Abstract

Magnetic refrigeration based on the magnetocaloric effect (MCE) is an environment-friendly, high-efficiency technology. It has been believed that a large MCE can be realized in the materials with a first-order magnetic transition (FOMT). Here, we found that TlFe3Te3 is a ferromagnetic metal with a first-order magnetic transition occurring at Curie temperature TC = 220 K. The maximum values of magnetic entropy change (Δ ) along the crystallographic c-axis, estimated from the magnetization data, reach to 5.9 J kg−1K−1 and 7.0 J kg−1 K−1 for the magnetic field changes, ΔH = 0–1 T and 0–2 T, respectively, which is significantly larger than that of MCE materials with a second-order magnetic transition (SOMT). Besides the large ΔSM, the low-level both thermal and field hysteresis make TlFe3Te3 compound an attractive candidate for magnetic refrigeration. Our findings should inspire the exploration of high performance new MCE materials.

) along the crystallographic c-axis, estimated from the magnetization data, reach to 5.9 J kg−1K−1 and 7.0 J kg−1 K−1 for the magnetic field changes, ΔH = 0–1 T and 0–2 T, respectively, which is significantly larger than that of MCE materials with a second-order magnetic transition (SOMT). Besides the large ΔSM, the low-level both thermal and field hysteresis make TlFe3Te3 compound an attractive candidate for magnetic refrigeration. Our findings should inspire the exploration of high performance new MCE materials.

Similar content being viewed by others

Introduction

Magnetic refrigeration based on MCE is an environment-friendly, high-efficiency technology compared to the traditional gas-cycle refrigeration1,2,3,4. After the discovery of the first magnetic refrigeration prototype near room temperature5 and the giant MCE in Gd5(Si2Ge2)6,7, a large MCE has been realized in a lot of materials in the past two decades, such as ReCo2 (Re = Er, Ho and Dy) alloys8,9, manganite oxides (Re, M)MnO3 (Re = Lanthanide, M = Ca, Sr and Ba)10,11, Ni-Mn-X (X = Ga, In and Sn) based Heusler alloys12,13,14,15,16, MnAs based compounds3,17,18,19, La(Fe, Si)13 and related compounds20,21,22,23, as well as rare earth based intermetallic compounds24,25,26,27,28,29,30. Amongst the families of MCE materials, the compounds with first-order magnetic transition (FOMT) have been found promising due to their large and/or sharp changes in magnetization and the strong coupling between crystallographic structure and magnetism, such as Gd5Ge4−xSix7, MnAs1−xSbx18,31, MnFe(As, P, Si, Ge)17,32, LaFe13−xSix(Hδ)14,21,23 and Heusler-type magnetic shape-memory alloys14,16. However, in these materials, the magnetic transitions are frequently accompanied by significant thermal and/or magnetic hysteresis, which would limit the life span of refrigerants or even make the refrigeration cycle impossible3,33. In order to reduce or even eliminate the magnetic hysteresis losses, there have been two strategies. One is to treat the giant MCE materials by special methods, such as microstructure-tuning, as porosity34, fragmentation35,36,37, melt-spun38,39,40, or chemical tuning, as doping41. Another is to search for new high performance compounds with SOMT42. However, the performances in materials with SOMT are rather modest when compared with that with FOMT. It is therefore interesting to search for new FOMT materials with low-level hysteresis and without any additional treatments.

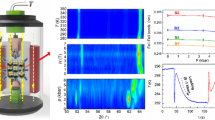

The crystal structure and physical properties of TlFe3Te3 were reported by two groups in 198443,44. TlFe3Te3 crystalizes in a hexagonal structure with space group P63/m, which consists of one-dimensional metallic cluster |Fe3Te3|∞ chains along the hexagonal c-axis, separated by the parallel chains of Tl atoms (see Fig. 1). The authors concluded that the compound undergoes a first-order transition from paramagnetic to ferromagnetic at 220 K based on their physical property measurements. However, neither of them observed discernible thermal and field hysteresis. Since the absence of hysteresis is appealing for magnetic refrigerant, in this report, we recheck the type of the magnetic transition and elucidate the MCE of TlFe3Te3 by performing resistivity and magnetization measurements. We found that this compound exhibits a large MCE with a small magnetic field change, ΔH and with a low-level thermal and field hysteresis, thus identifying it to be another class of solids for the magnetic refrigerants.

