Abstract

Magnetoelectric effect, arising from the interfacial coupling between magnetic and electrical order parameters, has recently emerged as a robust means to electrically manipulate the magnetic properties in multiferroic heterostructures. Challenge remains as finding an energy efficient way to modify the distinct magnetic states in a reliable, reversible and non-volatile manner. Here we report ferroelectric switching of ferromagnetic resonance in multiferroic bilayers consisting of ultrathin ferromagnetic NiFe and ferroelectric Pb0.92La0.08Zr0.52Ti0.48O3 (PLZT) films, where the magnetic anisotropy of NiFe can be electrically modified by low voltages. Ferromagnetic resonance measurements confirm that the interfacial charge-mediated magnetoelectric effect is dominant in NiFe/PLZT heterostructures. Non-volatile modification of ferromagnetic resonance field is demonstrated by applying voltage pulses. The ferroelectric switching of magnetic anisotropy exhibits extensive applications in energy-efficient electronic devices such as magnetoelectric random access memories, magnetic field sensors and tunable radio frequency (RF)/microwave devices.

Similar content being viewed by others

Introduction

Recent development of spintronic memory, logic and signal processing devices requires direct manipulation of magnetism by electric field, which is more power efficient and scalable than by magnetic field. Voltage-induced magnetism change arising from coupling between the magnetic and electrical order parameters (i.e., magnetoelectric (ME) coupling) in magnetic/dielectric composites has recently emerged as a robust means of controlling magnetic properties in the adjacent magnetic layer1,2,3,4,5,6,7,8,9. In particular, the magnetoelectric coupling has been demonstrated to modify the magnetic properties as varied as magnetic ordering10, magnetic anisotropy11,12,13,14,15,16,17,18,19,20,21, spin polarization22, Curie temperature23 and ferromagnetic resonance24,25. Several mechanisms including strain-, charge- and exchange bias-mediated effects have been identified in different magnetoelectric heterostructures26,27,28,29,30,31,32.

Strong ME coupling has been achieved in magnetostrictive/piezoelectric composites using high-quality piezoelectric single crystals such as BaTiO333,34, lead magnesium niobate-lead titanate (PMN-PT)35,36, lead zinc niobate-lead titanate (PZN-PT)19 and lead indium niobate-lead magnesium niobate-lead titanate (PIN-PMN-PT)37, where the voltage applied to the piezoelectric substrates exerts a mechanical deformation on the magnetostrictive materials and thus produces a strain-mediated ME effect35,36,37,38,39. Generally, the piezo-crystal used in these heterostructures has a thickness of ~0.5 mm, which requires a high operating voltage of ~400 V to generate a strong mechanical coupling. Although piezoelectric thin films can be grown by carefully optimizing the deposition process, the weak piezoelectric strength due to substrate clamping effect has hindered the facile fabrication of reliable and compact devices. Attention has therefore been turned to magnetic/high-k dielectric bilayers such as Fe/MgO11,40, CoFe/MgO41,42, Co/GdOx20 and NiFe/SrTiO343, etc., in which the magnetic anisotropy depends sensitively on voltage-driven charge accumulation or ionic migration at the interface. In general, the ME coupling based on high-k dielectric is inherently volatile, despite its outstanding performance and compatibility with Si substrates. Of particular recent scientific and technological interests are ferromagnetic/ferroelectric multiferroic bilayers, such as LSMO/PZT28, Co/P(VDF-TrFE)12 and CoFe/BST44, where the functionality is similar to recently proposed magnetic/high-k dielectric stacks but the associated volatile challenges have been addressed by replacing the dielectric layer with a well-established charge-screening ferroelectric thin film. In these multiferroic bilayers, the remanent polarization in ferroelectric layer offers a convenient source of switchable charges and satisfies the need for low power-consumption, non-volatile behaviour in electrically controlled magnetic devices. Nevertheless, the charge-mediated ME effect in multiferroic bilayers has suffered from small coupling coefficient caused by low remanent polarization and the understanding of ferroelectric switching of ferromagnetic resonance has been limited9.

