Abstract

Ge-Sb-Te alloys have been widely used in optical/electrical memory storage. Because of the extremely fast crystalline-amorphous transition, they are also expected to play a vital role in next generation nonvolatile microelectronic memory devices. However, the distribution and structural properties of vacancies have been one of the key issues in determining the speed of melting (or amorphization), phase-stability and heat-dissipation of rock-salt GeSbTe, which is crucial for its technological breakthrough in memory devices. Using spherical aberration-aberration corrected scanning transmission electron microscopy and atomic scale energy-dispersive X-ray mapping, we observe a new rock-salt structure with high-degree vacancy ordering (or layered-like ordering) at an elevated temperature, which is a result of phase transition from the rock-salt phase with randomly distributed vacancies. First-principles calculations reveal that the phase transition is an energetically favored process. Moreover, molecular dynamics studies suggest that the melting of the cubic rock-salt phases is initiated at the vacancies, which propagate to nearby regions. The observation of multi-rock-salt phases suggests another route for multi-level data storage using GeSbTe.

Similar content being viewed by others

Introduction

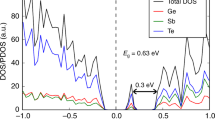

The important technological material GeSbTe (GST), especially on the GeTe-Sb2Te3 pseudo-binary line, shows an extraordinary potential in optical/electrical applications due to the outstanding switching behavior1,2,3,4. GST is supposed to be a good candidate for the non-volatile phase change memory (PCM)2,3,4,5 and in recent years, GST have also been applied to the brain-like computing systems6 and electronic displays7. With assistance of electrical (or laser) pulse, GST can switch between the amorphous and crystalline phases within tens of nanosenconds1,2,3,4 and are accompanied by considerable changes in the resistivity or reflectivity1,2,3. Knowledge about the atomic structure is crucial to understand the mechanism of the fast reversible phase transformation8,9,10,11 and to further improve the performance of its relevant devices. According to the previous literatures1,12,13,14, GST possesses at least two crystalline phases, i.e., the cubic metastable and hexagonal (or trigonal) stable phases. The metastable phase has a rock-salt-like structure where anion sites are occupied by Te and cation sites are randomly occupied by Ge/Sb plus a certain amount of vacancies15,16,17. The concentration of the vacancies in the cation sites depends on the chemical composition17 and is 20% for Ge2Sb2Te5. However, there is controversies with respect to the vacancy distribution, which was reported as a random distribution based on the X-ray diffraction (XRD) data15,16, but some theoretical studies predicted that the vacancies could be highly ordered and even form layers on the (111) planes8,14 or be more complicated18. Recently, it was proposed that vacancy ordering in cubic GST may be controlled by thermal annealing3,19 or electronic beam radiation20 and a vacancy semi-ordered21 cubic GST has been observed. The vacancy distribution affects not only the structural stability and the phase transition behavior8,14, but also the physical properties, such as the electronic3 and thermal19 transports. Another issue is the structural transition from the cubic phase to the hexagonal phase, as which share considerable structural similarities8,13, except that the vacancies are mostly ordered in the latter case.

Many efforts9,10,11,22,23 have been made to understand the transition between the cubic and amorphous phases of GST, in which the vacancies are believed to play a vital role9,10,11,24. In particular, amorphization (reset operation in PCM) is a key step for PCM devices, which is usually achieved through the melt-quench process by applying an intense laser (or electric) pulse2,4. Thus, the melting behavior of the GST is important for its PCM applications. In the past, studies were mainly interested in understanding the structure evolution during the melting (or disorder) of GST25,26,27,28,29. For example, through first-principles calculations, Sun et al.25, found a unique melting behavior of some hypothetical vacancy-ordered GST cubic structure in which some ordered structural motifs remain intact after the melting. However, the roles of the vacancies and their distribution during the real-time melting process have not been reported. Often, amorphization (or melting) can be a multi-level process30,31, which could be beneficial for GST-based PCM devices. Recently, eight-level storage and three-bits in a single cell have been reported32. Currently, multi-level storage32,33,34 has been realized by controlling the fraction of the crystalline33 or amorphous35 regions within one storage cell. However, realizing multi structures in GST could offer another way to achieve multi-level storage, for example, by creating and manipulating multi-levels in cubic GST with different degrees of vacancy ordering and resistivity3.

