Abstract

Superconducting wires are widely used in fabricating magnetic coils in fusion reactors. In consideration of the stability of 11B against neutron irradiation and lower induced radio-activation properties, MgB2 superconductor with 11B serving as boron source is an alternative candidate to be used in fusion reactor with severe irradiation environment. In present work, a batch of monofilament isotopic Mg11B2 wires with amorphous 11B powder as precursor were fabricated using powder-in-tube (PIT) process at different sintering temperature, and the evolution of their microstructure and corresponding superconducting properties was systemically investigated. Accordingly, the best transport critical current density (Jc) = 2 × 104 A/cm2 was obtained at 4.2 K and 5 T, which is even comparable to multi-filament Mg11B2 isotope wires reported in other work. Surprisingly, transport Jc vanished in our wire which was heat-treated at excessively high temperature (800 °C). Combined with microstructure observation, it was found that lots of big interconnected microcracks and voids that can isolate the MgB2 grains formed in this whole sample, resulting in significant deterioration in inter-grain connectivity. The results can be a constructive guide in fabricating Mg11B2 wires to be used as magnet coils in fusion reactor systems such as ITER-type tokamak magnet.

Similar content being viewed by others

Introduction

Fusion power is one of the most promising candidate energy sources that may solve global energy problems, considering its safer and greener merits compared with the conventional mineral energy sources. In the world-class International Thermonuclear Experimental Reactor (ITER) fusion energy project, the superconducting magnet system serves as a key determinant. A high and steady magnetic field needs to be produced to confine the deuterium (D)–tritium (T) burning plasma inside the ITER tokamak nuclear fusion reactor. According to the previous ITER plan, hundreds of tons of superconducting magnets made from NbTi and Nb3Sn will be fabricated to assemble 18 Nb3Sn toroidal field (TF) coils, a 6-module Nb3Sn central solenoid (CS) coil, 6 Nb-Ti poloidal field (PF) coils, and 9 pairs of Nb-Ti correction coils (CC)1,2. There is one major drawback, however, for the application of Nb-based superconductors in this project. After irradiation, 93Nb will be transformed into the long-lived nuclide 94Nb with a half-life of about 20,000 years3,4. Hence, before irradiated Nb-based alloys are safe to be recycled, tens of thousands of years are required for them to “cool down”, and meanwhile, thicker shielding is necessary for long-term operation. For the convenience of radioactive waste treatment and environmental protection, the radioactivation properties of superconducting components within the fusion reactor should be taken into account. Compared with conventional Nb-based superconductors, MgB2 features “low activation” and a much shorter decay time. Within 1 year, the dose rate of MgB2 materials will be reduced to the hands-on maintenance level, which is considered as desirable for a fusion reactor magnet system3. Additionally, because of the reaction 10B + n → 7Li + He (gas) under the heavy irradiation condition, 10B can no longer guarantee the stability of the MgB2 superconducting magnet. By replacing 10B with the isotope 11B, Mg11B2 superconducting wires will be much more stable in a neutron irradiation environment due to the smaller neutron capture cross-section of 11B5. Considering the abundant reserves of 11B on Earth (20 wt% for 10B, 80 wt% for 11B), the anticipated cost for extracting the isotope from natural boron is expected to be decreased during the chemical synthesis.

The superconductivity of MgB2 was discovered in 20016. It is well-known for its simple binary chemical composition and much higher critical transition temperature (Tc) of 39 K than that of NbTi at 9.3 K. In order to operate Nb-based low-temperature superconductors, the core of the magnet needs to be cooled down to 4 K. The only eligible cryogen is liquid helium, which is extremely expensive, not always available on hand, and very difficult to handle. In the case of MgB2, a working temperature as high as 20 K is low enough to achieve acceptable performance. Remarkably, the operating cost is expected to be cut by over 50% by substituting cryocooler-cooled MgB2 materials for liquid-helium-cooled Nb-based superconductors. Furthermore, the fabrication cost of MgB2 superconducting wire itself ($2.64/kA∙m) is less than 1/3 of that of Nb3Sn wire ($9/kA∙m). Therefore, due to the advantages of cost-effectiveness, lower radioactivation, and the shorter decay time of isotopic Mg11B2, fundamental research on Mg11B2 superconducting wires will be valuable for improving the efficiency of practical application in high-irradiation environments such as fusion reactors.