Results and Discussion

Figure 1 presents the powder x-ray diffraction (XRD) pattern of TlFe3Te3 and its Rietveld refinement. All the diffraction peaks could be indexed by a hexagonal structure with space group P63/m. The lattice parameters a = 9.355(1) Å and c = 4.224(5) Å were obtained by the refinement, which are in good agreement with previous reports44. The electron probe micro-analyzer (EPMA) experiments performed on several single crystals verified that the sample composition (the average atomic ratio) is of Tl : Fe : Te = 0.99(1) : 2.95(2) : 3.00(1), which is in consistent with the nominal composition. The temperature dependence of electrical resistivity along c-axis, ρ(T), for a TlFe3Te3 crystal is shown in Fig. 2(a). In the whole measuring temperature range, the positive resistivity-temperature coefficient of ρ(T) indicates its metallic behavior. The resistivity has a very sharp drop at 220 K with detectable thermal hysteresis [see the inset of Fig. 2(a)], which is associated with the first-order ferromagnetic transition. The resistivity at 300 K and 1.8 K are of 120 μΩ cm and 1.8 μΩ cm, respectively. The small resistivity should be viewed as a merit since a good thermal conductivity is required for a high performance magnetic refrigerant material45. Both a rather low residual resistivity and a considerable large residual resistivity ratio (RRR) = 67 indicate that our crystals are of high quality.

(a) The temperature dependence of resistivity with a current applied parallel to c-axis and the expansion near the transition temperature (inset). (b) The temperature dependence of magnetization, M(T), for both H || c-axis and H ⊥ c-axis. The M(T) near the transition temperature for (c) H || c-axis, (d) H ⊥ c-axis, the arrows show the cooling and heating process during measurements.

Figure 2(b) shows the magnetization as a function of temperature, M(T), measured from 2 to 300 K in an applied magnetic field H = 1000 Oe, aligned both || and ⊥ the c-axis, with a field cooling process. A sharp increase of M for both directions at the Curie temperature, TC ~ 220 K, confirms the occurrence of a ferromagnetic transition. Larger magnetization along c-axis suggests that the easy axis of magnetization is in the c axis. As discussed by Uhl et al.43 and Pelizzone et al.44, the strong magnetic anisotropy observed in the ferromagnetic state is certainly related to its peculiar structure being composed of |Fe3Te3|∞ chains, whose central part is a column of edge-sharing octahedral Fe clusters. The Fe-Fe distance of 2.6 Å within the clusters are comparable to the interatomic distance in metallic iron, while the nearest two Fe atoms belong to different |Fe3Te3|∞ chains are 6.7 Å apart. Thus, a strong anisotropy of the exchange coupling is to be expected. As shown in Fig. 2(c,d), it is clear that the M(T) curves near TC exhibit a small thermal hysteresis for both directions, which is in contrast to that reported by Uhl et al.43 and Pelizzone et al.44, who did not observe any hysteresis in their measurements. We observed a distinguishable but very small hysteresis, (i.e., the hysteresis temperature ΔThy = 0.2 K for H || c-axis and 0.1 K for H ⊥ c-axis), which suggests that a first-order ferromagnetic transition occurs at ~220 K.

