Abstract

Y2O3/Y2O2S:Eu3+ nanocomposites were successfully prepared by reducing Y2O3:Eu3+ nanocrystals. The obtained Y2O3/Y2O2S:Eu3+ nanocomposites not only can emit enhanced red luminescence excited at 338 nm, but also can be used to improve the efficiency of the dye sensitized solar cells, resulting an efficiency of 8.38%, which is a noticeable enhancement of 12% compared to the cell without Y2O3/Y2O2S:Eu3+ nanocomposites. The results of the incident photon to current, dynamic light scattering, and diffuse reflectance spectra indicated that the enhancement of the cell efficiency was mainly related to the light scattering effect of Y2O3/Y2O2S:Eu3+ nanocomposites. As a phosphor powder, the emission at ~615 nm of Y2O3/Y2O2S:Eu3+ was split into two sub-bands. Compared with Y2O3:Eu3+, the 5D0 → 7F0 and 5D0 → 7F1 emissions of Y2O3/Y2O2S:Eu3+ showed a little red-shift.

Similar content being viewed by others

Introduction

Rare earth (RE) compounds were extensively applied in the fields of high-performance magnets, luminescence devices, catalysts, and other functional materials. Most of these functions depend strongly on the composition and structure of materials1,2,3,4,5. In particular, nano-sized luminescent materials have attracted considerable attention since Bhargava et al. reported that doped nanocrystalline phosphors yielded high luminescence efficiencies6,7,8,9. With rapidly shrinking size, nanomaterials usually exhibit novel physical and chemical properties due to their extremely small size and relatively large specific surface areas10,11,12,13.

It is well known that host material is an important factor to obtain high efficient luminescent properties. Among various host materials, Y2O3 not only has good chemical and photochemical stabilities and high melting points, but also can be easily doped with RE ions. Especially, Y2O3:Eu3+ phosphor is used for high efficiency cathode-ray tubes and field emission displays because of its excellent luminescence efficiency under ultraviolet excitation14,15,16,17. Y2O2S:Eu3+ has been used as a red “no mill” phosphor for decades. Its high brightness, excellent color definition, and linear response in the wide range of current density make it promising for the future generation of display equipment18,19,20,21,22.

Composite materials formed by combining two or more materials could present complementary properties that have shown important technological applications23,24. However, Y2O3/Y2O2S composite nanocrystals have never been reported. It is well known that the excitation spectrum of Y2O3:Eu3+ was dominated by the excitation band centered at 259 nm, while that of Y2O2S:Eu3+ was dominated by the excitation band centered at 338 nm. In addition, the emission spectrum of Y2O3:Eu3+ was dominated by the emission at ~615 nm, while that of Y2O2S:Eu3+ was dominated by the emission at ~630 nm. And thus, novel luminescent properties could be obtained by combining Y2O3:Eu3+ and Y2O2S:Eu3+.

In the past decade, the dye-sensitized solar cell (DSSC) has become one of the most promising solar cells in the renewable energy research and development field for its potentially low fabrication cost and relatively good efficiency25,26,27. The concept of integrating a down-conversion layer into a solar cell has attracted significant attention because it not only can remove the load of spectral matching from the semiconductor itself, minimize the thermalization losses in cells, and move this task to a separation component, but also can offer the opportunity to improve light harvesting and thereby the efficiency of the solar cells28,29,30. Herein, we successfully prepared Y2O3/Y2O2S:Eu3+ nanocomposites by reducing Y2O3:Eu3+ nanocrystals for the first time. The obtained Y2O3/Y2O2S:Eu3+ nanocomposites not only can present excellent luminescence performance, but also can be chosen to design TiO2-Y2O3/Y2O2S:Eu3+ composite cell with improved photoelectrochemical properties. The mechanism for the enhancement of the cell efficiency was investigated in detail.

