Abstract

Unexpected reactor accidents and radioisotope production and consumption have led to a continuous increase in the global-scale contamination of radionuclides. In particular, anthropogenic radioiodine has become critical due to its highly volatile mobilization and recycling in global environments, resulting in widespread, negative impact on nature. We report a novel biostimulant method to effectively scavenge radioiodine that exhibits remarkable selectivity for the highly difficult-to-capture radioiodine of >500-fold over other anions, even under circumneutral pH. We discovered a useful mechanism by which microbially reducible copper (i.e., Cu2+ to Cu+) acts as a strong binder for iodide-iodide anions to form a crystalline halide salt of CuI that is highly insoluble in wastewater. The biocatalytic crystallization of radioiodine is a promising way to remove radioiodine in a great capacity with robust growth momentum, further ensuring its long-term stability through nuclear I− fixation via microcrystal formation.

Similar content being viewed by others

Introduction

The growing amount of radionuclides and radioactive wastes from various nuclear and medical fields is causing public concern due to their short- and long-term radiotoxic impact on nature1,2,3,4. In particular, the anthropogenic radioiodine that has been released into nature for decades has become a key issue due to its global recycling5,6,7, which affects the worldwide ecosystem and human health8,9. Anthropogenic iodine radioisotopes mainly originate from human activities that are performed in the nuclear, industrial and medical fields1,2,3,8,9. The radioisotopes are damaging to human health because of their active participation in human metabolic processes. For example, repeated exposure to iodine radioisotopes could lead to metabolic disorders, mental retardation and thyroid cancer in humans10. Large increases of thyroid cancer in children have been reported11. In addition, high radioiodine depositions (up to 0.13 MBq/m2/month) are also known6. As a consequence, the absolute concentrations of radioiodine in some river and lake waters have exceeded pre-anthropogenic levels by several orders of magnitude12.

Iodine has only one stable isotope (127I) and more than 30 radioisotopes6. The iodine radioisotopes are characteristically fast spreading in the global environment (atmosphere, biosphere and ocean) because they are able to vaporize as I2 molecules13,14 or to freely mobilize as soluble anion species (e.g., I−). Soluble iodine species are not easily adsorbed by most minerals and adsorbents because they are strongly excluded from the solid surface by negative repulsion. These features make these iodine species the most difficult isotopes to sequester using conventional methods, such as adsorption technology15,16,17,18. In the UNSCEAR-2000 Report19, radioiodine is regarded as one of the most difficult radionuclides to treat and manage due to its large quantity and high mobilization.

In recent decades, a large quantity of 129I (half-life: 16 million y) from the Sellafield (U.K.) and La Hague (France) nuclear reprocessing facilities has continued to enter the Baltic Sea20. Up until 1998, for example, a total of 2300 kg of 129I had been discharged into the marine environment by the two European facilities, an amount that is 50 times the total release from nuclear weapon tests21. Moreover, the iodine isotopes with short half-life (several min to 60 days) are also problematic to natural environments because of their enormous release and subsequent bioaccumulation22. During the global recycling of radioiodine that is released into the environment, it is enriched in seaweed and fish, which are consumed by people for food, with a high accumulation factor (maximum of 104)23. The short- and long-term recycling of radioiodine could continue to be a potential risk to humans; thus, a new strategy and new technology are urgent to suppress the gradual widespread bioaccumulation of radioiodine.