In this work, we report the ferroelectric switching of ferromagnetic resonance (FMR) in multiferroic bilayers consisting of ultrathin ferromagnetic Ni80Fe20 (NiFe) and ferroelectric Pb0.92La0.08Zr0.52Ti0.48O3 (PLZT) films, where a large magnetic anisotropy change of 1.7 μJ/m2 is demonstrated under the application of ±10 V voltage pulses at room temperature. Moreover, angular-dependent ferromagnetic resonance measurement is utilized to investigate the interfacial charge-mediated ME effect, providing a mechanism to distinguish the origin of complex and subtle ME coupling in multiferroic bilayers.

Results

PLZT is selected as the ferroelectric material because of its relatively low coercive field and high remanent polarization, which would reduce the power consumption and enhance the ME coupling. Structural, electrical and morphological properties of PLZT are summarized in Fig. 1(a–c). X-ray diffraction pattern of the 350 nm thick PLZT films is indexed by a pseudocubic structure and compared with that of the PtSi substrates, as shown in Fig. 1(a). Well-crystallized perovskite structure is confirmed in the PLZT samples without any traceable secondary phase. The high intensity of (111) peak indicates a preferred (111) orientation in PLZT thin films, consistent with previous report45. The dielectric constant and loss of PLZT are shown in Fig. 1(b) as a function of applied voltage, which display typical butterfly shaped hysteresis. At zero voltage bias, a high dielectric constant of 1500 and a low dielectric loss of 0.04 are observed for PLZT films on PtSi substrates. Under an applied voltage of 10 V, the dielectric constant and loss decreases to 760 and 0.02, respectively. Figure 1(c) shows the polarization-voltage (P-V) hysteresis loop at a maximum applied voltage of 10 V and a frequency of 100 Hz. The saturation polarization (Ps) and remanent polarization (Pr) are measured as 35 and 7 μC/cm2, respectively. The inset of Fig. 1(c) presents the surface morphology of PLZT examined by atomic force microscopy (AFM). A well-defined smooth surface is observed with grain size in the range of 20–100 nm. The root-mean-square roughness (Rms) of the PLZT surface obtained by AFM is ~0.9 nm, which is further reduced by plasma etching before NiFe deposition. These results demonstrate superior electrical performance of PLZT thin film, making it a suitable ferroelectric layer for improving the ME coupling in multiferroic heterostructures.

Structural, electrical and ferromagnetic properties of NiFe/PLZT heterostructures.

(a) X-ray diffraction patterns of PLZT thin films grown on PtSi Substrates showing a preferred (111) orientation. (b) Voltage-dependent dielectric constant and dielectric loss of PLZT. (c) Polarization-voltage hysteresis loop and surface morphology of PLZT. (d) Ferromagnetic resonance spectra of NiFe/PLZT bilayers with various NiFe thicknesses tN.

Magnetically soft alloy of Ni80Fe20 (NiFe) is selected as the ferromagnetic material because of its narrow resonance linewidth that enables precise detection of small voltage-induced resonance modification38. NiFe dots with a diameter of 500 μm and nominal thicknesses tN = 1.2, 1.5, 2.0, 2.8 and 3.2 nm were prepared on the PLZT films through a shadow mask by magnetron sputtering. Figure 1(d) shows the FMR spectra of the NiFe/PLZT bilayer with various tN, measured with the applied magnetic field in the film plane. The decrease in tN leads to an increase in resonance field μ0HFMR, due to the change in magnetic anisotropy. When tN is reduced to below 1.2 nm, the resonance signal deteriorates with a very broad linewidth (Wpp > 50 mT), due to the increased damping induced by interfacial defects and surface roughness. Therefore, we could not detect any systematic resonance field change in NiFe with tN < 1.2 nm. For samples with tN ≥ 1.2 nm, the FMR spectra are sharp with fairly narrow peak-to-peak linewidth (Wpp < 10 mT) that permits resolving small linewidth changes of ~0.1 mT.

