogenerated carriers and accelerate the electron transfer.

The photocatalytic activity of the as-prepared samples is also evaluated for hydrogen evolution under the simulated solar light (AM 1.5) irradiation. As indicated in Fig. 8a, the pure g-C3N4 only shows a H2 generation rate of 108.2 μmol h−1 g−1. This is probably due to the high recombination of photoinduced electron-holes. For pure TiO2, very little H2 is produced. The hydrogen generation rate of b-TiO2, TiO2/g-C3N4 and b-TiO2/g-C3N4 are 130.5, 388.4 and 555.8 μmol h−1 g−1, respectively. These results indicate that the b-TiO2/g-C3N4 materials have the highest photocatalytic activity among the as-prepared samples, revealing that the Ti3+ and the heterojunction structure contribute to high photocatalytic activity. To evaluate the stability of b-TiO2/g-C3N4, recycling experiments were carried out on hydrogen evolution reaction for five times. As shown in Fig. 8b, the b-TiO2/g-C3N4 exhibits no obvious loss in hydrogen evolution activity after five cycles lasting 25 h in total, indicating the high stability of the photocatalyst.

As can be seen from Fig. 9a, the electrochemical impedance spectra (EIS) result reflects that the impedance arc radius of b-TiO2/g-C3N4 is smaller than that of TiO2 and g-C3N4 under visible light, indicating that b-TiO2/g-C3N4 composite demonstrates enhanced separation efficiency of the photoexcited charge carriers compared with that of pure TiO2 and g-C3N4. Figure 9b shows the fluorescence (FL) intensity of these samples in 1 h under Xenon lamp irradiation with a 420 nm cut-off filter. It is clearly observed that the fluorescence intensity of b-TiO2/g-C3N4 is the strongest than any other samples at 425 nm, indicating that the b-TiO2/g-C3N4 can produce the largest amount of ·OH radicals under visible light irradiation, consisting with the excellent photodegradation efficiency of MO.

On the basis of the results above, a sufficient contact interface between g-C3N4 nanosheet and TiO2 nanobelt is achieved. As shown in Fig. 10, the Ti3+ and oxygen vacancies are detected at the bottom of the TiO2 conduction band (CB), which can be easily narrow the bandgap of TiO2 nanobelt and improve the optical absorption properties12. When the catalyst is exposed to visible-light irradiation, g-C3N4 can produce photo-induced electron-hole pairs. The photogenerated electrons in the conduction band of g-C3N4 can transfer to the conduction band of TiO219. Since the CB levels of TiO2 is more negative than the potential of O2/·O2− (−0.046 eV vs. NHE at pH = 7), as a result, the electrons in CB of TiO2 can be trapped by dissolved oxygen to generate ·O2− radical species. And compared with the potential of ·OH/H2O (2.27 eV vs. NHE at pH = 7), the remained h+ on the VB of g-C3N4 can not react with H2O to generate ·OH radicals due to the lower VB level of g-C3N4 (1.63 eV vs. NHE at pH = 7)7,51. Subsequently, the radical species ·O2− and h+ can directly degrade organic pollutants. In this system, the ·OH is mainly produced by the b-TiO2, not g-C3N4. The separated electrons on the CB of TiO2 can also split water to produce H27. The effective electron-holes separation will enhance the photocatalytic activity as compared to pure TiO2 and g-C3N4 due to the compact interface between the two materials.

Conclusions

In conclusion, based on a hydrothermal-calcination method, b-TiO2/g-C3N4 laminated heterojunctions were prepared by mixing the melamine and the as-prepared TiO2 nanobelt, followed by an in-situ controllable solid-state reaction approach. The formation of a strong contact between TiO2 and g-C3N4 by this method greatly enhanced the separation efficiency of photoinduced electrons and holes. The narrow band gap of b-TiO2/g-C3N4 composite was attributed to the introduction of g-C3N4 and the Ti3+ species. Under visible light irradiation, b-TiO2/g-C3N4 composite exhibited higher photocatalytic activity than g-C3N4, TiO2, b-TiO2 and TiO2/g-C3N4 towards the degradation of methyl orange and hydrogen evolution. Based on this work, the b-TiO2/g-C3N4 composite is expected to be a highly effective visible light photocatalyst for practical applications.