In order to further identify the type of the transition and to explore the MCE, we performed the isothermal magnetization measurements near the TC. Figure 3 shows the magnetization as a function of magnetic field, M(H), measured at various temperatures around TC with both H || c-axis and H ⊥ c-axis and with both increasing and decreasing magnetic field. A small magnetic hysteresis was again observed. The maximum hysteresis is 50 Oe for H || c-axis [see Fig. 3(a)], while for H ⊥ c-axis, the hysteresis is rather small and becomes even indiscernible [see Fig. 3(b)]. The M(H) curves for both H || c-axis and H ⊥ c-axis exhibit a different behavior, which is associated with the large anisotropy of magnetization discussed above. The M2 versus H/M curves for both directions are shown in Fig. 3(c,d), respectively. According to the Banerjee criterion46, the curves at some temperatures have a negative slope and a inflection, which confirms further the occurrence of the first-order ferromagnetic transition around 220 K. The small hysteresis in M(H) curves enables us to use the Maxwell equation to estimate the isothermal magnetic entropy change (ΔSM). The ΔSM is calculated by a formula:

The isothermal magnetization near TC as a function of magnetic field, M(H), measured with a temperature step of 1 K for H (a) || and (b) ⊥ the c axis. The arrows indicate the measurements with increasing and decreasing magnetic field process. The corresponding M2 vs H/M curves for H (c) || and (d) ⊥ the c axis.

which is an approximation of the integral form of the Maxwell equation.

Figure 4(a,b) present the temperature dependence of −ΔSM with the magnetic field changes ΔH up to 0–5 T, for both H || c-axis and H ⊥ c-axis. For H || c-axis, the −ΔSM(T) curve with ΔH = 0–1 T shows a pronounced peak around TC and a table-like behavior can be observed in the −ΔSM(T) curves with ΔH = 0–2 T and 0–3 T, i.e., there is a temperature range corresponding to the maximum value of magnetic entropy change, which is beneficial for application. With ΔH = 0–1, 0–2, 0–3, 0–4 and 0–5 T, −Δ = 5.9, 7.0, 8.2, 8.5 and 8.9 J/kg K, respectively, which increases continuously with the increasing field change and tends to almost saturate at higher magnetic field change. It is known that a “table-like” behavior and no strong ΔH dependence of −Δ

= 5.9, 7.0, 8.2, 8.5 and 8.9 J/kg K, respectively, which increases continuously with the increasing field change and tends to almost saturate at higher magnetic field change. It is known that a “table-like” behavior and no strong ΔH dependence of −Δ value are the typical behaviors for FOMT materials2,45. Although −Δ

value are the typical behaviors for FOMT materials2,45. Although −Δ values are smaller than that for the some giant MCE materials (see Table 1), these values of TlFe3Te3 are comparable with the most potential magnetic refrigerant materials with the a first-order ferromagnetic transition (see Table 1). For the H ⊥ c-axis case, all the −ΔSM(T) curves with different ΔH values exhibit a peak around TC without table-like behavior and the maximum value of magnetic entropy change −Δ

values are smaller than that for the some giant MCE materials (see Table 1), these values of TlFe3Te3 are comparable with the most potential magnetic refrigerant materials with the a first-order ferromagnetic transition (see Table 1). For the H ⊥ c-axis case, all the −ΔSM(T) curves with different ΔH values exhibit a peak around TC without table-like behavior and the maximum value of magnetic entropy change −Δ is smaller than that for the H || c-axis. The anisotropy of MCE may origin from the peculiar magnetic structure, as discussed above.

is smaller than that for the H || c-axis. The anisotropy of MCE may origin from the peculiar magnetic structure, as discussed above.

Another important quality factor of magnetic refrigerant materials is the relative cooling power (RCP) or/and refrigeration capacity (RC), defined29 usually as the product of −Δ and the full width at half maximum in the −ΔSM(T) curve, as an example, i.e., Thot − Tcold for ΔH = 0–1 T in Fig. 4(a). RCP/RC is a measurement of the amount of heat transfer between the cold and hot reservoirs in an ideal refrigeration cycle. Due to the limitation of data measured in our experiments, we only estimated that the RCP values for the ΔH = 0–1, 0–2 and 0–3 T, are of 13, 50 and 74.6 J/kg, respectively. Recently, as a figure of merit for the magnetic refrigerant materials, the dimensionless materials efficiency47,48, η = |Q/W|, is taken into consideration, where electrical or mechanical work, W, is done to drive highly reversible caloric effects in an isothermal body, whose entropy is thus modified such that heat, Q, flows to (Q < 0) or from (Q > 0). Here, we estimated the mass-normalized values of |W| by integrating −μ0MdH0 from the M(H0) data at TC and evaluated the mass-normalized value of heat Q by integrating μ0T0(∂M/∂T)H with respect to H from the M(H0) data at TC, which follows from the Maxwell relation μ0(∂M/∂T)H = (∂S/∂H)T. The materials efficiency η values at TC was estimated to be of 65.7, 32.0, 23.2, 17.1 and 13.9 for ΔH = 0–1, 0–2, 0–3, 0–4 and 0–5 T, respectively.

