Abstract

In recent years, the worldwide use of polyethylene terephthalate (PET) has increased exponentially. PET wastewater contains ethylene glycol (EG) and terephthalic acid (TPA). In this study, we present a unique method for producing combustible gases like CH4 and H2 from PET wastewater by electrochemical reaction of EG and TPA. The non-diaphragm-based electrochemical (NDE) method was used to treat PET wastewater. The electrochemical removal of EG and TPA from PET wastewater was examined and the optimal conditions for their reduction to CH4 and H2 were determined. Using the proposed system, 99.9% of the EG and TPA present in the PET wastewater samples were degraded to produce CH4 and H2, at applied voltages lower than 5 V. The highest Faradaic efficiency achieved for EG and TPA reduction was 62.2% (CH4, 25.6%; H2, 36.6%), at an applied voltage of 0.8 V. Remarkably, CH4 was produced from EG decomposition and H2 from TPA decomposition. To the best of our knowledge, this is the first reported instance of CH4 and H2 production from EG and TPA, respectively. The electrochemical reductive treatment will be an important discovery for reducing water contamination and replacing fossil fuels with respect to generating green energy.

Similar content being viewed by others

Introduction

The production of synthetic fibers of polyethylene terephthalate (PET) has increased exponentially in recent years1,2,3,4,5,6. PET can be synthesized directly by polymerization of ethylene glycol (EG) and terephthalic acid (TPA), or from dimethyl terephthalate (DMT) by what is known as the DMT method7,8,9,10.

Some of the raw materials used for PET production, such as EG and TPA, are extracted from natural gases and crude oils and are very expensive. Unused amounts of these compounds are, therefore, collected and recycled following PET production, using methanolysis, ethanolysis and glycolysis3,11,12,13,14. Although the aforesaid recycling processes allow for the recovery of most of the EG and TPA, small quantities (<0.2%) of these compounds remain in solution and are discharged into the environment. This effluent is known as PET polymerization wastewater15,16,17.

To remove EG and TPA from PET wastewater, PET manufacturers employ activated carbon filters or advanced water-treatment methods such as anaerobic digestion and ozone treatment. However, these methods are expensive and inefficient17,18,19,20. Recently, it is reported that electrochemical treatments can efficiently remove EG or TPA through a redox reaction driven by a direct current power source25,26,27,28,29. These results also reported that electrochemical treatment can produce combustible gases for use as fuels.

Until now, various technologies have been applied to remove EG and TPA from PET wastewaters30,31,32,33. However, no one has considered EG and TPA as energy sources. Electrochemical reduction of CO2 can produce ethylene (C2H4) and EG, which in turn can be converted to methane (CH4) and ethane (C2H6)34,35,36. These findings suggest that EG and TPA from PET wastewater could be converted into energy sources because of their structural characteristics, as well as their carbon and hydrogen contents. Therefore, the research into methods to transform the wastewater contents into energy sources should necessarily be combined with an efficient method for their removal.

In this study, we present a unique method for producing combustible gases such as CH4 and H2 from PET wastewater by electrochemical reaction of EG and TPA. Furthermore, to the best of our knowledge, this is the first reported study on the cost reduction of PET wastewater treatment. The electrochemical reductive treatment is a potentially important method for decreasing water contamination and for replacing fossil fuels with respect to generating green energy.

This study examines the electrochemical removal of EG and TPA from PET wastewater and determines the optimal conditions for their reduction to CH4 and H2, to develop a method for producing fuels from waste via wastewater treatment.

Results

Current density as a function of the applied voltage and the electrolyte

Electrochemical analysis was conducted to elucidate the mechanisms of EG and TPA reductions in PET wastewater generating CH4 and H2. To analyze electrochemical power, linear-sweep voltammetry (LSV) and cyclic voltammetry (CV) experiments were conducted using an electrochemical analyzer (PAR VersaSTAT3, AMETEK).