Methods

Materials

TiO2 (P25) power was purchased from Deguassa Co. Ltd, Germany. Absolute ethanol (EtOH), sulfuric acid (H2SO4), and sodium hydroxide (NaOH), were purchased from Tianjin Kermel Chemical Reagent Co. LTD, China. Sodium boron hydride (NaBH4, 98%) was purchased from Aladdin Reagent Company, China. All reagents used in the experiments were analytical grade and employed without further purification, and the deionized (DI) water was used throughout this study.

Preparation of TiO2 nanobelt

0.2 g of P25 was mixed with 40 mL of 10 M NaOH aqueous solution. The suspension was transferred to a 50 mL Teflon-lined autoclave and maintained at 180 °C for 72 h. The obtained products were washed thoroughly with deionized water and immersed in 0.1 M HCl aqueous solution for 24 h. Then the samples were immersed in a 0.02 M H2SO4 aqueous solution and maintained at 100 °C for 10 h. Finally, the products were washed with deionized water for several times and dried at 70 °C for 10 h. The sample was annealed at 600 °C for 2 h.

Preparation of TiO2/g-C3N4 photocatalyst

TiO2/g-C3N4 photocatalyst was fabricated by calcining the mixtures of the melamine and TiO2 nanobelt powder. A given amount of melamine was ground with the TiO2 nanobelts (weight ratios of TiO2 nanobelt to melamine: 1:6). Finally, the mixture was calcined in a muffle furnace for 2 h at 550 °C with a heating rate of 20 °C min−1 in air atmosphere. For comparison, g-C3N4 was also synthesized by directly calcining melamine under air atmosphere at 550 °C for 2 h.

Preparation of b-TiO2/g-C3N4 photocatalyst

At room temperature, 2 g of the prepared sample was mixed with 4 g of NaBH4 and the mixture was ground for 30 min thoroughly. Then the mixture was placed in a porcelain boat and heated in a tubular furnace for 1 h at 350 °C with a ramping rate of 5 °C min−1 under Ar atmosphere. After naturally cooling down to room temperature, the b-TiO2/g-C3N4 was obtained (Fig. 11). The obtained sample was washed with deionized water and absolute ethanol for several times. For comparison, the pure black TiO2 (b-TiO2) was also synthesized under the same condition.

The Ti3+ species are created due to the Ti4+ reduction of TiO2 by the treatment with NaBH4, so the white TiO2 nanobelt is turned to black52. NaBH4 reduction induces a distinctly increase in the peak intensity of Ti3+ and the result shows that more Ti3+ is formed on the surface or subsurface of b-TiO2, which may change the surface chemical bonding environment of TiO253.

Characterization

The powder X-ray diffraction (XRD) patterns were acquired on a Bruker D8 Advance diffractometer by using Cu Kα radiation (λ = 1.5406 Å). X-ray photoelectron spectroscopy (XPS) was measured on a PHI-5700 ESCA instrument with Al-Kα X-ray source. The Fourier transform infrared spectra (FI-IR) of the samples were collected with a PerkinElmer spectrum one system, using KBr as diluents. The morphology of the samples was observed on a field emission scanning electron microscope (FE-SEM, Hitachi S-4800). Transmission electron microscopy (TEM) was performed using a JEM-2100 electron microscope (JEOL, Japan). Surface area determination was performed by the Brunauer-Emmett-Teller (BET) method with an AUTOSORB-1 (Quantachrome Instruments) nitrogen adsorption apparatus. The UV-vis absorption spectra of the samples were measured by a UV-vis spectrophotometer (UV-2550, Shimadzu) with an integrating sphere attachment, and BaSO4 was used as the reference material. The ·OH radicals were detected by the fluorescence probe technique with terephthalic acid (FL-TA) on a RF-5301PC fluorescence spectrophotometer. The electrochemical impedance spectroscopy (EIS) was performed with a computer-controlled IM6e Impedance measurement unit (Zahner Elektrik, Germany).

