Abstract

The potential that lies in harnessing the chemical synthesis capabilities inherent in living organisms is immense. Here we demonstrate how the biosynthetic machinery of Lactococcus lactis, can be diverted to make (3R)-acetoin and the derived 2,3-butanediol isomers meso-(2,3)-butanediol (m-BDO) and (2R,3R)-butanediol (R-BDO). Efficient production of (3R)-acetoin was accomplished using a strain where the competing lactate, acetate and ethanol forming pathways had been blocked. By introducing different alcohol dehydrogenases into this strain, either EcBDH from Enterobacter cloacae or SadB from Achromobacter xylosooxidans, it was possible to achieve high-yield production of m-BDO or R-BDO respectively. To achieve biosustainable production of these chemicals from dairy waste, we transformed the above strains with the lactose plasmid pLP712. This enabled efficient production of (3R)-acetoin, m-BDO and R-BDO from processed whey waste, with titers of 27, 51, and 32 g/L respectively. The corresponding yields obtained were 0.42, 0.47 and 0.40 g/g lactose, which is 82%, 89%, and 76% of maximum theoretical yield respectively. These results clearly demonstrate that L. lactis is an excellent choice as a cell factory for transforming lactose containing dairy waste into value added chemicals.

Similar content being viewed by others

Introduction

Acetoin and 2,3-butanediol (2,3-BDO) are valuable bio-based chemicals that have a wide range of applications. Acetoin is an important flavor compound, which is found naturally in various foods and is commonly used as a food additive. It also serves as a building block for the synthesis of cosmetics, pharmaceuticals and various chemicals1,2. Like acetoin, 2,3-BDO is a versatile chemical with many applications, e.g. it is used as a component in perfumes and fumigants, for making synthetic rubber, pharmaceuticals and plastics, and it is also considered to be an excellent biofuel2,3.

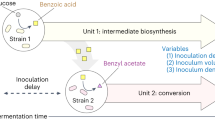

Acetoin and 2,3-BDO can be formed in few steps from pyruvate, where the first step is the decarboxylative condensation of two pyruvate molecules into α-acetolactate, which is a reaction catalyzed by α-acetolactate synthase (Als). One possible fate for α-acetolactate is to be converted into (3R)-acetoin, a reaction catalyzed by the enzyme α-acetolactate decarboxylase (Ald). (3R)-acetoin can be reduced into either (2R,3R)-butanendiol (R-BDO) or meso-(2,3)-butanediol (m-BDO) by specific 2,3-butanediol dehydrogenases (BDHs) (Fig. 1). Alternatively, α-acetolactate, because of its unstable nature, spontaneously can decompose into diacetyl through oxidative decarboxylation. Diacetyl can subsequently be reduced into (3S)-acetoin, where (3S)-acetoin can give rise to either m-BDO or (2S, 3S)-butanediol (S-BDO), again depending on the type of BDHs involved (Fig. S1). In addition to the dedicated BDHs, there are also certain secondary alcohol dehydrogenases (sADH) that are able to accept 2,3-BDO as a substrate4,5,6,7,8,9. Specifically sADH from Clostridium beijerinckii and Thermoanaerobacter brockii have been shown to convert (3R)-acetoin into R-BDO9.

Rewiring the metabolic pathway for synthesis of (3R)-Acetoin, R-BDO and m-BDO in L. lactis.

Als (α-acetolactate synthase); Ald, (α-acetolactate decarboxylase); NoxE, (NADH oxidase); EcBDH (butandediol dehydrogenase from E. cloacae; SadB (alcohol dehydrogenase from A. xylosooxidans). The blue crosses indicate enzyme activities that have been eliminated. The final product obtained depends on the enzyme activities present, where (3R)-acetoin is formed when no additional enzyme activities are introduced, and m-BDO and R-BDO are formed when EcBDH and SadB are heterologously expressed respectively.

There are several native producers of 2,3-BDO, e.g. Klebsiella oxytoca and Klebsiella pneumoniae. However these organisms are not considered to be safe, and another disadvantage could be that mixtures of the various 2,3-BDO isomers are produced. The pure isomers sometimes have useful properties or specific applications, which make them very valuable, e.g. aqueous solutions of the stereoisomers of 2,3-butanediol have very low freezing points, as low as −65 °C, and they could therefore be used as antifreeze agents10. Another important application for stereoisomers is as chiral building blocks for making drugs10,11,12. Despite the many reports describing efficient production of 2,3-BDO by native and engineered microorganisms, current production is still based on chemical synthesis, indicating that microbial production is still not sufficiently cost efficient. One way to address this could be to base production on low-value waste streams rich in carbohydrates. Whey derived waste from the dairy industry is a good example, and it is generated in large amounts. We have recently demonstrated that the lactic acid bacterium Lactococcus lactis is well-suited for converting lactose-rich dairy waste into bioethanol13. L. lactis is a safe microbe used extensively in the dairy industry, especially for making cheese, and this lactic acid bacterium already possesses the metabolic pathway for producing (3R)-acetoin14. L. lactis has been engineered into producing a broad range of other useful compounds and shows great general potential as a cell factory for several reasons: It has a high glycolytic flux, is able to metabolize most of the common sugars, has a well-characterized metabolic network and is simple to manipulate genetically15,16.