In this work, we report a combined experimental and theoretical study on the vacancy ordering in cubic GST, in connection with its role in the cubic-to-hexagonal phase transition and amorphization and the possibility of multi-level cubic and amorphous GST phases for PCM. Using spherical aberration-corrected (Cs-corrected) high angle annular dark field scanning transmission electron microscopy (HAADF-STEM) combined with atomic energy-dispersive X-ray (EDX) mapping, we verify two states for cubic GST, one with vacancies randomly distributed (the primarily cubic phase) and one with highly ordered vacancies [the vacancy-ordered cubic (VOC) phase]. First-principles molecular dynamics (MD) studies reveal that the vacancy ordering is in fact energetically favorable. In addition, melting (or amorphization) in the cubic phases occurs at the vacancies and then propagates into nearby regions.

Results and Discussion

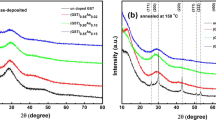

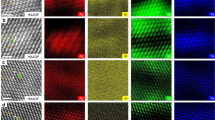

Crystallization of the pulse-laser deposited (PLD) amorphous GST during in-situ annealing was studied by transmission electron microscopy (TEM) [see Fig. S1, Supplementary Information (SI)]. The crystallization temperature is determined to be ~150 °C, which is similar to that of the as-deposited films1, although the grain sizes are slightly larger ranging from dozens to hundreds of nanometers. Figure 1 shows the structure and atomic arrangement of the primarily cubic GST (160 °C -annealed), that was obtained by Cs-HAADF-STEM and EDX mapping. The HAADF image (the so-called Z contrast image) is chemically selective36, because the brightness of the HAADF image is roughly proportional to the square of the atomic number (Z2). Therefore, the appearance of the regular alternative bright (green circles) and dark (white circles) spots in Fig. 1(a) corresponds to Te and Ge/Sb/Vacancy atoms in different sites or columns (vertical to the shown plane). However, complexity due to the coexistence of Te (52), Sb (51), Ge (32) and Vacancy (0) may arise. Therefore, the atomic EDX mappings, depicted in Fig. 1(b,d–f), are considered to be more accurate and straightforward for such structural studies. These mappings confirm that Te and Ge/Sb/Vacancy atoms reside on different sublattices as reported by the previous XRD measurements15,16.

Structural and chemical identification of the GST primarily cubic structure projected along the [110] direction.

(a) HAADF image. (b) The mixture EDX mapping and (d–f) the individual mappings for the corresponding element in (a,c). The corresponding schematic of atomic model with Te (green) and Ge/Sb/Vacacny (purple). The sites of Te and Ge/Sb/Vacancy are marked by green and white circles in (a,d–f).

Multi-levels in the structures in the GeSbTe cubic phase

To investigate the multi-levels in the cubic-GST with different vacancy ordering, two samples were annealed at 160 °C and 300 °C for 10 minutes. Figure 2 shows their comparison based on the projected structures along the [110] direction. The sample annealed at 160 °C shows a homogenous structure as the primarily cubic phase [Fig. 2(a)]. However, the sample annealed at 300 °C exhibits a lamella-like structure (which is similar to the hexagonal phase), as the VOC phase [see Fig. 2(c)], where the periodically dark stripes originate from the vacancy accumulation. Before determining this VOC structure (i.e., it is the cubic or hexagonal phase), a detailed structure comparison between these two phases was performed as shown in Fig. S2 (in SI). In the cubic phase, the Te (or Ge/Sb/Vacancy) sites are always arranged in lines and in the local area five neighboring Te (or Ge/Sb/Vacancy) sites can form a rectangle with four dots as corners and one as center, see the dotted lines and rectangles in Figs 2(a) and S2(a). However, both of these structural features have been interrupted across the Te-Te vacancy layers in the hexagonal phase, see Fig. S2(b). Therefore, the two distinguishable features in the VOC phase [in Fig. 2(c)] suggest its cubic structural stacking. Namely, the VOC phase is a lamella-like cubic phase. In addition, the fast Fourier transition (FFT) patterns [in the inset of Fig. 2 (a,c)] also confirm the cubic structural similarity (as indicated by yellow arrows) between the VOC phase and the primarily cubic phase. Compared to the case in the primarily cubic phase, some extra diffraction spots (with a shorter reciprocal lattice distance compared to the original reciprocal lattice constant along the [111] direction) in the VOC phase [inset in Fig. 2(c)] correspond to the vacancy-ordered layers.

