Abstract

It is shown that all heat effects taking place upon annealing of a metallic glass within the glassy and supercooled liquid states, i.e. heat release below the glass transition temperature and heat absorption above it, as well as crystallization-induced heat release, are related to the macroscopic shear elasticity. The underlying physical reason can be understood as relaxation in the system of interstitialcy-type ”defects” (elastic dipoles) frozen-in from the melt upon glass production.

Similar content being viewed by others

Introduction

The basic feature of all glasses consists in thermal effects occurring upon heating. In general, these effects appear as i) heat release below the glass transition temperature Tg, ii) heat absorption above Tg and iii) crystallization-induced heat release1,2,3,4,5. In the literature, these effects are discussed mostly from the phenomenological viewpoint while their physical nature remains elusive for all types of glasses. It is not even known whether the heat effects occurring within the glassy state and those taking place upon crystallization are determined by the same mechanism or not. In this paper, the origin of heat effects is considered using experimental data taken on a typical Zr-based metallic glass.

A well known interpretation of heat effects in metallic glasses is based on the free volume notion, which states that a change of the “free volume” below or above Tg (within the non-crystalline state) yields release or absorption of the internal energy6,7. However, this hypothesis provides only qualitative interpretation of calorimetric data7,8 and was repeatedly criticized (e.g. ref. 9). Recently, rather clear evidence was obtained that the heat release and heat absorption in metallic glasses below the crystallization onset temperature are determined by the macroscopic shear elasticity, which is probed by measurements of the shear modulus10,11,12,13. The underlying physical reason can be understood as relaxation in the system of dumbbell interstitial-type “defects”, which can be treated as elastic dipoles. Here we first show for a typical Zr-based glass that the same conclusion applies for the largest thermal effect—crystallization-induced heat release and, therefore, all thermal phenomena are determined by shear modulus relaxation. Thus, our study outlines a new promising approach for the understanding of thermal effects and nature of “defects” in glasses.

The general idea that the unrelaxed shear modulus G (i.e. G measured during the time much smaller than the characteristic time of structural relaxation) represents the key physical quantity controlling the relaxation kinetics of supercooled liquids and glasses was introduced long ago14 and now becomes more and more accepted15,16,17,18. The reason consists in the basic understanding that elementary atomic rearrangements take place during the time of about inverse Debye frequency so that the reaction of the surrounding structure is purely elastic and, therefore, controlled by the unrelaxed shear modulus. The activation energy for these rearrangements then becomes proportional to G14,15,16,17. Besides that, the unrelaxed shear modulus constitutes a thermodynamic parameter because it is defined as the second derivative of the free energy with respect to the shear strain19.

Meanwhile, the instantaneous shear modulus is the key physical quantity in the Interstitialcy theory proposed by Granato20,21. The theory was inspired by the observation22 that dumbbell (split) interstitials (=interstitialcies) introduced into copper by soft neutron irradiation at low temperatures lead to a strong decrease of the shear modulus so that a hypothetical defect concentration of 2–3% should provide a vanishing G, which is a signature of liquid23. To date, it is generally accepted that dumbbell interstitials exist in all main crystalline structures and represent the basic state of interstitials in metals24,25,26. It was suggested that melting of simple metallic crystals takes place through rapid multiplication of interstitialcy defects20,21,27, which retain their individuality in the liquid state28. Subsequent melt quenching freezes the defects in solid glass, which become inherent structural elements rather than “defects” of the structure. Then, structural relaxation of glass can be interpreted in terms of the change of interstitialcy “defect” concentration. This hypothesis leads to rather numerous successful interpretations of various relaxation phenomena in metallic glasses at different conditions (for a review, see ref. 29 and papers cited therein).

