Abstract

Abundant and low-cost Ce has attracted considerable interest as a prospective alternative for those critically relied Nd/Pr/Dy/Tb in the 2:14:1-type permanent magnets. The (Nd, Ce)2Fe14B compound with inferior intrinsic magnetic properties to Nd2Fe14B, however, cannot provide an equivalent magnetic performance. Since Ce valence is sensitive to local steric environment, manipulating it towards the favorable trivalent state provides a way to enhance the magnetic properties. Here we report that such a desirable Ce valence can be induced by La-Ce co-doping into [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B (0 ≤ x ≤ 0.5) compounds via strip casting. As verified by X-ray photoelectron spectroscopy results, Ce valence shifts towards the magnetically favorable Ce3+ state in the composition range of x > 0.3, owing to the co-doping of large radius La3+ into 2:14:1 phase lattice. As a result, both crystallographic and magnetic anomalies are observed in the same vicinity of x = 0.3, above which lattice parameters a and c and saturation magnetization Ms increase simultaneously. Over the whole doping range, 2:14:1 tetragonal structure forms and keeps stable even at 1250 K. This finding may shed light on obtaining a favorable Ce valence via La-Ce co-doping, thus maintaining the intrinsic magnetic properties of 2:14:1-type permanent magnets.

Similar content being viewed by others

Introduction

Larger energy product (BH)max to reduce the size/weight of permanent magnets (PMs) has long been the goal of material scientists and engineers. An extraordinary progress occurred in 1980s with the discovery of Nd2Fe14B1, the strongest PM existing today, which has become an indispensable component of many mass-market consumer goods and industrial products. Under the new circumstance of global rare earth (RE) criticality, especially for those closely-relied REs Nd/Pr/Dy/Tb in the 2:14:1-type PMs, price-favorable and high-abundant La/Ce has triggered intense research as prospective alternatives2,3,4,5,6,7,8. The substitution of Nd with La and Ce in the tetragonal RE2Fe14B phase, however, is inevitably accompanied with magnetic dilution due to inferior intrinsic magnetic properties of (La, Ce)2Fe14B to Nd2Fe14B (room-temperature saturation magnetic polarization JS and anisotropy field HA for La2Fe14B/Ce2Fe14B/Nd2Fe14B are 1.38/1.17/1.60 T and 20/26/73 kOe, respectively)9,10,11. Consequently, preparation of 2:14:1 tetragonal compounds with high La/Ce substitution and sustained intrinsic magnetic performance simultaneously is still a big challenge.

Since the La2Fe14B tetragonal structure is unstable12,13,14, the most abundant and cheapest Ce has attracted considerable interest for decades15,16,17,18,19,20,21,22,23. Different from Pr3+, Nd3+ and La3+ with stable valence, Ce generally exhibits a mixed valence of 3.44 due to the coexistence of trivalent 4f1 and tetravalent 4f0 electronic states in Ce2Fe14B8. Stabilizing the Ce3+ configuration with one localized 4f moment is beneficial for higher intrinsic magnetic properties, thus suppressing the magnetic dilution of Ce-doping RE2Fe14B compounds. Previous investigations on melt-spun ribbons6,10,17,23, hot-pressed6,18, die-upset6,18 and sintered magnets19,20 have revealed gradually decreased lattice constants of the 2:14:1 phase with increasing Ce content, which can be explained by the smaller lattice parameters of Ce2Fe14B compound (a = 8.76 Å and c = 12.11 Å) than those of Nd2Fe14B (a = 8.80 Å and c = 12.20 Å)9. Since the ion radius follows the relation r (Ce3+) > r (Nd3+) > r (Ce4+), the monotonic decreasing a and c implies that Ce valence keeps basically unchanged within the whole doping range, otherwise the lattice parameters will deviate from the monotonic variation.