In this study, we engineer L. lactis into producing (3R)-acetoin and the two 2,3-BDO stereoisomers m-BDO and R-BDO. First we demonstrate efficient (3R)-acetoin formation using an L. lactis strain where all the major by-product pathways involving pyruvate have been eliminated. We subsequently introduce codon-optimized versions of the robust butanediol dehydrogenase (EcBDH) from E. cloacae and the alcohol dehydrogenase (SadB) from A. xylosooxidans17, which leads to the production of m-BDO and R-BDO respectively. Finally, we show the efficient production of these chemicals from processed whey waste and thus demonstrate that it is feasible to develop sustainable bioprocesses based on L. lactis.

Results

Tolerance of L. lactis to acetoin and 2,3-butanediol

When selecting a candidate organism for bio-production, it is relevant to determine the tolerance towards the compound produced. Acetoin has previously been shown to be toxic to bacteria18 and so has 2,3-BDO, although 2,3-BDO is less toxic than other alcohols12,19. When compared to other microbes, lactic acid bacteria in general are quite tolerant to organic acids and alcohols like butanol and ethanol20,21, and thus, this group of organisms fulfills an important success criterion within bio-based production.

In this study we found only a slight effect on growth from having 20 g/L acetoin or 2,3-BDO present during anaerobic growth (Table 1). In general acetoin or 2,3BDO toxicity on cell growth was more pronounced during aerobic conditions. For 2,3-BDO, as expected, there was a direct correlation between concentration and the effect on growth, and at the highest concentration tested (100 g/L) the specific growth rate was reduced by 64% and 78% during aerobic and anaerobic cultivation respectively when compared to the control without any added 2,3-BDO. Acetoin appeared to be more toxic than 2,3-BDO, and at 60 g/L the growth rate was reduced by almost 80 and 96% respectively and growth almost ceased at 80 g/L.

Construction of an L. lactis platform for enantiopure (3R)-acetoin production

For most wild type strains of L. lactis, including the one we use in this study (MG1363), lactate is the dominant fermentation product when growing on readily fermentable sugars13, which enables the regeneration of the NAD+ consumed in glycolysis. When lactate formation is prevented, e.g. through inactivation of the lactate dehydrogenase activity, L. lactis is able to maintain the redox balance by changing product formation, and the outcome is usually formate, ethanol and acetate, as well as smaller amounts of other products such as m-BDO13. To fully redirect the flux towards (3R)-acetoin and 2,3-BDO, it is necessary to inactivate all the competing pathways at the pyruvate node and as a starting point we used our previously constructed strain CS4363 where genes encoding three lactate dehydrogenase (LDH) homologues (ldh, ldhB, ldhX), phosphotransacetylase (PTA) and alcohol dehydrogenase (ADHE) had been deleted20. This strain had lost its ability to grow under anaerobic conditions since all the pathways for NAD+ regeneration were inactive. Under aerobic conditions, however, the water-forming NADH oxidase (NOX) can regenerate NAD+ and thus allow for growth. When this strain was grown under aerobic conditions, the endogenous activities of Als and Ald, efficiently ensured that pyruvate was transformed into mainly (3R)-acetoin (Table 2).

L. lactis has two genes encoding butanediol dehydrogenases namely butB and butA. It has previously been shown that when butA was over-expressed in an engineered L. lactis strain, m-BDO could be formed22. To completely eliminate m-BDO formation and achieve (3R)-acetoin as the sole fermentation product, we therefore further inactivated the native butB and butA genes, which are co-located in an operon, thus generating VJ017 (MG1363 Δ3ldh Δpta ΔadhE ΔbutBA) (Table 3). This strain had a slightly higher yield of (3R)-acetoin when compared to CS4363.

We found that the recombinant strain VJ017, when grown in aerobic conditions in shake flask with M17 medium supplemented with around 40 g/L glucose, could synthesize 14 g/L of enantiopure (3R)-acetoin, i.e. an enantiomeric excess (e.e.) of 100%, in 24 h with yield of 0.37 g/g glucose which is 76% of theoretical maximum (Fig. 2A).