In particular, the interstitialcy formation enthalpy H is proportional to the shear modulus, H = αΩG, (Ω is the volume per atom, the invariant of interstitialcy elastic strain field α30 is assumed to be close to unity20,21,27) and, therefore, any change of the “defect” concentration should lead to heat release or heat absorption depending on the sign of “defect” concentration change. This can be precisely monitored by measurements of the shear modulus because the latter is exponentially dependent on the “defect” concentration c, i.e.20,21

where Gx is the shear modulus of the maternal crystalline state (reference crystal thereafter, i.e. the one, which was used for glass production), β is the dimensionless shear susceptibility20,21 and α is the same as in the above expression for the interstitialcy formation enthalpy. The quantity β is defined as negative ratio of the 4th-order shear modulus to the 2nd-order shear modulus20,21,30 (the latter is commonly referred to as simply “shear modulus”). Experimental investigations on different metallic glasses show10,11,12,13,29 that β-values are about 17–20, depending on chemical composition. Analytically, the heat flow (heat per unit time and unit mass) due to a change of the “defect” concentration within the framework of this approach is given as10

where Grt and  are the shear moduli of glass and reference crystal at room temperature, respectively,

are the shear moduli of glass and reference crystal at room temperature, respectively,  is the heating rate and ρ is the density. According to Eq. (1), the ratio

is the heating rate and ρ is the density. According to Eq. (1), the ratio  in the relationship (2) defines room-temperature concentration crt of “defects” frozen-in upon glass production as

in the relationship (2) defines room-temperature concentration crt of “defects” frozen-in upon glass production as  . If the melt is quenched to another temperature, this ratio must be taken for this temperature.

. If the melt is quenched to another temperature, this ratio must be taken for this temperature.

It was shown that Eq. (2) gives a good description of the heat release below Tg as well as the heat absorption in the Tg-region for several metallic glasses10,11,12,13,29. However, an issue of major importance is the lack of understanding whether this equation can be also applied to the most pronounced thermal effect in metallic glasses—heat release occurring upon crystallization. There is only a general expectation for that and theoretical estimates30,31,32 implying that since the interstitialcy “defect” concentration is decreasing upon crystallization, the enthalpy related them will be also released and, therefore, Eq. (2) may be valid.

The experimental verification of this hypothesis poses a problem, which essentially lies in shear modulus measurements near and above the crystallization onset temperature Tx and, if such measurements are possible, in their quality. Indeed, Eq. (2) shows that calculations of the heat flow require very precise input G-data because W is determined by the difference between two derivatives of the shear moduli G and Gx with respect to temperature. In the experiments mentioned above10,11,12,13, the error of precise G-measurements rapidly increases at high temperatures due to the exponential growth of the internal friction and related exponential decrease of the shear viscosity that makes automatic measurements at temperatures slightly above Tg eventually impossible. We solved this problem (see below) and performed high precision shear modulus measurements on a typical Zr-based metallic glass not only far above Tg but also in the whole crystallization range. We found that Eq. (2) provides a very good description of all thermal effects—heat release below Tg, heat absorption in the Tg-region due to structural relaxation and, which is most important, heat release upon crystallization. The results suggest that all heat effects have common structural origin, which can be understood as a change of the concentration of interstitialcy-type “defects” (elastic dipoles).

Results

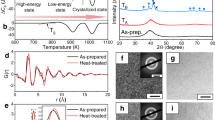

Figure 1 shows temperature dependences of the shear modulus of this glass in the initial state and after full crystallization at Ta = 890 K together with the corresponding internal friction data taken at a rate of 3 K/min. The shear modulus of the initial sample first linearly decreases with temperature due to the anharmonicity up to ≈500 K while at higher temperatures there is an upward change of G (i.e. above the dotted line) due to structural relaxation, which is accompanied by heat release (see Fig. 2 below). At about calorimetric  K (shown by the arrow), G starts to rapidly decrease, which is common to metallic glasses10,13,29. Crystallization begins at Tx ≈ 726 K leading to a very fast increase of the shear modulus by 24.4%. The internal friction Q−1 of the initial sample increases very rapidly at T > 600 K, reaches the maximum at T ≈ Tx, abruptly falls down next and runs up to the second maximum after that. The second Q−1 peak at ≈810 K clearly indicates the phase transition in the crystalline state, which, however, results in minor changes of the shear modulus. It is to be noticed that Q−1 near Tx is several times smaller than that in other metallic glasses at similar frequencies13. It is the relatively low internal friction as well as the high viscosity, which allow performing measurements far above Tg and in the whole crystallization range.