and the full width at half maximum in the −ΔSM(T) curve, as an example, i.e., Thot − Tcold for ΔH = 0–1 T in Fig. 4(a). RCP/RC is a measurement of the amount of heat transfer between the cold and hot reservoirs in an ideal refrigeration cycle. Due to the limitation of data measured in our experiments, we only estimated that the RCP values for the ΔH = 0–1, 0–2 and 0–3 T, are of 13, 50 and 74.6 J/kg, respectively. Recently, as a figure of merit for the magnetic refrigerant materials, the dimensionless materials efficiency47,48, η = |Q/W|, is taken into consideration, where electrical or mechanical work, W, is done to drive highly reversible caloric effects in an isothermal body, whose entropy is thus modified such that heat, Q, flows to (Q < 0) or from (Q > 0). Here, we estimated the mass-normalized values of |W| by integrating −μ0MdH0 from the M(H0) data at TC and evaluated the mass-normalized value of heat Q by integrating μ0T0(∂M/∂T)H with respect to H from the M(H0) data at TC, which follows from the Maxwell relation μ0(∂M/∂T)H = (∂S/∂H)T. The materials efficiency η values at TC was estimated to be of 65.7, 32.0, 23.2, 17.1 and 13.9 for ΔH = 0–1, 0–2, 0–3, 0–4 and 0–5 T, respectively.

As a comparison of MCE properties, we choose several compounds with a similar magnetic transition temperature, TM, as well as some typical materials with a near room temperature, TM, focusing on the performence under ΔH = 0–2 T (the maximum magnetic field generated by a permanent magnet is about 2 T). As listed in Table 1, although the −Δ of TlFe3Te3 is less than that in the some pronounced materials with FOMT, such as GdSi2Ge2, MnFeP0.45As0.55, LaFe11.7Si1.3 and 20-LaFe11.57Si1.43 materials, −Δ

of TlFe3Te3 is less than that in the some pronounced materials with FOMT, such as GdSi2Ge2, MnFeP0.45As0.55, LaFe11.7Si1.3 and 20-LaFe11.57Si1.43 materials, −Δ of TlFe3Te3 is significantly larger than that with SOMT. Both the RCP and η values of TlFe3Te3 are comparable with the most MEC materials, except for some special compounds, such as Tb5Si4, LaFe11.7Si1.3, GdSi2Ge2 and MnFeP0.45As0.55. Besides having a larger ΔSM, TlFe3Te3 has some other advantages, such as a rare-earth-free element, a low synthesis temperature, as well as a low-level hysteresis in the as-grown crystals. But it should be pointed out that the toxicity of Tl element is not so good for the commercial utilization, which may be improved by the replacement of In, Ba, K for Tl in the future.

of TlFe3Te3 is significantly larger than that with SOMT. Both the RCP and η values of TlFe3Te3 are comparable with the most MEC materials, except for some special compounds, such as Tb5Si4, LaFe11.7Si1.3, GdSi2Ge2 and MnFeP0.45As0.55. Besides having a larger ΔSM, TlFe3Te3 has some other advantages, such as a rare-earth-free element, a low synthesis temperature, as well as a low-level hysteresis in the as-grown crystals. But it should be pointed out that the toxicity of Tl element is not so good for the commercial utilization, which may be improved by the replacement of In, Ba, K for Tl in the future.