Discussion

Sample numbers and corresponding experimental conditions are given in Table 1. When the content of sulfur powder was 1.0 or 1.5 g, Y2O3/Y2O2S:Eu3+ was obtained. When the content of sulfur powder was 2.0 g, Y2O2S:Eu3+ was obtained. It is noted that the diffraction peaks of Y2O3:Eu3+ can be indexed to the cubic phase Y2O3 (JCPDS 43-1036), and the diffraction peaks of Y2O2S:Eu3+ can be indexed to the hexagonal phase Y2O2S (JCPDS 24-1424). The corresponding XRD patterns of Y2O3:Eu3+, Y2O3/Y2O2S:Eu3+, and Y2O3/Y2O2S:Eu3+ nanocomposites were shown in Fig. 1.

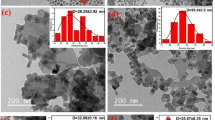

Figure 2(a–c) shows the TEM and HRTEM images of Y2O3/Y2O2S:Eu3+ nanocomposites. Typical HRTEM image shows interplanar spacings of 0.306 and 0.294 nm corresponding to the (222) plane of Y2O3 and (101) plane of Y2O2S, respectively. The results indicated that Y2O3:Eu3+ and Y2O2S:Eu3+ coexist in the Y2O3/Y2O2S:Eu3+ nanocomposites. In order to determine the content of Y2O2S:Eu3+ in nanocomposites, Y2O3/Y2O2S:Eu3+ nanocomposites were measured using energy dispersive X-ray (EDX) analysis, as shown in Fig. 2(d). The result indicated that the content of Y2O2S:Eu3+ was 43 mol% in Y2O3/Y2O2S:Eu3+ nanocomposites.

Figure 3 shows the Raman spectrum of Y2O3/Y2O2S:Eu3+ nanocomposites. The results further indicated that Y2O3:Eu3+ and Y2O2S:Eu3+ coexist in Y2O3/Y2O2S:Eu3+ nanocomposites. The Raman active modes of Y2O3:Eu3+ are featured by three bands at about 300~430 cm−1, which can be assigned to the Fg+Eg and Fg+Ag modes. The Raman active modes of Y2O2S:Eu3+ observed at 143, 254, 443 cm−1 were cause by the intense Eg, A1g, and Eg modes, respectively.

Figure 4 shows the XPS spectrum of Y2O3/Y2O2S:Eu3+ nanocomposites. Obviously, Y3+ was identified by its Y 3 s, Y 3p, Y 3d, and Y 4 P speaks, O2− was identified by the O 1 s and O KLL peaks, Eu3+ was identified by the Eu 4d peak, and S2+ was identified by the S 2p peak. The Y 3d3/2 spectral peaks were at 156.7, 158.3, and 158.8 eV, and the S 2p2/3 spectral peaks were at 167.7 and 170.1 eV. In addition, the O 2 s spectrum can be fitted by three peaks located at 628.8, 531.1, and 532.0 eV.

For comparison, the luminescence properties of the Y2O3:Eu3+ (without sulfuration) nanocrystals were investigated first, as shown in Fig. 5. For the excitation spectra of Y2O3, the broad band extending from 200 to 300 nm is assigned to the charge transfer transition from the 2p orbital of O2− to the 4 f orbital of Eu3+, which is related closely to the covalency between O2− and Eu3+ and the coordination environment around Eu3+. The sharp lines in Fig. 5(a) correspond to the f-f transitions of the Eu3+ ions. Figure 5(b) shows the emission spectra of Y2O3:Eu3+ excited at different wavelengths. It is found that the peak at ~615 nm of Y2O3:Eu3+ was much stronger than that at ~630 nm. When the excitation wavelength was 259 nm, the emission intensities were the strongest.