Notably, the Ce valence is highly dependent on its steric environment. The Ce valence decreases with expanding site volume, which suggests the potential of tuning Ce valence via alloying24,25. For instance, Ce2Fe14B exhibits lattice expansion after hydriding, meanwhile the Ce valence shifts towards the moment-carrying 4f1 (+3) state compared to the unhydrided parent24,25. Calculations based on the density-functional theory also predict that La can function like interstitial hydrogen in the (La, Ce)2Fe14B compound to induce a favorable Ce3+ state15. Thus, if La, with largest atomic radius among all REs, co-dope with Ce into the (Nd, Pr)2Fe14B lattice, may be able to produce a similar crystal lattice expansion and induce a preferable Ce3+ configuration accordingly. In this work, we found that stable 2:14:1 tetragonal phase is formed in [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B compounds even with x up to 0.5 by the commercialized strip casting technique for Nd-Fe-B sintered magnets26,27. XPS results verify a valence shift towards the favorable Ce3+ state merely in the composition range of x > 0.3. As a result, nonmonotonic dependences of lattice parameters a/c and saturation magnetization Ms on the La-Ce content x are observed simultaneously.

Results and Discussions

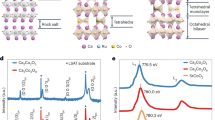

Figure 1 shows the Ce 3d spectra of [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B (x = 0.1∼0.5) strips, suggesting that Ce valence changes with increasing La-Ce content. A Tougaard procedure28 is used to remove the background (blue color in Fig. 1a). When x ≤ 0.3 (as indicated by the composition range I in Fig. 1b), no obvious change in the Ce 3d spectra can be detected. Further increasing La-Ce content from 0.3 to 0.4 and 0.5 (composition range II), the peak intensity declines for Ce3d5/2 fo lines (indicated by red arrows) and increases for the Ce3d3/2 f2 ones (indicated by blue arrows). The ratio r0 ( ) is calculated to evaluate the mixed valence of Ce, where

) is calculated to evaluate the mixed valence of Ce, where  represents the weight of the fx peak in the spectrum. As shown in Fig. 1b, where the

represents the weight of the fx peak in the spectrum. As shown in Fig. 1b, where the  intensity is normalized to 1,

intensity is normalized to 1,  diminishes gradually from 0.1343 to 0.0913 and 0.0564 with x gradually increased from 0.3 to 0.4 and 0.5. This relatively lowered Ce4+ ratio (r0) with enhanced Ce3+ ratio reveals the shift of Ce valence towards the favorable Ce3+ state with 4f moment, verifying that La-Ce co-doping provides a way to manipulate the Ce valence by changing the La-Ce concentration.

diminishes gradually from 0.1343 to 0.0913 and 0.0564 with x gradually increased from 0.3 to 0.4 and 0.5. This relatively lowered Ce4+ ratio (r0) with enhanced Ce3+ ratio reveals the shift of Ce valence towards the favorable Ce3+ state with 4f moment, verifying that La-Ce co-doping provides a way to manipulate the Ce valence by changing the La-Ce concentration.

As Ce3+ ion possesses a substantially larger radius (∼1.14 Å) than that of Ce4+ (∼0.97 Å), the appearance of Ce valence towards +3 state (carrying one 4f electron) is expected to be accompanied by an anomalous lattice expansion at the composition range of x > 0.3. Further step-scanned X-ray diffraction (XRD) patterns and the derived crystallographic parameters for [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B (x = 0∼0.5) powders verify such an anomaly, as displayed in Figs 2, 3, 4. Figure 2 shows that 2:14:1 tetragonal phase is formed for all samples with the characteristic diffraction peaks corresponding to those of RE2Fe14B (space group P42/mnm). To identify the structural changes and lattice parameters of 2:14:1 tetragonal phase in La-Ce co-doped specimen concretely, Rietveld refinements of experimental XRD profiles (black colors) have been performed. The optimized theoretical fits (red colors) and differences (blue colors) are also plotted. The difference pattern in each curve indicates a good matching between the calculated and experimental values. The refined structural parameters a, c and V (unit cell volume) and R factors are summarized in Table 1. Besides the matrix RE2Fe14B phase, small fractions of Fe and Nd phases (space group  and P63/mmc, respectively) are also identified. Meanwhile, for specimens with high La-Ce content (x ≥ 0.3), REFe2 phase (space group

and P63/mmc, respectively) are also identified. Meanwhile, for specimens with high La-Ce content (x ≥ 0.3), REFe2 phase (space group  ) also appears, as verified by the appearance of additional diffraction peak (220) at 2θ ≈ 34.6° (Fig. 3a). Thermomagnetic characterizations for the sample with x = 0.3 in Fig. 3b further confirm the existence of REFe2 phase, whose Curie temperature corresponds to the observed phase transition peak at ∼229.1 K. Rietveld analysis in Fig. 2 also provides the detailed content of REFe2 phase (0.15, 0.23 and 0.09 wt.% for samples with x = 0.3, 0.4 and 0.5, respectively). Despite the appearance of minor impurities, La-Ce concentration in the 2:14:1 phase is rather close to the nominal composition, as characterized by EDS results (Table S1).