The multi-states of GST cubic phase.

(a) The primarily cubic and (c) vacancy ordered cubic (VOC) phase. Their cubic structural features are highlighted and demonstrated by the white dash-dot lines and the red rectangles. The corresponding FFT patterns are shown in their insets. (b,d) are the corresponding normalized intensity mapping for Ge/Sb/Vacancy sites (to reflect the concentration of vacancy) in (a,c) with color bar on the right-side.

To quantitatively estimate the vacancy distribution from the HAADF images, a method based on image processing (see the details in Fig. S3 in SI) was introduced. We only picked out the Ge/Sb/Vacancy columns (sites), as shown in Fig. 2(b,d). The normalized intensity with different colors roughly reflects the relative concentration of vacancy in each Ge/Sb/Vacancy columns. Blue-to-white represents a vacancy-rich (or atom-poor) distribution. Red-to-yellow indicates a vacancy-poor (or atom-rich) distribution and green is for an average vacancy distribution. Figure 2(b) shows a distribution with small deviation from green indicating a random distribution of vacancies and Ge/Sb atoms in the primarily cubic phase. However, Fig. 2(d) shows a series of blue-to-white columns suggesting vacancy ordering in the (111) layers in the VOC phase. Such vacancy layers divide the cubic matrix into pieces of lamellas. Interestingly, two vacancy-poor layers (red-to-yellow) are always found adjacent to the vacancy-ordering layer. In other words, vacancies in these neighboring layers tend to fully diffuse into the vacancy-ordering layer, whereas the vacancies in the far-away cation layers are more difficult to diffuse. According to the composition of Ge2Sb2Te5, the average concentration of vacancies in the cation sublattice is 20%15,16,17. As such, 60% is the expected concentration of vacancies in these (111) vacancy-ordering layers, based on the vacancies from the two adjacent layers. Of course, we cannot exclude some Sb may aggregate into the two “red-to-yellow” layers due to the large atomic number.

Stability and distortion of the VOC phase

In this section, we further investigated the stability and the lattice distortion of the VOC phase. The theoretical results are obtained by first-principles calculations. According to the estimation of the concentration of vacancy (~60%) in the vacancy-ordering layer, a range from 30% to 70% is used in the calculations. Figure 3(a) shows that the vacancy aggregation is energetically favored because the energy decreases with increasing concentration, which is consistent with a previous report37. For lattice distortion, Fig. 3(b) shows the distance between the two Te layers, which sandwich the vacancy-ordering layer, decreases with the vacancy accumulation. To estimate the lattice distortion of the VOC phase from the HAADF images, we measured the Te-Te interlayer distance and depicted in Fig. 3(c) according to the relevant vacancy concentration mapping [Fig. 2(d)]. The local Te-Te interlayer distance is indeed slightly decreased with the increase of the vacancy accumulation (the decrease of the normalized intensity is a rough indication of vacancy accumulation). It should be stressed that the Te-Te interlayer distances in the VOC phase is close to those in the primarily cubic phase but are much larger than in the hexagonal phase, as shown in Fig. S1(b).

The effect of the vacancy ordering in GST cubic phases on the stability and the lattice distortion.

(a) The calculated energy and (b) the Te-Te interlayer distance upon the vacancy-ordering degree on the (111) layer. (c) The experimentally measured Te-Te interlayer distances in the VOC phase [in Fig. 2(c)] rely on the normalized intensity mapping of Ge/Sb/Vacancy columns as those in Fig. 2(d).