Figure 6(a) shows the excitation spectra of Y2O3:Eu3+ and Y2O3/Y2O2S:Eu3+ monitored at 620 nm. Obviously, the excitation spectrum of Y2O3/Y2O2S:Eu3+ was different from that of Y2O3:Eu3+. The broad band centered at ~338 nm was due to the host lattice of Y2O2S. Figure 6(b) shows the excitation spectra of Y2O3:Eu3+ and Y2O3/Y2O2S:Eu3+ monitored at 630 nm. The excitation spectrum of Y2O3:Eu3+ was dominated by the excitation band centered at 259 nm, while the excitation spectrum of Y2O2S:Eu3+ was dominated by the excitation band centered at 338 nm.

Figure 7(a) shows the emission spectra of Y2O3:Eu3+ and Y2O3/Y2O2S:Eu3+ (YO/YOS-2) excited at 259 nm. For the Y2O3:Eu3+, the 5D0 → 7F0 (~583 nm), 5D0 → 7F1 (509–602 nm), and 5D0 → 7F2 (614–633 nm) transitions of the Eu3+ ions were observed. The luminescence was dominated by the emission at ~615 nm. The 5D0 → 7F1 emission was split into three sub-bands due to local fields around Eu3+ and their separations depend on the energy for the direct excitation from the 7F0 ground level to the 5D0 excited level. For the Y2O3/Y2O2S:Eu3+, the 5D0 → 7F0 and 5D0 → 7F1 showed a little red-shift. The luminescence was dominated by the emission at ~630 nm. In addition, the emission at ~615 nm was split into two sub-bands. Figure 7(b) shows the emission spectra of Y2O3:Eu3+ and Y2O3/‘’Y2O2S:Eu3+ (YO/YOS-2) excited at 338 nm. The luminescence intensity of Y2O3:Eu3+ has been enhanced by hybridization with Y2O2S:Eu3+.

Figure 8(a) shows the excitation spectra of the Y2O3/Y2O2S:Eu3+ nanocomposites monitored at different wavelengths. It is noted that the excitation spectrum monitored at 615 nm was different from those monitored at other wavelengths. The results further prove that Y2O3:Eu3+ and Y2O2S:Eu3+ coexist in Y2O3/Y2O2S:Eu3+ nanocomposites. Figure 8(b) shows the emission spectra of the Y2O3/Y2O2S:Eu3+ nanocomposites excited at different wavelengths. When the excitation wavelength was 338 nm, the emission intensities were the strongest. Figure 9 shows the luminescence decay curve for the Y2O3/Y2O2S:Eu3+ nanocomposites excited at 280 nm and monitored at 620 nm. It is noted that the decay curve cannot be fitted with the single exponential function, while a biexponential function may reproduce the decay data well and lead to two lifetimes of 0.42 and 0.12 ms. The relative contribution of the exponentials to the decay of the hybrid spheres is about 0.51:0.49.

In order to investigate the effects of Y2O3/Y2O2S:Eu3+ on the photoelectric properties of DSSCs, the DSSC prototype devices were fabricated by using N719-sensitised TiO2-Y2O3/Y2O2S:Eu3+ composite electrodes. Figure 10(a) shows the photocurrent density-voltage (J-V) curves of pure TiO2 cell, TiO2-Y2O3/Y2O2S:Eu3+ composite cells, and TiO2-Y2O2S:Eu3+ composite cell. The corresponding values of the open-circuit voltage (Voc), short-circuit current density (Jsc), fillfactor (FF), and overall conversion efficiency (η), obtained from the curves of solar cells, are shown in Table 2. The result indicated that the photoelectric conversion efficiencies of the TiO2-Y2O3/Y2O2S:Eu3+ composite cells were higher than those of pure TiO2 cell and TiO2-Y2O2S:Eu3+ composite cell. The best photoelectric conversion performance was observed when the mass concentration of Y2O3/Y2O2S:Eu3+ was 0.5%.

(a) The J-V curves and (b) IPCE spectra of pure TiO2 cell, TiO2-Y2O3/Y2O2S:Eu3+, and TiO2-Y2O2S:Eu3+ composite cells under simulated solar light radiation. (c) Dynamic light scattering (DLS) of Y2O3/Y2O2S:Eu3+ nanocomposites in water. (d) Comparison of diffuse reflectance spectra of TiO2 and TiO2-Y2O3/Y2O2S:Eu3+ photoanodes.