) also appears, as verified by the appearance of additional diffraction peak (220) at 2θ ≈ 34.6° (Fig. 3a). Thermomagnetic characterizations for the sample with x = 0.3 in Fig. 3b further confirm the existence of REFe2 phase, whose Curie temperature corresponds to the observed phase transition peak at ∼229.1 K. Rietveld analysis in Fig. 2 also provides the detailed content of REFe2 phase (0.15, 0.23 and 0.09 wt.% for samples with x = 0.3, 0.4 and 0.5, respectively). Despite the appearance of minor impurities, La-Ce concentration in the 2:14:1 phase is rather close to the nominal composition, as characterized by EDS results (Table S1).

Rietveld refinement of step-scanned XRD patterns of [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B powders for (a) x = 0, (b) x = 0.1, (c) x = 0.3, (d) x = 0.4 and (e) x = 0.5 at room temperature. Experimental pattern, calculated pattern and their differences are given in black, red and blue colors, respectively. Bottom ticks mark the characteristic Bragg positions of RE2Fe14B, Nd, REFe2 and Fe phases and serve as a guide to the eye.

Figure 4a shows the enlarged XRD profiles with 2θ from 41 to 44.2°, illustrating the shift of those characteristic diffraction peaks of 2:14:1 phase with varied x. For example, (410) peak, as pointed out by dotted lines and arrows, firstly shifts to higher Bragg angle (0 ≤ x ≤ 0.3) and then turns to the lower side (0.3 < x ≤ 0.5), suggesting a non-linear dependence of lattice spacing on the La-Ce content x. The corresponding lattice parameters a, c, a/c and unit cell volume V for the tetragonal phase determined from the Rietveld refinements are plotted in Fig. 4b. a and c for (Pr, Nd)2Fe14B (x = 0) are 8.8096 Å and 12.2224 Å, respectively, in good agreement with the previously established results9. For the La-Ce co-doped samples, a, c and V do not linearly decrease or increase with higher La-Ce content. When x is below 0.3 (composition range I in Fig. 4b), lattice parameters decrease and can be approximately estimated by:

Further increasing La-Ce content to 0.4 and 0.5 (composition range II), a, c and V follow the opposite tendencies given by:

The linear reductions of a and c in composition range I (0 ≤ x ≤ 0.3) are commonly observed when Ce substitutes for Nd, following the empirical alloying theory. In composition range II (0.3 < x ≤ 0.5), however, the lattice parameters increase with growing La-Ce content, being consistent with the observed shift of Ce valence towards the +3 configuration in Fig. 1b. Besides, as demonstrated in Fig. S1, the electronic states of B/Fe/La/Nd remain unchanged with increasing La-Ce content, excluding their possible influences on the anomalous change of lattice parameters.

Figure 5a shows the initial magnetization curves of the [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B strips at 295 K. The magnetization saturates at 90 kOe for all the samples, the value at which is then regarded as the saturation magnetization Ms. In the composition range I (Fig. 5d), Ms decreases monotonically from 162.7 emu/g to 147.0 emu/g when x is increased from 0 to 0.3. On the contrary, in the composition range II, samples with x = 0.4 and 0.5 possess much larger Ms (156.5 and 151.1 emu/g, respectively). Though Ms of [(Pr, Nd)0.5(La, Ce)0.5]2.14Fe14B is smaller than that of [(Pr, Nd)0.6(La, Ce)0.4]2.14Fe14B due to the deteriorated interaction between the RE-Fe, it remains anomalously higher than the value for x = 0.3. Since the moment of REFe2 phase is smaller than that of the RE2Fe14B phase29, its appearance can only deteriorate the net magnetization. Figure 3b also indicates that REFe2 phase is paramagnetic at 295 K. Moreover, its fraction is quite small as revealed by the rietveld analysis in Fig. 2. Consequently, the abnormal increase in Ms for x = 0.4 and 0.5 cannot be attributed to the existence of secondary REFe2 phase. Meanwhile, characterizations on the Curie temperature TC (Fig. 5b,d) also reveal a decreasing trend with increased La-Ce concentration, further excluding the effects of TC on the abnormal magnetization enhancement at 295 K in the composition range II. Instead, it is resulted from the shift of Ce valence towards the +3 state (as indicated by the XPS spectra in Fig. 1) and the extra contribution of 4f electron. Further characterizations on the spin reorientation temperature TSR (Fig. 5c,d) also show that TSR diminishes with increased La-Ce content and deviates from the linear fit of decrease with x = 0.3, 0.4 and 0.5. It suggests that the Ce valence change with one localized 4f moment also has an appreciable effect on lowering the spin reorientation temperature and retaining a [001] easy-axis alignment of magnetization in the low temperature range.