Results and Discussion

Aqueous iodine species usually exist as iodide (I−) and iodate (IO3−), depending on the redox conditions in water24. Under a reducing environment or low levels of oxygen, iodine generally exists as I−. An experiment for the removal of soluble iodide (I−) from anion-rich anaerobic solutions was performed at near-neutral pH (Fig. 1) to determine how background anions (Cl−, HCO3− and SO42−) affect the behaviour of iodide under anaerobic conditions. Soluble iodide is hardly precipitable and capturable without specific adsorbents, regardless of the amount of competitive anions. As expected, there was little decline of the soluble iodide concentrations in the absence of adsorbents (Fig. 1a). However, a decrease of iodide was observed in a medium with bacteria and trace copper, even under highly competitive anion concentrations. The initial iodide concentration (1 mM) quickly dropped to a very low level along with a decrease of the copper concentration (Fig. S1) when the metal-reducing bacteria (MRB) and copper were added to the medium. The mixture of natural common anions did not appreciably interfere with the iodide removal and selectivity. The decrease of iodide concentration contrasted with the increase of the MRB population in the medium (Fig. 1b). Metal-reducing bacteria can obtain energy for growth by electron transport to Cu(II). In general, the metal-reducing microorganisms grow under anaerobic environments by enzymatically coupling the oxidation of organic matter with the reduction of metals25,26.

Changes in iodide concentrations and microbial population in anion-rich, anaerobic solutions (pH ~ 7.3).

(a) Declining behaviours of anionic iodide under different aqueous conditions over time. A rapid decrease in the iodide concentration was observed in a medium with MRB and copper(II). (b) MRB growth in the media was monitored with time. A moderate growth of the microbial population was observed in the medium with reducible copper.

During the microbially induced Cu reduction, characteristic halide crystals were generated as a solid phase grown to micrometre-sizes, even in the low iodine concentration (i.e., I− ≤ 1 mM). A mineralogical study of the newly formed solid phase was performed by X-ray diffraction (XRD) (Fig. 2a). The powder XRD indicated that the unique biomineralization product derived from the system was cuprous iodide (CuI) crystal. However, other precipitable samples from copper-free media were amorphous, with no characteristic XRD patterns. The scanning electron microscopy (SEM) image shows highly crystalline forms of iodide in Fig. 2b and its major element (I) is confirmed by the strong EDS peaks. The analytical results shown in Fig. 2a,b reveal that iodide is selectively bound to cuprous Cu+, even in the presence of competitive anions. The iodic halide nuclei that formed continued to grow by outcompeting other anions even at room temperature and circumneutral pH (e.g., pH 7.3). In a control experiment (e.g., the loading of Ag+ instead of Cu2+), however, the crystallization of iodide by combining with silver ions was not largely developed just showing relatively smaller AgI particles with sizes of less than 1.0 μm (Fig. S2).

Characterization of the biosynthetic iodide sample and its mineralizing process.

(a) XRD patterns of the samples that were collected from the media biostimulated with MRB and/or copper. Only in the case of both MRB and copper was the halide mineral (CuI) produced in a nearly pure and highly crystalline form. (b) SEM image of the solid sample with microscale crystals of iodide, showing strong EDS peaks of iodine. (c,d) High-resolution XPS spectra of the Cu 2p and I 3d regions of the solid sample. (e) Schematic of the microbial copper reduction and biogenic growth of radioiodine under competitive conditions.

The XPS analysis of the CuI solid sample shows that the oxidation state for copper was almost +1 (Fig. 2c). The peak at 932.4 eV, which only appeared as Cu(I) after biological Cu(II)-reduction, corresponds to the Cu 2p3/2 binding energy of CuI. Furthermore, the presence of anionic iodide (I−), as indicated by the I 3d5/2 signal at 619.1 eV in Fig. 2d, proves the formation of the CuI crystal phase.

The schematic model for our operating system shown in Fig. 2e exhibits the central role of a biocatalytic process that isolates iodide and allows it to grow in large crystals through a microbial metal reduction25,26,27,28. The microbe-driven biological process can be useful to skillfully regulate the mobility of iodide by transforming its aqueous form. A gradual change from water-soluble to insoluble cuprous iodic form may be crucial for the free iodic anions to be restrictive in mobilizing and to join the solid form in water. The continuous and robust bioconversion of copper (Cu2+ → Cu1+) functions as a driving force to make the CuI nuclei grow to the large solid phase. Copper acts as an important inorganic binder to strongly bond the iodide and iodide ions. As long as the system is sustained, the cuprous iodic nuclei do not remain as halide molecules or colloids but continue to grow into euhedral crystalline solids (~μm) with well-formed faces. The newly formed phase is a very rigid compound, where iodide can be fixed tightly, resulting in its low solubility in water. Because the new phase is extremely insoluble (<0.00042 g/L at 25 °C), it is not perceptibly decomposed in water.