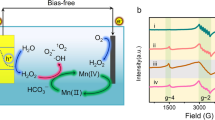

Figure S1 shows the results of LSV with three 50 wt% methanol solutions: the first with 0.2 M KOH, the second with 0.2% EG and TPA content and the third containing both. Electrical current was not generated in the absence of KOH, indicating that KOH is an essential ingredient for the electrochemical reduction of EG and TPA. KOH generates OH radicals, a useful property for application in electrochemical reactions44,45, which play an important role in reducing EG and TPA to CH4 and H2. When KOH has a lower bonding energy than H2O, KOH is dissociated into K+ ions and OH radicals at low electric potential and its electric currents flow. Produced K+ ions induce to decompose H2O and generating H+ ions and OH radicals. The excessive OH radicals generated by the above reaction possess higher reaction rates than proton and are strong oxidizing agents for dissolved organic matter (DOM). These OH radicals attack benzene rings of TPA and EG. The produced H2O in the process of EG decomposition transforms into OH radicals and recycles the TPA and EG decomposition52,53,54,55. This KOH electrolyte was mixed with methanol because the methanolysis has generally been used to produce biogases17,18,41,42,43. However, KOH is a strongly alkaline substance requiring an appropriate pH for reaction in the general diaphragm electrochemical method46,47,48. Our NDE method system was unicellular, pH-independent and showed highly efficient generation and flow of electrons.

Electrical current was observed both in presence and absence of EG and TPA in the NDE method cell. Especially, current density abruptly increased from a potential of −0.5 V onwards. Therefore, electric power greater than −0.5 V was acceptable for degrading EG and TPA to produce CH4 and H2, indicating that increasing potential causes greater degradation of EG and TPA.

Current densities were measured for voltages ranging from −3 to 3 V applied to a 0.2 M KOH solution in methanol (50 wt%) containing 0.2% EG/TPA (Fig. 1). High current densities were observed at relatively low applied voltages, indicating that current density increased when the applied voltage exceeded 0.2 V. After the voltages were added, small reduction peaks were generated at the 0.2 V. This meant that the reduction was initiated at 0.2 V and the reduction occurred preferentially compared to the oxidation reaction, at 0.5 V. The highest reduction peak was obtained at 0.8 V, with increasing numbers of CV cycles. This showed that the reduction of EG/TPA presumably happened at 0.8 V and many products (CH4 and H2) were produced at low added voltages. To evaluate this reaction pattern, EG and TPA degradations were analyzed by applying voltages of various magnitudes, for different durations.

Comparison of CH4 and H2 production rates

Figure 2 shows the hourly results of residual mass obtained from a 0.2% EG solution and a 0.2% TPA solution. The solutions were incubated for 5 h, with applied voltages in the 0–10 V range used to determine their degradation patterns. At applied voltages below 0.2 V, EG and TPA did not degrade sufficiently. However, sufficient degradation was observed at voltages as low as 0.5 V. A voltage of 2 V applied for 1 h degraded EG and TPA by as much as 90%, while an applied voltage of 5 V achieved 99% degradation in the same period. These results are consistent with the CV results (Fig. 1), which indicated the current required to degrade EG and TPA.

From these results, it can be concluded that a 0.2% EG and a 0.2% TPA solution can be efficiently degraded with an applied voltage of 5 V.

CO2 and 1,4-dioxane are intermediates and byproducts in the polymerization reaction involving EG and TPA. GC-MSD analyses of the decomposition products confirmed these intermediates and other byproducts (Fig. S2, Supplementary Information). 1,4-dioxane was generated with a fractional rate (~100 μmol/mol) in the polymerization of a 0.2% solution of EG and TPA sampled from PET wastewater, consistent with the industrial process of PET production. As is common, 1,4 dioxane content has been used as a marker for the efficiency of PET wastewater treatments in this study. The residual mass was determined for a variety of applied voltages over 5 h (Fig. 3). The degradation pattern observed for 1,4-dioxane was similar to that for EG/TPA. Applied voltages greater than 0.5 V were more effective than the lower voltages. Thus, the efficiency of 1,4-dioxane degradation increases with increasing voltage. This is the first demonstration of an NDE method proving highly efficient at 1,4-dioxane removal. This study demonstrated that applied voltages in the 0–10 V range can degrade EG, TPA and 1,4-dioxane.