(a) Initial magnetization curves measured at 295 K, (b) M-T and dM/dT-T curves in the temperature range of 380~670 K, (c) M-T and dM/dT-T curves in the low temperature range of 25∼200 K for [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B (x = 0∼0.5) samples. Inset in (a) is an enlarged view of the high-field regime. (d) The derived saturation magnetization Ms, Curie temperature TC and spin reorientation temperature TSR as a function of La-Ce content x.

The above results have demonstrated that well-controlled La-Ce addition contributes to manipulating Ce valence towards the favorable +3 state. Besides the Ce valence, stable 2:14:1-type tetragonal structure also plays an indispensable role in affording high Ms9. It should be noted that in terms of sole La substitution, unstable La2Fe14B phase tends to transform into α-Fe and La-B upon annealing at elevated temperatures in both as-cast and melt-spun La-Fe-B systems due to the large atomic radius of La12. Consequently, high substitution of La for Nd in the (Nd, La)2Fe14B compounds cannot be achieved as La prefers to enter into the grain boundary region7. However, in the present work of La-Ce co-doping, the c/a ratio keeps basically unchanged (Fig. 4b) despite of crystallographic anomalies in a, c and V. It suggests that increasing La-Ce substitution for Pr-Nd will not deteriorate the stability of tetragonal 2:14:1 structure even with x up to 0.5.

To further investigate the stability of 2:14:1 phase, a thermal DSC analysis is carried out (upon heating to 1550 K as shown in Fig. 6a). An obvious endothermic peak is observed at 1471.4 K for the (Pr, Nd)2.14Fe14B specimen, which corresponds to the melting point of the RE2Fe14B phase30. Increasing La-Ce substitution for Pr-Nd lowers the melting point to 1455.6 K for x = 0.1, 1438.9 K for x = 0.3 and 1419.6 K for x = 0.5, respectively. When x is increased to 0.3 and 0.5, other relatively weak endothermic transitions are observed at 1356.4 K and 1348.6 K, respectively, which match the previously reported melting point of REFe2 phase31. Based on the thermal analysis, the strip with x = 0.5 was quenched into ice-water after annealing at 1250 K for 1 h to evaluate the high-temperature stability of the 2:14:1 phase. The XRD profile (Fig. 6b) on the wheel side of specimen shows that after quenching, the 2:14:1 matrix phase is stable. Minor REFe2 impurity also exists in this high La/Ce-containing specimen. Consequently, we can conclude that the 2:14:1-type tetragonal structure is well retained by La and Ce co-doping into the (Pr, Nd)2.14Fe14B compounds.

Previous research has shown that sole La substitution for Nd is beneficial to enlarge the unit cell size of 2:14:1 phase and Ce incorporation alone decreases the lattice9. In this study, La and Ce co-doping into the (Pr, Nd)2.14Fe14B compounds during induction melting, however, results in non-linear variation of lattice parameters with increasing La-Ce content x. At low La-Ce doping levels (x below 0.3), the reduced lattice constants are dominated by Ce addition. Afterwards, when the La-Ce content is above 0.3, the influence of La on expanding the unit cell increases (Fig. 4) and induces a Ce valence shift towards the +3 state (Fig. 1). Upon tuning the preferable Ce3+ valence, one 4f electron plays a positive role in enhancing the total magnetization as Ce is ferromagnetically coupled with Fe. Hence the magnetization measured in this work exhibits abnormal increment when x exceeds 0.3 (Fig. 5).