Extending the metabolic pathway from (3R)-acetoin to m-BDO

As shown above, the main fermentation product of VJ017 was (3R)-acetoin. Since (3R)-acetoin is a precursor for m-BDO we decided to introduce a 2,3-butanediol dehydrogenase from E. cloacea, EcBDH, which has been reported to be highly efficient at reducing acetoin into m-BDO and which in addition is an extremely robust enzyme23. We transformed VJ017 with our previously generated vector, pJM00124 containing EcBDH driven by high strength synthetic promoter to generate mBD001. We found that mBD001 was able to synthesize m-BDO (sole isomer detected) with a high yield (Table 2). Within 13 h, mBD001 could consume 40 g/L of glucose, and (3R)-acetoin was not detected in the medium, which demonstrated that the conversion from (3R)-acetoin to m-BDO indeed was efficient. The strain produced 16 g/L m-BDO in 13 h with a yield of 0.4 g/g glucose which is 80% of theoretical maximum (Fig. 2B). When the fermentation was prolonged after glucose exhaustion, the m-BDO titer decreased to 14 g/L with formation of 1.46 g/L (3R)-acetoin between 13 h and 18 h, and this was due to the reversibility of the (3R)-acetoin to m-BDO reaction.

Extending the metabolic pathway from (3R)-acetoin to enantiopure R-BDO

(3R)-acetoin is also the precursor of another 2,3-BDO isomer, namely R-BDO. Several specific R-BDO forming 2,3-butanediol dehydrogenases have been reported previously12,25,26, but as mentioned in the introduction there are secondary alcohol dehydrogenases (sADH) that can carry out this transformation just as efficiently10. We used an sADH from A. xylosooxidans, which we first expressed in the wild type (VJ021 = MG1363 expressing SadB). Crude enzyme extracts of VJ021 were tested for activity towards R-BDO, and where the control (crude extract of MG1363) did not display any activity, the extract of VJ021 rapidly oxidized R-BDO in the presence of NAD+ (data not shown).

Next, we expressed SadB in the acetoin-producing platform VJ017, and obtained the strain VJ018, which was able to produce R-BDO at high yields (Table 2). HPLC analysis was used to differentiate between the meso-form and the R-form of BDO, and it was clear that R-BDO was the product when (3R)-acetoin was used as substrate. Formation of S-BDO could be ruled out, since this isomer is formed from diacetyl24, which we also substantiated by GC analysis (Fig. S3). We found that VJ018 could consume 40 g/L glucose within 18 h and produce 14 g/L of enantiopure R-BDO (Fig. 2C). During the first 8 h we detected (3R)-acetoin formation, which indicated that there was an imbalance in the cofactor-partitioning between NOX and SadB.

Interestingly, after substrate exhaustion, the strain oxidized some of the R-BDO formed back into (3R)-acetoin, thus the R-BDO titer decreased from 14 g/L to 10 g/L (between 18 h and 24 h). To avoid R-BDO oxidation we increased the initial glucose concentration to 103 g/L, and interestingly the (3R)-acetoin produced in the initial growth phase (around 6 g/L) was reduced into R-BDO in the later phase (Fig. 2D). In this case more glucose was consumed during the growth phase, while the glucose consumption rate decreased during the stationary phase, and 43 g/L R-BDO was obtained by 42 h with a yield of 0.41 g/g glucose, which corresponds to 83% of theoretical maximum (Fig. 2D).

