Abstract

Electrocatalytic materials for oxygen reduction reaction, currently dominated by platinum/carbon catalyst is marred by drawbacks such as use of copious amount of Pt and use of “non-green” sacrificial reducing agent (SRA) during its synthesis. A single stroke remedy for these two problems has been achieved through an in-situ aqueous photoreduction void of even trace amounts of SRA with an enhanced activity. Reduction of PtCl62− salt to Pt nano particles on carbon substrate was achieved solely using solar spectrum as the source of energy and TiO2 as photocatalyst. Here, we demonstrate that this new procedure of photoreduction, decorates Pt over different types of conducting allotropes with the distribution and the particle size primarily depending on the conductivity of the allotrope. The Pt/C/TiO2 composite unveiled an ORR activity on par to the most efficient Pt based electrocatalyst prepared through the conventional sacrificial reducing agent aided preparation methods.

Similar content being viewed by others

Introduction

The rise in greenhouse gases and the depletion of fossil fuels lead the researchers to look for efficient alternative energy conversion and storage devices. Two major flagship devices in energy conversion and storage technologies are fuel cell and Li-air battery respectively. For complete realization of these technologies, the following interdependent challenges have to be addressed, sluggish kinetics of oxygen reduction reaction (ORR), non-green methods for catalyst production and high cost of catalyst preparation. Though there has been many attempts to make non-platinum based ORR catalyst, Pt has been a universal choice due to its efficient and reliable electro-catalytic activity. In general, Pt based carbon catalysts, one of the most widely employed ORR catalyst, are prepared by employing polyols and/or other reducing agents and are subjected to elevated temperatures. The use of these procedures stray outside the “green-way”. Few researchers have showed surfactant free but pyrolytic methods of ORR catalyst preparation on carbon nitride based substrates to reduce the cost of the catalyst1,2. Lookout for alternative green procedures has recently ended up in looking into exploiting photo-reduction processes. Alongside ‘green’ aspect, large scale commercial applications are precluded by the high manufacturing cost of the ORR catalyst. Hence, researcher have been focusing on reducing the cost of the catalyst by reducing the amount of Pt used by adapting to a variety of carbon materials, use of transition metal oxides and doping of nitrogen in carbon. The year 2015, has seen more developments and attempts to improve the ORR activity by the addition of a metal oxide such as MoOx3, TiOx4 and CeOx5,6, on the Pt/C catalyst. Incidentally some or most of these metal oxides fall in the category of photo-catalyst. Generation of charges on impingement of light, characteristic to any photo-catalyst, can potentially involve in various photo-physical phenomenon like trapping of charges, radiative and non-radiative charge recombination along with interfacial charge transfer. The interfacial charges are available for further redox reactions of the molecules adsorbed onto the surface of the photo-catalyst.

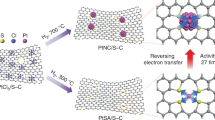

In this regard, TiO2 nanostructures have been studied in-depth and have proven to be an excellent choice for photocatalytic reduction of many materials ranging from fullerenes7, inorganic8 and many organic compounds9. Here, the high conducting band of TiO2 (approx. −0.5 V vs NHE at 7.00 pH) enables controlled reduction of chemical species, which is highly necessary. This validates the thermodynamic feasibility to transfer the photo-generated charges especially electrons to any conducting carbon for further reduction of metal salts10. In the recent past among many strategies to control the recombination of electron–hole, carbon-TiO2 hybrid are more looked upon due to its efficiency11,12,13,14,15,16,17,18,19. The control of recombination in TiO2/C hybrid is achieved owing to the placement of the conduction band of carbon marginally lower than that of TiO2 allowing a predominant passage of electrons from conduction band of TiO2. This process of interfacial charge transfer to the pre-adsorbed conducting carbons, was found to be a working alternative to control the rapid recombination of the photo-generated charges of TiO2. This spill-over of electrons from the conduction band, when happens on a highly conducting matrix, the electrons tend to travel over the conducting matrix until it finds a suitable reducing species. Recently few researchers20,21,22 tapped these photo-electrons for recovering few transition metals from industrial wastes in aqueous media without any added SRA. Yunteng et al.23 and Ian et al.24 contributed significantly in photo-reducing the metals salts to metal nanoparticles on to carbon substrates. However, they added a determined amount of SRA and it was not straight a forward reaction to scale them up industrially. Along with the novelty in the method, some of the recent works23,25,26 have reported that Pt-carbon-TiO2 three component system shows enhanced electro-catalytic activity with high durability.