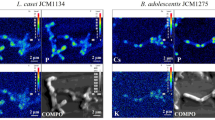

As shown in Fig. 3, we microscopically investigated the CuI crystals that were synthesized and grown to micrometre sizes in our biostimulant system. Copper(I) iodide is an inorganic polymer with a zinc-blende structure. Unlike the usual iodide entrapped by common anion-exchangers or adsorbents, the solid phase grew by the continuous attachment of iodide (Fig. 3a). Some specific lattice fringes of the CuI crystal were examined by a high-resolution nanoscale probe and were identified as {111} with a ~0.35-nm-spaced set (Fig. 3b). The TEM-EDS spectrum identified the crystal as almost pure CuI with trace chlorine (0.08 atomic%), demonstrating the higher selectivity of iodine (49.56 atomic%) of >500-fold over chlorine (Fig. 3c). Cl− is unfavourable to be shared by the halide phase due to its lower binding energy with copper. The elemental distribution analysis for the cross-sectioned sample revealed that the iodine component was not locally but homogeneously distributed in the microstructure (Fig. 3d).

Cross-sectioned HRTEM images of the crystallized iodide sample.

(a) A thin section (~50 nm) TEM image of the iodide solid sample biosynthesized under the anion-rich system. (b) Enlarged view of a small square in (a) showing some distinctive lattice fringes (d = 0.35 nm) of the crystalline CuI phase. (c) TEM-EDS spectrum showing the ratios of the major components. (d) Nanoscale probe maps that show homogeneous distributions of copper and iodine in the microcrystal.

A large quantity of radioiodine with high radioactivity in water that contains competitive anions was targeted to be reduced by our system and an actual test was successfully performed, as shown in Fig. 4, where strong 125I radioactivity (2.2 MBq/L) was decreased to a near non-detectable level for several days. In general, the radioactivity of iodine does not easily decrease in highly competitive anionic environments. Previous studies showed that some aqueous anions, such as chlorine and bicarbonate, act as strong competitors to I−16,29. In our microbial Cu-reducing system, however, the selective isolation and enrichment of radioactive 125I− was not strongly influenced by Cl− and HCO3− or OH−species. More interestingly, most of the water-soluble radioiodine, such as 125I, was separable from the anion-rich water as a solid phase.

Various anion-exchanger and getter materials have been developed and evaluated for their capacities to sequester radioiodine in wastewater15,16,17,18. These materials generally have a good performance under acidic conditions, ranging from pH 2 to 630,31. In higher pH ranges (e.g., pH ≥ 7.0), however, the anionic forms of iodine are repelled due to the negative charges resulting from growing effects of anionic OH− and HCO3− species. Furthermore, the capacity to remove iodine is restricted by innate properties, such as the specific surface area and adsorbing affinity. Recently, Ag+-doped materials32,33 have attracted attention as getter materials. They have shown better uptake for I− compared to other substances, but they have several shortcomings for direct application to bulky wastewaters because of their high usage cost and limited capacity due to the monotonous chemical adsorption. Our new method that is proposed here, however, provides drastic cost reduction by using copper (Cu2+) ions, which are much cheaper than silver (Ag+). Moreover, the selective enrichment of iodide can further lower the disposal costs by reducing the radioactive waste volume.

In the past, there has been attempts to remove soluble iodide by using copper powder/plate plus azurite mineral34 or cuprous chloride (CuCl)35. However, the inorganic chemical method raised a problem to generate a large volume of waste due to the use of significant copper mass (solid or reagent) and final redundant discharge. When copper(I) was directly used as CuCl35, for example, considerable copper byproducts were produced, such as cuprous oxide (Cu2O) and copper sulphides. The major cause for this seems to be resulted from a condition of very fast and instant chemical reactions between copper(I) and soluble anions, which could prevent the copper(I) from stably interacting with iodide alone. In contrast, the gradual copper reduction from Cu(II) to Cu(I) based on the microbial redox reaction can generate favourable conditions, where stepwise CuI nucleation and growth are feasible, leading to the continuous growth to microscale crystals.