(3R)-Acetoin and 2,3-BDO isomers production using whey waste

The strains used in this study, for producing (3R)-acetoin (VJ017) and 2,3-BDO (mBD001 and VJ018), are derived from the laboratory strain MG1363, a derivative of the dairy strain NCDO712 which cannot use lactose as sole carbon source. To enable production of these compounds from lactose containing whey waste, we therefore re-introduced the lactococcal plasmid-pLP712 (55.395 kbp) derived from NCDO712, which carries all the genes needed for metabolizing lactose, including lacEF, lacG and lacABCD, into VJ017, VJ018 and mBD001 to generate AL002, VJ031 and mL001 respectively. The strains transformed with this plasmid were all able to grow in defined medium (SAL) containing lactose as sole carbon source. Residual whey permeate (RWP), which is a lactose rich side stream generated when Arla Foods Ingredients Group P/S (http://www.arlafoodsingredients.com/) processes whey permeate, was subsequently tested as a feedstock. RWP contains around 15% lactose but has an insufficient level of amino acids to support growth13. As detailed in Materials and Methods we supplemented this feedstock with yeast extract as a nitrogen source and characterized growth and production of the (3R)-acetoin and BDO-producing strains in this medium. AL002 produced 27 g/L (3R)-acetoin in 42 h (Fig. 3A) from an initial lactose concentration of 70 g/L and around 6 g/L lactose was left unconsumed even after 72 h. The productivity was 0.64 g/L·h and the yield was 82% of the theoretical yield. In contrast, mL001 consumed 108 g/L lactose and produced a high titre of 51 g/L m-BDO with the yield and volumetric productivity of 0.47 g/g and 1.46 g/L·h respectively and the yield obtained was 89% of theoretical maximum (Fig. 3B). Similar to what was observed when M17 medium was applied, mL001 produced m-BDO as the sole product and (3R)-acetoin was not detected during throughout the fermentation. For VJ018, large amounts of (3R)-acetoin were formed in addition to R-BDO (equimolar amounts) when using RWP under the same conditions used for mL001 (data not shown). Although the reason is unclear, this could be due to a higher NOX activity in the RWP medium than in the M17 medium used previously. It is well-known that NOX activity can vary with the aeration level27,28, and for this reason we tried to limit aeration by changing flask to medium ratio to 2.5 : 1 (100 ml medium in 250 ml flask). We used two different initial lactose concentrations 80 and 110 g/L, and observed that the final biomass achieved was 27% lower at the high lactose concentration and also the lactose consumption rate was affected negatively. With initial 80 g/L lactose, the R-BDO titer reached 32 g/L in 52 h with the yield of 0.4 g/g lactose (76% of theoretical maximum) with the productivity of 0.62 g/L·h (Fig. 3C). The strain also formed (3R)-acetoin to a final titer of 3.5 g/L with a yield of 0.044 g/g lactose, which was much lower than when using higher flask volume to medium ratio (8.5:1) where the (3R)-acetoin yield was around 0.2 g/g lactose.

Discussion

In the present study, we used a metabolically engineered L. lactis strain, VJ017 (MG1363 Δ3ldh Δpta ΔadhE ΔbutBA) for making (3R)-acetoin, and harness the intracellular NOX activity for regenerating NAD+. A similar strategy has been used where NOX from L. lactis was heterologously expressed in other bacteria to provide a redox sink and improve production of chemicals like pyruvate, acetoin and 2,3-BDO29,30,31.

We also extended the pathway to produce the two 2,3-butanediol isomers m-BDO and R-BDO using EcBDH from E. cloacae and the secondary activity of the alcohol dehydrogenase SadB from A. xylosooxidans respectively. Formation of the specific isomers of 2,3-BDO involves the use of specific BDHs (butanediol dehydrogenases) and which isomers that are formed also depends on the stereoisomeric form of acetoin32,33,34,35. (3R)-acetoin can be converted to either m-BDO or R-BDO and (3S)-acetoin can be converted to m-BDO and S-BDO. The enzymes characterized as (2R,3R)-BDHs from P. polymyxa, and B. subtilis can convert (3R)-acetoin and (3S)-acetoin to R-BDO and m-BDO respectively10,36. In the present study, when we expressed SadB in L. lactis the outcome was R-BDO and formation of R-BDO is in line with previous work where secondary alcohol dehydrogenases have been found to catalyze formation of this isomer9.

Normally when 2,3-BDO is formed from glucose, only one of the two NADH generated in glycolysis is consumed, thus creating an excess of one NADH. Since L. lactis harbors a cytosolic NOX activity it is possible to regenerate NAD+ by using aerobic growth conditions. The 2,3-BDO forming strains VJ018 and mBD001 consumed glucose more efficiently than the (3R)-acetoin strain VJ017 (Fig. 2), which could be due to limitations in NAD+ regeneration. For VJ017, NOX activity is required for regenerating two molecules of NAD+ for each glucose molecule metabolized, whereas for the strains VJ018 and mBD001 only one NAD+ needs to be regenerated, and this apparently enhances glucose utilization. The maximum titers of (3R)-acetoin, R-BDO and m-BDO obtained in this study were 27, 43 and 51 g/L respectively and the yield achieved was around 78 to 89% of theoretical maximum. The yield of 2,3-BDO achieved in this study for L. lactis was higher than obtained by Gaspar et al.22 (67% of theoretical maximum), where formate and ethanol were additional by-products.