In this article we present a novel and facile photochemical reaction tapping the photo-electron generated by semiconductor when irradiated with simulated solar light. The photo-electron is successfully tapped onto carbon which further reduces chloroplatinic acid to nano particle of high electrocatalytic activity. The whole process is carried out without any SRA, pH adjustment or temperature variation in water. To the best of our knowledge this article will be the first of its kind highlighting successful photo-reduction of metal salts to metal nano particles on to any electron conducting substrate using TiO2 nano particles as photo catalysts. The three component system thus prepared, exhibited promising ORR activity with ultralow amount of Pt capable to replace ORR catalysts with high Pt content.

Results and Discussion

The exact quantity of Pt loading on each sample quantified using (inductively coupled plasma mass spectrometry) ICP-MS was found to be 4.3, 1.6 and 2.6 wt% in Photo-Pt-Graphite-TiO2, Photo-Pt-GO-TiO2 and Photo-Pt-CNT-TiO2, respectively. The TEM images obtained for the carbon/TiO2 surfaces after subjecting to photo-irradiation was observed to possess dark, particle-like contrast. Similar textural aspect was observed on both CNT as well as graphite/TiO2 hybrids. Figure 1A,B shows the TEM micrographs of both the materials (Photo-Pt-graphite-TiO2 and Photo-Pt-CNT-TiO2) made using photo-reduction method. Closely looking at Fig. 1A, uniformly distributed particles were seen over graphite sheet. Figure 1B shows a dark spot of ~50 nm, correlating to the structure of TiO2 on a 2-dimensional sheet of graphite, which was seemingly embedded over vast span of dark minute particulate embodies. Closer look reveals that the TiO2 particle is evidently covered by the dark particle. The particles are uniformly distributed without any agglomerations all through the graphite. The average size of the particles were 2.3 ± 1.5 nm on graphite and 5–8 nm on TiO2. Similar results were observed on CNT i.e., Photo-Pt-CNT-TiO2 (Fig. 1C) and the average size of the particle over CNT was observed to be 1 ± 03 nm and 2–4 nm on TiO2 (Fig. 1D). As a spin-off, similar methodology was adapted with Graphene Oxide (GO), in case of GO, when TiO2 was used as photo-catalyst the particles decorated only the TiO2 (Figure ESI 1) with the size ranging around 2–6 nm and not on GO.