Modification of FMR spectra by constant dc voltages of opposite polarity is shown in Fig. 2. The shift of resonance field (μ0ΔHFMR) at applied voltages of ±10 V is small for NiFe/PLZT with tN = 3.2 nm (Fig. 2(a)). When tN = 1.2 nm, μ0HFMR increases from 241.7 mT at −10 V to 248.8 mT at +10 V, with a pronounced modification of resonance field μ0ΔHFMR = 7.1 mT (Fig. 2(b)). The voltage-induced resonance field change decreases as the NiFe thickness tN increases from 1.2 to 3.2 nm, which reveals that the interfacial effect plays an important role, which is consistent with recent phenomenological theory and experimental study on multiferroic bilayer structures43,44,46,47,48. Figure 2(d) shows the resonance field as a function of applied voltage for NiFe/PLZT with tN = 1.2 nm. The sample displays hysteresis behaviour that follows the polarization-voltage curve of PLZT showing in Fig. 1(c).

Modification of FMR spectra by constant voltages.

(a,b) Voltage-induced shift of FMR spectra for NiFe/PLZT with (a) tN = 3.2 nm and (b) tN = 1.2 nm. (c) Dependence of the ME coupling coefficient on NiFe thickness tN, the inset is the magnetic surface anisotropy KS as a function of applied voltage. (d) Resonance field as a function of applied voltage for NiFe/PLZT with tN = 1.2 nm.

Discussion

As to the origin of the voltage-induced shift of resonance field, one possibility is that a strain effect causes the magnetic anisotropy change by the application of piezo-strain to the magnetic layer. The strain is generated by piezoelectric effect in the ferroelectric layer and transferred to magnetic layer through mechanical interaction, which results in magnetic property change due to magnetostrictive effect, as has been shown for FeGaB/PZNPT19, FeGaB/PIN-PMN-PT37 and NiFe/PMNPT38 heterostructures. The other possibility is that an interfacial charge effect causes the magnetic anisotropy change. More specifically, the influence of voltage on the resonance field arises from charge accumulation at the magnetic/ferroelectric interface, thereby inducing unequal screening for spin-up and spin-down electrons in the magnetic layer that changes the surface anisotropy for the few atomic layers near the interface11. The strength of the charge-mediated ME coupling is therefore proportional to the surface charge accumulation, or rather, the polarization of the ferroelectric layer44. Moreover, since the surface anisotropy of ultrathin magnetic film is dominant in the total magnetic anisotropy energy, the anisotropy change would be more significant in thinner magnetic films. In contract, the anisotropy change in strain-induced ME coupling is independent on magnetic film thickness.

In order to distinguish the origin of the ME coupling effect in NiFe/PLZT, angular dependence of in-plane FMR spectra was acquired at different voltages. If the strain effect dominates, the anisotropic piezo-strain distribution inherent in the (111)-oriented ferroelectric thin film would induce anisotropic ME coupling, implying that the resonance field modification would have different values along different in-plane directions38. In contract, if the charge effect dominates, due to the highly isotropic in-plane distribution of charge carriers, the resonance field shift measured in the film plane would be essentially equivalent44. Figure 3(a,b) show the angular dependence of μ0HFMR for NiFe/PLZT with tN = 3.2 and 1.2 nm, respectively. There is no clear shift in resonance field at any angle for the sample with tN = 3.2 nm, meaning that the anisotropy change is negligible. When tN reduces to 1.2 nm, an isotropic μ0ΔHFMR of 1.6 mT is observed under the application of voltage pulses (±10 V). This μ0ΔHFMR keeps constant along all in-plane angles, indicating that the strain effect should be negligible and the resonance field shift might be induced by a perpendicular (out-of-plane) magnetic anisotropy change due to the interfacial charge effect44. This is understandable since, on one hand, both the piezoelectric coefficient (−e31,f < 8 C/m2)49 of (111)-oriented PLZT film and the magnetostriction (λs < 1 ppm for tN = 1.2 nm)50 of ultrathin NiFe are very small, permitting a convenient assumption of zero strain-mediated ME coupling when interfaced together; on the other hand, the resonance field modification described in Figs 2 and 3(a,b) is thickness dependent and strongly related to the polarization charges trapped at the NiFe/PLZT interface, consistent with an interfacial charge-mediated ME coupling. In contract, the anisotropy change of strain-induced ME coupling would be independent on magnetic film thickness within this thickness range. For example, we do not observe any clear shift in resonance field for the sample with tN = 3.2 nm, meaning that the strain-mediated ME coupling is negligible. Note that the PLZT films are granular, so the anisotropy in the voltage-induced strain may be destroyed or reduced by the presence of differently oriented grains. Therefore, a strain effect may still be present within each grain but averaged out for the whole film. Based on the experimental evidence, we believe that the charge effect is the dominant mechanism for the ME coupling, while the strain effect is negligible in ultrathin NiFe/PLZT heterostructures.