Unlike the R-BDO strain VJ018, mBD001 did not produce any detectable amounts of (3R)-acetoin throughout the fermentation, which indicates that the cofactor partitioning between NOX and EcBDH is efficient. Ideally, NOX and EcBDH each have to regenerate one NAD+ per mole of glucose consumed. Excess NAD+ regeneration by NOX could cause formation of the more oxidized product (3R)-acetoin (Fig. 4). Lack of (3R)-acetoin formation during m-BDO fermentation is most likely due to the highly efficient EcBDH (Figs 2B and 3B). In an earlier study EcBDH was demonstrated to be the most efficient enzyme for 2,3-BDO production in recombinant E. coli when compared to other BDHs from native producers like K. pneumoniae, B. subtilis, S. marcesens and B. licheniformis23. Similarly by screening for efficient (2R,3R)-BDHs from different microorganisms it should be possible to avoid (3R)-acetoin formation entirely during R-BDO fermentation. Alternatively, since (3R)-acetoin formation indicates excess NAD recycling via NOX activity, one solution could be to limit aeration. Indeed previous reports have shown that the NOX activity can be varied from 0.16 to 0.6 U/mg when the aeration level is varied, and this has an influence on the intracellular availability of NADH27,28. In this study when we limited the aeration level by decreasing flask to medium ratio, the (3R)-acetoin yield (0.044 g/g lactose) was significantly reduced by a factor of approximately 4.5 (Fig. 3C). Interestingly, the availability of glucose also seemed to be critical to achieve a condition that prevents oxidation of R-BDO to (3R)-acetoin (Fig. 2C). We observed that as soon as glucose had been depleted, R-BDO was oxidized, and this probably provided the NADH needed for NOX to maintain a reduced intracellular environment and thereby prevent unnecessary oxidative stress. 2,3-BDO oxidation upon substrate exhaustion has also been observed in previous studies37.

Cofactor regeneration in various L. lactis strains.

(A) Redox balance is achieved by NOX activity during acetoin production with the strain VJ017, (B) Co-factor partitioning between NOX and EcBDH during m-BDO production with the strain mBD001, (C) Fluctuation in co-factor partitioning between NOX and SadB during R-BDO production with strain VJ018.

We also successfully demonstrated the potential of L. lactis for converting processed whey waste streams into value added products by using RWP for making (3R)-acetoin and BDO isomers. The final biomass obtained (OD600 = 10 to 16) was comparable to that obtained with M17 medium with glucose (Figs 2 and 3). The maximum (3R)-acetoin, R-BDO and m-BDO yield reached were 0.42, 0.47 and 0.40 g/g lactose with productivities of 0.64, 1.46 and 0.62 g/L·h respectively. The m-BDO productivity was comparable to that obtained using native 2,3-BDO producers like K. oxytoca38. RWP is a cheap carbon source, and for this study we also added YE as a nitrogen source. We have however previously demonstrated that cheap corn steep liquor hydrolysate can be used to replace YE and thus further lower the medium costs13.

Summing up, we have engineered L. lactis to efficiently produce the valuable chemicals (3R)-acetoin, R-BDO and m-BDO. High yield and product titres were obtained using an abundant and cheap substrate, RWP, and this encourages further optimization of the bioprocess using these strains.

Materials and Methods

Strains and plasmids

MG1363 is a plasmid-free derivative of L. lactis subsp. cremoris strain NCD0712 and other derivatives of MG1363 used for this study are described in Table 3. The plasmid pCS4518 and pTD6 were used to express SadB and EcBDH respectively. For cloning purposes E. coli strain Top10 (Invitrogen) {F- mcrA Δ(mrr-hsdRMS-mcrBC) Φ80lacZΔM15 Δ lacX74 recA1 araD139 Δ(araleu)7697 galU galK rpsL (StrR) endA1 nupG} was used. E. coli strains were grown aerobically at 37 °C either in Luria-Bertani broth/agar39. For growth, MG1363 and its derivatives were cultured in M17 broth/agar supplemented with glucose at 30 °C. When required, antibiotics were added in the following concentrations: erythromycin: 200 μg/ml for E. coli and 5 μg/ml for L. lactis, tetracycline: 8 μg/ml for E. coli and 5 μg/ml for L. lactis, chloramphenicol: 20 μg/ml for E. coli and 5 μg/ml for L. lactis.

DNA techniques

All manipulations were performed according to Sambrook et al.39. PfuX7 polymerase was used for PCR applications. Electrocompetent cells of L. lactis were prepared by growing in GM17 medium with 1% glycine and transformed by electroporation as described previously. Chromosomal DNA from L. lactis was isolated using method described for E. coli with the modification that cells were treated with 20 μg of lysozyme per ml for 2 h before lysis. The plasmid vector pCS196640 was used for deleting genes in L. lactis. Gene inactivation was achieved by deleting part of the gene, briefly 800-bp regions upstream and downstream of the target to be deleted were PCR amplified and inserted into pCS1966. The resulting plasmids were used as described previously24.