Mg11B2 wires using isotopically pure 11B powder always show lower critical current density (Jc) values, however, than the wires fabricated with natural boron powder. According to previous work7,8, this lower Jc is a result of the increased amount of non-reactive precursor, which decreases the superconducting fraction. On the other hand, inter-grain connectivity is considered another crucial factor in the current-carrying capability of Mg11B2 superconducting wires9,10,11. In this work, with the aim of further improving Jc in Mg11B2 wires, the evolution of the microstructure and superconducting performance in Mg11B2 wires sintered at different temperatures was investigated in detail. The influence of both the superconducting fraction and the inter-grain connectivity on the Jc performance is discussed. We optimized the temperature of the heat-treatment at which the best transport performance can be obtained. Surprisingly, in the case of Mg11B2 wire sintered at high temperature, the transport Jc vanished, although magnetic Jc was still detected. According to detailed microstructure observations, this could be ascribed to the formation of a unique microstructure that was only obtained in the sample sintered at excessively high temperature. This kind of microstructure leads to significant deterioration in inter-grain connectivity and ultimately, poor transport current performance.

Experimental Details

The standard in-situ powder-in-tube (PIT) procedure was applied to all the samples. The starting materials for the Mg11B2 wire consisted of 11B amorphous powder (from Pavezyum Kimya, Turkey, Moissan method12, 95.5%) and magnesium powder (100–200 mesh, 99%). The isotopic purity and particle size with respect to the 11B enriched boron powder was >99.5% and 840 nm, respectively. After mixing the precursor powders, the mixture was tightly packed into Nb/Monel tubes with 10 mm outer diameter and 6 mm inner diameter. The composite wire was swaged and drawn to a final outer diameter of 1.08 mm. Then, the fabricated Mg11B2 wires were sintered at different temperatures ranging from 700 °C, 750 °C, 770 °C, and 800 °C for 60 min (ramp rate: 5 °C/min) under high purity flowing argon gas. Finally, the samples were furnace-cooled to room temperature.

The transport critical current (Ic) measurements were carried out by using an American Magnetics superconducting magnet with DC current (with the upper limit of the current source 200 A) under possible magnetic field up to 15 T, with the standard four-probe method and the criterion of 1 μV/cm. The critical current density Jc was calculated by dividing Ic by the cross-section of the Mg11B2 core, which was examined with an optical microscope (Leica M205A). Scanning electron microscopy (SEM, JEOL JSM-6490LV & JEOL JSM-7500) was employed to observe the microstructure under different magnifications. X-ray diffraction (XRD) θ–2θ scans (GBC-MMA) were used to identify the phase composition. Measurements of electrical resistivity and magnetic moment were conducted in a 9 T Physical Properties Measurement System (PPMS, Quantum Design). In case of XRD, SEM, and PPMS measurements, the outer sheaths of the Mg11B2/Nb/Monel wires were removed for better data accuracy.

Results and Discussion

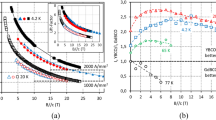

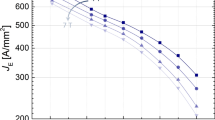

Typical transport Jc - B performances of all four wires sintered at different temperatures are shown in Fig. 1. For reference purposes, transport Jc data of for the multi-filament Mg11B2/Ta/Cu wire reported by Hishinuma7 is also plotted in the figure. It should be noted that our best monofilament Mg11B2 wire shows comparable transport Jc performance to the multifilament wire fabricated by the National Institute for Fusion Science (NIFS)7. This result is considered as a big breakthrough, and it strongly supports the feasibility of replacing commercial NbTi by high-performance Mg11B2 wires in highly radioactive fusion reactors. In our Mg11B2 wires, 750 °C is the optimized temperature for heat treatment. The corresponding wire possesses a Jc value near 2 × 104 A/cm2 at 4.2 K and 5 T. Slight Jc degradation is observed in the wire treated at temperatures deviating from 750 °C. Surprisingly, no transport current was detected in the wire treated at 800 °C. For verification, five attempts at measurement were carried out on three batches of wires produced under the same sintering conditions. Ultimately, none of them gave detectable transport current data. It is speculated that some unexpected qualitative change inside the wire might occur once the heating temperature reaches a certain level. This should probably be attributed to a unique property of the 11B starting powder. It is believed that investigations of the phase composition, microstructure, and inter-grain connectivity will give an explanation for this abnormal phenomenon.