Residual mass of 1,4-dioxane as a function of time for different applied voltages using the NDE method (conditions as described in Fig. 2).

We next conducted a series of GC experiments in order to determine the degradation products of EG, TPA and 1,4-dioxane. Since EG and TPA are mainly composed of carbon and hydrogen, the main reduction products were CH4 and H2.

The amounts of CH4 and H2 produced (shown in Fig. 4a,b, respectively) increased with increasing applied voltage. CH4 production was largely unchanged over the voltage range 0.5–5 V. H2 production was fifteen times greater than CH4 production at applied voltages ≤2 V. In the absence of an applied voltage, CO2 was the only product detected from the solution (Fig. S3, Supplementary Information).

CH4 and (b) H2 produced as a function of time for various applied voltages (conditions as described in Fig. 2).

These results represent an important step forward in PET wastewater treatment, not only for removing a carcinogen from both CH4 and H2 were produced through EG and TPA degradation in the NDE method. H2O and CH3OH, used as electrolytes, were also expected to contribute to CH4 and H2 production. For further investigation, a blank experiment was run in the absence of EG and TPA (Fig. 5). In the reaction mixture containing 100 μmol/mol 1,4-dioxane (Fig), both CH4 and H2 were produced. However, in the reaction mixture containing only H2O, 50 wt% CH3OH and KOH, only H2 was produced (albeit in a smaller amount) and CH4 was not (Fig. 5b), by the electrochemical conversion of H2O43,49,50,51. These results demonstrated that 1,4-dioxane participates in the production of both CH4 and H2. The concentration of 1,4-dioxane gradually decreased over time (Fig. 3), providing further evidence for its involvement in CH4 and H2 production.

Masses of CH4 and H2 produced as a function of time under 0.8 V applied voltage.

Reaction mixture (a) contains 1,4-dioxane, while (b) does not (conditions as described in Fig. 2).

Further experiments were performed to understand the role of CO2 in the production of CH4 and H2. In Fig S3, CO2 concentration was constantly maintained after 1 hr. In Fig S4, CH4 was not produced. Therefore, CO2 cannot be considered as a carbon source in the reaction, as it did not play any role in CH4 production. In Fig S4, the increasing voltages were related to electrolysis of water, increasing the H2 concentration. Therefore, CO2 is an intermediate which is not related to the CH4 and H2 generation.

Faradaic efficiency

The Faradaic efficiencies of CH4 and H2 production were calculated for a range of voltages (0–10 V) applied to a reaction mixture containing 0.2 M KOH, 0.2% EG/TPA and 50 wt% CH3OH (Fig. 6). Current density and Faradaic efficiency were both enhanced by increasing the applied voltage from 0.2 to 0.8 V. The highest Faradaic efficiency, 62.2% (CH4, 25.6%; H2, 36.6%), was achieved at 0.8 V. This result is consistent with those of LSV and CV (Fig. S1, Fig. 1), with the current density and Faradaic efficiency increasing with increase in applied voltage up to 0.8 V. However, Faradaic efficiency decreased at voltages above 0.8 V, decreasing to less than 10% at 5 V. These results indicated that the removal of EG and TPA and the consequent production of CH4 and H2 are best achieved in this electrochemical system at an applied voltage of 0.8 V. Therefore, applied voltages <1 V are most suited to CH4 and H2 production from PET wastewater.

Faradaic efficiencies of CH4 and H2 productions versus applied voltage (conditions as described in Fig. 2, except that the reaction mixture contains 0.2% EG/TPA).

