Abstract

To realize a high-temperature capacitor, uniaxially (001)-oriented CaBi4Ti4O15 films with various film thicknesses were prepared on (100)cSrRuO3/Ca2Nb3O10− nanosheet/glass substrates. As the film thickness decreases to 50 nm, the out-of-plane lattice parameters decrease while the in-plane lattice ones increase due to the in-plane tensile strain. However, the relative dielectric constant (εr) at room temperature exhibits a negligible degradation as the film thickness decreases to 50 nm, suggesting that εr of (001)-oriented CaBi4Ti4O15 is less sensitive to the residual strain. The capacitance density increases monotonously with decreasing film thickness, reaching a value of 4.5 μF/cm2 for a 50-nm-thick nanofilm and is stable against temperature changes from room temperature to 400 °C irrespective of film thickness. This behaviour differs from that of the widely investigated perovskite-structured dielectrics. These results show that (001)-oriented CaBi4Ti4O15 films derived using Ca2Nb3O10− nanosheets as seed layers can be made candidates for high-temperature capacitor applications by a small change in the dielectric properties against film thickness and temperature variations.

Similar content being viewed by others

Introduction

The demand is increasing for capacitors that can function at elevated temperatures in electronic circuits in automobiles, power devices and light-emitting diodes1,2,3,4. One of the most promising candidates is a ceramic capacitor due to its thermal stability. Recently, various approaches have been used to improve the performance of ceramic capacitors, including the preparation of thin-film capacitors composed of inorganic dielectrics such as perovskite-structured oxides. Although (Ba, Sr)TiO3-based dielectrics, which have a high dielectric constant (εr) near room temperature, are the most widely investigated ceramic capacitor materials5,6,7, they are not suitable for high-temperature capacitor applications due to their temperature instability within the required temperature range (i.e., εr changes drastically around the phase transition temperature). Consequently, they cannot achieve high εr and a small-temperature dependence of the capacitance simultaneously due to the trade-off relationship5,7.

In addition, the εr of thin-film capacitors produced using (Ba, Sr)TiO3-based materials as the dielectric layer is severely degraded as the film thickness decreases, making it difficult to enhance the capacitance density by decreasing the film thickness8,9,10. One possible reason for this sensitivity to film thickness may be the high strain sensitivity of εr, which remains as the film thickness decreases. These phenomena are common material problems for conventional perovskite dielectrics, suggesting that another novel capacitor material is necessary.

To realize novel dielectrics with a large capacitance density and small change in εr at elevated temperatures, we previously proposed bismuth layer-structured dielectrics (BLSDs)11. BLSDs have a natural superlattice structure along the c-axis [(001)-orientation], which consists of two kinds of two-dimensional monolayers (i.e., a bismuth oxide (Bi2O2)2+ layer and a pseudoperovskite layer generally described as (Am−1BmO3m+1)2−, where m is the number of BO6 octahedra in the pseudoperovskite layer)12,13. Compared to BaTiO3-based materials, some BLSDs exhibit a high Curie temperature and their εr shows small temperature dependence along the stack direction (i.e., the c-axis) up to the high temperature region14,15,16. These materials also have important additional features in which the degradation in εr as the film thickness decreases is small (i.e., a small “size effect”), allowing a high capacitance density to be realized17. This behaviour showing the small strain sensitivity of εr, which is attributed to the structural two-dimensionality of BLSDs, differs from conventional perovskite-based dielectrics.

We have already investigated the dielectric properties of 500-nm-thick (001)-oriented epitaxial films of CaBi4Ti4O15, which are BLSDs prepared on (100)cSrRuO3/(100)SrTiO3. These films not only have an εr of about 190 at room temperature, but they also display a stable capacitance against the applied electric field as well as temperature variations up to 500 °C11. Moreover, the εr for epitaxial thin films of SrBi4Ti4O15, which is another BLSD, does not drastically degrade as the film thickness decreases to 15 nm17. These reports clearly show that the εr of thin-film capacitors of epitaxial BLSDs have a superior temperature-dependent performance compared to BaTiO3-based ones and may overcome issues observed in conventional BaTiO3-based materials in high-temperature applications.