The cubic-to-hexagonal phase transition is another key issue for GST which has been intensely studied8,14,38,39. According to the above results, we can propose a model of this phase transition. Firstly, vacancies are randomly distributed in the primarily cubic phase. Then, with annealing at high temperature (for example at 200 °C21), the vacancies are gradually accumulated and ordered into the (111) planes in the form of a local “vacancy plate” as a vacancy semi-ordered cubic structure21. With further increasing of the temperature, more vacancies are moved into the “vacancy plates”. During the vacancy ordering process, the energy is decreased and the lattice is compressed slightly along the [111] direction. When most of the vacancies are ordered in the (111) layers (for example 60%), the VOC phase is formed with lamella structures similar to those in the hexagonal phase. Since the hexagonal phase in GST has a definite number of layers in each lamella for a specific composition, such as nine layers for Ge2Sb2Te5 and seven layers for Ge1Sb2Te4. Therefore, most of the nine-layer lamellas in the VOC phase as shown in Fig. 2(c), demonstrate that the samples are indeed the Ge2Sb2Te5. The hexagonal phase of GST, is in the form of stacking lamellas separated by Te-Te gaps and is always energetically favorable compared to the cubic phase. As the concentration of vacancies approaches to 100% in the layer (as a true Te-Te gap) or a critical high value, the cubic-to-hexagonal phase transition occurs by sliding the building blocks8 (lamellas) and collapsing the vacancy layer. Thus, the vacancy-ordering process plays a critical role in the phase switching13,37. We expect the in-situ observation of vacancy ordering and the phase transition to be important in future research. Currently, there are at least three cubic phases in GST: the primarily cubic phase (random distribution of vacancies), the vacancy semi-ordered21 cubic phase and the VOC phase. These multi-level structures in GST hint the possible application to multi-level storage. Additionally, the VOC phase should be an important intermediate state during the cubic-to-hexagonal transition because it is compatible with the structural characteristics of both structures.

Melting in the VOC phase

In PCM devices, amorphization (reset operation) is usually achieved via a melt-quenching process by an intense laser (or electrical) pulse2,4 although some reports have proposed the solid-state amorphization can also be achieved by photoassist40 or electronic excitation41. In the following section, the melting behavior of the VOC phase is investigated by first-principles MD simulation. As shown in Fig. 4(a), a supercell with 172 atoms (Ge38Sb38Te96) is used to mimic the VOC phase where the vacancy layer is highlighted by a red shading rectangle in Fig. 4(a). We firstly increase the temperature form 300 K to 900 K within 6 ps. Then, the annealing is performed at 1300 K for 12 ps to observe the melting process. To observe the atomic diffusion in the melt, an image at every 1.5 ps (including 5 snapshots, one per 0.3 ps) is extracted during the annealing. In the first stage [1.5–3 ps, Fig. 4(a)], all of the atoms shake intensely but the whole structure is still highly ordered, which is also reflected by its pair correlation function (PCF) in Fig. 4(f). From 3 to 4.5 ps, the atoms near the vacancy layer start to diffuse into the layer and melt, whereas the atoms far away maintain order, [Fig. 4(b)]. Therefore, the PCF maintains crystalline features. In the next 1.5 ps, the atoms far from the original vacancy layer start to diffuse significantly and the structure becomes disordered. However, some of the atoms (far from the vacancy layer) are still ordered, such as the Te marked with a circle [Fig. 4(c)]. At 12 ps, the structure becomes completely disordered. The crystal characteristic in PCF at r >6 Å, which correspond to the long-range order, disappears [Fig. 4(f)]. The mean square displacement (MSD) during the melting process provides valuable information. We divide the MSD into two parts: one is for atoms around the vacancy layer [as shown in the red empty rectangle in Fig. 4(a,b)] and the other is for the atoms outside of the vacancy layer. Figure 4(e) shows the MSD around the vacancy layer increases more significantly before 6 ps. Therefore, the VOC phase starts to melt from the region near the vacancy layer. The MSD outside of the vacancy layer starts to increase after more time passes (i.e., >6 ps), with an indication that the melt extends to this region. This phenomenon is possibly due to the vacancy layers, which provide space for atomic diffusion.