K (shown by the arrow), G starts to rapidly decrease, which is common to metallic glasses10,13,29. Crystallization begins at Tx ≈ 726 K leading to a very fast increase of the shear modulus by 24.4%. The internal friction Q−1 of the initial sample increases very rapidly at T > 600 K, reaches the maximum at T ≈ Tx, abruptly falls down next and runs up to the second maximum after that. The second Q−1 peak at ≈810 K clearly indicates the phase transition in the crystalline state, which, however, results in minor changes of the shear modulus. It is to be noticed that Q−1 near Tx is several times smaller than that in other metallic glasses at similar frequencies13. It is the relatively low internal friction as well as the high viscosity, which allow performing measurements far above Tg and in the whole crystallization range.

Shear modulus data for the initial state (red circles) and after crystallization (blue triangles) at Ta = 890 K are shown. The calorimetric glass transition temperature Tg and crystallization onset temperature Tx are indicated by the arrows. Structural relaxation-induced shear modulus increase at temperatures T > 500 K and shear softening in the range Tg < T < Tx as well as strong crystallization-induced increase of G at T > Tx constitute the basic features of the elastic shear behavior of metallic glasses. The two internal friction peaks reflect the two stages of glass crystallization.

It is seen that Eq. (2) gives a very good reproduction of all basic thermal effects—structural relaxation-induced heat release below Tg, heat absorption above Tg and the first crystallization-induced heat release above Tx. According to Eq. (2), these heat effects are controlled by relaxation of the shear modulus. The underlying physical reason can be understood as relaxation in the system of internal “defects”, which can be identified as dumbbell interstitials or elastic dipoles.

The solid red curve in Fig. 2 gives the experimental heat flow obtained by DSC for the same glass at the same heating rate. A significant structural relaxation-induced heat release corresponding to the increase of the shear modulus is clearly observed in the same range of 500 K < T < 660 K (see left inset). The heat flow gradually transforms into heat absorption above Tg and finally leads to a big crystallization heat release peak above Tx, which is typical of metallic glasses4,5.

Figure 3 shows temperature dependencies of the temperature derivative of the shear modulus in the initial state taken with the opposite sign (−dG/dT) and temperature derivative of the shear modulus after crystallization (dGx/dT). While dGx/dT is almost temperature independent, one can point out a close correlation between −dG/dT and experimental heat flow curve given in Fig. 2.

It is seen that while dGx/dT is nearly constant, −dG/dT clearly correlates with the heat flow shown in Fig. 2.

Thus, both terms in Eq. (2) are now available and one can use them to calculate the heat flow. This is done in Fig. 2, which gives W(T)-curve calculated using Eq.(2) with ρ = 7021 kg/m3,  K/min, G(T), Gx(T)-dependences shown in Fig. 1 and the shear susceptibility β = 18 determined as the least-square fit to the experimental heat flow curve. It is to be noticed that this β-value is quite close to the shear susceptibilities determined for other metallic glasses10,11,12,13. Figure 2 convincingly demonstrates that Eq. (2) gives an excellent description of the experimental heat release below Tg, heat absorption above Tg and crystallization-induced heat release. In particular, the height and temperature of crystallization heat release peak coincide with the experiment within less than 10% and ≈3 K, respectively. The calculation also roughly reproduces the heat release upon 2nd stage of crystallization at about 820 K (right inset in Fig. 2), but the agreement with the experiment is worse.

K/min, G(T), Gx(T)-dependences shown in Fig. 1 and the shear susceptibility β = 18 determined as the least-square fit to the experimental heat flow curve. It is to be noticed that this β-value is quite close to the shear susceptibilities determined for other metallic glasses10,11,12,13. Figure 2 convincingly demonstrates that Eq. (2) gives an excellent description of the experimental heat release below Tg, heat absorption above Tg and crystallization-induced heat release. In particular, the height and temperature of crystallization heat release peak coincide with the experiment within less than 10% and ≈3 K, respectively. The calculation also roughly reproduces the heat release upon 2nd stage of crystallization at about 820 K (right inset in Fig. 2), but the agreement with the experiment is worse.