However, the dielectric properties of BLSDs include a strong anisotropy due to the crystal structure of BLSDs16. In fact, our group has previously reported that the dependence of the film thickness on the dielectric property in BLSDs is strongly influenced by the tilting angle of the c-axis from the substrate normal18. Therefore, reproducible growth of (001)-oriented BLSDs films (i.e., the stack direction of the layers) is a critical issue to achieve a stable εr as both the film thickness and temperature decrease.

From the viewpoint of practical applications, reproducible fabrication of uniaxially (001)-oriented BLSDs films on various common substrates, including amorphous glasses and (100) Si wafers, is a critical issue for practical applications even if the in-plane orientation of these films is more random than that of epitaxial films. Shibata et al. reported the {100} orientation control of SrTiO3 films on amorphous glass using a seed layer of Ca2Nb3O10− nanosheets19. Based on their work, we envisioned that a Ca2Nb3O10− seed layer could control the (001) orientation of BLSD films because (001)-oriented BLSD films were grown on (100)SrTiO3 single crystals15.

In the present study, we sought to enhance the capacitance density of Pt/(001)-oriented CaBi4Ti4O15/(100)cSrRuO3 capacitors by decreasing the film thickness of the CaBi4Ti4O15 layer. This should allow the capacitor size to be scaled down or the total capacitance to be increased. In the case of (Ba, Sr)TiO3 film capacitors, εr is reported to change drastically not only with film thickness but also with temperature, which makes it difficult to design a capacitor with a small capacitance change over a wide temperature range8,9,10. For (001)-oriented CaBi4Ti4O15 films, the capacitance density reaches 4.5 μF/cm2 as the film thickness is decreased to 50 nm and the capacitance has a small temperature coefficient from room temperature to 400 °C despite the increase in the residual strain as the film thickness decreases. The present results indicate that nanosheet-buffered uniaxially (001)-oriented CaBi4Ti4O15 thin films are promising alternatives to (Ba, Sr)TiO3-based films in high temperature capacitors.

Results and discussion

Crystal structure and microstructure

The out-of-plane XRD θ–2θ patterns for CaBi4Ti4O15 films with various thicknesses show only the h00c and 00 l diffraction peaks of SrRuO3 and CaBi4Ti4O15 (Fig. 1(a)), respectively, suggesting a (001) single orientation of CaBi4Ti4O15 regardless of the film thickness. The X-ray pole figure measurement at a fixed 2θ angle corresponding to CaBi4Ti4O15 119 (2θ = 30.6°) shows strong ring-shape-peaks at Psi ≑ 50° for 780-nm-thick films (inset of Fig. 1(a)), indicating a uniaxial (001)-orientation along the substrate surface normal with an in-plane random orientation.

Out-of-plane XRD θ–2θ patterns of the films with various thicknesses in the region of (a) 2θ = 10–50° and (b) 2θ = 42–50° along with (c) the in-plane XRD θ–2θ patterns of the films in the region of 2θ = 45–48°. The inset in (a) shows the X-ray pole measured at a fixed 2θ angle corresponding to CaBi4Ti4O15 119 (2θ = 30.6°) for 780-nm-thick films.

Figure 1(b) presents the enlarged XRD patterns around the CaBi4Ti4O15 0020 peak in Fig. 1(a). The diffraction angles of the CaBi4Ti4O15 0020 peak become higher as the film thickness decreases, indicating that the c-axis lattice parameters along the substrate normal decrease. Moreover, the in-plane XRD patterns around CaBi4Ti4O15 220 are shown in Fig. 1(c). The CaBi4Ti4O15 220 peaks shift toward a lower diffraction angle with decreasing film thickness, suggesting an increase in the in-plane lattice parameter (i.e., the a(b)-axis).