A series of experiments was conducted to determine the mechanisms of CH4 and H2 production from EG or TPA. It was determined that CH4 is the predominant product of the reaction mixture that contained only EG (Fig. 7a), while H2 production was dramatically higher in the reaction mixture containing only TPA (Fig. 7b). The reaction mixture containing both EG and TPA generated three times more CH4 and H2 than the samples containing either EG or TPA (Fig. S6, Supplementary Information). From these results, we concluded that CH4 production is primarily affected by the EG content, while TPA content primarily affects H2 production. The absolute amounts of CH4 and H2 produced are a result of TPA degradation.

Production of CH4 and H2 with elimination of (a) EG and (b) TPA as a function of time (reaction conditions as described in Fig. 2).

We performed 30 day experiments to prove physiochemical stabilities of Cu and Pt electrodes in electrolytes through reactions. Measurements were taken twice a day for one month. Within these days, abrasion and leaching of Cu and Pt electrodes were not found. Faradaic efficiency was presented using the results obtained from these experiments (Fig. S5). With the batch experiment, Faradaic efficiency of CH4 and H2 production decreased for the first 5 days because the supplied and consumed reactants were limited. Afterwards, the Faradaic efficiency was constantly maintained throughout the 30 days. These results indicate the stability of Cu and Pt electrodes in the electrolytes through the reaction. A schematic explaining the electrochemical reactions of EG/TPA and the reactions that generate CH4 and H2 from EG and TPA, respectively, are shown in Fig. 8.

Schematics for the electrochemical reduction of EG/TPA (conditions as described in Fig. 2).

Reaction mechanism

We have demonstrated that CH4 and H2 are produced by reducing PET wastewater via NDE. During this process, applied voltages generated electronic and protonic currents, which initiated EG and TPA reduction within the mixture. Likely reaction mechanisms are proposed below.

From equations (1) and (2), OH radicals generated from KOH and H2O electrolyses were strong oxidizing agents to degrade EG, TPA and 1,4-dioxane. From Equation (4), CH4 was produced after OH radicals reacted with EG. It is concurrent to the results of Fig. 7 showing that production of methane is primarily related to EG. At Equation (5), TPA generated methane, H2 and CO2 after reactions with 8 OH radicals and it is considered to preferentially produce H2 rather than CH4 gas. The intermediate CO2 gas is equivalent to the analytical results shown in Fig. S2. At Equation (6), 1,4-dioxane is reduced to methane after reactions with OH radicals and removed.

Discussion

In this study, an NDE method was developed to produce high-value fuels from EG and TPA in PET wastewater by applying relatively low voltages. Nearly 99.9% of the EG and TPA present in PET wastewater samples were removed with an applied voltage of 5 V. The highest Faradaic efficiency for EG and TPA reduction was 62.2% (CH4, 25.6%; H2, 36.6%), achieved using an applied voltage of 0.8 V. Based on our findings, we have proposed reaction mechanisms describing CH4 and H2 production, suggesting that EG produces only CH4, while TPA produces both CH4 and H2. Overall, valueless and environmentally hazardous PET wastewater was easily treated, using a simple electrochemical method, to produce high-value fuels (CH4 and H2) from EG and TPA. This report represents a proof of concept and further pilot-scale studies will be required before the technology can be marketed.

Methods

Electrochemical reduction

We have previously reported the development of a highly efficient, high-current-density non-diaphragm-based electrochemical (NDE) method to achieve electrochemical reduction35. The same method, involving the use of acrylic materials (60 mm × 45 mm × 95 mm), was applied to the removal of EG and TPA from PET wastewater. There are many reports, that hydrocarbons such as CH4 and C2H4, are easily produced using the Cu cathode. Cu is also cheaper than other metal electrodes, which is why the cu electrode was used as working electrodes to produce CH456,57,58. Insoluble Pt and Cu plates were used as anode and cathode, respectively. The plates had same dimensions (40 mm × 40 mm × 1 mm), were positioned at the same height, with 10-mm separation. Ag/AgCl electrolyte surrounded the electrodes. The entire electrochemical system was incorporated into an electrochemical analyzer (PAR VersaSTAT3, AMETEK). Experiments were conducted for 5 h on EG (99.9%, Sigma Aldrich) and TPA (99.9%, Sigma Aldrich) using 0.2 M KOH (Extra pure, Sigma Aldrich) electrolyte solutions containing 50 wt% CH3OH (99.999%, Sigma Aldrich). Voltages were applied over the range 0–10 V and the generated currents were measured.