Non-volatile ferroelectric switching of ferromagnetic resonance by voltage pulses.

(a,b) Angular dependence of resonance field at various voltage pulses for NiFe/PLZT with tN = 3.2 nm (a) and tN = 1.2 nm (b). (c) Voltage-pulse-induced shift of FMR spectra for NiFe/PLZT with tN = 1.2 nm. (d) Reversible, non-volatile resonance field shift induced by voltage pulses for NiFe/PLZT with tN = 1.2 nm.

The resonance field can be modified by applying voltage pulses (Fig. 3) instead of constant voltages (Fig. 2). The non-volatile modification of resonance field is further investigated for the sample with tN = 1.2 nm, as shown in Fig. 3(c,d). By applying voltage pulses of opposite polarity with amplitude of 10 V and duration of 100 ms, a non-volatile and reversible resonance field switching of 1.6 mT is obtained, arising from the two remanent polarization states within the PLZT thin films. The ferroelectric PLZT thin film acts as a capacitor and is charging under the application of voltages. After removing the external voltage an internal electric field induced by the remanent polarization remains and continues to modify the magnetic anisotropy of the NiFe layer12,44. Therefore, the resonance field remains modified until the next pulse is applied due to long retention time of the ferroelectric layer, implying non-volatile functioning of NiFe/PLZT ME devices that stems from the ferroelectric layer. Note that the resonance field changes are different for the case of static voltage drive (Fig. 2(d)) and the case of pulse voltage drive (Fig. 3(d)), which is due to the two ferroelectric polarization states, i.e., saturation polarization (Ps) and remanent polarization (Pr) of PLZT thin film. When static voltage 10 V is applied, the ferroelectric capacitor is charging to saturation state. When voltage pulse 10 V is applied, the ferroelectric capacitor is rapidly charging to saturation state and then reducing to remanent polarization state. Higher surface charge density is expected for static voltage since Ps (35 μC/cm2) is much larger than Pr (7 μC/cm2) in PLZT, which would induce a larger modification on the magnetic anisotropy of the NiFe layer due to charge-mediated ME coupling. In contract, voltage pulse would lead to lower ME coupling, but this process is non-volatile and consumes lower power, which are beneficial for device applications.

Having established that electrostatic screening is responsible for the observed ME effect and considering that the modifications of resonance field arises from the perpendicular magnetic anisotropy change, we can quantify the charge-induced surface anisotropy change ΔKs(V) using the energy equation11,

where Eperp is the perpendicular magnetic anisotropy energy, μ0 is the permeability of free space, μ0MS = 1.1 T is the saturation magnetization of 1.2 nm NiFe38, Ku is the bulk anisotropy, KS is the surface anisotropy and tN is the magnetic film thickness. Following the resonance condition and minimizing the total energy of magnetic films, the resonance field HFMR is then determined by the Kittel equation,

where f is the resonance frequency, γ/2π = 28 GHz/T is the gyromagnetic ratio, Hk = 2Ku/μ0MS is the bulk anisotropy field and Meff is the effective saturation magnetization incorporating out-of-plane magnetic anisotropy,

At a fixed frequency f = 9.76 GHz, the change in resonance field ΔHFMR induced by the charge effect is solved as,