The simulation of melting process in the VOC phase.

(a–d) The structural evolution during the melting process at 1300 K. Five snapshots in 1.5 ps are collected in each figure. The initial vacancy layer is highlighted by the red shading rectangle and the nearby atoms are marked by the red empty rectangle. A Te far from the initial vacancy layer is marked by a red circle. (e) The MSD for the atoms around the vacancy layer (inside the red empty rectangle) and out of the vacancy layer during melting process. (f) The PCFs with time evolution.

To understand the roles of the multi-level vacancy distributions in the melting behavior in GST, we also performed the melting MD on the other two cubic models: the random vacancy distribution and the VOC phase with less ordered vacancies in the vacancy-ordering layer. As expected, Fig. S4 (in SI) shows the melting always occurs in the region near the vacancies. Compared to the case in the VOC phase, Fig. S4 shows that these two models (with less ordered distribution of the vacancies) melt faster. In other words, the VOC phase requires a longer time to become completely disordered. Thus, it may provide an opportunity to controlling the disorder degree by a series of hierarchic amorphization processes. Here, we quenched the 1300 K-annealing VOC phase at different periods (with different melting times) to 300 K. The imaginary part of the dielectric constant (ε2) for these quenched structures is calculated. Figure S5 (in SI) shows that ε2 decreases continuously with the melting time. In this way, we can obtain structures with different optical/electrical properties, which is a potential technique to achieve multi-level storage.

In summary, the multi-structural properties of cubic GST have been studied both experimentally and theoretically. In addition to the well-known cubic phase with primarily random vacancy distribution, a VOC phase is identified at elevated annealing temperature such as 300 °C. This new phase is energetically more stable but its lattice is only slightly distorted from that of the rock-salt structure. We suggest that this VOC phase, as an intermediate state between the primarily cubic phase and hexagonal phase, plays a vital role in the transition among the cubic phase, the hexagonal phase and even the amorphous phase. Moreover, MD simulation reveals that the amorphization of the VOC phase occurs from ordered vacancies and then propagates to other regions. These findings address some of the key questions about the structural properties and amorphization behavior of the popular GST memory alloys, which could be vital for further optimization of the materials for practical PCM devices.

Methods

Sample preparation

The amorphous PLD-Ge2Sb2Te5 films with thickness of few micrometers were deposited on the Si substrate (covered with an amorphous SiO2 film) using a stoichiometric Ge2Sb2Te5 alloy target. The composition of the films were confirmed as nearly Ge2Sb2Te5 by energy dispersive X-ray (EDX) Spectrum. The cross sectional samples for TEM and STEM study were performed by the focused ion beam system (FIB). To minimize the beam damage during the FIB sample preparation, the multiple processes with reducing voltages and beam current are used. The parameters were 5 kV and 23 pA when the sample was thinner than 300 nm and were further reduced to 2 kV and 16 pA as the thickness of the sample was under ~100 nm.

TEM measurements

The in-situ annealing study was performed on the JEOL 2010 TEM with heating rate of 10 K/min and hold for 10 minutes at 150 °C and 300 °C, respectively. The samples for the HAADF investigation were annealed at 160 °C and 300 °C for 10 minutes in TEM. The HAADF images and EDX mappings were obtained on a FEI Titan ChemiSTEM 80–200 Cs-TEM with a super-X detector. Both of the TEM and STEM were performed at 200 kV. The details of the image processing was described in SI in Fig. S3.

Calculation detail

Our calculation employs density functional theory (DFT)42 as implemented in the Vienna Ab-initio Simulation Package (VASP) code43. The projector augmented wave (PAW)44 pseudopotential is used to describe the electron-ion interaction and the electronic exchange-correlation interaction is described by generalized gradient approximation (GGA) with the Perdew-Burke-Ernzerhof (PBE) functional45. In the MD simulation, we use the NVT canonical ensemble, in which the Nosé thermostat is used to control the temperature46. For both structure optimize and MD simulation, we employs an energy cutoff of 200 eV, K-point set of 1 × 1 × 1, Gaussian smearing with 0.1 eV and no spin.