Presumably, three mechanisms might be responsible for the enhancement of the efficiencies of TiO2-Y2O3/Y2O2S:Eu3+ composite cells. (a) The improvement of the efficiencies of the TiO2-Y2O3/Y2O2S:Eu3+ composite cells were related to the luminescence of Y2O3/Y2O2S:Eu3+ nanocomposites. However, the results of the incident photon to current spectra (IPCE) indicated that the luminescence of Y2O3/Y2O2S:Eu3+ only has a little effect on the performance improvement, as shown in Fig. 10(b). (b) The enhancement of the efficiencies of the TiO2-Y2O3/Y2O2S:Eu3+ composite cells were related to the light scattering of Y2O3/Y2O2S:Eu3+, as shown in Fig. 10(c,d). (c) It is noted that the sintering process was necessary during preparation of the photoelectrode, which has been described in the Experimental section. And thus, some Ti4+ ions will be substituted by S6+ during the sintering process, which was beneficial for enhancing photoelectric properties31. In addition, the decrease of the efficiency of TiO2-1%Y2O3/Y2O2S:Eu3+ was related to the decrease of the amount of dye adsorption and lower interfacial electron transfer32.

In summary, Y2O3:Eu3+ nanocrystals were synthesized by a hydrothermal method first, and then Y2O2S:Eu3+ nanocrystals and Y2O3/Y2O2S:Eu3+ nanocomposites were obtained by reducing Y2O3:Eu3+ nanocrystals. The luminescence of Y2O3/Y2O2S:Eu3+ excited at 338 nm was much stronger than that of Y2O3:Eu3+ nanocrystals. Compared with Y2O3:Eu3+, the 5D0 → 7F0 and 5D0 → 7F1 emissions of Y2O3/Y2O2S:Eu3+ showed a little red-shift. In addition, the emission at ~615 nm of Y2O3/Y2O2S:Eu3+ was split into two sub-bands. In addition to the aforementioned luminescence properties, these Y2O3/Y2O2S:Eu3+ nanocomposites also can be chosen to design TiO2-Y2O3/Y2O2S:Eu3+ composite cell, which have the ability to improve the photoelectric conversion efficiency. We suggested that the enhancement of the efficiency of the TiO2-Y2O3/Y2O2S:Eu3+ composite cell was mainly related to the light scattering of Y2O3/Y2O2S:Eu3+ nanocomposites.

Methods

Preparation of samples

All of the chemicals used in this paper were analytical grade and used as received without further purification. In the synthesis of Y2O3/Y2O2S:Eu3+, 3 mL of Ln(NO3)3 (Ln = Y and Eu) aqueous solution (0.5 mol/L) was added to 3 mL deionized water, and the solution was thoroughly stirred, then an aqueous solution of NaOH (0.25 M) was added into the above solution. Subsequently, the milky colloidal solution was transferred to a 50 mL Teflon-lined autoclave, and heated at 100 °C for 5 h. The systems were then allowed to fast cool to room temperature. The final products were collected by means of centrifugation, washed with deionized water and ethanol, dried at 80 °C for 4 h in air. And then the Y2O3:Eu3+ precursor was obtained. 0.1 g of the Y2O3:Eu3+ precursor and some (1.0, 1.5, and 2.0 g) sulfur powder were put into a porcelain boat with different proportions of sulfur powder, and then sintered at 600 °C for 1 h in N2 atmosphere.