Clearly the change in resonance field is isotropic and dependent on the magnetic surface anisotropy change, consistent with the results shown in Fig. 3. The magnetic surface anisotropy KS and the ME coupling coefficient is calculated and shown in Fig. 2(c). Under the application of ±10 V constant voltages, the change in perpendicular surface anisotropy is estimated to be 7.5 μJ/m2 for NiFe/PLZT films with tN = 1.2 nm. This would correspond to a giant electric field effect on magnetic anisotropy of 263 f J/Vm, higher than the experimental results of 30–50 f J/Vm and theoretical prediction of 100 f J/Vm (10−8 erg/V cm) for Fe/MgO and FeCoB/MgO system40,51,52. However, for PLZT with a large dielectric constant of 1500, an even larger ME coupling coefficient is expected in NiFe/PLZT based on interfacial charge effect. Recently it has been reported that NiO clusters may form at the NiFe/PMN-PT interface due to oxygen diffusion, which was confirmed by EELS and EDS measurements53. Similarly, NiO could form at the NiFe/PLZT interface with a significantly lower dielectric constant, which might be the reason for the low experimental value. No significant NiFe thickness dependence of ME coupling coefficient is observed over the measured thickness range, which is consistent with previous reports51,52, indicating that the electric field control of magnetic anisotropy originates primarily from the NiFe/PLZT interface. Most remarkably, ΔKS = 1.7 μJ/m2 is achieved under the application of ±10 V voltage pulses at room temperature, comparable to the previously reported value in the Fe/MgO heterostructures11. In the first demonstration in Fe/MgO, the charge effect was produced by applying relatively high voltages of ±200 V and persisted only as long as the voltage was applied11. Later the voltage was reduced to less than 1 V by removing the thick polyimide layer54. The non-volatile ferroelectric switching of magnetic anisotropy in NiFe/PLZT allows short voltage pulses instead of constant voltages, to manipulate magnetic parameters in multiferroic heterostructures, which would significantly enhance the power efficiency for integrated RF and spintronic devices.

Conclusions

In summary, our work shows that magnetic anisotropy of ultrathin magnetic films can be electrically modified in magnetic/ferroelectric bilayers at low voltage. Specifically for NiFe/PLZT bilayers, where perpendicular magnetic anisotropy is sensitive to interfacial charge accumulation and depletion, we use voltage control of interfacial charge screening to achieve control over magnetic anisotropy. In fact, this piezoelectric-free structure provides better reliability and longer lifetime for device applications since piezoelectric deformation potentially leads to fatigue and fracture over time. Moreover, we show that by simply applying voltage pulses, a robust, non-volatile and reversible modification of magnetic anisotropy is demonstrated due to the remanent polarization in the ferroelectric layer. Therefore, considerable further improvement in non-volatile performance and functionality can probably be anticipated by examining ferroelectrics with higher remanent polarization such as PZT, BiFeO3, or doped HfO2. Our results thus provide a pathway towards ferroelectric switching of magnetism that could be useful for compact, reconfigurable and energy-efficient tunable RF and spintronic devices.

Methods

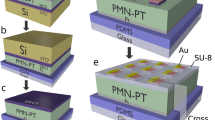

Sample preparation

Ferroelectric PLZT thin films were prepared by chemical solution deposition on platinized silicon Pt/Ti/SiO2/Si(001) wafers. After spin-coating, the PLZT films were pyrolyzed at 450 °C for 10 min and crystallized at 650 °C for 15 min. The film thickness was estimated to be 350 nm. To check the electrical properties, Pt top electrodes with a diameter of 250 μm and a thickness of 100 nm were deposited on PLZT films by electron-beam evaporation. For magnetic layer deposition, the PLZT thin films were loaded into a magnetron sputtering chamber with a background pressure of ~1 × 10−7 Torr. Plasma etching was carried out to clean the surface and reduce the roughness. NiFe dots, with a diameter of 500 μm and nominal thicknesses tN = 1.2, 1.5, 2.0, 2.8 and 3.2 nm, were DC sputtered onto the PLZT films through a shadow mask at room temperature under 3 mTorr Ar. 5 nm Cu was then deposited on top at the same condition as the capping layer. The uncertainty in the film thickness was estimated to be <10% from x-ray reflectivity.