Modeling process

Our GST model is build based on the rock-salt structure. In order to form a vacancy layer penetrating the (111) plane, we redefine a new lattice vectors in the calculation cell: (1 1 1), (−1 1 0), (−1 −1 2), in terms of the rock-salt lattice. The initial lattice parameter is set to match the density measured by experiment47. Therefore, the parameters of initial supercell are a = 20.8369 Å, b = 17.0124 Å, c = 14.7331 Å and the model contains 38 Ge, 38 Sb, 96 Te atoms and 20 vacancies. Then the models with different degree of vacancies accumulation are optimized with volume variation.

Additional Information

How to cite this article: Zhang, B. et al. Vacancy Structures and Melting Behavior in Rock-Salt GeSbTe. Sci. Rep. 6, 25453; doi: 10.1038/srep25453 (2016).

References

Yamada, N., Ohno, E., Nishiuchi, K., Akahira, N. & Takao, M. Rapid-phase transitions of GeTe-Sb2Te3 pseudobinary amorphous thin films for an optical disk memory. J. Appl. Phys. 69, 2849–2856 (1991).

Wuttig, M. & Yamada, N. Phase-change materials for rewriteable data storage. Nat. Mater. 6, 1004–1004 (2007).

Siegrist, T. et al. Disorder-induced localization in crystalline phase-change materials. Nat. Mater. 10, 202–208 (2011).

Raoux, S., Ielmini, D., Wuttig, M. & Karpov, I. Phase change materials. Mater. Res. Bull. 37, 118–123 (2012).

Lencer, D., Salinga, M. & Wuttig, M. Design rules for phase-change materials in data storage applications. Adv. Mater. 23, 2030–2058 (2011).

Kuzum, D., Jeyasingh, R. G. D., Lee, B. & Wong, H.-S. P. Nanoelectronic Programmable Synapses Based on Phase Change Materials for Brain-Inspired Computing. Nano Lett. 12, 2179–2186 (2011).

Peiman, H., David, W. C. & Harish, B. An optoelectronic framework enabled by low-dimensional phase-change films. Nature 511, 206–211 (2014).

Sun, Z. M., Zhou, J. & Ahuja, R. Structure of Phase Change Materials for Data Storage. Phys. Rev. Lett. 96, 055507 (2006).

Akola, J. & Jones. R. O. Structural phase transitions on the nanoscale: The crucial pattern in the phase-change materials Ge2Sb2Te5 and GeTe. Phys. Rev. B 76, 235201 (2007).

Lee, T. H. & Elliott, S. R. Structural role of vacancies in the phase transition of Ge2Sb2Te5 memory materials. Phys. Rev. B 84, 094124 (2011).

Da Silva, J. L. F., Walsh, A., Wei, S. H. & Lee, H. Atomistic origins of the phase transition mechanism in Ge2Sb2Te5 . J. Appl. Phys. 106, 113509 (2009).

Kooi, B. J. & De Hosson, J. T. M. Electron diffraction and high-resolution transmission electron microscopy of the high temperature crystal structures of GexSb2Te3+x (x = 1, 2, 3) phase change material. J. Appl. Phys. 92, 3584–3590 (2002).

Matsunaga, T., Yamada, N. & Kubota, Y. Structures of stable and metastable Ge2Sb2Te5 an intermetallic compound in GeTe-Sb2Te3 pseudo-binary systems. Acta. Cryst. B 60, 685–691 (2004).

Da Silva, J. L. F., Walsh, A. & Lee, H. Insights into the structure of the stable and metastable (GeTe)m(Sb2Te3)n compounds. Phys. Rev. B 78, 224111 (2008).

Yamada, N. & Matsunage, T. Structure of laser-crystallized Ge2Sb2+xTe5 sputtered thin films for use in optical memory. J. Appl. Phys. 88, 7020–7028 (2000).