The increasing release and recycling of radioiodine has recently become a subject of intense public concern due its negative impact on the global ecosystem5,6,7,12,20,21,22,23. Thus, stronger preventive measures must be developed. Conventional methods based on anion-exchange and adsorption cannot cope with the growing release of radioiodine. We suggest a new solution that uses a simple biostimulant way to skillfully isolate radioiodine in the form of a solid salt that is easily separable from wastewater as an insoluble and precipitable phase. This study reveals that natural metal-reducing bacteria can make the free iodic anions grow into large crystal forms by iodine enrichment via the bioreduction of copper. Through the iodine enrichment process, halide nuclei can obtain momentum for robust growth. The basis of our system is to strongly restrict the volatile mobilization of iodide by dramatically transforming the mobile phase to an immobile crystal. The merit of the crystallization is to fix the iodide in a structurally rigid framework, preventing I− remobilization later on. For example, marshite (CuI), which is a native mineral that is naturally synthesized by iodine and copper, is found to be a stable solid phase that has been preserved for long geologic times in the field36,37. This strong natural evidence indicates that the microcrystallization of radioiodine is a promising isolation method because the immobile solid phase is secure and stable in natural environments.

Methods

Anaerobic bacteria culturing

The anaerobic mixed culture containing a sulphate-reducing bacterium (Desulphosporosinus auripigmenti) was isolated from a bentonite sample located in a sedimentary rock in Kyongju (KJ), Korea. The culture (KJ) was obtained from the bentonite by a series of enrichment for approximately one year. Details of the enrichment process are described elsewhere38. The KJ culture’s phylogenetic tree and iron sulphide formation are shown in Figs S3 and S4. The components of the microbial-growth medium (per litre of deionized water) were as follows: NH4Cl, 20 mM; K2HPO4, 3 mM; MgSO4, 18 mM; CaSO4, 8 mM; sodium citrate, 25 mM; sodium lactate, 30 mM; and yeast extract, 1.0 g. A 100-ml volume of this medium was dispensed in a 120-ml glass serum bottle. Then, the medium was purged with pure N2 gas for 40 min, sealed with a butyl rubber septum and capped with an aluminum seal. After the serum bottle was autoclaved, 5% ferrous ammonium sulphate (2 ml) was aseptically added to the medium using a syringe and needle. The medium was inoculated with the KJ culture for growth at 30 °C.

Aqueous iodide removal experiment

To study the selective iodide removal from anion-rich water, we anaerobically prepared various anion-rich solutions of Cl−, HCO3− and SO42− in serum bottles. The selected anions are common in natural waters and their concentrations were as follows (mM): sodium chloride, 1.0; sodium bicarbonate, 3.0; and sodium sulphate, 1.0. Prior to the addition of iodide into the solution (100 ml), an iodide stock solution (100 mM) was prepared by dissolving a known amount of powder NaI in distilled water. From the iodide stock solution, 1 mM sodium iodide was aseptically added to the serum bottles containing the above anions.

To perform a practical test using an iodine radioisotope, a stock solution of radioactive 125I (half-life: 60 days) was prepared at 185 MBq/l from a reagent of 5 mCi Na125I (Perkin Elmer, Inc.). From the radioactive stock solution, 125I was injected to achieve 2.2 MBq/l radioactivity. In the radiological experiment, stable iodide (Na127I) was supplied to the solution at less than 1 mM to prompt iodide nucleation in the early stage.