Structural, electrical and ferromagnetic characterization

Phase identification was performed on a Bruker D8 AXS x-ray diffractometer with Cu Kα radiation. Microstructure and surface morphology of PLZT were examined by Atomic Force Microscope (AFM). Dielectric measurements were conducted with an Agilent E4980A LCR meter using an oscillator level of 0.1 V in conjunction with a Signatone QuieTemp probe station. Polarization vs applied voltage (P-V) loops of PLZT thin films were measured at a maximum applied voltage of 10 V and frequency of 100 Hz on a Radiant Technologies’ Precision Premier II tester. Ferromagnetic resonance (FMR) spectra were measured using a Bruker EMX electron paramagnetic resonance (EPR) spectrometer with a TE102 cavity, operated at a microwave field frequency of 9.76 GHz and power of 10 mW. The voltage-dependent FMR spectra were obtained by applying voltages across the film thickness direction during FMR field sweeping. The 100 ms voltage pulses used in the experiments were controlled by an electric relay. For angular-dependent FMR spectra measurements, the NiFe/PLZT bilayers were attached to a sample holder with a precise angle rotator. All measurements were conducted at room temperature.

Additional Information

How to cite this article: Hu, Z. et al. Non-Volatile Ferroelectric Switching of Ferromagnetic Resonance in NiFe/PLZT Multiferroic Thin Film Heterostructures. Sci. Rep. 6, 32408; doi: 10.1038/srep32408 (2016).

References

Eerenstein, W., Mathur, N. D. & Scott, J. F. Multiferroic and magnetoelectric materials. Nature 442, 759–765 (2006).

Nan, C.-W., Bichurin, M. I., Dong, S., Viehland, D. & Srinivasan, G. Multiferroic magnetoelectric composites: historical perspective status and future directions. J. Appl. Phys. 103, 031101 (2008).

Zhai, J., Xing, Z., Dong, S., Li, J. & Viehland, D. Magnetoelectric laminate composites: an overview. J. Am. Ceram. Soc. 91, 351–358 (2008).

Vaz, C. A. F., Hoffman, J., Ahn, C. H. & Ramesh, R. Magnetoelectric coupling effects in multiferroic complex oxide composite structures. Adv. Mater. 22, 2900–2918 (2010).

Sun, N. X. & Srinivasan, G. Voltage Control of magnetism in multiferroic heterostructures and devices. Spin 02, 1240004 (2012).

Oleg, O. B., Pedro, R.-D., Tamene, R. D. & Valeri, S. S. Controlling magnetism on metal surfaces with non-magnetic means: electric fields and surface charging. J. Phys.: Conden. Matt. 26, 093001 (2014).

Matsukura, F., Tokura, Y. & Ohno, H. Control of magnetism by electric fields. Nat. Nano. 10, 209–220 (2015).

Hu, J.-M., Chen, L.-Q. & Nan, C.-W. Multiferroic heterostructures integrating ferroelectric and magnetic materials. Adv. Mater. 28, 15–39 (2016).

Yang, X. et al. Recent advances in multiferroic oxide heterostructures and devices. J. Mater. Chem. C 4, 234–243 (2016).

Cherifi, R. O. et al. Electric-field control of magnetic order above room temperature. Nat. Mater. 13, 345–351 (2014).

Maruyama, T. et al. Large voltage-induced magnetic anisotropy change in a few atomic layers of iron. Nat. Nano. 4, 158–161 (2009).

Mardana, A., Ducharme, S. & Adenwalla, S. Ferroelectric control of magnetic anisotropy. Nano Lett. 11, 3862–3867 (2011).

Hu, J.-M., Li, Z., Chen, L.-Q. & Nan, C.-W. High-density magnetoresistive random access memory operating at ultralow voltage at room temperature. Nat. Commun. 2, 553 (2011).

Zhu, J. et al. Voltage-induced ferromagnetic resonance in magnetic tunnel junctions. Phys. Rev. Lett. 108, 197203 (2012).

Hu, J. M., Li, Z., Chen, L. Q. & Nan, C. W. Design of a voltage-controlled magnetic random access memory based on anisotropic magnetoresistance in a single magnetic layer. Adv. Mater. 24, 2869–2873 (2012).

Pantel, D., Goetze, S., Hesse, D. & Alexe, M. Reversible electrical switching of spin polarization in multiferroic tunnel junctions. Nat. Mater. 11, 289–293 (2012).

Chanthbouala, A. et al. Solid-state memories based on ferroelectric tunnel junctions. Nat. Nano. 7, 101–104 (2012).

Chanthbouala, A. et al. A ferroelectric memristor. Nat. Mater. 11, 860–864 (2012).