The finding that Ce valence can be manipulated by La-Ce co-doping may lead to a number of advantages. Firstly, high La-Ce substitution for Nd and excellent magnetic performance are generally recognized as contradictions for RE-Fe-B PMs due to the inferior intrinsic magnetic properties of La2Fe14B and Ce2Fe14B to Nd2Fe14B9. Our work, however, provides direct evidence that the Ce valence engineering via La-Ce co-doping is an effective approach to maintain the intrinsic magnetic properties, thus suppressing the magnetic dilution in La/Ce-containing RE2Fe14B system. Secondly, La-Ce co-doping provides a substantial possibility for developing high-performance RE-Fe-B magnets at significantly reduced material cost. As of February 2016, the cost of La-Ce alloy is approximately one-twelfth of Pr-Nd alloy (up-to-date RE cost is available at the website32), thus the total material cost can be lowered by about 57% with 50 at.% La-Ce replacement for Pr-Nd, e.g. $ 22 per kg for (Pr, Nd)2Fe14B versus $ 9.5 per kg for [(Pr, Nd)0.5(La, Ce)0.5]2.14Fe14B. In our on-going work, bulk (Pr, Nd, La, Ce)-Fe-B sintered magnets are prepared with La-Ce content as high as 50%. As shown in Fig. S2, sintered magnet with 50 at.% La-Ce co-substitution for Pr-Nd exhibits a much higher remanence Br of 12.8 kGs, compared to those with single doping of La (12.2 kGs) or Ce (12.4 kGs) at the same concentration and processing routine. Thirdly, La-Ce co-substitution also provides a new recipe that the most abundant Ce and La can be utilized simultaneously in the hard magnets, contributing to the sustainable and balanced development of RE industry. Especially for La, which plays an indispensable role in inducing a favorable Ce valence shift and intrinsic magnetic properties accordingly. From the fundamental research view, it opens a new door to focus on the joint effect of multi rare earth substitution for those critical Nd/Pr/Dy/Tb.

In summary, it has been found that Ce valence shifts towards +3 configuration by co-doping La-Ce into (Pr, Nd)2Fe14B compounds when the doping level is above 0.3. This shifted valence with larger localized 4f moment is beneficial to strengthen the magnetization. Such an anomaly is ascribed to the expanded 2:14:1 phase lattice induced by the incorporation of La with larger atomic radius. Consequently, high La-Ce substitution for Pr-Nd allows the development of high-performance RE-Fe-B PMs at significantly reduced material cost and acts as a part of endeavor to the balanced utilization of RE sources.

Methods

Alloys with the nominal composition of [(Pr, Nd)1−x(La, Ce)x]2.14Fe14B (x = 0, 0.1, 0.2, 0.3, 0.4 and 0.5) were prepared by induction melting and subsequent strip-casting at a copper wheel velocity of 1∼4 m/s, which is commonly used for mass production of Nd-Fe-B sintered magnets. The raw materials include high-purity (above 99.5%) La-Ce alloy (35 wt.% La-65 wt.% Ce), Pr-Nd alloy (20 wt.% Pr-80 wt.% Nd), Fe-B (81.5 wt.% Fe-18.5 wt.% B) alloy and Fe metal. After grinding the strips, X-ray diffraction (XRD, SHIMADZU XRD-6000, Cu Kα radiation) patterns of the powders were recorded in 10° ≤ 2θ ≤ 100° angular range with a step of 0.01° and a counting time of 4s per step. Structural analysis was carried out with the Rietveld structural refinement program using Rietica software. Low temperature M-T curves (from 200 to 300 K, 200 Oe, 2 K/min) were measured using a superconducting quantum interference device (SQUID) to detect possible phase transitions. The chemical states of Ce/La/Nd/Fe/B were studied by means of X-ray photoelectron spectroscopy (XPS, Escalab 250Xi) after scraping the sample surface in high vacuum conditions. Room-temperature magnetization curves were measured by a Physical Property Measurement System (PPMS-9, Quantum Design) magnetometer up to 90 kOe. Curie temperature TC and spin reorientation temperature TSR of 2:14:1 phase were determined via the thermomagnetic curve in the temperature range of 380∼670 K and 25∼200 K, respectively, at 2 K/min with an external field of 200 Oe. Differential scanning calorimetric (DSC, NETZSCH TSA449) curves were measured upon heating to 1550 K at 20 K/min to determine the melting points of existing phases.

Additional Information

How to cite this article: Jin, J. et al. Manipulating Ce Valence in RE2Fe14B Tetragonal Compounds by La-Ce Co-doping: Resultant Crystallographic and Magnetic Anomaly. Sci. Rep. 6, 30194; doi: 10.1038/srep30194 (2016).