Finally, cells were injected into the serum bottles, providing approximately 0.75 mg/l cell protein to determine the microbial effect on iodide removal. Organic matter (10 mM of sodium lactate) was injected through a 0.2-μm filter into the solution as an electron donor. To investigate a potential binder for mobile iodide (I−) in the microbial redox system, reducible cationic copper was selected and provided as a special electron acceptor and counterion in the iodide-containing media at less than 1.0 mM of Cu(NO3)2·3H2O. For a control test, silver (Ag+) ions were selected and injected at a concentration of 1.0 mM as AgNO3. The overall solution pH was ~7.3. The prepared serum bottles were then placed in a rotary-shaker (120 rpm at 30 °C) in the dark for 10 days. Periodically, liquid samples were removed by syringe and needle through 0.2-μm cellulose acetate filters and were analysed for changes in the stable iodide (127I) and copper concentrations using inductively coupled plasma-mass spectroscopy (ICP-MS). The inoculated cells were frequently removed to track their variation with time. Prior to the analysis of their protein quantity using a UV-Vis spectrophotometer (Cary 300, Agilent Technologies) at 562 nm, the cells were pretreated using a Micro BCATM Protein Assay Kit (Thermo Scientific).

Analytical techniques

In the radiological test (10 days), the radioactivity (MBq/l) of 125I in a liquid sample that was passed through a 0.2-μm filter was measured by a liquid scintillation counter (LSC, Perkin Elmer, Tri-Carb 2910 TM) in the range of 0 to 100 keV for 30 min. A diluted solution of the liquid sample (0.5 ml) and distilled water (4.5 ml) was mixed with 15 ml of a cocktail solution (Ultima GoldTM). The prepared solution was kept in a cold and dark place for at least 20 hours before the gamma-ray measurement by the LSC.

To confirm the chemistry and structure of the solid samples produced in the system, the precipitable products were collected by centrifugation (10,000 rpm for 3 min) and were investigated by spectroscopic and microscopic analysers. For the purpose of the analyses, the solid samples that were separated from the solution were frozen and freeze-dried for 48 hours (Bondiro, Ilshin Co.). X-ray photoelectron spectroscopy (XPS) was performed to analyse the oxidation state using an AXIS Ultra DLD (Kratos Inc.) system with monochromatic Al Kα (1486.7 eV) and a 150 W source. To identify the mineral species and crystallinity, X-ray diffraction (XRD) analysis was performed with a Bruker D8 Advance automatic horizontal goniometer diffractometer, which was equipped with a scintillation counter and a Cu X-ray tube operated at 40 kV/30 mA in continuous scan mode.

For the electron microscope observation, a field emission scanning electron microscope (FESEM; S-4700, Hitachi) was used to acquire the morphological and chemical information of the solid samples. For the SEM observation, the samples were uniformly sprayed onto a carbon tape pasted on the specimen holder. To avoid charging during observation, the samples were coated with a thin OsO4 (~10 nm) layer. Chemical analysis was performed using an energy dispersive X-ray spectrometer (EDS; EMAX, Horiba). High-resolution transmission electron microscopy (HRTEM) was conducted for the iodide solid sample. To microscopically examine the internal structure of the solid phase, the specimen was washed three times in deionized water and embedded in Caldofix resin. Then, the blocks were sectioned into 50–70-nm-thick pieces using an ultramicrotome to obtain cross-sections of the sample. The sections were mounted on 200-mesh nickel grids, which were coated with carbon-sputtered Formvar support film for the HRTEM observation. The samples were examined by a JEOL JEM 2100F high-resolution field emission TEM at 200 kV. Elemental analyses were performed using an Oxford EDS system equipped with a SiLi detector coupled to the HRTEM and analysed by ISIS software.

Additional Information

How to cite this article: Lee, S. Y. et al. Microbial copper reduction method to scavenge anthropogenic radioiodine. Sci. Rep. 6, 28113; doi: 10.1038/srep28113 (2016).

References

Yoshida, N. & Kanda, J. Tracking the Fukushima radionuclides. Science 336, 1115–1116 (2012).