Fabrication of photoelectrodes

Fabrication of photoelectrode and the assembly of DSSCs: several pastes, from homogeneously mixing Y2O3/Y2O2S:Eu3+ and TiO2 (Degussa P25) into 1.5 mL of TiO2 colloid. The TiO2 colloid was prepared following the previously published synthesis procedure33. A screen-printed double layer of TiO2-Y2O3/Y2O2S:Eu3+ was used as the photoanode. The first layer of TiO2-Y2O3/Y2O2S:Eu3+ was prepared by a doctor-blade method on the FTO substrate and then sintered at 450 °C for 30 min. Subsequently, the second layer of TiO2-Y2O3/Y2O2S:Eu3+ was covered on the first TiO2-Y2O3/Y2O2S:Eu3+ film and then sintered at 450 °C for 30 min again. The sensitization of the photoelectrodes was achieved by immersing them into 0.5 mM ((C4H9)4N)2[Ru(4-carboxy-4′-carboxylate-2,2′ bipyridine)2 (NCS)2] dye (N719, Solaronix SA, Switzerland) in acetonitrile and tert-butanol (volume ratio, 1:1) for 48 h at room temperature. The Pt counter electrodes were prepared following the previous literature34. The dye-sensitized photoanode was assembled with a Pt counter electrode into a sandwichtype cell. The sandwich-type cell was further fixed together with epoxy resin. The space between the electrodes was filled with the electrolyte, which comprised 0.6 M 1-propyl-2,3-dimethyl-imidazolium iodide, 0.05 M I2, 0.1 M LiI, and 0.5 M tert-butylpyridine (TBP) in 3-methoxypropionitrile (3-MPN), by capillary action.

Materials Characterization

The crystal structure was analyzed by a Rigaku (Japan) D/MAX-rA X-ray diffraction meter equipped with graphite monochromatized Cu Kα radiation (λ = 1.541874 Å), keeping the operating voltage and current at 40 kV and 40 mA, respectively. The sizes and morphologies of the final products were determined by using a JEOL JEM-2010F transmission electron microscope (TEM) operated at 200 kV. X-ray photoelectron spectroscopy (XPS) analysis was performed using a VG ESCALABMK II with a Mg KR (1253.6 eV) achromatic X-ray source. The photoluminescence spectra were recorded using a Hitachi F-4600 fluorescence spectrophotometer at room temperature. For comparison of the luminescence properties of different samples, the luminescence spectra were measured with the same instrument parameters (2.5 nm for slit width and 700 V for PMT voltage). The luminescence decay curve was recorded by a Spex 1403 spectrometer under the excitation of a third harmonic (355 nm) of a Nd:YAG pulsed laser.

Photovoltaic properties

Photovoltaic measurements were carried out with a solar simulator (Oriel, USA) equipped with an AM 1.5 G radiation (1 sun conditions, 100 mW cm−2) filter was used as the light source. The irradiation area of DSSCs is 0.09 cm2. The electron transport and recombination properties were measured by intensity-modulated photocurrent spectroscopy (IMPS) and intensity-modulated photovoltage spectroscopy (IMVS) (Zahner Elektrik, Germany).

Additional Information

How to cite this article: Yuan, G. et al. In situ synthesis, enhanced luminescence and application in dye sensitized solar cells of Y2O3/Y2O2S:Eu3+ nanocomposites by reduction of Y2O3:Eu3+. Sci. Rep. 6, 37133; doi: 10.1038/srep37133 (2016).

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Wang, G. F., Peng, Q. & Li, Y. D. Lanthanide-Doped Nanocrystals: Synthesis, Optical-Magnetic Properties, and Applications. Acc. Chem. Res. 44, 322–332 (2011).

Li, Y. et al. Formation and down/up conversion luminescence of Ln3+ doped NaY(MoO4)2microcrystals. Dalton Trans. 42, 3366–3372 (2013).

Eliseeva, S. V. & Bünzli, J. G. Lanthanide luminescence for functional materials and bio-sciences. Chem. Soc. Rev. 39, 189–227 (2010).

Bünzli, J. G. & Piguet, C. Taking advantage of luminescent lanthanide ions. Chem. Soc. Rev. 34, 1048–1077 (2005).