In summary, after successfully growing TlFe3Te3 single crystals, we carried systematically out the measurements of its resistivity and magnetization to investigate the nature of the magnetic phase transition and the MCE. It was found that TlFe3Te3 is a FOMT metal with TC = 220 K and has a small thermal and field hysteresis near TC. The relative large MCE at a low ΔH makes this compound a promising candidate for magnetic refrigeration around 220 K. Further efforts should be done to substitute Tl by other nontoxic elements in order to utilize this type of materials widely.

Methods

Single crystals of TlFe3Te3 were grown using a self-flux method. A mixture with a ratio of Tl:Fe:Te = 1:3:3 was placed in an alumina crucible, sealed in an evacuated quartz tube, heated at 923 K for 5 days. The product was a black powder from which needle-like single crystals with a typical dimension of ~0.4 × 0.4 × 4 mm3 could be isolated. Powder XRD measurements on crushed single crystals were carried out at room temperature on a PANalytical x-ray diffractometer (Model EMPYREAN) with a monochromatic Cu Kα1 radiation to identify the phase purity and the crystal structure. The composition was confirmed by an electron probe micro-analyzer (EPMA) (Jeol JXA-8100). The magnetic measurements were performed on a Quantum Design Magnetic Property Measurement System (SQUID-VSM, MPMS-5) and the resistivity measurements were carried out on a Physical Property Measurement System (PPMS-9).

Additional Information

How to cite this article: Mao, Q. et al. Large low field magnetocaloric effect in first-order phase transition compound TlFe3Te3 with low-level hysteresis. Sci. Rep. 6, 34235; doi: 10.1038/srep34235 (2016).

References

Gschneidner Jr, K. A., Pecharsky, V. K. & Tsokol A. O. Recent developments in magnetocaloric materials. Rep. Prog. Phys. 68, 1479–1539 (2005).

Gschneidner Jr, K. A. & Pecharsky, V. K. Magnetocaloric materials. Annu. Rev. Mater. Sci. 30, 387 (2000).

Brück, E. Developments of magnetocaloric refrigeration. J. Phys. D: Appl. Phys. 38, R381 (2005).

Smith, A. et al. Materials challenges for high performance magnetocaloric refrigeration devices. Adv. Energy Mater. 2, 1288 (2012).

Zimm, C. et al. Description and performance of a near-toom temperature magnetic refrigerator. Adv. Cryog. Eng. 43, 1759 (1998).

Pecharsky, V. K. & Gschneidner Jr, K. A. Giant magnetocaloric effect in Gd5(Si2Ge2). Phys. Rev. Lett. 78, 4494 (1997).

Pecharsky, V. K. & Gschneidner Jr, K. A. Tunable magnetic regenerator alloys with a giant magnetocaloric effect for magnetic refrigeration from ~20 to ~290 K. Appl. Phys. Lett 70, 3299 (1997).

Singh, N. K. et al. Itinerant electron metamagnetism and magnetocaloric effect in RCo2-based Laves phase compounds. J. Magn. Magn. Mater. 317, 68 (2007).

Gratz, Z. & Markosyan, A. S. Physical properties of RCo2 Laves phases. J. Phys.: Condens. Matter 13, R385 (2001).

Zhong, W., Au, C. K. & Du, Y. W. Review of magnetocaloric effect in perovskite-type oxides. Chin. Phys. B 22, 057501 (2013).

Phan, M. H. & Yu, S. C. Review of the magnetocaloric effect in manganite materials. J. Magn. Magn. Mater. 308 325 (2007).

Liu, J. Optimizing and fabricating magnetocaloric materials. Chin. Phys. B 23, 047503 (2014).

Hu, F. X., Shen, B. G. & Sun, J. R. Magnetic entropy change involving martensitic transition in NiMn-based Heusler alloys. Chin. Phys. B 22, 037505 (2013).

Hu, F. X. et al. Influence of negative lattice expansion and metamagnetic transition on magnetic entropy change in the compound LaFe11.4Si1.6 . Appl. Phys. Lett. 78, 3675 (2001).

Hu, F. X., Shen, B. G., Sun, J. R. & Wu, G. H. Large magnetic entropy change in a Heusler alloy Ni52.6 Mn23.1 Ga24.3 single crystal. Phys. Rev. B 64, 132412 (2000).