Discussion

Our experiment conclusively shows that there is a fundamental relationship of the heat flow of a Zr-based metallic glass in the initial state with the shear moduli and their temperature derivatives of this glass in the amorphous and crystalline states. The excellent fit of Eq. (2) to the experimental heat flow (excluding the 2nd crystallization peak) provides support that the heat effects due to both structural relaxation and crystallization of glass are intrinsically connected with the relaxation in the system of frozen-in dumbbell interstitial-type “defects”. Heat release below Tg is then conditioned by a decrease of the “defect” concentration (manifested by the increase of the shear modulus)10,29 while the heat absorption above Tg in the supercooled liquid state can be considered as a result of the increase of the “defect” concentration (revealed as shear softening) towards the metastable equilibrium29.

On the other hand, interstitialcy defects represent a particular case of “elastic dipoles”—atomic configurations with the local symmetry, which is lower than that of surrounding matrix33. Elastic dipoles interact with external stress and define certain amount of frozen-in elastic energy. Crystallization of glass leads to a decrease of the “defect” concentration and corresponding release of their formation enthalpy. Accepting that dumbbell interstitials are in fact elastic dipoles, one can calculate the kinetics of heat flow due to dissipation of their elastic energy30,34. This approach (see Eq. (13) in ref. 34) describes structural relaxation- and crystallization-induced heat effects shown in Fig. 2 equally good if compared with Eq. (2). This confirms that dumbbell interstitials can be indeed considered as elastic dipoles and the observed thermal effects are due to the dissipation of their stored elastic energy. The major decrease of the concentration of elastic dipoles takes place during the first crystallization stage explaining the most pronounced exothermal heat reaction. Since a only small part of “defects” remains in the structure after that, rather poor correspondence between calculated and experimental heat flow data for the 2nd crystallization stage is quite understandable.

It is worthy of notice that the heat flow given by Eq. (2) can be presented in another useful form. The difference between the enthalpies of glass and reference crystal is given as

where Wg is the heat flow from glass and the heat flow from crystal Wx can be considered as a constant according to the Dulong-Petit law. At room temperature T rt and slightly above it, structural relaxation is absent and the heat flow from glass equals to that from crystal so that Wg − Wx = 0. This is actually seen in the inset of Fig. 2 and for the glass under consideration takes place in the range T rt ≤ T < 480 K. The underlying physical reason consists in the equality of the heat capacities of glass and reference crystal in the temperature range with no structural relaxation (e.g. refs 35,36). At higher temperatures, the difference Wg − Wx equals to the heat flow due to a change of the “defect” concentration as given by Eq.(2). Then, Equation (3) after integration from Trt to a current temperature T can be rewritten as

where V is the volume and ΔGx, ΔG are the changes of the corresponding shear moduli due to heating from Trt to T. Equation (4) explicitly shows that the difference between the enthalpies of glass and reference crystal is conditioned by i) room-temperature shear moduli of the initial glass and reference crystal and ii) changes of these moduli taking place upon heating. While the change of the shear modulus of crystal is solely of anharmonic nature, the change of the shear modulus of glass includes both anharmonic and relaxation components (this is actually clearly seen in Fig. 1). Since temperature coefficients of the shear moduli of glass and reference crystal in the absence of structural relaxation are equal37, the corresponding anharmonic shear modulus changes are also equal. The relaxation contribution into the shear modulus of glass is determined by a change of the concentration of frozen-in interstialcy “defects” (elastic dipoles), which is given by Eq. (1) (see also ref. 29 and papers cited therein).

Overall, the simple relationship (4) clearly indicates the relationship of heat effects in metallic glasses with the macroscopic shear elasticity of glass and reference crystal. However, anharmonic components of the shear moduli of glass and crystal have to be considered only in order to provide a correct calculation of the “defect” concentration c upon changing the temperature (since the shear modulus of glass in Eq. (1) is temperature dependent not only because of relaxation change of c but also due to temperature change of Gx) and the heat effects considered above are conditioned solely by the relaxation change of the “defect” concentration. The fact that Eq. (2) correctly describes all heat effects including those occurring upon crystallization provides new evidence that the difference between the internal energies of glass and reference crystal is determined mainly by the elastic strain fields of interstitialcy “defects” (elastic dipoles), which relax both during structural relaxation and crystallization of glass, as suggested earlier30,31.