Liu, M. et al. Voltage tuning of ferromagnetic resonance with bistable magnetization switching in energy-efficient magnetoelectric composites. Adv. Mater. 25, 1435–1439 (2013).

Bauer, U. et al. Magneto-ionic control of interfacial magnetism. Nat. Mater. 14, 174–181 (2015).

Bauer, U., Przybylski, M., Kirschner, J. & Beach, G. S. Magnetoelectric charge trap memory. Nano. Lett. 12, 1437–1442 (2012).

Garcia, V. et al. Ferroelectric control of spin polarization. Science 327, 1106–1110 (2010).

Chiba, D. et al. Electrical control of the ferromagnetic phase transition in cobalt at room temperature. Nat. Mater. 10, 853–856 (2011).

Jia, C., Wang, F., Jiang, C., Berakdar, J. & Xue, D. Electric tuning of magnetization dynamics and electric field-induced negative magnetic permeability in nanoscale composite multiferroics. Sci. Rep. 5, 11111 (2015).

Nan, T. et al. Control of magnetic relaxation by electric-field-induced ferroelectric phase transition and inhomogeneous domain switching. Appl. Phys. Lett. 108, 012406, (2016).

Weisheit, M. et al. Electric field-induced modification of magnetism in thin-film ferromagnets. Science 315, 349–351 (2007).

Chu, Y.-H. et al. Electric-field control of local ferromagnetism using a magnetoelectric multiferroic. Nat. Mater. 7, 478–482 (2008).

Molegraaf, H. J. A. et al. Magnetoelectric effects in complex oxides with competing ground states. Adv. Mater. 21, 3470–3474 (2009).

Wu, S. M. et al. Reversible electric control of exchange bias in a multiferroic field-effect device. Nat. Mater. 9, 756–761 (2010).

Baek, S. et al. Ferroelastic switching for nanoscale non-volatile magnetoelectric devices. Nat. Mater. 9, 309–314 (2010).

Lei, N. et al. Strain-controlled magnetic domain wall propagation in hybrid piezoelectric/ferromagnetic structures. Nat. Commun. 4, 1378 (2013).

Hu, J.-M., Nan, T., Sun, N. X. & Chen, L.-Q. Multiferroic magnetoelectric nanostructures for novel device applications. MRS Bulletin 40, 728–735 (2015).

Eerenstein, W., Wiora, M., Prieto, J. L., Scott, J. F. & Mathur, N. D. Giant sharp and persistent converse magnetoelectric effects in multiferroic epitaxial heterostructures. Nat. Mater. 6, 348–351 (2007).

Duan, C.-G. et al. Surface magnetoelectric effect in ferromagnetic metal films. Phys. Rev. Lett. 101, 137201 (2008).

Liu, M. et al. Giant electric field tuning of magnetic properties in multiferroic ferrite/ferroelectric heterostructures. Adv. Funct. Mater. 19, 1826–1831 (2009).

Buzzi, M. et al. Single domain spin manipulation by electric fields in strain coupled artificial multiferroic nanostructures. Phys. Rev. Lett. 111, 027204 (2013).

Hu, Z. et al. Voltage control of magnetism in FeGaB/PIN-PMN-PT multiferroic heterostructures for high-power and high-temperature applications. Appl. Phys. Lett. 106, 022901 (2015).

Nan, T. et al. Quantification of strain and charge co-mediated magnetoelectric coupling on ultra-thin Permalloy/PMN-PT interface. Sci. Rep. 4, 3688 (2014).

Lee, Y. et al. Large resistivity modulation in mixed-phase metallic systems. Nat. Commun. 6, 5959 (2015).

Niranjan, M. K., Duan, C.-G., Jaswal, S. S. & Tsymbal, E. Y. Electric field effect on magnetization at the Fe/MgO(001) interface. Appl. Phys. Lett. 96, 222504 (2010).

Ikeda, S. et al. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 9, 721–724 (2010).

Wang, W.-G., Li, M., Hageman, S. & Chien, C. L. Electric-field-assisted switching in magnetic tunnel junctions. Nat. Mater. 11, 64–68 (2012).