Doll, C. G. et al. Abatement of xenon and iodine emissions from medical isotope production facilities. J. Environ. Radioact. 130, 33–43 (2014).

Braghirolli, A. M. S., Waissmann, W., Silva, J. B. & Santos, G. R. Production of iodine-124 and its applications in nuclear medicine. Appl. Radiat. Isot . 90, 138–148 (2014).

Alvarado, J. A. C. et al. Anthropogenic radionuclides in atmospheric air over Switzerland during the last few decades. Nature Commun . 5, 3030 (2014).

Muramatsu, Y., Yoshida, S., Fehn, U., Amachi, S. & Ohmomo, Y. Studies with natural and anthropogenic iodine isotopes: iodine distribution and cycling in the global environment. J. Environ. Radioact. 74, 221–232 (2004).

Toyama, C. et al. Variations of 129I in the atmospheric fallout of Tokyo, Japan: 1963–2003. J. Environ. Radioact. 113, 116–122 (2012).

Hou, X. et al. Iodine-129 in seawater offshore Fukushima: distribution, inorganic speciation, sources and budget. Environ. Sci. Technol. 47, 3091–3098 (2013).

Peplow, M. Chernobyl’s legacy. Nature 471, 562–565 (2011).

Butler, D. Fukushima health risks scrutinized. Nature 472, 13–14 (2011).

Vitti, P., Delange, F., Pinchera, A., Zimmerman, M. & Dunn, J. T. Europe is iodine deficient. Lancet 361, 1226 (2003).

Kazakov, V. S., Demidchik, E. P. & Astakhova, L. N. Thyroid cancer after Chernobyl. Nature 359, 21 (1992).

Snyder, G. & Fehn, U. Global distribution of 129I in rivers and lakes: implications for iodine cycling in surface reservoirs. Nucl. Instr. Meth. B 223–224, 579–586 (2004).

Lawler, M. J., Mahajan, A. S., Saiz-Lopez, A. & Saltzman, E. S. Observations of I2 at a remote marine site. Atmos. Chem. Phys. 14, 2669–2678 (2014).

Nitschke, U., Dixneuf, S., Ruth, A. A., Schmid, M. & Stengel, D. B. Molecular iodine (I2) emission from two Laminaria species (Phaeophyceae) and impact of irradiance and temperature on I2 emission into air and iodide release into seawater from Laminaria digitata. Mar. Environ. Res. 92, 102–109 (2013).

Inoue, H., Kagoshima, M., Yamasaki, M. & Honda, Y. Radioactive iodine waste treatment using electrodialysis with an anion exchange paper membrane. Appl. Radiat. Isot . 61, 1189–1193 (2004).

Goh, K. H., Lim, T. T. & Dong, Z. Application of layered double hydroxides for removal of oxyanions: a review. Water Res . 42, 1343–1368 (2008).

Kosaka, K. et al. Removal of radioactive iodine and cesium in water purification processes after an explosion at a nuclear power plant due to the great East Japan earthquake. Water Res . 46, 4397–4404 (2012).

Sato, I., Kudo, H. & Tsuda, S. Removal efficiency of water purifier and adsorbent for iodine, cesium, strontium, barium and zirconium in drinking water. J. Toxicol. Sci. 36, 829–834 (2011).

UNSCEAR-2000 Report. Globally dispersed radionuclides, Iodine-129 (United Nations, 2000).

He, P., Aldahan, A., Possnert, G. & Hou, X. Temporal variation of iodine isotopes in the North Sea. Environ. Sci. Technol. 48, 1419–1425 (2014).

Fréchou, C. & Calmet, D. 129I in the environment of the La Hague nuclear fuel reprocessing plant-from sea to land. J. Environ. Radioact. 70, 43–59 (2003).

Morita, T. et al. Detection and activity of iodine-131 in brown algae collected in the Japanese coastal areas. Sci. Total Environ. 408, 3443–3447 (2010).