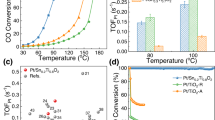

The elemental composition of the electrocatalytic materials prepared was determined by XPS. Figure 2A,B are the typical survey spectra of the samples exhibiting the peaks at their respective binding energies for C1s, O1s, Pt4f and Ti2p. The high resolution Pt4f peak of the Photo-Pt-graphite-TiO2 consisted of three individual peaks at 71.2, 72.4 and 73.7 eV corresponding to Pt0, PtII and PtIV oxidation states (Fig. 2C). The Pt0 was found to be the predominant oxidation state with 65.5% followed by 27.3% of PtII and 7.2% of PtIV. Figure 2D shows the decomposition of Pt 4 f peak for Photo-Pt-CNT-TiO2. This too consists of three peaks at 71.4, 72.0, and 73.5 corresponding to Pt0, PtII and PtIV respectively. Similar to graphite based material Photo-Pt-CNT-TiO2 also consists predominantly Pt0 with around 62.6% along with small proportions of PtII (17.6%) and PtIV(19.8%). The shift of Pt4f peak in the case of Photo-Pt-CNT-TiO2 can be ascribed to strong metal substrate interaction. Corroborating the results from TEM and XPS, it can be understood that no/less Pt-nps on GO and different particle sizes on different substrates are all based on the electronic conductivity of the carbon allotropes. Electronic conductivity in graphite, CNT and graphene are solely due to the continuous π electron cloud. When this π electron cloud is interrupted by some oxygen containing functional groups, the electronic conductivity gets hindered. Hence, the presence of various oxygen functional groups on the surface of graphene oxide makes it insulating in nature. Whereas, in case of graphite and CNT, the conductivity is higher as these materials have been used without any functionalization. The diffusion length of the photoelectron depends on the electronic conductivity of the substrate used. CNT is a better electronic conductor than graphite. This enables better conduction of photoelectrons with which Pt precursor is reduced all over the surface of CNT with many nucleation sites to generate small and well distributed Pt-nps. In the same line, CNT being better electronic conductor than that of graphite, smaller and more uniform Pt-np distribution resulted as expected. On the other hand, in case of GO, covalently bonded oxygen functionalities are readily reduced than that of adsorbed reducing species in the presence of photo-electron27 resulting in reduced graphene oxide (RGO) with fewer or no Pt particles. The cyclic voltammetry (CV) and linear sweep voltammetry using rotating disc electrode studies for evaluating the ORR behavior was benchmarked with commercial TEC10E50E. Cyclic voltammograms given in Fig. 3A showed a typical Pt-carbon type fingerprint peaks for H2 adsorption and desorption at 0.05 > E < 0.3 V. The electrochemical active surface area (ECSA) of the materials (see ESI for formula) was determined. Figure 3B shows the ECSA of all the electrocatalysts mentioned above. ECSA of the materials was found to be in the following range, Photo-Pt-CNT-TiO2 (74.13 m2/g), Photo-Pt-Graphite-TiO2 (53.08 m2/g). Highest ECSA of Photo-Pt-CNT-TiO2 can be attributed to the smallest particle size (1 ± 0.3 nm) of other 2 materials. Pt-nps in these materials can be seen as two types, the ones present on the TiO2 and the other on the surface of carbon. In Photo-Pt-TiO2-GO the majority of Pt-nps are present only on the surface of TiO2 and less/no Pt-nps on GO. With 1.6 wt% of Pt Photo-Pt-GO-TiO2 showed less ECSA of 11 m2g−1. This shows that the Pt on TiO2 is active for ORR but not as efficient as Pt on conducting carbon. The week catalytic activity can be ascribed to moderate electrochemical interaction between Pt-nps and semiconductor28,29.

ORR characteristics of electrocatalysts.

(A) CV of Photo-Pt-Graphite-TiO2 and Photo-Pt-CNT-TiO2 in N2 saturated 0.1 M HClO4 aq. at scan rate of 50 mVs−1. (B) ECSA calculated from the CVs and comparison with commercial material. (C) RDE linear sweep voltammograms for all the samples under study and (D) Mass activity and Specific activity obtained from K-L plots at 0.90 V vs RHE.

Further to understand the ORR kinetics, RDE measurements were carried out. Figure 3C compares the polarization curves of both the indigenous materials. Both Photo-Pt-CNT-TiO2 and Photo-Pt-graphite-TiO2 exhibited high ORR activity with the onset potential of 0.93 V and half wave potential of 0.85 V. A marginal photo generated catalysts compared to commercial catalyst (Figure ESI 4E) can be due to the decrease in the electronic conductivity of the sample by containing TiO2. But, this can be trade-off parameter compared to the amount of Pt loaded. The diffusion limiting current for all the samples was obtained at a potential region E < 0.6 V. Rotation dependent polarization curves were recorded to evaluate the kinetic parameters (Figure ESI 4) of ORR. The number of electrons transfer during the ORR calculated employing Koutecky–Levich (K–L) plots (Figure ESI 4) was found to be ~4 at 0.8–0.9 V. This corroborates that the ORR is a single step 4 electron process and not sequential 2 electrons process. The mass activity (MA) and specific activity (SA) based on the normalization of Pt loading and it’s ECSA respectively have been evaluated (Fig. 3D). Interestingly, though the ECSA of the home-made materials were slightly lesser than that of the commercial reference, MA of all the samples were found to be same (around 350 A/g) and SA was found to be in the order of Pt-Graphite-TiO2 (6.6 A/m2) >Pt-CNT-TiO2 (4.8 A/m2) >TEC10E50E (4.6 A/m2). The high SA of Pt-Graphite-TiO2 can be ascribed to low ECSA and larger particle size. The limiting current (IL) normalized with mass fraction of platinum on working electrode was another figure of merit to appreciate the ORR catalytic activity of the photo-generated catalysts with low Pt content (Fig. 4). In Fig. 4, high limiting current of the materials under study was equal to that of commercial catalyst and this high current normalized with low mass fraction of Pt to the corresponding sample showed high capacity. This showed a 2 times higher activity in case of CNT based material and a marginal increase in case of graphite based compared to the reference material. Here it would be worthy to emphasize that photo generated Pt materials contain approximately ~15 times less Pt in Photo-Pt-graphite-TiO2 and ~20 times in the case of Photo-Pt-CNT-TiO2 than that of reference material (TEC10E50E) with 50 wt% of Pt. This clearly demonstrates that the home-materials are highly active. The high performance in these hybrid material can be ascribed to, i) uniform distribution of Pt nano particles resulting in high ECSA, enabling easy diffusion of oxygen on Pt, ii) strong metal substrate interaction (SMSI) i.e., strong anchoring of Pt to carbon will lead to efficient electron transfer to reactant and, iii) moderate strength of Pt-oxygen coordination (because of SMSI) allows easy desorption of intermediates and the final product viz., H2O. These reasons can be attributed to efficient catalytic reaction as seen in this work.