References

Sagawa, M., Fujimura, S., Togawa, N., Yamamoto, H. & Matsuura, Y. New material for permanent magnets on a base of Nd and Fe. J. Appl. Phys. 55, 2083–2087 (1984).

Eggert, R. G. Minerals go critical. Nature Chem. 3, 688–691 (2011).

Massari, S. & Ruberti, M. Rare earth elements as critical raw materials: Focus on international markets and future strategies. Resour. Pol. 38, 36–43 (2013).

Gutfleisch, O. et al. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter and More Energy Efficient. Adv. Mater. 23, 821–842 (2011).

Coey, J. M. D. Permanent magnets: Plugging the gap. Scripta Mater. 67, 524–529 (2012).

Pathak, A. K. et al. Cerium: An Unlikely Replacement of Dysprosium in High Performance Nd-Fe-B Permanent Magnets. Adv. Mater. 27, 2663–2675 (2015).

Liu, X. B., Altounian, Z., Huang, M., Zhang, Q. & Liu, J. P. The partitioning of La and Y in Nd-Fe-B magnets: A first-principles study. J. Alloys Compd. 549, 366–369 (2013).

Alam, A., Khan, M., McCallum, R. W. & Johnson, D. D. Site-preference and valency for rare-earth sites in (R-Ce)2Fe14B magnets. Appl. Phys. Lett. 102, 042402 (2013).

Herbst, J. F. R2Fe14B materials: Intrinsic properties and technological aspects. Rev. Mod. Phys. 63, 819–898 (1991).

Herbst, J. F., Meyer, M. S. & Pinkerton, F. E. Magnetic hardening of Ce2Fe14B. J. Appl. Phys. 111, 07A718 (2012).

Xing, M. et al. Anisotropic ternary Ce13Fe80B7 powders prepared by hydrogenation-disproportionation-desorption-recombination process and the diffusion of Ce-Cu eutectic alloys. J. Magn. Magn. Mater. 331, 140–143 (2013).

Hadjipanayis, G. C., Tao, Y. F. & Gudimetta, K. Formation of Fe14La2B phase in as-cast and melt-spun samples. Appl. Phys. Lett. 47, 757–758 (1985).

Tang, W., Zhou, S. & Wang, R. Preparation and microstructure of La-containing R-Fe-B permanent magnets. J. Appl. Phys. 65, 3142–3145 (1989).

Zhou, S. X., Wang, Y. G. & Høier, R. Investigations of magnetic properties and microstructure of 40Cedidymium-Fe-B based magnets. J. Appl. Phys. 75, 6268–6270 (1994).

Alam, A. & Johnson, D. D. Mixed valency and site-preference chemistry for cerium and its compounds: A predictive density-functional theory study. Phys. Rev. B 89, 235126 (2014).

Fuerst, C. D., Capehart, T. W., Pinkerton, F. E. & Herbst, J. F. Preparation and characterization of La2−xCexFe14B compounds. J. Magn. Magn. Mater. 139, 359–363 (1995).

Li, Z. B., Shen, B. G., Zhang, M., Hu, F. X. & Sun, J. R. Substitution of Ce for Nd in preparing R2Fe14B nanocrystalline magnets. J. Alloys Compd. 628, 325–328 (2013).

Chu, L. H., Liu, Y., Li, J., Ma, Y. L. & Li, C. Y. Structural and Magnetic Study of Hot-Pressed and Hot-Deformed Nd13.5−xCexFe80.4Ga0.5B5.6 (x = 0, 0.5, 0.1) Prepared by Spark Plasma Sintering. IEEE Trans. Magn. 48, 2092–2095 (2012).

Zhu, M. et al. Influence of Ce Content on the Rectangularity of Demagnetization Curves and Magnetic Properties of Re-Fe-B Magnets Sintered by Double Main Phase Alloy Method. IEEE Trans. Magn. 50, 1000104 (2014).

Niu, E. et al. Achievement of high coercivity in sintered R-Fe-B magnets based on misch-metal by dual alloy method. J. Appl. Phys. 115, 113912 (2014).

Yan, C., Guo, S., Chen, R., Lee, D. & Yan, A. Enhanced Magnetic Properties of Sintered Ce-Fe-B-Based Magnets by Optimizing the Microstructure of Strip-Casting Alloys. IEEE Trans. Magn. 50, 1–4 (2014).