Martinez, N. E., Johnson, T. E. & Pinder III, J. E. Influence of lake trophic structure on iodine-131 accumulation and subsequent cumulative radiation dose to trout thyroids. J. Environ. Radioact. 131, 62–71 (2014).

Whitehead, D. C. The distribution and transformations of iodine in the environment. Environ. Int. 10, 321–339 (1984).

Lovley, D. R., Phillips, E. J. P., Gorby, Y. A. & Landa, E. R. Microbial reduction of uranium. Nature 350, 413–416 (1991).

Labrenz, M. et al. Formation of sphalerite (ZnS) deposits in natural biofilms of sulfate-reducing bacteria. Science 290, 1744–1747 (2000).

Lee, S. Y. et al. Uranium(IV) remobilization under sulfate reducing conditions. Chem. Geol. 370, 40–48 (2014).

Lee, S. Y. et al. Abiotic reduction of uranium by mackinawite (FeS) biogenerated under sulfate-reducing condition. J. Radioanal. Nucl. Chem. 296, 1311–1319 (2013).

Um, W., Serne, R. J. & Krupka, K. M. Linearity and reversibility of iodide adsorption on sediments from Hanford, Washington under water saturated conditions. Water Res . 38, 2009–2016 (2004).

Nagata, T., Fukushi, K. & Takahashi, Y. Prediction of iodide adsorption on oxides by surface complexation modeling with spectroscopic confirmation. J. Colloid. Interface Sci. 332, 309–316 (2009).

Choung, S., Um, W., Kim, M. & Kim, K. G. Uptake mechanism for iodine species to black carbon. Environ. Sci. Technol. 47, 10349–10355 (2013).

Sánchez-Polo, M., Rivera-Utrilla, J. & Gunten, U. Bromide and iodide removal from waters under dynamic conditions by Ag-doped aerogels. J. Colloid. Interface Sci. 306, 183–186 (2007).

Liu, S. et al. Efficient removal of radioactive iodide ions from water by three-dimensional Ag2O-Ag/TiO2 composites under visible light irradiation. J. Hazard. Mater. 284, 171–181 (2015).

Lefèvre, G., Alnot, M., Ehrhardt, J. J. & Bessière, J. Uptake of iodide by a mixture of metallic copper and cupric compounds. Environ. Sci. Technol. 33, 1732–1737 (1999).

Liu, Y., Gu, P., Jia, L. & Zhang, G. An investigation into the use of cuprous chloride for the removal of radioactive iodide from aqueous solutions. J. Hazard. Mater. 302, 82–89 (2016).

Website of Mindat. Marshite, http://www.mindat.org/min-2580.html (Date of access: 12/02/2016).

Marsh, C. W. On native copper iodide (marshite) and other minerals from Broken Hill, N.S. Wales. Proc. Roy. Soc. N. S. W . 26, 326–332 (1892).

Lee, J. Y., Lee, S. Y., Baik, M. H. & Jeong, J. T. Existence and characteristics of microbial cells in the bentonite to be used for a buffer material of high-level wastes. J. Nucl. Fuel Cycle Waste Technol . 11, 95–102 (2013).

Acknowledgements

We thank T.-S. Bae and H.-R. Kim in KBSI (Korea Basic Science Institute) for SEM analysis. The measurement of aqueous iodide concentrations was assisted by C.-M. Kim in Sang-Ji University. This research work was supported by the National Nuclear R&D Program (2012M2A8A5025589) through the National Research Foundation (NRF) funded by The Ministry of Science ICT & Planning (MSIP) of Korea. Y. Lee thanks the support of Global Research Laboratory program of the MSIP.

Author information

Authors and Affiliations

Contributions

S.Y.L. designed the study and wrote the paper. S.Y.L. and J.Y.L. performed the research. J.H.M. and S.S.K. measured the activity of radioiodine. M.H.B. analysed the data. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Lee, S., Lee, J., Min, J. et al. Microbial copper reduction method to scavenge anthropogenic radioiodine. Sci Rep 6, 28113 (2016). https://doi.org/10.1038/srep28113

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep28113

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.