Wang, L. Y. & Li, Y. D. Na(Y1.5Na0.5)F6 Single-Crystal Nanorods as Multicolor Luminescent Materials. Nano Lett. 6, 1645–1649 (2006).

Li, Y. et al. NaYF4:Er3+/Yb3+–graphene composites: preparation, upconversion luminescence, and application in dye-sensitized solar cells. J. Mater. Chem. 22, 20381–20386 (2012).

Wang, F. & Liu, X. G. Recent advances in the chemistry of lanthanide-doped upconversion nanocrystals. Chem. Soc. Rev. 38, 976–989 (2009).

Wang, G. F. et al. Synthesis, Growth Mechanism, and Tunable Upconversion Luminescence of Yb3+/Tm3+-Codoped YF3 Nanobundles. J. Phys. Chem. C 112, 12161–12167 (2008).

Lin, L. W. et al. Sol-hydrothermal synthesis and optical properties of Eu3+, Tb3+-codoped one-dimensional strontium germanate full color nano-phosphors. Nanoscale. 5, 12518–12531 (2013).

Li, L. et al. Biomimetic Surface Engineering of Lanthanide-Doped Upconversion Nanoparticles as Versatile Bioprobes. Angew. Chem. Int. Ed. 51, 6121–6125 (2012).

Cao, M. H. et al. Synthesis and characterization of MgF2 and KMgF3 nanorods. J. Solid State Chem. 177, 2205–2209 (2004).

Yang, D. et al. Y2O3:Yb,Er@mSiO2–CuxS double-shelled hollow spheres for enhanced chemo-/photothermal anti-cancer therapy and dual-modal imaging. Nanoscale. 7, 12180–12191 (2015).

Bai, X. et al. Size-dependent upconversion luminescence in Er3+/Yb3+-codoped nanocrystalline Yttria: Saturation and thermal effects. J. Phys. Chem. C 111, 13611–13617 (2007).

Zhang, J. et al. Infrared to visible upconversion luminescence in Er3+:Y2O3transparent ceramics. J. Lumin. 122, 8–10 (2007).

Xia, Z. et al. Ca2Al3O6F:Eu2+: a green-emitting oxyfluoride phosphor for white light-emitting diodes. J. Mater. Chem. 22, 15183–15189 (2012).

Xu, Z. et al. General and facile method to fabricate uniform Y2O3:Ln3+ (Ln3+ = Eu3+, Tb3+) hollow microspheres using polystyrene spheres as templates. J. Mater. Chem. 22, 21695–21703 (2012).

Xia, Z., Zhuang, J. & Liao, L. Novel Red-Emitting Ba2Tb(BO3)2Cl:Eu Phosphor with Efficient Energy Transfer for Potential Application in White Light-Emitting Diodes. Inorg. Chem. 51, 7202–7209 (2012).

Sobon, L. E. et al. Growth and Properties of Lanthanum Oxysulfide Crystals. J. Appl. Phys. 42, 3049–3054 (1971).

James, W. H. & Jesse, J. B. Preparation and Luminescence of Selected Eu3+-Activated Rare Earth-Oxygen-Sulfur Compounds. J. Electrochem. Soc. 1968, 115, 1060–1066 (1968).

Faucher, M. D., Morlotti, R. & Moune, O. K. The effects of added foreign ions in Gd2O2S: Tb3+; crystal field calculations, lifetimes, photo-luminescence and absorption spectra. J. Lumin. 96, 37–49 (2002).

Hirai, T. & Orikoshi, T. Preparation of yttrium oxysulfide phosphor nanoparticles with infrared-to-green and -blue upconversion emission using an emulsion liquid membrane system. J. Collide Interface Sci. 273, 470–477 (2004).

Liu, G. K. et al. Confinement of electron–phonon interaction on luminescence dynamics in nanophosphors of Er3+:Y2O2S. J. Solid State Chem. 171, 123–132 (2003).