To confirm the phase composition, Mg11B2 cores were removed from their outer sheaths and finely ground as XRD specimens. In Fig. 2(a), the main peaks indexed as Mg11B2 can be observed in all spectra, indicating that the temperature is high enough to permit the formation of Mg11B2 phase. Very little oxidation was detected, according to the negligible MgO peak. Un-reacted Mg and 11B-rich phase are found in the wire sintered at relatively low temperature. Apparently, it is very hard for Mg to completely diffuse into boron particles, if the sintering temperature is not high enough. A diminishing gradient of Mg concentration exists along the radial direction of the boron particle. As a result, Mg11B2 phase can only be formed on the outer layers of boron particles. The rest of the Mg will either stay in the elemental state (un-reacted Mg) or participate in other secondary reactions. Hence, 11B-rich phase is prone to form in this case, which can be deduced from the Mg-B phase diagram13. The presence of those impurities (un-reacted Mg and 11B-rich phase) will reduce the fraction of superconducting phase, which is crucial for the final performance of superconductors. It has to be pointed out that the chemical activity of 11B is lower in comparison with natural B due to the isotope kinetic effect14. This might explain why 700 °C is not high enough for the complete reaction in this work. Figure 2(b) shows the mass fractions of Mg11B2 phase in the wires as a function of sintering temperature. The mass fractions were calculated by using Rietveld refinement. The smallest Mg11B2 fraction, as low as 84.7%, is found in the wire treated at 700 °C. This is mainly due to the presence of impurities, as reflected by the XRD results. Furthermore, the degradation in transport Jc performance also confirms its relatively poor superconductivity (see Fig. 1). With increasing sintering temperature, un-reacted Mg peaks become smaller and almost disappear. Correspondingly, the mass fractions of Mg11B2 phase in the rest of the wires all remain at a high level (>90%). Since the crystallization of Mg11B2 phase is confirmed to be good in the Mg11B2 wire sintered at 800 °C, while its mass fraction of superconducting phase is also satisfactory, the observed abrupt disappearance of transport current in the wire sintered at 800 °C is related to neither the phase composition nor a low superconducting fraction.

(a) XRD θ–2θ patterns of all Mg11B2 wires sintered at different temperatures. The numbered labels (hkl) represent Mg11B2 reflections. The pound sign (hashtag) stands for unreacted Mg. A small amount of B-rich phase (with its peak marked by the plus sign) is detected only in samples sintered at 700 °C. (b) Mass fractions, obtained from Rietveld refinement, of Mg11B2 and Mg as functions of the different sintering temperatures.

Figure 3(a) shows the zero-field-cooled (ZFC) and field-cooled (FC) demagnetization results as functions of the sintering temperature for all four samples. H = 100 Oe was applied in this measurement. A clear normal-superconducting transition was observed in all samples, including the wire sintered at 800 °C, which did not show any current value in the transport measurements. The magnetic Jc (H) of the samples was estimated at 5 K based on the magnetization hysteresis loops and the Bean critical state model. Generally, the formula for a rectangular shaped sample is: Jc = 20(ΔM/V)/[a(1−a/3b)], where ΔM = [M(+) − M(−)] is the difference between the upper and lower branches of the M(H) loop, V is the volume, and a and b (a < b) are the length and width of the cross-section which is perpendicular to the direction of the applied magnetic field15. In our case, the Mg11B2 cores are cylindrical in shape. So, the formula can be simplified to Jc = 30(ΔM/V)/d, where d is the diameter of the circular cross-sectional area16,17. According to the calculations, the magnetic Jc (H) results at 5.0 K are shown in Fig. 3(b). The wire sintered at 750 °C shows the best magnetic Jc (H) performance throughout the entire range of fields, which is consistent with the transport Jc results shown in Fig. 1. Some differences can be found between the values of magnetic Jc and transport Jc. Other than measurement deviation, the intrinsic distinction between the magnetic Jc signal and the transport Jc signal also needs to be taken into consideration. Generally, due to the existence of negative structures such as porosity and cracks, not all the MgB2 in a sample is capable of passing transport current. Inter- or intra-grain connectivity should always be considered when dealing with transport performance. On the contrary, as long as they possess superconductivity, all the MgB2 fragments will contribute to the magnetic Jc. It should be noted that the magnetic Jc was detected and showed good performance in the wire sintered at 800°C. This means that the Mg11B2 superconducting phase in the wire was not badly damaged by the high sintering temperature. Hence, after ruling out the effects of inferior superconducting phase, it can be speculated that the transport current in the wire sintered at 800 °C disappeared as a result of a problem with inter-grain connectivity. A high sintering temperature might introduce some defects and significantly destroy the connection between Mg11B2 superconducting grains.