In summary, all three thermal effects in the metallic glass under investigation—structural relaxation-induced heat release below Tg, heat absorption above Tg as well as crystallization-induced heat release—are related with the changes of the shear moduli of glass and reference crystal, which take place upon heating. The underlying physical reason can be understood as thermoactivated relaxation in the system of interstitialcy-type “defects”, which behave as elastic dipoles frozen-in upon glass production.

Methods

Glassy Zr46Cu45Al7Ti2 (at.%) under investigation was prepared by melt suction and X-ray checked to be entirely amorphous. Differential scanning calorimetry (DSC) was performed using a Perkin Elmer DSC 8000 instrument in flowing Ar atmosphere. Measurements of the heat flow were done for initial glassy and crystallized states. To remove the uncertainties related with the baseline of the DSC instrument, the heat flow of crystallized sample was subtracted from the heat flow of initial glassy sample.

Shear modulus measurements were carried out by the electromagnetic acoustic transformation (EMAT) method, which is based on the Lorentz interaction of surface currents in a metallic sample induced by the exciting coil with the external magnetic field10. The basic advantage of this method consists in the absence of direct acoustic contact between the sample and exciting/signal coils. The transverse resonant vibration frequency f (about 450–550 kHz depending on heat treatment) of sample (5 × 5 × 2 mm3) was determined as the frequency corresponding to the maximum of the shear vibration amplitude upon frequency scanning. The latter was automatically performed every 10–30 s depending on temperature. The shear modulus was calculated as  , where G0 = 33.61 GPa38 is the shear modulus at room temperature and

, where G0 = 33.61 GPa38 is the shear modulus at room temperature and  is the change of the shear modulus with f0 being the resonant frequency at room temperature. The relative error in the calculation of absolute shear modulus is estimated to be ≈5 × 10−3 while the relative error for the shear modulus change is unprecedented—from ≈5 ppm at temperatures far below Tg to about 100 ppm at high temperatures far above Tg. The internal friction was calculated as

is the change of the shear modulus with f0 being the resonant frequency at room temperature. The relative error in the calculation of absolute shear modulus is estimated to be ≈5 × 10−3 while the relative error for the shear modulus change is unprecedented—from ≈5 ppm at temperatures far below Tg to about 100 ppm at high temperatures far above Tg. The internal friction was calculated as  , where f1 and f2 were determined upon scanning as the frequencies corresponding to the vibration amplitude equal to 0.707 × Ar with Ar being the resonant vibration amplitude33. In order to perform precise measurements at high internal friction (i.e. deep in the supercooled liquid state far above Tg as well as in the crystallization range), we carried out an extensive modification of the setup. The measurements were carried out in vacuum of about 0.013 Pa.

, where f1 and f2 were determined upon scanning as the frequencies corresponding to the vibration amplitude equal to 0.707 × Ar with Ar being the resonant vibration amplitude33. In order to perform precise measurements at high internal friction (i.e. deep in the supercooled liquid state far above Tg as well as in the crystallization range), we carried out an extensive modification of the setup. The measurements were carried out in vacuum of about 0.013 Pa.

The main problem consisted in the choice of glass for the experiment. We tested quite a few Pd- and Zr-based metallic glasses and found that most of them are unsuitable for precise automatic G-measurements because of the high internal friction and low shear viscosity (the latter sometimes leads to a change of sample’s dimensions even under the action of its own weight) above Tg, which eventually result in the loss of signal tracking. The situation becomes slightly better upon using low heating rates, which lead to a decrease of the internal friction and increase of the shear viscosity. However, low heating rates strongly promote oxidation of small samples (tens of milligrams) during DSC measurements even at increased Ar flow rate and while applying other efforts for preventing oxidation (oxidation of bulk samples during shear modulus measurements is not significant). Samples’ oxidation heavily corrupts DSC thermograms complicating their comparison with calculated heat flow from G-data using Eq. (2). Eventually, after a number of trials-and-errors, we ended up with Zr46Cu45Al7Ti2 glass, which combines low Q−1 and high viscosity above Tg together with relatively low oxidation propensity.