Nonaka, T., Ohbayashi, G., Toriumi, Y., Mori, Y. & Hashimoto, H. Crystal structure of GeTe and Ge2Te2Te5 meta-stable phase. Thin Solid Films 370, 258–261 (2000).

Matsunaga, T. et al. Structural characteristics of GeTe-rich GeTe–Sb2Te3 pseudobinary metastable crystals. J. Appl. Phys. 103, 093511 (2008).

Eom, J. H. et al. Global and local structures of the Ge-Sb-Te ternary alloy system for a phase-change memory device. Phys. Rev. B 73, 21 (2006).

Zalden, P. et al. Specific Heat of (GeTe)x(Sb2Te3)1−x Phase-Change Materials: The Impact of Disorder and Anharmonicity. Chem. Mater. 26, 2307–2312 (2014).

Lotnyk, A. et al. Real-space imaging of atomic arrangement and vacancy layers ordering in laser crystallized Ge2Sb2Te5 phase change thin films. Acta. Mater. 105, 1–8 (2016).

Ross, U., Lotnyk, A., Thelander, E. & Rauschenbach, B. Direct imaging of crystal structure and defects in metastable Ge2Sb2Te5 by quantitative aberration-corrected scanning transmission electron microscopy. Appl. Phys. Lett. 104, 121904 (2014).

Kolobov, A. V. et al. Understanding the phase-change mechanism of rewritable optical media. Nat. Mater. 3, 703–708 (2004).

Lang, C., Song, S. A. D., Nguyen-Manh, D. & Cockayne, D. J. H. Building blocks of amorphous Ge2Sb2Te5 . Phys. Rev. B 76, 054101 (2007).

Wuttig, M. et al. The role of vacancies and local distortions in the design of new phase-change materials. Nat. Mater. 6, 122 (2007).

Sun, Z. M., Zhou, J. & Ahuja, R. Unique Melting Behavior in Phase-Change Materials for Rewritable Data Storage. Phys. Rev. Lett. 98, 055505 (2007).

Bichara, C., Johnson, M. & Gaspard, J. P. Octahedral structure of liquid GeSb2Te4 alloy: First-principles molecular dynamics study. Phys. Rev. B. 75, 060201(R) (2007).

Akola, J. & Jones, R. O. Density functional study of amorphous, liquid and crystalline Ge2Sb2Te5: homopolar bonds and/or AB alternation? J. Phys. Condens. Matter. 20, 465103 (2008).

Sun, Z. M., Zhou, J., Blomqvist, A., Xu, L. & Ahuja, R. Local structure of liquid Ge1Sb2Te4 for rewritable data storage use. J. Phys. Condens. Matter. 20, 205102 (2008).

Hegedüs, J. & Elliott, S. R. Microscopic origin of the fast crystallization ability of Ge-Sb-Te phase-change memory materials. Nat. Mater. 7, 399–405 (2008).

Loke, D. et al. Ultrafast phase-change logic device driven by melting processes. Proc. Natl. Acad. Sci. USA 111, 13272 (2014).

Skelton, J. M., Loke, D., Lee, T. H. & Elliott, S. R. Understanding the multistate SET process in Ge-Sb-Te-based phase-change memory. J. Appl. Lett. 112, 064901 (2012).

Ríos, C. et al. Integrated all-photonic non-volatile multi-level memory. Nat. Photon. 9, 725–732 (2015).

Nakayama, K., Takata, M., Kasai, T., Kitagawa, A. & Akita, J. Pulse number control of electrical resistance for multi-level storage based on phase change. J. Phys. D. Appl. Phys. 40, 5061–5065 (2007).

Zhou, X. L. et al. Sb-rich Si-Sb-Te phase change material for multilevel data storage: The degree of disorder in the crystalline state. Appl. Phys. Lett. 99, 032105 (2011).

Papandreou, N. et al. Estimation of amorphous fraction in multilevel phase-change memory cells. Solid-State Electron. 54, 991–996 (2010).

Pennycook, S. J. & Boatner, L. A. Chemically Sensitive Structure-Imaging with a Scanning-Transmission Electron-Microscope. Nature 336, 565–567 (1988).