Guo, X. Y. et al. Synthesis of amino functionalized magnetic graphenes composite material and its application to remove Cr(VI), Pb(II), Hg(II), Cd(II) and Ni(II) from contaminated water. J. Hazard. Mater. 278, 211–220 (2014).

Yao, W. et al. Graphene/Fe3O4@polypyrrole nanocomposites as a synergistic adsorbent for Cr(VI) ion removal. Compos. Sci. technol. 99, 15–22 (2014).

McGehee, M. D. Paradigm Shifts in Dye-Sensitized Solar Cells. Science. 334, 607–608 (2011).

Grätzel, M. Recent Advances in Sensitized Mesoscopic Solar Cells. Acc. Chem. Res. 42, 1788–1798 (2009).

Hagfeldt, A. et al. Dye-Sensitized Solar Cells. Chem. Rev. 110, 6595–6663 (2010).

Yao, N. et al. Efficiency enhancement in dye-sensitized solar cells with down conversion material ZnO: Eu3+, Dy3+. J. Power Sources, 267, 405–410 (2014).

Hafez, H., Saif, M. & Abdel-Mottaleb, M. Down-converting lanthanide doped TiO2 photoelectrodes for efficiency enhancement of dye-sensitized solar cells. J. Power Sources. 196, 5792–5796 (2011).

Huang, J. H. et al. Improvement efficiency of a dye-sensitized solar cell using Eu3+ modified TiO2 nanoparticles as a secondary layer electrode. J. Mater. Chem. 20, 6505–6511 (2010).

Sun, Q. et al. Sulfur-doped TiO2 nanocrystalline photoanodes for dye-sensitized solar cells. J Renew. Sustain. Energy 4, 133–137 (2012).

Li, Y. et al. Enhanced photoelectric conversion efficiency of dye-sensitized solar cells by the incorporation of dual-mode luminescent NaYF4:Yb3+/Er3+. Dalton Trans. 42, 7971–7979 (2013).

Wang, P. et al. Ambient Temperature Plastic Crystal Electrolyte for Efficient, All-Solid-State Dye-Sensitized Solar Cell. J. Am. Chem. Soc. 126, 13590–13591 (2004).

Hagfeldt, A. & Grätzel, M. Molecular Photovoltaics. Acc. Chem. Res. 33, 269–277 (2000).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (21471050) and Heilongjiang Province Natural Science Foundation of Key Projects (ZD201301).

Author information

Authors and Affiliations

Contributions

G.H.Y. performed synthesis experiments, G.F.W. and H.G.F. designed the experiment. G.F.W. carried out photo-electrochemical evaluation and discussion. M.X.L, Mingqi Yu and C.G.T. carried out HRTEM and dynamic light scattering experiments. G.H.Y. and G.F.W. wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yuan, G., Li, M., Yu, M. et al. In situ synthesis, enhanced luminescence and application in dye sensitized solar cells of Y2O3/Y2O2S:Eu3+ nanocomposites by reduction of Y2O3:Eu3+. Sci Rep 6, 37133 (2016). https://doi.org/10.1038/srep37133

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep37133

This article is cited by

-

Green, affordable, and unprecedented photoluminescence investigation on white emission of Y2O3:Clitoria ternatea floral extract complex to replace conventional Dy3+ doping for wLED

Applied Nanoscience (2024)

-

Using different ratios of glycine to citric acid as fuel mixture in microwave-assisted combustion synthesis of Eu-doped Y2O3–Gd2O3 nanophosphors

Journal of Materials Science: Materials in Electronics (2024)

-

Nano-topological luminophor Y2O3:Eu3+ + Ag with concurrent photoluminescence and electroluminescence

Journal of Materials Science: Materials in Electronics (2019)

-

Plasma-electrochemical synthesis of europium doped cerium oxide nanoparticles

Frontiers of Chemical Science and Engineering (2019)

-

Morphology-tailored synthesis and luminescent properties of Y2O3:Eu3+ phosphors

Journal of Materials Science: Materials in Electronics (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.