Conclusions

In conclusion, a highly reproducible, environmentally benign and ultrafast method was developed for the preparation of active ORR catalyst (for use in fuel cell and lithium-air battery). The method uses solar light as the only source of energy in the preparation of this catalytically efficient composite utilizing abundant and environmentally benign TiO2 as photo-catalyst. Using this green methodology, preparation of novel composites containing TiO2 particles, CNT/Graphite substrates and platinum nanoparticles was successfully carried out. As prepared material showed excellent ORR activity comparable to the best of commercial ORR catalysts. Both materials made showed comparable MA and higher SA than that of commercial one. It can also be confirmed that this method is feasible for all the conducting carbon substrates. The above results clearly demonstrates that the novel, green and a very viable method of Pt decoration method is as efficient as rather more efficient as that of well-established methods using SRA.

Methods

Graphite, TiO2 and chloroplatinic acid were purchased from Sigma Aldrich. Graphene oxide (GO) and CNT were prepared by modified Hummers method and CVD process respectively (see ESI for procedure).

For the photo-reduction process, graphite, GO or CNTs weighing 90 mg was ultrasonicated in deionized water for nearly 2 hrs to obtain a uniform dispersion. To this uniform dispersion, 10 mg (10 wt%) of TiO2 (anatase commercially obtained from Sigma Aldrich with the particle size of 50–60 nm) was introduced and ultrasonicated for 15 min. 800 μL of 0.045 M aq. chloroplatinic acid solution was added to this mixture and was irradiated by a simulated solar light (Peccel, PEC-L15 solar simulator) with a maximum of 1 sun intensity (100 mWcm−1) for 5 hrs under constant stirring. The material was filtered, washed with deionized water and dried under vacuum overnight at room temperature. To determine the exact amount of Pt present on all the three catalysts (Photo-Pt-graphite-TiO2, Photo-Pt-GO-TiO2 and Photo-Pt-CNT-TiO2), inductively coupled plasma mass spectrometry (ICP-MS) measurements were done using Shimadzu ICPE-9000 (see ESI for procedure). The material was then subjected to morphological characterization and elemental analysis was carried out by using transmission electron microscopy (TEM) on Hitachi H-7650 model and X-ray photoelectron spectroscopy (XPS) on S-probe TM 2803 instrument.

Further, the material was studied for its electro catalytic activity by observing the ORR behaviour using cyclic voltammetry (CV) and rotating disc electrode (RDE) measurements (Automatic polarization system HZ-5000, Dynamic electrode HR-301 and Dynamic electrode controller HR-502). These electrochemical studies were performed using conventional three electrode system; electrocatalyst coated on to glassy carbon electrode as working electrode, platinum wire as counter and reversible hydrogen electrode (RHE) was used as reference electrode at 30 °C in 0.1 M HClO4 aq. The Pt loading on the electrodes made of home-made materials were maintained at 5.07 μg/cm2 and that of reference material TEC10E50E (received from Tanaka Kikinzoku Kogyo K.K., contains ~50 wt% of Pt on high surface area carbon) at 20.26 μg/cm2. CV was measured by sweeping the voltage between 0.05 V–1.20 V at the sweep rate of 50 mVs−1 in nitrogen saturated 0.1 M HClO4 aq. at 30 °C. Linear sweep voltammetry was studied using RDE technique across 0.05–1.00 V with the voltage sweep rate of 20 mVs−1 in oxygen saturated 0.1 M HClO4 aq. solution. The rate of rotation in RDE was varied from 400–3600 rpm.