Additional Information

How to cite this article: Mitrofanov, Y. P. et al. Towards understanding of heat effects in metallic glasses on the basis of macroscopic shear elasticity. Sci. Rep. 6, 23026; doi: 10.1038/srep23026 (2016).

References

Elliott, S. R. Physics of Amorphous Materials (Longman, London, New York, 1984).

Hodge, I. M. Enthalpy relaxation and recovery in amorphous materials. J. Non-Cryst. Sol. 169, 211–266 (1994).

Schmelzer, J. W. P. & Gutzow, I. S. Glasses and the Glass Transition (Wiley-VCH, Weinheim, 2011).

Suryanarayana, C. & Inoue, A. Bulk Metallic Glasses (CRC Press, Boca Raton, London, New York, 2011).

Greer, A. L. Metallic glasses. In Physical Metallurgy Vol. I, Laughlin, D. E., Hono, K. Eds. 305–385 (Elsevier, Oxford, 2014).

Van den Beukel, A. & Sietsma, J. The glass transition as a free volume related kinetic phenomenon. Acta Metall. Mater. 38, 383–389 (1990).

Slipenyuk, A. & Eckert, J. Correlation between enthalpy change and free volume reduction during structural relaxation of Zr55Cu30Al10Ni5 metallic glass. Scr. Mater. 50, 39–44 (2004).

Zhang, Y. & Hahn, H. Quantication of the free volume in Zr 45.0 Cu 39.3 Al 7.0 Ag 8.7 bulk metallic glasses subjected to plastic deformation by calorimetric and dilatometric measurements. J. Alloys Comp. 488, 65–71 (2009).

Cheng, Q. & Ma, E. Indicators of internal structural states for metallic glasses: Local order, free volume, and configurational potential energy. Appl. Phys. Lett. 93, 051910 (2008).

Mitrofanov, Yu. P. et al. On the nature of enthalpy relaxation below and above the glass transition of metallic glasses. Appl. Phys. Lett. 101, 191903 (2012).

Makarov, A. S., Khonik, V. A., Mitrofanov, Yu. P., Granato, A. V. & Joncich, D. M. Determination of the susceptibility of the shear modulus to the defect concentration in a metallic glass. J. Non-Cryst. Sol. 370, 18–20 (2013).

Makarov, A. S., Khonik, V. A., Wilde, G., Mitrofanov, Yu.P. & Khonik, S.V. “Defect”-induced heat flow and shear modulus relaxation in a metallic glass. Intermetallics 44, 106–109 (2014).

Tsyplakov, A. N., Mitrofanov, Yu.P., Khonik, V. A., Kobelev, N. P. & Kaloyan, A. A. Relationship between the heat flow and relaxation of the shear modulus in bulk PdCuP metallic glass. J. Alloys Comp. 618, 449–454 (2015).

Nemilov, S. V. The kinetics of elementary processes in the condensed state. II. Shear relaxation and the equation of state for solids. Zh. Fiz. Khim. (Russ. J. Phys. Chem.) 42, 1391–1396 (1968).

Dyre, J. C., Olsen, N. B. & Christensen, T. Local elastic expansion model for viscous-flow activation energies of glass-forming molecular liquids. Phys. Rev. B 53, 2171–2174 (1996).

Nemilov, S. V. Interrelation between shear modulus and the molecular parameters of viscous flow for glass forming liquids. J. Non-Cryst. Sol. 352, 2715–2725 (2006).

Dyre, J. C. The glass transition and elastic models of glass-forming liquids. Rev. Mod. Phys. 78, 953–972 (2006).

Wang, W. H. The elastic properties, elastic models and elastic perspectives of metallic glasses. Prog. Mater. Sci. 57 487–656 (2012).

Landau, L. D. & Lifshitz, E. M. Theory of Elasticity (Pergamon Press, Oxford, 1970).

Granato, A. V. Interstitialcy model for condensed matter states of face-centered-cubic metals. Phys. Rev. Lett. 68, 974–977 (1992).

Granato, A. V. Interstitialcy theory of simple condensed matter. Eur. Phys. J. B 87, 18 (2014).

Holder, J., Granato, A. V. & Rehn, L. E. Effect of self-interstitials and close pairs on the elastic constants of copper. Phys. Rev. B 10, 363–375 (1974).