Figure 2(a,b) plot the out-of-plane c-axis and in-plane a(b)-axis lattice parameters calculated from the diffraction data shown in Fig. 1(a–c) as functions of film thickness, respectively. Additionally, reference data for the CaBi4Ti4O15 powder are shown14. The in-plane XRD measurements confirm that clear peak splitting is not detected for the 200/020 peak irrespective of the film thickness because the lattice parameters of the a- and b-axes are very close in the CaBi4Ti4O15 crystal lattice (data not shown). The out-of-plane and in-plane lattice parameters for the 780-nm-thick film are almost the same as the reported data for strain-free CaBi4Ti4O15 powder. As the film thickness decreases, the out-of-plane c-axis lattice parameter decreases and drops drastically below 200 nm, whereas the in-plane a-axis and b-axis lattice parameters increase from 5.42 to 5.46 Å.

To analyse the change in the lattice parameter of CaBi4Ti4O15 films, Fig. 2(b) also plots the in-plane lattice parameter of the underlying SrRuO3 bottom electrodes obtained from Fig. 1(c) as well as the in-plane lattice parameter of the as-deposited SrRuO3 layer before CaBi4Ti4O15 film deposition along with the reference data of Ca2Nb3O10−20. The in-plane lattice parameter of CaBi4Ti4O15 for a 780-nm-thick film is almost equivalent to that of the CaBi4Ti4O15 powder, suggesting that the crystal lattice of the 780-nm-thick CaBi4Ti4O15 film is almost relaxed. Meanwhile, the in-plane lattice parameter of CaBi4Ti4O15 increases as the film thickness decreases. A similar trend is observed for the in-plane lattice parameters of SrRuO3. It should be noted that the in-plane lattice parameter of SrRuO3 is almost identical to that of the as-deposited 50-nm-thick SrRuO3 films before CaBi4Ti4O15 deposition but not to that of the Ca2Nb3O10− nanosheets (Fig. 2(b)) because the crystal lattice of the as-deposited SrRuO3 layer is not fully clamped on the lattice of the Ca2Nb3O10− nanosheets. CaBi4Ti4O15 also possesses a different in-plane lattice parameter from those of the SrRuO3 and Ca2Nb3O10 nanosheets, indicating that the change in the lattice parameter of CaBi4Ti4O15 films is not perfectly clamped by the crystal lattice of the underlying SrRuO3 electrode layer. The increase in the in-plane lattice parameter of the CaBi4Ti4O15 film (Fig. 2(b)) suggests that the in-plane residual strain of CaBi4Ti4O15 films increases as the film thickness decreases. The large in-plane lattice parameter of thin CaBi4Ti4O15 is considered to be a response to the larger lattice parameter of the underlying SrRuO3 layer, because the CaBi4Ti4O15 films are thinner than the 50 nm-thick SrRuO3 layer. Here, as-deposited SrRuO3 films have a larger unit cell than SrRuO3 powders, i.e., a larger in-plane strain, due to the damage occurring under the sputtering process using the present deposition conditions, as reported previously21,22. The in-plane lattice parameter of CaBi4Ti4O15 relaxed and approached the bulk value together with the SrRuO3 layer with the increase in the total thickness.

Figure 3(a,b) shows atomic force microscopy (AFM) topographic images of Ca2Nb3O10 nanosheets on glass substrates and CaBi4Ti4O15 films. Ca2Nb3O10 nanosheets have a flat surface with 1–2 units in thickness and 3–10 μm in-plane width. On the other hand, the lateral grain sizes of CaBi4Ti4O15 films are about 100 nm, which is smaller than the grain sizes of Ca2Nb3O10 nanosheets. Figure 3(c) shows the cross sectional low-angle annular dark field-scanning transmission electron microscope (LAADF-STEM) image of the films. Dense CaBi4Ti4O15 films are found to be deposited and their grain sizes look almost identical to those from AFM observations.