It is estimated that the vanishing of transport current in the Mg11B2 wire is caused by the severe deterioration of inter-grain connectivity, which can be visually confirmed by SEM micrographs. The low-magnification SEM images of the cross-sections of Mg11B2 wires sintered at 700 °C, 750 °C and 800 °C are presented in Fig. 4(a–c). Obvious evolution of the surface morphology is exhibited with increasing temperature. In the wire treated at 700 °C, it was already proved by the XRD results that the Mg had partially reacted with the boron. As the particle size of the Mg powder is much bigger than for the boron powder, un-reacted Mg melted and smoothly covered the Mg11B2 grains. Therefore, the morphology of this sample was fairly plain and incompact. A dense surface is observed in Fig. 4(b) on the optimal sample sintered at 750 °C, indicating complete reaction and good inter-grain connectivity. This is consistent with the Jc - B and XRD results discussed above. Once the sintering temperature reached 800 °C, big cracks (marked by black arrows) were observed, as shown in Fig. 4(c). They are much bigger than the normal microcracks in other samples. Note that most of the big cracks are connected with each other. This feature is considered to be highly detrimental to the inter-grain connectivity. The resultant superconducting fragments are isolated from each other, and eventually, very little current can pass through the entire wire, which will significantly reduce the transport performance. On further increasing the magnification, porous structure is found in the same sample (marked by white arrows in Fig. 4(d)). When the wire was heat-treated at 800 °C, both the grain size and the mobility of the Mg11B2 grains were increased. The separate grains are prone to aggregate with each other, leaving plenty of voids in the morphology. Consequently, the effective current capacity is sharply reduced with the emergence of the porous structure. This is considered to be another barrier to obtaining high transport current in Mg11B2 wires. In addition, this kind of microstructure with abundant voids can be more brittle and thus be more prone to fracture and form big microcracks (see Fig. 4c) resulting from heat stress during the furnace-cooling process from high temperature to room temperature.

SEM micrographs of cross-sections of Mg11B2 wires sintered at (a) 700 °C, (b) 750 °C, and (c) 800 °C. Evolution of the surface morphology is clearly shown. Black arrows indicate big cracks. (d) SEM image of the wire sintered at 800 °C under higher magnification. White arrows indicate porous structure in the sample sintered at 800 °C.

High-resolution SEM was employed to investigate the details of the crystalline structure in the four Mg11B2, wires, and the results are presented in Fig. 5. In the sample with the lowest sintering temperature, the crystalline grains have a wide range of sizes, and all of them are dispersed in a melted matrix, as shown in Fig. 5(a). Referring to the XRD results above, the melted matrix is un-reacted Mg, which cannot be fully reacted with B at a relatively low temperature. This is strong evidence for the smaller mass fraction of Mg11B2 phase and lower transport performance in this sample. In the wires sintered at higher temperature, the amount of un-reacted Mg is greatly reduced, and the Mg11B2 crystalline grains keep growing and form typical hexagonal shapes, which can be observed in Fig. 5(b,c). Figure 5(d) shows the morphology of the wire sintered at 800 °C, in which some grains abnormally grow, and abundant big clusters are found. These clusters are formed by the localized aggregation of Mg11B2 grains at the relatively high heat-treatment temperature. This phenomenon further increases the porosity on the macroscale and significantly reduces the effective superconducting fraction for transporting current. As a result, the inter-grain connectivity is badly degraded. Combining these results with the low-magnification SEM images, it is thus concluded that the vanishing of transport current in the Mg11B2 sintered at high temperature should be attributed to the depression of inter-grain connectivity in the wire that is caused by the big microcracks and high porosity.

Conclusions

The effects of sintering temperature on the superconducting performance and morphology of Mg11B2 monofilament wires made from isotopically pure boron powder were investigated in this work. It was found that increasing the sintering temperature led to the evolution of microstructure and characteristic changes in the transport current capacity. Un-reacted Mg and B-rich phase existed in the wire sintered at low temperature. The Mg11B2 fraction, as well as the transport performance, was reduced because of the un-reacted Mg and B-rich phase impurities. With increasing sintering temperature, better phase composition and crystallinity were obtained. The best transport Jc = 2 × 104 A/cm2 was reached at 4.2 K and 5 T in the Mg11B2 wire sintered at 750 °C. It should be noted that although high magnetic Jc was detected in the wire sintered at 800 °C, the transport current was totally absent. The evolution of the morphology could be clearly seen in the wires corresponding to different sintering temperatures. Due to the abnormal growth and high mobility of Mg11B2 grains at relatively high ambient temperature, numerous big microcracks, voids, and Mg11B2 clusters formed in the wire sintered at 800 °C. As a result, the inter-grain connectivity was significantly suppressed, resulting in the inferior transport performance. The results obtained in our work can be a constructive guide for fabricating Mg11B2 wires to be used as magnet coils in fusion reactor systems such as ITER-type tokamak magnets.