Construction of strains

Derivatives of pCS1966 were used for inactivating butBA genes from CS4363, thus giving rise to VJ017. For producing R-BDO, a codon optimized sadB gene was amplified using the primers 5′-CTATGTCGACAAGTAATAAAATATTCGGAGGAATTTTGAAATGAAAGCATTAGTATATCATGGAG-3′and 5′-TCATCTGCAGTTATGCTGCTCCTGCATTACTAAG-3′ and gapB promoter from L. lactis was amplified was using the primers 5′-TCATGGTACCGAATAAAAATTACTGACAGCCTGC-3′ and 5′-TCAGTC TAGATAGTAGTTTCCTCCTTATAGGGATTAG-3′. The PCR products were further cloned at SalI/PstI and KpnI/XbaI sites of pCS4518 respectively resulting in the plasmid pVJ013. pVJ013 was further transformed to L. lactis strains MG1363, VJ017 (MG1363 Δ3ldh ΔptaΔadhEΔbutBA) to generate VJ021 and VJ018 respectively. Further the plasmid pJM001 encoding EcBDH driven by high strength synthetic promoter24 was transformed into VJ017 to generate mBD001. The lactose plasmid, pLP712 (55.395 kb), was isolated from L. lactis NCD0712 was transformed to VJ017, VJ018 and mBD001 and selected in minimal media (SAL) containing lactose as sole carbon source to generate AL002, VJ031 and mL001 respectively.

Enzyme activity analysis

Cell extract for enzyme assay was prepared as described previously24. Briefly, cells were harvested at exponential phase and washed with 0.2% KCl, resuspended in extract buffer and disrupted by glass beads (106-μm diameter; Sigma, Prod. No. G4649) using a FastPrep (MP Biomedicals, Santa Ana, USA). The SadB was assayed for 2,3-butanediol dehydrogenase activity using stereospecific R-BDO as substrate. The assay mixture contained 50 mM potassium phosphate, pH 7.0, and 0.2 mM NAD and cell free extract. The reaction was started by adding 0.2 M R-BDO and formation of NADH was monitored by measuring absorbance at 340 nm using the Infinite® M1000 PRO microplate reader (TECAN) and the accompanying software Magellan.

Metabolite analysis

Biomass density was measured at OD600 and samples were analysed by high-pressure liquid chromatography to determine product formation and glycolytic flux. HPLC analysis of the fermentation broth was carried out on an Ultimate 3000 high-pressure liquid chromatography system (Dionex, Sunnyvale, CA) equipped with an Aminex HPX-87H column (Bio-Rad, Hercules, CA) and a Shodex RI-101 detector (Showa Denko K.K., Tokyo, Japan). The column oven temperature was set at 60 °C, the mobile phase was 5 mM H2SO4, and the flow rate was 0.5 ml/min.

Tolerance studies

To study tolerance of L. lactis to acetoin and 2,3-BDO, the strain MG1363 was grown in M17 medium supplemented with 1% glucose at various initial concentration of acetoin and 2,3-BDO. Further, decrease in growth rate was calculated by taking specific growth rate of L. lactis without acetoin and 2,3-BDO as 100% using the formula

Fermentation conditions

For acetoin and 2,3-BDO production, the strains VJ017, VJ018 and mBD001 were grown in 250 ml conical flasks with 50 ml M17 broth supplemented with glucose. The cultivation was performed at 30 °C and 200 rpm. Alternatively, acetoin and 2,3-BDO fermentation with VJ031, AL002 and mL001 was performed using residual whey permeate (RWP). 30 ml of diluted RWP containing lactose and 2% (w/v) yeast extract in 250 ml conical flasks was used and the strains were grown aerobically at 30 °C and 200 rpm. Samples were collected periodically to analyze for biomass growth and metabolite formation.

Additional Information

How to cite this article: Kandasamy, V. et al. Synthesis of (3R)-acetoin and 2,3-butanediol isomers by metabolically engineered Lactococcus lactis. Sci. Rep. 6, 36769; doi: 10.1038/srep36769 (2016).

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Nielsen, D. R., Yoon, S. H., Yuan, C. J. & Prather, K. L. J. Metabolic engineering of acetoin and meso-2,3-butanediol biosynthesis in E. coli. Biotechnol. J. 5, 274–284 (2010).

Xiao, Z. et al. Thermophilic fermentation of acetoin and 2,3-butanediol by a novel Geobacillus strain. Biotechnol. Biofuels ls 5, 88 (2012).

Wang, Q., Chen, T., Zhao, X. & Chamu, J. Metabolic engineering of thermophilic Bacillus licheniformis for chiral pure D-2,3-butanediol production. Biotechnol. Bioeng. 109, 1610–1621 (2012).

Kotani, T., Yamamoto, T., Yurimoto, H., Sakai, Y. & Kato, N. Propane monooxygenase and NAD+-dependent secondary alcohol dehydrogenase in propane metabolism by Gordonia sp. strain TY-5. J. Bacteriol. 185, 7120–7128 (2003).

Raedts, J., Siemerink, M. a J., Levisson, M., van der Oost, J. & Kengen, S. W. M. Molecular characterization of an NADPH-dependent acetoin reductase/2,3-butanediol dehydrogenase from Clostridium beijerinckii NCIMB 8052. Appl. Environ. Microbiol. 80, 2011–2020 (2014).