Dielectric property

Figure 4(a) shows the εr for the (001)-oriented CaBi4Ti4O15 films measured at room temperature and 100 kHz as functions of the film thickness. The εr of these films is approximately 210, which is a negligible degradation as the film thickness decreases to 50 nm. This is almost equivalent to the results for epitaxial films17. As a reference of εr, the εr values for (Ba0.7 Sr0.3)TiO3 films reported by Parker et al., which continuously degrade as the film thickness decreases below 600 nm, are also plotted in Fig. 4(a) 9. The εr value of (Ba0.7 Sr0.3)TiO3 films becomes smaller than that of CaBi4Ti4O15 with a film thickness below 80 nm, suggesting that a CaBi4Ti4O15 layer less than 80-nm thick achieves a thin-film capacitor with a higher capacitance density than the conventional (Ba0.7 Sr0.3)TiO3 one.

(a) Relative dielectric constant (εr) and (b) capacitance density measured at room temperature as functions of film thickness. (○: CaBi4Ti4O15; △: (Ba0.7 Sr0.3)TiO3 in ref. 9).

Figure 4(b) shows the capacitance density at room temperature as a function of film thickness, where the dashed line indicates the estimated data assuming that the CaBi4Ti4O15 film has an almost constant εr value (εr = 210, which is equivalent with that of the 780-nm-thick specimen) as the film thickness changes. The theoretical capacitance density is generally proportional to the inverse of the film thickness. The capacitance densities of the obtained (001)-oriented CaBi4Ti4O15 films are almost identical to the estimated values. As the film thickness decreases, the density increases and reaches a value of 4.5 μF/cm2 at a thickness of 50 nm.

It is noteworthy that εr remains almost constant despite the increase in the residual strain as the thickness is scaled down to 50-nm (Fig. 2). Thus, we confirm that εr of the (001)-oriented CaBi4Ti4O15 films is free from the size-effect of the capacitance. This is an important feature not only for epitaxial (001)-oriented BLSD films, as already mentioned, but also for uniaxially (001)-oriented ones.

Figure 5 shows the frequency dependencies of the capacitance density and dielectric loss, tan δ, measured from room temperature to 400 °C for 70 and 140 nm-thick CaBi4Ti4O15 films. The capacitance density is almost independent of the measurement frequency from 100 to 10 kHz irrespective of the measurement temperature up to 400 °C. On the other hand, tan δ decreases with increasing measurement frequency from 100 to 10 kHz, but increases again above 10 kHz for 70 nm thick films as shown in Fig. 5(a). The relatively large dielectric loss at low frequency may originate from the leakage of the capacitor. The tan δ value increases as the measurement temperature increases due to the contribution from leakage current. However, the tan δ of 140 nm thick films remains at a low value below 4%, almost independent of the frequency from 10 to 10 kHz, even at the highest measurement temperature of 400 °C, as shown in Fig. 5.

It must be mentioned that no noticeable peel-off of CaBi4Ti4O15 films was detected, either in the case of as-deposited films or in the case of films at the highest measurement temperatures of up to 400 °C irrespective of the film thickness.

Figure 6 plots the temperature dependence of the capacitance density and tan δ for (001)-oriented CaBi4Ti4O15 films with different thicknesses. The capacitance density of these films has a negative slope versus temperature, but shows a small temperature coefficient of capacitance (TCC, TCC ≡ , which is based on the definition of the Electronic Industries Alliance) in the temperature range from 25 to 400 °C regardless of film thickness down to 50 nm23. These TCC values fall within the range from −350 to −120 ppm/°C; this characteristic is almost equivalent to that of the epitaxial films in our previous work11. These results imply that uniaxially (001)-oriented CaBi4Ti4O15 films with an in-plane random crystal orientation have dielectric and insulating properties with a small temperature dependence similar to epitaxial films. The capacitance density increases with decreasing film thickness for all temperature regions (Fig. 6(a)). On the other hand, the tan δ value increases with the temperature due to the increase of the leakage current, as shown in Fig. 6(b). However, it decreases with increasing film thickness, especially if it is below 10% up to 400 °C for the films above 100 nm in thickness.