CH4 and H2 production under various conditions

The gas-phase products were collected from an outlet placed near the top of the NDE apparatus. The compositions of the collected samples were determined by gas chromatography (GC) using a flame ionization detector (FID, Agilent HP6970) for CH4, or a thermal conductivity detector (TCD, PerkinElmer CALUS580) for H2. Various intermediates and by-products, including 1,4-dioxane, were analyzed using a mass-selective detector (MSD, Agilent HP6970). The results of these analyses were used to calculate the Faradaic efficiencies and thus to determine the fate of EG and TPA.

Additional Information

How to cite this article: Kim, N.-G. et al. High production of CH4 and H2 by reducing PET waste water using a non-diaphragm-based electrochemical method. Sci. Rep. 6, 20512; doi: 10.1038/srep20512 (2016).

References

Li, X.-K. et al. Reaction kinetics and mechanism of catalyzed hydrolysis of waste PET using solid acid catalyst in supercritical CO2 . AIChE J. 1, 200–214 (2015).

Hu, L.-C., Oku, A., Yamada, E. & Tomari, K. Alkali-decomposition of poly (ethylene terephthalate) in mixed media of nonaqueous alcohol and ether. Study on recycling of poly(ethylene terephthalate). Polym. J. 29, 708–712 (1997).

Aguado, A. et al. Chemical depolymerisation of PET complex waste: hydrolysis vs. glycolysis. J. Material Cycles Waste Manage. 16, 201–210 (2014).

Liu, Y., Wang, M. & Pan, Z. Chemical recycling of waste poly (ethylene terephthalate) fibers into azo disperse dyestuffs. J. Supercrit. Fluids. 62, 226–231 (2012).

Sinha, V., Patel, M. R. & Patel, J. V. PET waste management by chemical recycling: a review. J. Polym. Environ. 18(1), 8–25 (2010).

López-Fonseca, R., Duque-Ingunza, I., de Rivas, B., Arnaiz, S. & Gutiérrez-Ortiz, J. I. Chemical recycling of post-consumer PET wastes by glycolysis in the presence of metal salts. Polym. Degrad. Stab. 95, 1022–1028 (2010).

Oku, A., Hu, L. C. & Yamada, E. Alkali Decomposition of Poly(ethylene terephthalate) with Sodium Hydroxide in Nonaqueous Ethylene Glycol: A Study on Recycling of Terephthalic Acid and Ethylene Glycol. J. Appl. Polym. Sci. 63, 595–601 (1997).

Vaidya, U. R. & Nadkarni, V. M. Polyester polyols from glycolyzed PET waste: effect of glycol type on kinetics of polyesterification. J. Appl. Polym. Sci. 38, 1179–1190 (1989).

Siddiqui, M. N. et al. Chemical recycling of polycarbonate based wastes using alkaline hydrolysis under microwave irradiation. Macromol. Mater. Eng. 295, 575–584 (2010).

Imran, M., Kim B.-K., Han, M., Cho B. G. & Kim, D. H. Kinetics of catalytic glycolysis of PET wastes with sodium carbonate. Polym. Degrad. Stab. 95, 1686–1693 (2010).

Chen, J. Y., Ou, C. F., Hu, Y. C. & Lin, C. C. Depolymerization of poly(ethylene terephthalate) resin under pressure. J. Appl. Polym. Sci. 42, 1501–1507 (1991).

Sako, T. et al. Depolymerization of polyethylene terephthalate to monomers with supercritical methanol. J. Chem. Eng. Jpn. 30(2), 342–346 (1997).