Liu, J. et al. Giant magnetocaloric effect driven by structural transitions. Nat. Mater 11, 620 (2012).

Tegus, O., Brück, E., Buschow, K. H. J. & de Boer, F. R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 415, 150 (2002).

Wada, H. & Tanabe, Y. Giant magnetocaloric effect of MnAs1−xSbx . Appl. Phys. Lett. 79, 3302 (2001).

Yue, M., Zhang, H. G., Liu, D. M. & Zhang, J. X. MnFe(PGe) compounds: Preparation, structural evolution and magnetocaloric effects Chin. Phys. B 24, 017505 (2015).

Hu, F. X. et al. Very large magnetic entropy change near room temperature in LaFe11.2Co0.7Si1.1 . Appl. Phys. Lett. 80, 826 (2002).

Shen, B. G. et al. Recent progress in exploring magnetocaloric materials. Adv. Mate. 21, 4545 (2009).

Shen, B. G., Hu, F. X., Dong, Q. Y. & Sun, J. R. Magnetic properties and magnetocaloric effects in NaZn13-type La(Fe, Al)13-based compounds. Chin. Phys. B 22, 017502 (2013).

Fujita, A., Fujieda, S., Hasegawa, Y. & Fukamichi, K. Itinerant-electron metamagnetic transition and large magnetocaloric effects in La(FexSi1−x)13 compounds and their hydrides. Phys. Rev. B 67, 104416 (2003).

Zhang, H. & Shen, B. G. Magnetocaloric effects in RTX intermetallic compounds (R = Gd-Tm, T = Fe-Cu and Pd, X = Al and Si). Chin. Phys. B 24, 127504 (2015).

Franco, V., Blazquez, J. S., Ingale, B. & Conde, A. The Magnetocaloric Effect and Magnetic Refrigeration Near Room Temperature: Materials and Models. Ann. Rev. Mater. Res. 42, 305 (2012).

Li, L. W. et al. Two successive magnetic transitions induced large refrigerant capacity in HoPdIn compound. Appl. Phys. Lett. 103, 222405 (2013).

Li, L. W. et al. Giant low field magnetocaloric effect and field-induced metamagnetic transition in TmZn. Appl. Phys. Lett. 107, 132401 (2015).

Li, L. W. et al. Giant reversible magnetocaloric effect in ErMn2Si2 compound with a second order magnetic phase transition Appl. Phys. Lett. 100, 152403 (2012).

Li, L. W. Review of magnetic properties and magnetocaloric effect in the intermetallic compounds of rare earth with low boiling point metals. Chin. Phys. B 25, 037502 (2016).

Zhang, Y. K. et al. Magnetic properties and magnetocaloric effect in TmZnAl and TmAgAl compounds. J. Alloys Compd. 656, 635 (2016).

Morikawa, T. & Wada, H. Effect of deviation from stoichiometry on magnetic and magnetocaloric properties in MnAs1−x Sbx . J. Magn. Magn. Mater. 272–276, E583 (2004).

Cam Thanh, D. T. et al. Structure, magnetism and magnetocaloric properties of MnFeP1−xSix compounds. J. Appl. Phys. 103, 07B318 (2008).

Kuz’min, M. D. Factors limiting the operation frequency of magnetic refrigerators. Appl. Phys. Lett. 90, 251916 (2007).

Lyubina, J. et al. Novel design of La(Fe, Si)13 alloys towards high magnetic refrigeration performance. Adv. Mater. 22, 3735 (2010).

Moore, J. D. et al. Reducing the operational magnetic field in the prototype magnetocaloric system Gd5Ge4 by approaching the single cluster size limit. Appl. Phys. Lett. 88, 072501 (2006).

Morrison, K. et al. Capturing first- and second-order behavior in magnetocaloric CoMnSi0.92Ge0.08 . Phys. Rev. B 79, 134408 (2009).

Moore, J. D. et al. Reducing extrinsic hysteresis in first-order La(Fe, Co, Si)13 magnetocaloric systems. Appl. Phys. Lett 95, 252504 (2009).