Zhou, Z. et al. Quantifying thickness-dependent charge mediated magnetoelectric coupling in magnetic/dielectric thin film heterostructures. Appl. Phys. Lett. 103, 232906 (2013).

Zhou, Z. et al. Interfacial charge-mediated non-volatile magnetoelectric coupling in Co0.3Fe0.7/Ba0.6Sr0.4TiO3/Nb:SrTiO3 multiferroic heterostructures. Sci. Rep. 5, 7740 (2015).

Ma, B. et al. Temperature-dependent dielectric nonlinearity of relaxor ferroelectric Pb0.92La0.08Zr0.52Ti0.48O3 thin films. Appl. Phys. Lett. 102, 202901 (2013).

Hu, J.-M., Nan, C.-W. & Chen, L.-Q. Size-dependent electric voltage controlled magnetic anisotropy in multiferroic heterostructures: Interface-charge and strain comediated magnetoelectric coupling. Phys. Rev. B 83, 134408 (2011).

Shu, L. et al. Thickness-dependent voltage-modulated magnetism in multiferroic heterostructures. Appl. Phys. Lett. 100, 022405 (2012).

Spurgeon, S. R. et al. Thickness-dependent crossover from charge- to strain-mediated magnetoelectric coupling in ferromagnetic/piezoelectric oxide heterostructures. ACS Nano 8, 894–903 (2014).

Muralt, P. Recent progress in materials issues for piezoelectric MEMS. J. Am. Ceram. Soc. 91, 1385–1396 (2008).

Hung, C.-Y. et al. Magnetic properties of ultrathin NiFe and CoFe films. J. Appl. Phys. 87, 6618–6620 (2000).

Okada, A. et al. Electric-field effects on magnetic anisotropy and damping constant in Ta/CoFeB/MgO investigated by ferromagnetic resonance. Appl. Phys. Lett. 105, 052415 (2014).

Li, X. et al. Thermally stable voltage-controlled perpendicular magnetic anisotropy in Mo|CoFeB|MgO structures. Appl. Phys. Lett. 107, 142403 (2015).

Gao, Y. et al. Dynamic in situ observation of voltage-driven repeatable magnetization reversal at room temperature. Sci. Rep. 6, 23696 (2016).

Shiota, Y. et al. Induction of coherent magnetization switching in a few atomic layers of FeCo using voltage pulses. Nat. Mater. 11, 39–43 (2012).

Acknowledgements

This work was supported by the National Science Foundation Award 1160504, NSF Nanosystems Engineering Research Center for Translational Applications of Nanoscale Multiferroic Systems TANMS, the W.M. Keck Foundation and the Air Force Research Laboratory through Contract No. FA8650-14-C-5706. Work at Argonne was funded by the U.S. Department of Energy, Vehicle Technologies Program, under Contract No. DE-AC02-06CH11357. B.H. and G.B. gratefully acknowledge the financial support from the Air Force Office of Scientific Research (AFOSR).

Author information

Authors and Affiliations

Contributions

Z.H., M.L. and N.X.S. conceived and designed the experiments. Z.H. and X.W. wrote the manuscript with assistance from M.L. and N.X.S. and input from Z.Z. and T.N. B.M. prepared the PLZT thin films. Z.H. and X.W. deposited NiFe, performed measurements and analyzed the data with help from T.N., X.C., Y.G., H.L., Z.W., R.G., S.C., X.S., W.S. and H.S. D.B. assisted the FMR measurement. J.G.J., B.M.H. and G.J.B. discussed the results. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Hu, Z., Wang, X., Nan, T. et al. Non-Volatile Ferroelectric Switching of Ferromagnetic Resonance in NiFe/PLZT Multiferroic Thin Film Heterostructures. Sci Rep 6, 32408 (2016). https://doi.org/10.1038/srep32408

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep32408

This article is cited by

-

Higher ferromagnetic resonance frequency in NiFe/FeMn film obtained by flash annealing in reversing field

Journal of Materials Science: Materials in Electronics (2019)

-

Probing the dielectric, piezoelectric and magnetic behavior of CoFe2O4/BNT-BT0.08 composite thin film fabricated by sol-gel and spin-coating methods

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.