Photocatalytic hydrogen evolution

Photocatalytic hydrogen evolution tests were carried out in an online photocatalytic hydrogen generation system (AuLight, Beijing, CEL-SPH2N) at room temperature. The experiments were carried out by taking 50 mg of photocatalysts in a 100 mL of aqueous solution containing the 80 mL of deionized water and 20 mL of methanol used as the sacrificial reagent in closed-gas circulation reaction cell. Prior to the reaction, the system was vacuumized completely to remove O2 and CO2 dissolved in water. Then, the mixture solution was irradiated by a 300 W Xeon-lamp equipped with an AM 1.5 G filter (Oriel, USA). The hydrogen was periodically analyzed using an on-line gas chromatography with the interval of each 1 h (SP7800, TCD, molecular sieve 5 Å, N2 carrier, Beijing Keruida, Ltd).

Photocatalytic degradation

The measurement of photocatalytic activity was evaluated by the degradation of methyl orange (MO) under visible light irradiation. A 300 W Xeon-lamp with a 420 nm cutoff filter. The experimental procedures were as follows: at room temperature, 30 mg of photocatalyst was added to 30 mL of 10 mg/L MO aqueous solution, which was placed at 20 cm from the light source. Before irradiation, the suspension was magnetically stirred in the dark for 30 min to ensure an adsorption-desorption equilibrium between the photocatalysts and MO. At certain intervals, the reaction solution was centrifuged to remove the particles. Finally, the concentration of MO was measured at λ = 464 nm by using a T6 UV-vis spectrophotometer.

Additional Information

How to cite this article: Shen, L. et al. Black TiO2 nanobelts/g-C3N4 nanosheets Laminated Heterojunctions with Efficient Visible-Light-Driven Photocatalytic Performance. Sci. Rep. 7, 41978; doi: 10.1038/srep41978 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Xing, Z. P. et al. A floating macro/mesoporous crystalline anatase TiO2 ceramic with enhanced photocatalytic performance for recalcitrant wastewater degradation. Dalton Transactions 43, 790–798 (2014).

Zhang, L. L. et al. High thermostable ordered mesoporous SiO2-TiO2 coatedcirculating-bed biofilm reactor for unpredictable photocatalytic and biocatalytic performance. Applied Catalysis B: Environmental 180, 521–529 (2016).

Zhou, W. et al. Ordered Mesoporous Black TiO2 as Highly Efficient Hydrogen Evolution Photocatalyst. Journal of the American Chemical Society 136, 9280–9283 (2014).

Chen, Y. F., Huang, W. X., He, D. L., Situ, Y. & Huang, H. Construction of Heterostructured g-C3N4/Ag/TiO2 Microspheres with Enhanced photocatalysis Performance under Visible-Light Irradiation. ACS Applied Materials Interfaces 6, 14405–14414 (2014).

Ong, W. J., Tan, L. L., Chai, S. P., Yong, S. T. & Mohamed, A. R. Highly reactive {001} facets of TiO2-based composites: synthesis, formation mechanism and characterization. Nanoscale 6, 1946–2008 (2014).

Weng, X. L., Zeng, Q. S., Zhang, Y. L., Dong, F. & Wu, Z. B. Facile Approach for the Syntheses of Ultrafine TiO2 Nanocrystallites with Defects and C Heterojunction for Photocatalytic Water Splitting. ACS Sustainable Chemistry & Engineering 4, 4314−4320 (2016).

Jiang, Z. F., Zhu, C. Z., Wan, W. M., Qian, K. & Xie, J. M. Constructing graphite-like carbon nitride modified hierachical yolk-shell TiO2 spheres for water pollution treatment and hydrogen production. Journal of Materials Chemistry A 4, 1806–1818 (2016).

Wu, Y., Liu, X. W., Yang, Z. Z., Gu, L. & Yu, Y. Nitrogen-Doped Ordered Mesoporous Anatase TiO2 Nanofibers As Anode Materials for High Performance Sodium-Ion Batteries. Small 12, 3522–3529 (2016).

Xing, Z. P. et al. Hierarchical Porous TiO2 Ceramics with Enhanced Photocatalytic Performance for Micropolluted Pesticide Degradation. ACS Applied Materials Interfaces 6, 16653–1660 (2014).

Cai, L. L. et al. Sol-flame synthesis of cobalt-doped TiO2 nanowires with enhanced electrocatalytic activity for oxygen evolution reaction. Phys. Chem. Chem. Phys. 16, 12299–12306 (2014).

Ardo, S. & Meyer, G. J. Photodriven heterogeneous charge transfer with transition-metal compounds anchored to TiO2 semiconductor surfaces. Chemical Society Reviews 38, 115–164 (2009).