Gutfleisch, O., Yan, A. & Müller, K. H. Large magnetocaloric effect in melt-spun LaFe13−xSix . J. Appl. Phys. 97, 10M035 (2005).

Lyubina, J., Gutfleisch, O., Kuzin, M. D. & Richter, M. La (Fe, Si)13-based magnetic refrigerants obtained by novel processing routes. J. Magn. Magn. Mater 321, 3571 (2009).

Yan, A., Müller, K. H., Schultz, L. & Gutfleisch, O. Magnetic entropy change in melt-spun MnFePGe (invited). J. Appl. Phys. 99, 08K903 (2006).

Provenzano, V., Shapiro, A. J. & Shull, R. D. Reduction of hysteresis losses in the magnetic refrigerant Gd5Ge2Si2 by the addition of iron. Nature 429, 853 (2004).

Tan, X. Y., Chai, P., Thompson, C. M. & Shatruk, M. Magnetocaloric Effect in AlFe2B2: Toward Magnetic Refrigerants from Earth-Abundant Elements. J. Am. Chem. Soc. 135, 9553 (2013).

Uhl, E. & Boller, H. The magnetic properties and anisotropy of the linear chain compound TlFe3Te3 . J. Phys. Chem. Solids. 45, 33 (1984).

Pelizzone, M. et al. First-order phase transition to strongly anisotropic ferromagnetism in Tl2Fe6Te6 . J. Magn. Magn. Mater. 42, 167 (1984).

Lyubina, J., Hannemann, U., Cohen, L. F. & Ryan, M. P. Novel La(Fe, Si)13/Cu Composites for Magnetic Cooling. Adv. Energy Mater. 2, 1323 (2012).

Banerjee, S. K. On a generalised approach to first and second order magnetic transition. Phys. Lett. 12, 16 (1964).

Defay, E. et al. The Electrocaloric Efficiency of Ceramic and Polymer Films. Adv. Mater. 25, 3337 (2013).

Moya, X., Defay E., Heine V. & Mathur N. D. Too cool to work. Nature Phys. 11, 202 (2015).

Zou, J. D., Shen, B. G. & Sun, J. R. Magnetic properties and magnetocaloric effect in TbCo2−xFex compounds. Chin. Phys. 16, 3843 (2007).

Tencé, S. & Chevalier, B. Magnetic and magnetocaloric properties of Gd2In0.8X0.2 compounds (X = Al, Ga, Sn, Pb). J. Magn. Magn. Mater. 399, 46 (2016).

Morellon, L. et al. Magnetocaloric effect in Tb5(SixGe1−x)4 . Appl. Phys. Lett. 79, 1318 (2001).

Liu, X. B., Altounian, Z. & Beath, A. D. Structure and magnetocaloric effect in the pseudobinary system LaFe11Si2 LaFe11Al2 . J. Appl. Phys. 95, 6924 (2004).

Krenke, T. et al. Magnetic superelasticity and inverse magnetocaloric effect in Ni-Mn-In. Phys. Rev. B 75, 104414 (2007).

Krenke, T. et al. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys. Nat. Mat. 4, 450 (2005).

Acknowledgements

This work was supported by the National Basic Research Program of China (Grant Nos 2016FYA0300402, 2015CB921004 and 2012CB821404), the National Natural Science Foundation of China (Grant Nos 11374261 and 11204059), Zhejiang Provincial Natural Science Foundation of China (Grant No. LQ12A04007) and the Fundamental Research Funds for the Central University of China.

Author information

Authors and Affiliations

Contributions

M.F. and Q.M. designed the study, analyzed the data and wrote the paper. Q.M. synthesized the samples and did the transport measurements with J.Y., H.W. and R.K.; J.D. collected, processed and refined the X-ray data; Y.Z., B.X. and Q.C. did the magnetization measurements. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Mao, Q., Yang, J., Wang, H. et al. Large low field magnetocaloric effect in first-order phase transition compound TlFe3Te3 with low-level hysteresis. Sci Rep 6, 34235 (2016). https://doi.org/10.1038/srep34235

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep34235

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.