, which is based on the definition of the Electronic Industries Alliance) in the temperature range from 25 to 400 °C regardless of film thickness down to 50 nm23. These TCC values fall within the range from −350 to −120 ppm/°C; this characteristic is almost equivalent to that of the epitaxial films in our previous work11. These results imply that uniaxially (001)-oriented CaBi4Ti4O15 films with an in-plane random crystal orientation have dielectric and insulating properties with a small temperature dependence similar to epitaxial films. The capacitance density increases with decreasing film thickness for all temperature regions (Fig. 6(a)). On the other hand, the tan δ value increases with the temperature due to the increase of the leakage current, as shown in Fig. 6(b). However, it decreases with increasing film thickness, especially if it is below 10% up to 400 °C for the films above 100 nm in thickness.

To analyse the effect of thickness on the capacitance density at elevated temperatures, Fig. 7(a) compares the capacitance densities for (001)-oriented CaBi4Ti4O15 films measured between 150 °C and room temperature. The dashed line indicates the case without a degraded capacitance density up to 150 °C. The measured data are almost located on the dashed line, indicating a negligible difference in the capacitance change between these two temperatures. Figure 7(a) also plots the data for (Ba0.7 Sr0.3)TiO3 films as a reference; as the temperature increases to 150 °C, the capacitance density for thicker films drastically decreases and has a negative TCC value9. In addition, Fig. 7(b) compares the capacitance densities at 400 °C and room temperature. The measured data are also located for (001)-oriented CaBi4Ti4O15 films on the dashed line even at temperatures as high as 400 °C. The estimated degradations of the capacitance density from room temperature to 150 and 400 °C are 7% and 9% for 50-nm-thick CaBi4Ti4O15 films, respectively. Unlike conventionally investigated (Ba0.7 Sr0.3)TiO3 films where the capacitance decreases to 55% between room temperature and 150 °C, the capacitance density for uniaxially (001)-oriented CaBi4Ti4O15 films shows a small degradation as the temperature increases to 400 °C. These results suggest that (001)-oriented CaBi4Ti4O15 films produced using Ca2Nb3O10− nanosheet seed layers are novel candidates for high-temperature adaptive capacitor applications due to the superior temperature stability of their electric properties up to 400 °C along with their high capacitance density, which is derived from the small “size effect” upon scaling down the film thickness.

Relationships between the capacitance densities for the films measured at room temperature and (a) 150 °C and (b) 400 °C. (○: CaBi4Ti4O15; △: (Ba0.7 Sr0.3)TiO3 in ref. 9).

Summary

Uniaxially (001)-oriented CaBi4Ti4O15 films with various film thicknesses were prepared on (100)cSrRuO3/Ca2Nb3O10− nanosheets/glass substrates. All films exhibited a (001) single orientation along the substrate surface normal, but had a random in-plane orientation. The continuous increase in the residual tensile strain as the film thickness decreases leads to a reduction in the out-of-plane “c-axis” lattice parameters and an increase in the in-plane “a- and b-axes” ones. However, the change in εr is unremarkable as the film thickness decreases to 50 nm. Consequently, the monotonous increase in the capacitance density is proportional to the inverse of the film thickness. The capacitance densities of the obtained films show small TCC values up to a temperature of 400 °C and are almost independent of film thickness between 50 and 780 nm. By contrast, conventional (Ba, Sr)TiO3-based films do not exhibit these behaviours. These results indicate that uniaxially (001)-oriented CaBi4Ti4O15 thin films prepared on Ca2Nb3O10− nanosheet–buffered substrates have potential in high-temperature capacitor applications.