Liu, X. F. et al. Fabrication of 3 D Mesoporous Black TiO2/MoS2/TiO2 Nanosheets for Visible-Light-Driven Photocatalysis. Chem. Sus. Chem. 9, 1118–1124 (2016).

Guo, S. E. et al. Phosphorus-Doped Carbon Nitride Tubes with a Layered Micro-nanostructure for Enhanced Visible-Light Photocatalytic Hydrogen Evolution. Angewandte Chemie 128, 1862–1866 (2016).

Wu, G. S., Thind, S. S., Wen, J. L., Yan, K. & Chen, A. C. A novel nanoporous α-C3N4 photocatalyst with superior high visible light activity. Applied Catalysis B: Environmental 142–143, 590–597 (2013).

Tian, J. Q. et al. Ultrathin graphitic carbon nitride nanosheets: a low-cost, green, and highly efficient electrocatalyst toward the reduction of hydrogen peroxide and its glucose biosensing application. Nanoscale 5, 8921–8924 (2013).

Yang, K. et al. A heterostructured TiO2-C3N4 support for gold catalysts: a superior preferential oxidation of CO in the presence of H2 under visible light irradiation and without visible light irradiation. Catalysis Science & Technology 6, 829–839 (2016).

Dai, K., Lu, L. H., Liang, C. H., Liu, Q. & Zhu, G. P. Heterojunction of facet coupled g-C3N4/surface-fluorinated TiO2 nanosheets for organic pollutants degradation under visible LED light irradiation. Applied Catalysis B: Environmental 156–157, 331–340 (2014).

Zhang, G. G., Huang, C. J. & Wang, X. C. Dispersing Molecular Cobalt in Graphitic Carbon Nitride Frameworks for Photocatalytic Water Oxidation. Small 11, 1215–1221 (2015).

Huang, Z. A. et al. Effect of contact interface between TiO2 and g-C3N4 on the photoreactivity of g-C3N4/TiO2 photocatalyst: (0 0 1) vs (1 0 1) facets of TiO2 . Applied Catalysis B: Environmental 164, 420–427 (2015).

Zhao, H. et al. In situ light-assisted preparation of MoS2 on graphitic C3N4 nanosheets for enhanced photocatalytic H2 production from water. Journal of Materials Chemistry A 3, 7375–7381 (2015).

Zang, Y. P., Li, L. P., Xu, Y. S., Zuo, Y. & Li, G. S. Hybridization of brookite TiO2 with g-C3N4: a visible-light-driven photocatalyst for As3+ oxidation, MO degradation and water splitting for hydrogen evolution. Journal of Materials Chemistry A 2, 15774–15780 (2014).

Li, G. S., Lian, Z. C., Wang, W. C., Zhang, D. Q. & Li, H. X. Nanotube-confinement induced size-controllable g-C3N4 quantum dots modified single-crystalline TiO2 nanotube arrays for stable synergetic photoelectrocatalysis. Nano Energy 19, 446–454 (2016).

Pan, X. Y., Chen, X. X. & Yi, Z. G. Porous TiO2 Nanosheets with Pt Decoration as an Efficient Photocatalyst for Ethylene Oxidation Synthesized by a C3N4 Templating Method. ACS Applied Materials Interfaces 8, 10104–10108 (2016).

Wang, X. D., Li, Z. D., Shi, J. & Yu, Y. H. One-Dimensional Titanium Dioxide Nanomaterials: Nanowires, Nanorods, and Nanobelts. Chemical Reviews 114, 9346–9384 (2014).

Tian, J., Hao, P., Wei, N., Cui, H. Z. & Liu, H. 3D Bi2MoO6 Nanosheet/TiO2 Nanobelt Heterostructure: Enhanced Photocatalytic Activities and Photoelectochemistry Performance. ACS Catalysis 5, 4530–4536 (2015).

Chen, G. H. et al. High-Energy Faceted SnO2-Coated TiO2 Nanobelt Heterostructure for Near-Ambient Temperature-Responsive Ethanol Sensor. ACS Applied Materials Interfaces 7, 24950–24956 (2015).

Zhao, H. X., Chen, S., Quan, X., Yu, H. T. & Zhao, H. M. Integration of microfiltration and visible-light-driven photocatalysison g-C3N4 nanosheet/reduced graphene oxide membrane for enhanced water treatment. Applied Catalysis B: Environmental 194, 134–140 (2016).