Additional Information

How to cite this article: Rajashekar, B. et al. Sacrificial Reducing Agent Free Photo-Generation of Platinum Nano Particle over Carbon/TiO2 for Highly Efficient Oxygen Reduction Reaction. Sci. Rep. 6, 37006; doi: 10.1038/srep37006 (2016).

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Negro, E. et al. Interplay between nitrogen concentration, structure, morphology, and electrochemical performance of PdCoNi “core–shell” carbon nitride electrocatalysts for the oxygen reduction reaction. ChemElectroChem. 1, 1359–1369 (2014).

Di Noto, V. et al. Origins, developments, and perspectives of carbon nitride-based electrocatalysts for application in low-temperature FCs. Electrochem. Soc. Interface. 2, 59–64 (2015).

Martins, P. F. B. D. & Ticianelli, E. A. Electrocatalytic activity and stability of platinum nanoparticles supported on carbon–molybdenum oxides for the oxygen reduction reaction. ChemElectroChem. 2, 1298–1306 (2015).

Esfahani, R. A. M., Videla, A. H. M., Vankova, S. & Specchia, S. Stable and methanol tolerant Pt/TiOx-C electrocatalysts for the oxygen reduction reaction. Int. J. Hydrogen. Energy. 40, 14529–14539 (2015).

Chauhan, S. et al. Design of low Pt concentration electrocatalyst surfaces with high oxygen reduction reaction activity promoted by formation of a heterogeneous interface between Pt and CeOx Nanowire. ACS Appl. Mater. Interfaces. 8, 9059–9070 (2016).

Luo, Y. et al. A highly efficient and stable oxygen reduction reaction on Pt/CeOx/C electrocatalyst obtained via a sacrificial precursor based on a metal-organic framework. Appl. Catal. B: Environ. 189, 39–50 (2016).

Kamat, P. V., Bedja, I. & Hotchandani, S. Photoinduced charge transfer between carbon and semiconductor clusters. One-electron reduction of C60 in colloidal TiO2 semiconductor suspensions. J. Phys. Chem. 98, 9137–9142 (1994).

Habisreutinger, S. N., Schmidt-Mende, L. & Stolarczyk, J. K. Photocatalytic reduction of CO2 on TiO2 and other semiconductors. Angew. Chem. Int. Ed. Engl. 52, 7372–7408 (2013).

Ferry, J. L. & Glaze, W. H. Photocatalytic reduction of nitro organics over illuminated titanium dioxide: role of the TiO2 surface. Langmuir. 14, 3551–3555 (1998).

De Tacconi, N. R. et al. Photocatalytically generated Pt ∕ C – TiO2 electrocatalysts with enhanced catalyst dispersion for improved membrane durability in polymer electrolyte fuel cells. J. Electrochem. Soc. 155, B1102–B1109 (2008).

Zhou, Y., Liu, L., Zhao, Z. & Sun, L. Anatase TiO2 nanocrystals with exposed {001} facets on graphene sheets via molecular grafting for enhanced photocatalytic activity. Nanoscale, 4, 613–620 (2012).

Chavez, C. A. et al. Large area mosaic films of graphene–titania: self-assembly at the liquid–air interface and photo-responsive behavior. Nanoscale, 3, 188–191 (2011).

Li, M., Tang, P., Hong, Z. & Wang, M. High efficient surface-complex-assisted photodegradation of phenolic compounds in single anatasetitania under visible-light. Colloids and Surfaces A: Physicochem. Eng. Aspects. 318, 285–290 (2008).

Li, M., Hong, Z., Fang, Y. & Huang, F. Synergistic effect of two surface complexes in enhancing visible-light photocatalytic activity of titanium dioxide. Materials Research Bulletin. 43, 2179–2186 (2008).

Li, M., Zhou, S., Zhang, Y., Chen, G. & Hong, Z. One-step solvothermal preparation of TiO2/C composites and their visible-light photocatalytic activities. Appl. Sur. Sci. 254, 3762–3766 (2008).

Khalid, N. R., Ahmed, E., Hong, Z., Zhang, Y. & Ahmad, M. Nitrogen doped TiO2 nanoparticles decorated on graphene sheets for photocatalysis applications. Curr. Appl. Phys. 12, 1485–1492 (2012).

Khalid, N. R., Ahmed, E., Hong, Z. & Ahmad, M. Synthesis and photocatalytic properties of visible light responsive La/TiO2-graphene composites. Appl. Surf. Sci. 263, 254–259 (2012).