Zhang, W. et al. Role of vacancies in metal–insulator transitions of crystalline phase-change materials. Nat. Mater. 11, 952–956 (2012).

Matsunaga, T. & Yamada, N. Structural investigation of GeSb2Te4: A high-speed phase-change material. Phys. Rev. B 69, 104111 (2004).

Park, Y. J., Lee, J. Y. & Kim, Y. T. In situ transmission electron microscopy study of the nucleation and grain growth of Ge2Sb2Te5 thin film. Appl. Surf. Sci. 252, 8102–8106 (2006).

Fons, P. et al. Photoassisted amorphization of the phase-change memory alloy Ge2Sb2Te5 . Phys. Rev. B 82, 041203(R) (2010).

Li, X. B. et al. Role of Electronic Excitation in the Amorphization of Ge-Sb-Te Alloys. Phys. Rev. Lett. 107, 015501 (2011).

Kohn, W. & Sham, L. J. Self-Consistent Equations Including Exchange and Correlation Effects. Phys. Rev. 140(4A), A1133–A1138 (1965).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Nosé, S. Constant Temperature Molecular Dynamics Methods. Prog. Theor. Phys. Suppl. 103, 1–46 (1991).

Njoroge, W. K., Wöltgens, H.-W. & Wuttig, M. Density changes upon crystallization of Ge2Sb2.04Te4.74 films. J. Vac. Sci. Technol. A. 20, 230–233 (2002).

Acknowledgements

We thank Qingsong Deng and Xuechao Sha for FIB samples preparation. B.Z., Y.J.C. and X.D.H acknowledge National Key Basic Research Program of China, (No. 2013CBA01900); Key Project of National Natural Science Foundation of China, (No. 11234011); Beijing High-level Talents (No. PHR20100503), the Beijing PXM201101420409000053 and National/Beijing 211 projects. X.-P.W. and X.B.L acknowledge the supporting from the National Natural Science Foundation of China (No. 11374119) and the High Performance Computing Center (HPCC) at Jilin University for calculation resources. S.B.Z acknowledges the support by US Department of Energy (DOE) under the Grant (No. DE-SC0002623). C.S.W. and J.-X.Z. acknowledge the supporting by the Opening Project of State Key Laboratory of High Performance Ceramics and Superfine Microstructure, Shanghai Institute of Ceramics, Chinese Academy of Sciences (Grant No. SKL201407SIC).

Author information

Authors and Affiliations

Contributions

The in-situ TEM measurements were performed by B.Z. and Y.-J.C., while the HAADF-STEM as well as EDX mapping experiments were performed mostly by B.Z. and Z.-J.S. with the help of J.-X.L. and Z.Z. The image processing was conducted by B.Z. Data analyses done by B.Z., X.-D.H. and Y.-J.C. The PLD-GeSbTe samples were provided J.-X.Z. and C.-S.W. DFT simulations were done by X.-P.W., X.-B.L. and S.-B.Z. The paper was written by B.Z., X.-P.W., X.-B.L. and X.-D.H. with the help of S.-B.Z. The project was initiated by X.-D.H., X.-B.L. and S.-B.Z. All authors participated in discussions.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhang, B., Wang, XP., Shen, ZJ. et al. Vacancy Structures and Melting Behavior in Rock-Salt GeSbTe. Sci Rep 6, 25453 (2016). https://doi.org/10.1038/srep25453

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep25453

This article is cited by

-

Direct atomic identification of cation migration induced gradual cubic-to-hexagonal phase transition in Ge2Sb2Te5

Communications Chemistry (2019)

-

Active-Tuning and Polarization-Independent Absorber and Sensor in the Infrared Region Based on the Phase Change Material of Ge2Sb2Te5 (GST)

Scientific Reports (2018)

-

Surface Energy Driven Cubic-to-Hexagonal Grain Growth of Ge2Sb2Te5 Thin Film

Scientific Reports (2017)

-

Role of interfaces on the stability and electrical properties of Ge2Sb2Te5 crystalline structures

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.