Ying, X. & Ma, K. Characterization of a zinc-containing alcohol dehydrogenase with stereoselectivity from the hyperthermophilic archaeon Thermococcus guaymasensis. J. Bacteriol. 193, 3009–3019 (2011).

Hou, C. T., Patel, R. N., Laskin, a. I., Barist, I. & Barnabe, N. Thermostable NAD-linked secondary alcohol dehydrogenase from propane-grown Pseudomonas fluorescens NRRL B-1244. Appl. Environ. Microbiol. 46, 98–105 (1983).

Hou, C. T., Patel, R., Barnabe, N. & Marczak, I. Stereospecificity and other properties of a novel secondary-alcohol-specific alcohol dehydrogenase. Eur. J. Biochem. 119, 359–364 (1981).

Yan, Y., Lee, C.-C. & Liao, J. C. Enantioselective synthesis of pure (R,R)-2,3-butanediol in Escherichia coli with stereospecific secondary alcohol dehydrogenases. Org. Biomol. Chem. 7, 3914–3917 (2009).

Knowlton et al. Physical chemical properties of the 2,3-butanediols. J. Am. Chem. Soc. 68, 208–210 (1946).

Fu, J. et al. Metabolic engineering of Bacillus subtilis for chiral pure meso-2,3-butanediol production. Biotechnol. Biofuels 9, 90 (2016).

Wang, Q., Chen, T., Zhao, X. & Chamu, J. Metabolic engineering of thermophilic Bacillus licheniformis for chiral pure D-2,3-butanediol production. Biotechnol. Bioeng. 109, 1610–1621 (2012).

Liu, J., Dantoft, S. H., Würtz, A., Jensen, P. R. & Solem, C. A novel cell factory for efficient production of ethanol from dairy waste. Biotechnol. Biofuels 9, 33 (2016).

Liu, J., Kandasamy, V., Würtz, A., Jensen, P. R. & Solem, C. Stimulation of acetoin production in metabolically engineered Lactococcus lactis by increasing ATP demand. Appl Microbiol Biotechnol (2016). doi: 10.1007/s00253-016-7687-1.

Kleerebezemab, M., Hols, P. & Hugenholtz, J. Lactic acid bacteria as a cell factory: Rerouting of carbon metabolism in Lactococcus lactis by metabolic engineering. Enzyme Microb. Technol. 26, 840–848 (2000).

Liu, J., Solem, C. & Jensen, P. R. Integrating biocompatible chemistry and manipulating cofactor partitioning in metabolically engineered Lactococcus lactis for fermentative production of (3S)-acetoin. Biotechnol. Bioeng. doi: 10.1002/bit.26038 (2016).

Eliot, A. C., Maggio-hall, L. A. & Charles, E. (12) United States Patent. 2, 1305–1316 (2012)

Luo, Q., Wu, J. & Wu, M. Enhanced acetoin production by Bacillus amyloliquefaciens through improved acetoin tolerance. Process. Biochem. 49, 1223–1230 (2014).

Köpke, M. et al. 2,3-Butanediol production by acetogenic bacteria, an alternative route to chemical synthesis, using industrial waste gas. Appl. Environ. Microbiol. 77, 5467–5475 (2011).

Solem, C., Dehli, T. & Jensen, P. R. Rewiring Lactococcus lactis for ethanol production. Appl. Environ. Microbiol. 79, 2512–2518 (2013).

Liu, S. & Qureshi, N. How microbes tolerate ethanol and butanol. N. Biotechnol 26, 117–121 (2009).

Gaspar, P., Neves, A. R., Gasson, M. J., Shearman, C. & Santos, H. High yields of 2,3-butanediol and mannitol in Lactococcus lactis through engineering of NAD+ cofactor recycling. Appl. Environ. Microbiol. 77, 6826–6835 (2011).

Xu, Y. et al. Systematic metabolic engineering of Escherichia coli for high-yield production of fuel bio-chemical 2,3-butanediol. Metab. Eng. 23, 22–33 (2014).

Liu, J. et al. Combining metabolic engineering and biocompatible chemistry for high-yield production of homo-diacetyl and homo-(S,S)-2,3-butanediol. Metab. Eng. 36, 57–67 (2016).

Zhang, L. et al. Mechanism of 2,3-butanediol stereoisomers formation in a newly isolated Serratia sp. T241. Sci. Rep. 6, 19257 (2016).

Larroy, C., Pare, X. & Biosca, J. A. Characterization of a (2R, 3R)-2,3-butanediol dehydrogenase as the Saccharomyces cerevisiae YAL060W gene product. J. Biol. Chem. 275, 35876–35885 (2000).