Methods

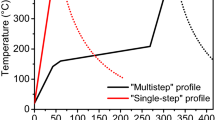

Uniaxially (001)-oriented CaBi4Ti4O15 films with various film thicknesses were prepared on (100)cSrRuO3/(Ca2Nb3O10− nanosheets)/glass substrates. The CaBi4Ti4O15 and about 50 nm-thick SrRuO3 layers were fabricated on (Ca2Nb3O10− nanosheets)/glass (Corning#1737) by the RF-magnetron sputtering method at substrate temperatures of 600 and 550 °C, respectively. The 1–2 unit-thick Ca2Nb3O10− nanosheet layers were coated onto glass substrates by the Langmuir-Blodgett process20,24,25. We chose CaBi4Ti4O15 as the dielectric layer because its high Curie temperature of 790 °C enables a small temperature dependence of the capacitance at elevated temperatures. The deposition time controlled the CaBi4Ti4O15 film thickness between 50 and 780 nm. Details of the deposition are described elsewhere11. After preparing circular Pt top electrodes (100 μmϕ) by electron-beam deposition, the Pt/CaBi4Ti4O15/SrRuO3 capacitors were annealed at 400 °C for 30 min under O2 gas flow.

The constituent phase and crystal orientation of the deposited films were identified by X-ray diffraction (XRD) using a Philips X’pert MRD with Cu Kα radiation. The residual strain state was also estimated by in-plane XRD measurements using a Rigaku Smart-lab diffractometer with Cu Kα radiation. The electrical properties under various temperatures were measured using an impedance analyser (HP4194A, Agilent) and a sample-heating stage.

Additional Information

How to cite this article: Kimura, J. et al. Thermally stable dielectric responses in uniaxially (001)-oriented CaBi4Ti4O15 nanofilms grown on a Ca2Nb3O10- nanosheet seed layer. Sci. Rep. 6, 20713; doi: 10.1038/srep20713 (2016).

References

Nishikawa, J., Hagiwara, T., Kobayashi, K., Mizuno, Y. & Kishi, H. Effect of microstructure on the Curie temperature in BaTiO3-Ho2O3-MgO-SiO2 . Jpn. J. Appl. Phys. 46, 6999–7004 (2007).

Simon, P. & Gogotsi, Y. Materials for electrochemical capacitors. Nature Mater. 7, 845–854 (2008).

Simon, P. & Gogotsi, Y. Capacitive energy storage in nanostructured carbon–electrolyte systems. Acc. Chem. Res. 46, 1094–1103 (2013).

Almeida, P. S., Soares, G. M., Pinto, D. P. & Braga, H. A. C. Integrated SEPIC buck-boost converter as an off-line LED driver without electrolytic capacitors. Proc. IECON 2012, 4551–4556 (2012).

Smolenskii, G. A. & Rozgachev, K. I. Dielectric properties of solid solutions in the system of barium titanate–strontium titanate. Zh. Tekh. Fiz. 24, 1751–1760 (1954).

Kang, D.–S., Han, M.–S., Lee, S.–G. & Song, S.–H. Dielectric and pyroelectric properties of barium strontium calcium titanate ceramics. J. Eur. Ceram. Soc. 23, 515–518 (2003).

Cockbain, A. G. & Harrop, P. J. The temperature coefficient of capacitance. J. Phys. D: Appl. Phys., 1, 1109–1115 (1968).

Huang, Y.-L., Lee, Y.-C., Tsai, D.-C., Yeh, Y.-Y. & Shieu, F.-S. A. Study of low-temperature sintering of (Ba0.6 Sr0.4)(Ti0.94 Cu0.06)O3 ceramics with B2O3 addition. Ferroelectrics 434, 147–156 (2012).

Parker, C. B., Maria, J.-P. & Kingon, A. I. Temperature and thickness dependent permittivity of (Ba, Sr)TiO3 thin films. Appl. Phys. Lett. 81, 340–342 (2002).

Lee, B. T. & Hwang, C. S. Influences of internal intrinsic low-dielectric layers on the dielectric properties of sputtered (Ba, Sr)TiO3 thin films. Appl. Phys. Lett. 77, 124–126 (2000).

Kimura, J. et al. Temperature and electric field stabilities of dielectric and insulating properties for c-axis-oriented CaBi4Ti4O15 films. J. Appl. Phys. 114, 027002-1-027002–7 (2013).

Aurivillius, B. Mixed bismuth oxides with layer lattice. 1. The structure type of CaNb2Bi2O9 . Ark. Kemi. 1, 463–480 (1949).