Additional Information

How to cite this article: Qiu, W. et al. Improvement in the transport critical current density and microstructure of isotopic Mg11B2 monofilament wires by optimizing the sintering temperature. Sci. Rep. 6, 36660; doi: 10.1038/srep36660 (2016).

References

Mitchell, N. et al. The ITER Magnet System. IEEE Trans. Appl. Supercond. 18, 435–440 (2008).

Devred, A. et al. Challenges and status of ITER conductor production. Supercond. Sci. Technol. 27, 044001 (2014)

Noda, T., Takeuchi, T. & Fujita, M. Induced activity of several candidate superconductor materials in a tokamak-type fusion reactor. J. Nucl. Mater. 329–333, 1590–1593 (2004).

Noda, T. et al. Induced activity and damage of superconducting materials for a fusion reactor. Fusion Eng. Des. 81, 1033–1037 (2006).

Mooring, F. P., Monahan, J. E. & Huddleston, C. M. Neutron cross sections of the boron isotopes for energies between 10 and 500 keV. Nucl. Phys. 82, 16–32 (1966).

Nagamatsu, J., Nakagawa, N., Muranak, T., Zenitani, Y. & Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 410, 63–64 (2001).

Hishinuma, Y. et al. Development of MgB2 superconducting wire for the low activation superconducting magnet system operated around core D-T plasma. Fusion Eng. Des. 98–99, 1076–1080 (2015).

Hishinuma, Y. et al. Effect of boron particle size on microstructure and superconducting properties of in-situ Cu addition MgB2 multifilamentary wire. J. Phys. Conf. Ser. 507, 022009 (2014).

Glowacki, B. A. et al. Superconductivity of powder-in-tube MgB2 wires. Supercond. Sci. Technol. 14, 193–199 (2001).

Matsumoto, A., Kumakura, H., Kitaguchi, H., Fujii, H. & Togano, K. The annealing effects of MgB2 superconducting tapes. Physica C 382, 207–212 (2002).

Serquis, A. et al. Microstructure and high critical current of powder-in-tube MgB2 . Appl. Phys. Lett. 82, 1754 (2003).

Markovskii, L. Y. Chemistry of magnesiothermal preparation of boron. Electron. Technol. 3, 95–102 (1970).

Massalski, T. B., Okamoto, H., Subramanian P. R. & Kacprzak, L. Binary Alloy Phase Diagrams. ASM International (1990).

Chkhartishvili, L. Isotopic effects of boron. Trends Inorg. Chem. 11, 105–167 (2009).

Bean, C. P. Magnetization of high-field superconductors. Rev. Mod. Phys. 36, 31–39 (1964).

Fietz, W. A. & Webb, W. W. Hysteresis in superconducting alloys—temperature and field dependence of dislocation pinning in niobium alloys. Phys. Rev. 178, 657 (1969).

Takano, Y., Oguro, N., Kaieda Y. & Togano, K. Superconducting properties of combustion synthesized MgB2 . Physica C 412–414, 125–129 (2004).

Acknowledgements

This work is supported by the Australian Research Council (Grant Nos DE140101333 and DE13010124). M. S. A. H thanks to Australian Nuclear Science and Technology Organization (ANSTO) for supporting H.J’s scholarship funding and beam time support (proposal no. 5436). The authors are grateful to the National Natural Science Foundation of China (Grant Nos 51302186 and 51574178). The authors are also thankful to Dr. Tania Silver for the critical reading of the manuscript. The authors acknowledge the use of facilities within the UOW Electron Microscopy Centre. The authors would also like to extend their sincere appreciation to the Deanship of Scientific Research at King Saud University for its funding of this research through the Research Group Project no. RGP-290.

Author information

Authors and Affiliations

Contributions

Z.M. and M.S.A.H. designed the experimental scheme. W.Q., Y.L., D.P. and H.J. prepared the samples and did most of the characterizations. M.S., V.L., A.D., J.H.K. and S.D. helped with the experiments and data analysis, and M.S. synthesized the special boron-11 isotope powder.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Qiu, W., Jie, H., Patel, D. et al. Improvement in the transport critical current density and microstructure of isotopic Mg11B2 monofilament wires by optimizing the sintering temperature. Sci Rep 6, 36660 (2016). https://doi.org/10.1038/srep36660

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep36660

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.