Liu, N. et al. “Black” TiO2 Nanotubes Formed by High-Energy Proton Implantation Show Noble-Metal-co-Catalyst Free Photocatalytic H2-Evolution. Nano Letters 15, 6815–6820 (2015).

Hu, W. Y. et al. Facile strategy for controllable synthesis of stable mesoporous black TiO2 hollow spheres with efficient solar-driven photocatalytic hydrogen evolution. Journal of Materials Chemistry A 4, 7495–7502 (2016).

Yang, C. Y. et al. Core-Shell Nanostructured “Black” Rutile Titania as Excellent Catalyst for Hydrogen Production Enhanced by Sulfur Doping. Journal of the American Chemical Society 135, 17831–17838 (2013).

Chen, X. B., Liu, L., Yu, P. Y. & Mao, S. S. Increasing Solar Absorption for Photocatalysis with Black Hydrogenated Titanium Dioxide Nanocrystals. Science 331, 746–750 (2011).

Chen, X. B., Liu, L. & Huang, F. Q. Black titanium dioxide (TiO2) nanomaterials. Chemical Society Reviews 44, 1861–1885 (2015).

Sinhamahapatra, A., Jeon, J. P. & Yu, J. S. A new approach to prepare highly active and stable black titania for visible light-assisted hydrogen production. Energy &Environmental Science 8, 3539–3544 (2015).

Teng, F. et al. Preparation of black TiO2 by hydrogen plasma assisted chemical vapor deposition and its photocatalytic activity. Applied Catalysis B: Environmental 148–149, 339–343 (2014).

Wang, Z. et al. Visible-light photocatalytic, solar thermal and photoelectrochemical properties of aluminium-reduced black titania. Energy &Environmental Science 6, 3007–3014 (2013).

Zhou, W. J. et al. Ag2O/TiO2 Nanobelts Heterostructure with Enhanced Ultraviolet and Visible Photocatalytic Activity. ACS Applied Materials Interfaces 8, 10104–10108 (2016).

Huo, J. C., Hu, Y. J., Jiang, H. & Li, C. Z. In situ surface hydrogenation synthesis of Ti3+ self-doped TiO2 with enhanced visible light photoactivity. Nanoscale 6, 9078–9084 (2014).

Xu, M., Han, L. & Dong, S. J. Facile Fabrication of Highly Efficient g-C3N4/Ag2O Heterostructured Photocatalysts with Enhanced Visible-Light Photocatalytic Activity. ACS Applied Materials Interfaces 5, 12533–12540 (2013).

Sridharan, K. Jang, E. & Park, T. J. Novel visible light active graphitic C3N4-TiO2 composite photocatalyst: Synergistic synthesis, growth and photocatalytic treatment of hazardous pollutants. Applied Catalysis B: Environmental 142–143, 718–728 (2013).

Kang, Q. et al. Sensitive detection of ascorbic acid and alkaline phosphatase activityby double-channel photoelectrochemical detection design based on g-C3N4/TiO2nanotubes hybrid film. Sensors and Actuators B 230, 231–241 (2013).

Cai, J. M. et al. In Situ Formation of Disorder-Engineered TiO2(B)-Anatase Heterophase Junction for Enhanced Photocatalytic Hydrogen Evolution. ACS Applied Materials Interfaces 7, 24987–24992 (2015).

Song, X., Hu, Y., Zheng, M. M. & Wei, C. H. Solvent-free in situ synthesis of g-C3N4/{0 0 1}TiO2 composite with enhanced UV- and visible-light photocatalytic activity for NO oxidation. Applied Catalysis B: Environmental 182, 587–597 (2016).

Liu, C. Y. et al. In Situ Co-Crystallization for Fabrication of g-C3N4/Bi5O7I Heterojunction for Enhanced Visible-Light Photocatalysis. The Journal of Physical Chemistry C 119, 17156–17165 (2015).

Kong, H. J., Won, D. H., Kim, J. & Woo, S. I. Sulfur-Doped g-C3N4/BiVO4 Composite Photocatalyst for Water Oxidation under Visible Light. Chemistry of Materials 28, 1318–1324 (2016).