Yan, C., Guo, S., Chen, R., Lee, D. & Yan, A. Effect of Ce on the magnetic properties and microstructure of sintered didymium-Fe-B magnets. IEEE Trans. Magn. 50, 1–5 (2014).

Pathak, A. K. et al. Magnetic properties of bulk and rapidly solidified nanostructured (Nd1−xCex)2Fe14−yCoyB ribbons. Acta Mater. 103, 211–216 (2016).

Reotier, P. Dalmas de. et al. Structural and magnetic properties of RE2Fe14BHx; RE=Y, Ce, Er. J. Less-Common Metals 129, 133–144 (1987).

Capehart, T. W., Mishra, R. K., Meisner, G. P., Fuerst, C. D. & Herbst, J. F. Steric variation of the cerium valence in Ce2Fe14B and related compounds. Appl. Phys. Lett. 63, 3642–3644 (1993).

Ko, K. Y., Yoon, S., Booth, J. G., Al-kanani, H. J. & Cho, S. K. Magnetic properties and microstructures of mischmetal-FeB-(Al, Ti and Al-Co) permanent magnets. J. Mater. Sci. 37, 1421–1427 (2002).

Bernardi, J., Fidler. J., Sagawa, M. & Hirose, Y. Microstructural analysis of strip cast Nd-Fe-B alloys for high (BH)max magnets. J. Appl. Phys. 83, 6396–6398 (1998).

Toliński, T., CheŁkowska, G., Falkowski, M. & Kowalczyk, A. X-ray photoemission and magnetometric studies of valence changes in Ce(Cu1−xNix)4Ga. J. Magn. Magn. Mater. 323, 1678–1681 (2011).

Paolasini, L. et al. Magnetic Ground State of Pure and Doped CeFe2 . Phys. Rev. Lett. 90, 057201 (2003).

Straumal, B. B. et al. Grain boundary wetting in the NdFeB-based hard magnetic alloys. J. Mater. Sci. 47, 8352–8359 (2012).

Morozkin, A. V., Seropegin, Yu. D., Gribanov, A. V. & Barakatova, J. M. Analysis of the melting temperatures of RT2 compounds (MgCu2 structure) (R=Rare Earth, T=Mn, Fe, Co, Ni, Ru, Rh, Pd, Os, Ir, Pt) and RT2X2 compounds (R=La, Ce, Sm, Er; T=Mn, Fe, Co, Ni, Cu, Ru, Rh, Pd, Pt; X=Si, Ge). J. Alloys Compd. 256, 175–191 (1997).

Shanghai Metals Market, Pricing of Rare Earth Metals. Available at: http://www.metal.com/pricing/rare-earch-metals (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos 51590881, 51571176 and 51401180).

Author information

Authors and Affiliations

Contributions

J.J., T.M. and M.Y. conceived and carried out the experiments. M.Y. supervised the project. J.J., Y.Z., G.B., C.W. and Z.Q. performed the data processing. J.J., T.M., B.S. and M.Y. wrote the manuscript and all authors discussed the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Jin, J., Zhang, Y., Bai, G. et al. Manipulating Ce Valence in RE2Fe14B Tetragonal Compounds by La-Ce Co-doping: Resultant Crystallographic and Magnetic Anomaly. Sci Rep 6, 30194 (2016). https://doi.org/10.1038/srep30194

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep30194

This article is cited by

-

Nanostructural Misch-Metal Magnets with Eutectic Nd-Al Alloy and Enhanced Magnetic Properties by Pre-annealing Process

Journal of Superconductivity and Novel Magnetism (2022)

-

Phase composition and magnetic properties of Pr–Nd–MM–Fe–B nanocrystalline magnets prepared by spark plasma sintering

Rare Metals (2020)

-

Maximizing the hard magnetic properties of melt-spun Ce–La–Fe–B alloys

Journal of Materials Science (2019)

-

Magnetic hardening of Nd-Ce-Fe-B films with high Ce concentration

Scientific Reports (2018)

-

Understanding the element segregation and phase separation in the Ce-substituted Nd-(Fe,Co)-B based alloys

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

(circles in red color) and (

(circles in red color) and ( ) (squares in blue color) are plotted as a variation of La-Ce content x.

) (squares in blue color) are plotted as a variation of La-Ce content x.