Jensen, N. B. S., Melchiorsen, C. R., Jokumsen, K. Væ. & Villadsen, J. Metabolic Behavior of Lactococcus lactis MG1363 in microaerobic continuous cultivation at a low dilution rate. Appl. Environ. Microbiol. 67, 2677–2682 (2001).

De Felipe, F. L., Starrenburg, M. & Hugenholtz, J. The role of NADH-oxidation in acetoin and diacetyl production from glucose in Lactococcus lactis subsp. lactis MG1363. FEMS Microbiology Letters 156, 15–19 (1997).

Bae, S., Kim, S. & Hahn, J. Efficient production of acetoin in Saccharomyces cerevisiae by disruption of 2,3-butanediol dehydrogenase and expression of NADH oxidase. Sci. Rep. 6, 27667 (2016).

Kim, S. & Hahn, J.-S. Efficient production of 2,3-butanediol in Saccharomyces cerevisiae by eliminating ethanol and glycerol production and redox rebalancing. Metab. Eng. 31, 94–101 (2015).

Wang, Z., Gao, C., Wang, Q., Liang, Q. & Qi, Q. Production of pyruvate in Saccharomyces cerevisiae through adaptive evolution and rational cofactor metabolic engineering. Biochem. Eng. J. 67, 126–131 (2012).

Wang, Y. et al. Engineering of cofactor regeneration enhances (2S,3S)-2,3-butanediol production from diacetyl. Sci. Rep. 3, 2643 (2013).

Zhang, L. et al. Production of diacetyl by metabolically engineered Enterobacter cloacae. Sci. Rep. 5, 9033 (2015).

Liu, Z. et al. Production of (2S,3S)-2,3-butanediol and (3S)-acetoin from glucose using resting cells of Klebsiella pneumonia and Bacillus subtilis. Bioresourc. Technol. 102, 10741–10744 (2011).

Ui, S., Matsuyama, N., Masuda, H. & Muraki, H. Mechanism for the formation of 2,3-butanediol stereoisomers in Klebsiella pneumoniae. J. Ferment. Technol. 62, 551–559 (1984).

Xiao, Z. J. et al. A novel whole-cell biocatalyst with NAD+ regeneration for production of chiral chemicals. PloS One 5, e8860 (2010).

Bao, T. et al. Regulation of the NADH pool and NADH/NADPH ratio redistributes acetoin and 2,3-butanediol proportion in Bacillus subtilis. Biotechnol. J. 10, 1298–1306 (2015).

Cho, S. et al. Enhanced 2,3-butanediol production by optimizing fermentation conditions and engineering Klebsiella oxytoca M1 through overexpression of acetoin reductase. PLoS ONE 10, 1–16 (2015).

Sambrook, J. & Russel, D. Molecular Cloning: A Laboratory Manual. Third edn, (Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY, 2001).

Solem, C., Defoor, E., Jensen, P. R. & Martinussen, J. Plasmid pCS1966, a new selection/counterselection tool for lactic acid bacterium strain construction based on the oroP gene, encoding an orotate transporter from Lactococcus lactis. Appl. Environ. Microbiol. 74, 4772–4775 (2008).

Acknowledgements

This work was supported by a grant from the Innovation fund Denmark (4106-00037B). We thank Würtz A from Arla Foods Ingredients Group P/S for providing the processed whey materials. We also thank Theis Brock-Nannestad from University of Copenhagen for his assistance in GC analysis.

Author information

Authors and Affiliations

Contributions

V.K., J.M.L. carried out all the experimental work, analyzed the data and wrote the manuscript. C.S. and P.R.J. conceived the project, designed the experimental work, and wrote the manuscript. S.H.D. participated in experimental design, provided useful suggestions and revised the manuscript critically. All authors reviewed the manuscript and approved the final version.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kandasamy, V., Liu, J., Dantoft, S. et al. Synthesis of (3R)-acetoin and 2,3-butanediol isomers by metabolically engineered Lactococcus lactis. Sci Rep 6, 36769 (2016). https://doi.org/10.1038/srep36769

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep36769

This article is cited by

-

Mechanism of microbial production of acetoin and 2,3-butanediol optical isomers and substrate specificity of butanediol dehydrogenase

Microbial Cell Factories (2023)

-

Regulatory role of cysteines in (2R, 3R)-butanediol dehydrogenase BdhA of Bacillus velezensis strain GH1-13

Journal of Microbiology (2022)

-

Increasing ATP turnover boosts productivity of 2,3-butanediol synthesis in Escherichia coli

Microbial Cell Factories (2021)

-

Metabolic engineering of non-pathogenic microorganisms for 2,3-butanediol production

Applied Microbiology and Biotechnology (2021)

-

Efficient 2,3-butanediol production from whey powder using metabolically engineered Klebsiella oxytoca

Microbial Cell Factories (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.