Dong, F., Ni, Z. L., Li, P. D. & Wu, Z. B. A general method for type I and type II g-C3N4/g-C3N4 metal-free isotype heterostructures with enhanced visible light photocatalysis. New J. Chem. 39, 4737–4744 (2015).

Zhu, Z. et al. Fabrication of conductive and high-dispersed Ppy@Ag/g-C3N4 composite photocatalysts for removing various pollutants in water. Applied Surface Science 387, 366–374 (2016).

Fang, W. Z., Xing, M. Y. & Zhang, J. L. A new approach to prepare Ti3+ self-doped TiO2 via NaBH4 reduction and hydrochloric acid treatment. Applied Catalysis B: Environmental 160, 240–246 (2014).

Pany, S. & Parid, K. M. A facile in situ approach to fabricate N,S-TiO2/g-C3N4 nanocomposite with excellent activity for visible light induced water splitting for hydrogen evolution. Phys. Chem. Chem. Phys. 17, 8075–8077 (2015).

Yu, X. et al. Hierarchical hybrid nanostructures of Sn3O4 on N doped TiO2 nanotubes with enhanced photocatalytic performance. Journal of Materials Chemistry A 3, 19129–19136 (2015).

Zuo, F. et al. Self-Doped Ti3+ Enhanced Photocatalyst for Hydrogen Production under Visible Light. Journal of the American Chemical Society 132, 11856–11857 (2010).

Hao, R. R. et al. Template-free preparation of macro/mesoporous g-C3N4/TiO2 heterojunction photocatalysts with enhanced visible light photocatalytic activity. Applied Catalysis B: Environmental 187, 47–58 (2016).

Liu, L. J. et al. Engineering Coexposed {001} and {101} Facets in Oxygen-Deficient TiO2 Nanocrystals for Enhanced CO2 Photoreduction under Visible Light. ACS Catalysis 6, 1097–1108 (2016).

Xin, X. Y., Xu, T., Yin, J., Wang, L. & Wang, C. Y. Management on the location and concentration of Ti3+ in anatase TiO2 for defects-induced visible-light photocatalysis. Applied Catalysis B: Environmental 176–177, 354–362 (2015).

Acknowledgements

We gratefully acknowledge the support of this research by the National Natural Science Foundation of China (21376065, 81302511, 81573134 and 51672073), the Natural Science Foundation of Heilongjiang Province (QC2012C001, QC2013C079, and E201456), the Heilongjiang Postdoctoral Startup Fund (LBH-Q14135), the Program for New Century Excellent Talents in University of Heilongjiang Province (1253-NCET-020), the University Nursing Program for Young Scholars with Creative Talents in Heilongjiang Province (UNPYSCT-2015014), and the Science and Technology Innovation Talent Program for Young Scholars in Heilongjiang Province (UNPYSCT-2016018).

Author information

Authors and Affiliations

Contributions

Xing Z.P. and Shen L.Y. conceived the experiments, Xing Z.P., Shen L.Y., Zou J.L., Li Z.Z., Wu X.Y., Zhang Y.C. and Zhu Q. conducted the experiments, Xing Z.P., Yang S.L. and Zhou W. analysed the results. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Shen, L., Xing, Z., Zou, J. et al. Black TiO2 nanobelts/g-C3N4 nanosheets Laminated Heterojunctions with Efficient Visible-Light-Driven Photocatalytic Performance. Sci Rep 7, 41978 (2017). https://doi.org/10.1038/srep41978

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep41978

This article is cited by

-

g-C3N4 quantum dots decorated on urchin-like TiO2 nanostructures for the photoelectrochemical water splitting

Journal of Materials Science (2024)

-

Zinc oxide@citric acid-modified graphitic carbon nitride nanocomposites for adsorption and photocatalytic degradation of perfluorooctanoic acid

Advanced Composites and Hybrid Materials (2024)

-

Biomimicking Activity Resembling Phenoxazinone Synthase of Heterogenized Oxidovanadium(V) and Its Analogous Homogeneous Complex

Topics in Catalysis (2024)

-

g-C3N4/graphene oxide/SnFe2O4 ternary composite for the effective sunlight-driven photocatalytic degradation of methylene blue

Environmental Science and Pollution Research (2023)

-

Photocatalytic Synthesis of Hydrogen Peroxide from Molecular Oxygen and Water

Topics in Current Chemistry (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.