Born, M. Thermodynamics of crystals and melting. J. Chem. Phys. 7, 591–603 (1939).

Schilling, W. Self-interstitial atoms in metals. J. Nucl. Mater. 69–70, 465–489 (1978).

Robrock, K. H. Mechanical Relaxation of Interstitials in Irradiated Metals (Springer-Verlag, Berlin, 1990).

Wolfer, W. G. Fundamental properties of defects in metals. In Comprehensive Nuclear Materials Konings, R. J. M. Ed. (Elsevier, Amsterdam, 2012).

Granato, A. V., Joncich, D. M. & Khonik, V. A. Melting, thermal expansion, and the Lindemann rule for elemental substances. Appl. Phys. Lett. 97, 171911 (2010).

Nordlund, K., Ashkenazy, Y., Averback, R. S. & Granato, A. V. Strings and interstitials in liquids, glasses and crystals. Europhys. Lett. 71, 625–631 (2005).

Khonik, V. A. Understanding of the structural relaxation of metallic glasses within the framework of the Interstitialcy theory. Metals 5, 504–529 (2015).

Kobelev, N. P. & Khonik, V. A. Theoretical analysis of the interconnection between the shear elasticity and heat effects in metallic glasses. J. Non-Cryst. Sol. 427, 184–190 (2015).

Kobelev, N. P., Khonik, V. A., Afonin, G. V. & Kolyvanov, E. L. On the origin of the shear modulus change and heat release upon crystallization of metallic glasses. J. Non-Cryst. Sol. 411, 1–4 (2015).

Kobelev, N. P., Khonik, V. A. & Afonin, G. V. Thermal and elastic effects upon crystallization of the metallic glass Pd40Cu30Ni10P20 . Phys. Sol. State (Pleiades Publishing) 57, 1715–1718 (2015).

Nowick, A. S. & Berry, B. S. Anelastic Relaxation in Crystalline Solids (Academic Press, New York, London, 1972).

Kobelev, N. P., Khonik, V. A., Makarov, A. S., Afonin, G. V. & Mitrofanov, Yu. P. On the nature of heat effects and shear modulus softening in metallic glasses: a generalized approach. J. Appl. Phys. 115, 033513 (2014).

Bünz, J. & Wilde, G. Direct measurement of the kinetics of volume and enthalpy relaxation of an Au-based bulk metallic glass. J. Appl. Phys. 114, 223503 (2013).

Evenson, Z. & Busch, R. Equilibrium viscosity, enthalpy recovery and free volume relaxation in a Zr 44 Ti 11 Ni 10 Cu 10 Be 25 bulk metallic glass. Acta Mater. 59, 4404–4415 (2011).

Makarov, A. S. et al. Interrelationship between the shear modulus of a metallic glass, concentration of frozen-in defects, and shear modulus of the parent crystal. Appl. Phys. Lett. 102, 091908 (2013).

Wang, D. P. et al. Understanding the correlations between Poisson’s ratio and plasticity based on microscopic flow units in metallic glasses. J. Appl. Phys. 115, 123507 (2014).

Acknowledgements

The work was supported by the Ministry of Education and Science of Russian Federation (project 3.114.2014/K). V.A.K. is grateful to Dr. N.P. Kobelev (Institute for Solid State Physics, Russian Academy Sciences) for fruitful cooperation. Yu.P.M. and A.S.M. are grateful to Dr. R.A. Konchakov and Dr. G.V. Afonin (Voronezh State Pedagogical University) for their kind help. W.H.W. acknowledges the support of the NSF of China (Grant No. 51271195) and MOST 973 (No. 2015CB856800).

Author information

Authors and Affiliations

Contributions

Y.P. and A.S. performed shear modulus experiments, D.P. prepared the samples and carried out DSC measurements. All authors discussed the results and commented on the study. W.H. and V.A. prepared the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Mitrofanov, Y., Wang, D., Makarov, A. et al. Towards understanding of heat effects in metallic glasses on the basis of macroscopic shear elasticity. Sci Rep 6, 23026 (2016). https://doi.org/10.1038/srep23026

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep23026

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.