Khalid, N. R. et al. Synergistic effects of Fe and graphene on photocatalytic activity enhancement of TiO2 under visible light. Appl. Surf. Sci. 258, 5827–5834 (2012).

Huang, Q. et al. Enhanced photocatalytic activity of chemically bonded TiO2/graphene composites based on the effective interfacial charge transfer through the C–Ti bond. ACS Catalysis. 3, 1477–1485 (2013).

Mahlamvana, F. & Kriek, R. J. Photocatalytic reduction of platinum(II and IV) from their chloro complexes in a titanium dioxide suspension in the absence of an organic sacrificial reducing agent. Appl. Catal. B: Environ. 148–149, 387–393 (2014).

Yu, J., Dai, G. & Huang, B. Fabrication and characterization of visible-light-driven plasmonicphotocatalyst Ag/AgCl/TiO2 nanotube arrays. J. Phys. Chem. C. 113, 16394–16401 (2009).

Kriek, R. J. & Mahlamvana, F. Dependency on chloride concentration and “in-sphere” oxidation of H2O for the effective TiO2-photocatalysed electron transfer from H2O to [PdCln(H2O)4−n]2−n (n = 0–4) in the absence of an added sacrificial reducing agent. Appl. Catal. A: Gen. 423–424, 28–33 (2012).

Qu, Y. et al. Pt-rGO-TiO2 nanocomposite by UV-photoreduction method as promising electrocatalyst for methanol oxidation. Int. J. Hydrogen Energy. 38, 12310–12317 (2013).

Lightcap, I. V., Murphy, S., Schumer, T. & Kamat, P. V. Electron hopping through single-to-few-layer graphene oxide films. Side-selective photocatalytic deposition of metal nanoparticles. J. Phys. Chem. Lett. 3, 1453–1458 (2012).

Ando, F. et al. Preparation of a PtPb/TiO2/cup-stacked carbon nanotube composite for enhancement of the electrocatalytic reaction of the oxygen reduction reaction. Chem. Lett. 44, 1741–1743 (2015).

Roy, N., Leung, K. T. & Pradhan, D. Nitrogen doped reduced graphene oxide based Pt–TiO2 nanocomposites for enhanced hydrogen evolution. J. Phys. Chem. C. 119, 19117–19125 (2015).

Williams, G., Seger, B. & Kamat, P. V. TiO2-graphene nanocomposites. UV-assisted photocatalytic reduction of graphene oxide. ACS Nano, 2, 1487–1491 (2008).

Selcuk, H. et al. Photocatalytic and photoelectrocatalytic performance of 1% Pt doped TiO2 for the detoxification of water. J. Appl. Electrochem. 34, 653–658 (2004).

Sakthivel, S. et al. Enhancement of photocatalytic activity by metal deposition: characterisation and photonic efficiency of Pt, Au and Pd deposited on TiO2 catalyst. Water Res. 38, 3001–3008 (2004).

Acknowledgements

Authors would like to thank Prof. Sundara Ramaprabhu, Alternative Energy and Nanotechnology Laboratory (AENL), Nano Functional Materials Technology Centre (NFMTC), Department of Physics, Indian Institute of Technology Madras, Chennai 600036, India, for providing MWCNT for the present research work. R.B. is grateful to MEXT scholarship of Japan.

Author information

Authors and Affiliations

Contributions

B.R. performed experiments and wrote the manuscript. B.R. compiled and analyzed all the results with due discussion with V.R. and N.M. K.O. and K.M. carried out electrochemical experiments. V.R. and N.M. designed the experiments.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Badam, R., Vedarajan, R., Okaya, K. et al. Sacrificial Reducing Agent Free Photo-Generation of Platinum Nano Particle over Carbon/TiO2 for Highly Efficient Oxygen Reduction Reaction. Sci Rep 6, 37006 (2016). https://doi.org/10.1038/srep37006

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep37006

This article is cited by

-

Unravelling the complex causality behind Fe–N–C degradation in fuel cells

Nature Catalysis (2023)

-

In situ synthesis of surfactant-free Pt nanoparticles supported on multi-walled carbon nanotubes under visible light

Chemical Papers (2020)

-

3D-polythiophene foam on a TiO2 nanotube array as a substrate for photogenerated Pt nanoparticles as an advanced catalyst for the oxygen reduction reaction

Polymer Journal (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.