Aurivillius, B. Mixed Bismuth oxides with layer lattice. 1. The structure type of Bi4Ti3O12 . Ark. Kemi. 1, 499–512 (1949).

Kennedy, B. J., Zhou, Q., Ismunandar, Kubota, Y. & Kato, K. Cation disorder and phase transitions in the four-layer ferroelectric Aurivillius phases ABi4Ti4O15 (A=Ca, Sr, Ba, Pb). J. Solid State Chem. 181, 1377–1386 (2008).

Watanabe, T. & Funakubo, H. Controlled crystal growth of layered-perovskite thin films as an approach to study their basic properties. J. Appl. Phys. 100, 051602-1-051602–11 (2006).

Irie, H. & Miyayama, M. Dielectric and ferroelectric properties of SrBi4Ti4O15 single crystals. Appl. Phys. Lett. 79, 251–253 (2001).

Takahashi, K. et al. Thickness dependence of dielectric properties in bismuth layer-structured dielectrics. Appl. Phys. Lett. 89, 082901-1-082901–3 (2006).

Kojima, T. et al. Anisotropic electrical properties in bismuth layer structured dielectrics with natural super lattice structure. Appl. Phys. Lett. 101, 012907-1-012907–4 (2012).

Shibata, T., Fukuda, K., Ebina, Y., Kogure, T. & Sasaki, T. One-nanometer-thick seed layer of unilamellar nanosheets promotes oriented growth of oxide crystal films. Adv. Mater. 20, 231–235 (2008).

Ma R. & Sasaki, T. Nanosheets of Oxides and Hydroxides. Ultimate 2D charge-bearing functional crystallites. Adv. Mater. 22, 5082–5104 (2010).

Takahashi, K. et al. Thermal stability of SrRuO3 bottom electrode and electric property of Pb(Zr,Ti)O3 thin film deposited on SrRuO3 . Jpn. J. Appl. Phsy. 41, 6873–6876 (2002).

Takahashi, K. et al. Effect of strain in epitaxially grown SrRuO3 thin films on crystal structure and electric properties. Jpn. J. Appl. Phsy. 41, 5376–5380 (2002).

Sun, C., Wang, X., Ji, A. & Li, L. Low-temperature sintering of negative-positive-zero-type temperature-stable ceramics with ZnO-B2O3 flux and SrCO3 additive. Jpn. J. Appl. Phys. 50, 081501-1-081501–4 (2011).

Osada, M. & Sasaki, T. Two-dimensional dielectric nanosheets: novel nanoelectronics from nanocrystal building blocks. Adv. Mater. 24, 210–228 (2012).

Li, B.-W. et al. Engineered interfaces of artificial perovskite oxide superlattices via nanosheet deposition process. ACS Nano 4, 6673–6680 (2010).

Acknowledgements

This work was partially funded by the MEXT Elements Strategy Initiative to Form Core Research Center. This work was partially supported by the Center for Integrated Nanotechnology Support at Tohoku University and the Nanotechnology Network Project of MEXT of the Japanese Government. The authors thank Ms. Yumiko Kodama and Kumiko Suzuki for preparing the samples in the microstructure analysis.

Author information

Authors and Affiliations

Contributions

J.K. mainly contributed to this work. H.F. supervised the project. I.T. and M.M. helped to prepare film samples and analyse the data. T.S. and H.U. discussed the results and helped write the paper. T.S., M.O. and T.S. prepared the Ca2Nb3O10− nanosheets on glass substrates and contributed to the paper. T.K., T.S. and T.K contributed to the microstructure analysis.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kimura, J., Takuwa, I., Matsushima, M. et al. Thermally stable dielectric responses in uniaxially (001)-oriented CaBi4Ti4O15 nanofilms grown on a Ca2Nb3O10− nanosheet seed layer. Sci Rep 6, 20713 (2016). https://doi.org/10.1038/srep20713

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep20713

This article is cited by

-

Effect of substrate temperature on the optical properties of CaBi4Ti4O15 thin films deposited by pulsed laser ablation

Journal of Materials Science: Materials in Electronics (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.