Wang, Q., Geng, Y., Lu, X. & Zhang, S. Chemical recycling of unsaturated polyester resin and its composites via selective cleavage of the ester bond. ACS Sustainable Chem. Eng. 3, 340−348 (2015).

Paszun, D. & Spychaj, T. Chemical recycling of poly (ethylene terephthalate). Ind. Eng. Chem. Res., 36, 1373 (1997).

Viana, M. E., Riul, A., Carvalho, G. M., Rubira, A. F. & Muniz, E. C. Chemical recycling of PET by catalyzed glycolysis: Kinetics of the heterogeneous reaction. Chem. Eng. J. 173, 210–219 (2011).

Shah, R. V., Borude, V. S. & Shukla, S. R. Recycling of PET waste using 3‐amino‐1‐propanol by conventional or microwave irradiation and synthesis of bis‐oxazin there from. J. Appl. Polym. Sci. 127, 323–328 (2013).

Yoshioka, T., Sato, T. & Okuwaki, A. Hydrolysis of waste PET by sulfuric acid at 150 °C for a chemical recycling. J. Appl. Polym. Sci. 52, 9, 1353–1355 (1994).

Hamelers, H. V. et al. Hydrogen gas production in a microbial electrolysis cell by electrohydrogenesis. Appl. Microbial. Biotechnol. 85(6), 1673–1685 (2010).

Heng, S., Yeung, K. L., Djafer, M. & Schrotter, J.-C. A novel membrane reactor for ozone water treatment. J. Membr. Sci. 289, 67–75 (2007).

Heng, S., Yeung, K. L., Julbe, A., Ayral, A. & Schrotter, J.-C. Preparation of composite zeolite membrane separator/contactor for ozone water treatment. Microporous Mesoporous Mater. 115, 137–146 (2008).

Kim, H. J. et al. Highly active and stable PtRuSn/C catalyst for electrooxidations of ethylene glycol and glycerol. Appl. Catal. B: Environ. 101, 366–375 (2011).

Lv, S., Wang, C. & Yang, X. Hierarchical semiconductor oxide photocatalyst: a case of the SnO2 microflower. Micro Nano Lett. 8(5), 234–237 (2013).

Zhang, Z. J., Cui, P. & Chen, X. Y. Structure and Capacitive Performance of Porous Carbons Derived from Terephthalic Acid–Zinc Complex via a Template Carbonization Process. Ind. Eng. Chem. Res. 52, 16211−16219 (2013).

Hu, S. et al. Modulation and effects of surface groups on photoluminescence and photocatalytic activity of carbon dots. Nanoscale, 5, 11665–11671 (2013).

Sako, T. et al. Depolymerization of Polyethylene Terephthalate to Monomers with Supercritical Methanol J. JCEJ. 55, 11, 685–690 (1998).

Anand, M. V., Srivastava, V. C., Singh, S., Bhatnagar, R. & Mall, I. D. Electrochemical treatment of alkali decrement wastewater containing terephthalic acid using iron electrodes J. Taiwan Inst. Chem. Eng. 45, 908–913 (2014).

Marchionni, A. et al. Electrooxidation of Ethylene Glycol and Glycerol on Pd‐(Ni‐Zn)/C Anodes in Direct Alcohol Fuel Cells. ChemSusChem. 6(3), 518–528 (2013).

Hong, W., Shang, C., Wang J. & Wang, E. Trimetallic PtCuCo hollow nanospheres with a dendritic shell for enhanced electrocatalytic activity toward ethylene glycol electrooxidation. Nanoscale. 7, 9985–9989 (2015).

Garg, K. K., Prasad, B. & Srivastava, V. C. Comparative study of industrial and laboratory prepared purified terephthalic acid (PTA) waste water with electro-coagulation process. Sep. Purif. Technol. 128, 80–88 (2014).

Adschiri, T., Lee, Y.-W., Goto, M. & Takami, S. Green materials synthesis with supercritical water. Green Chem. 13, 1380–1390 (2011).

Verma, S., Prasad, B. & Mishra, I. M. Thermochemical treatment (thermolysis) of petrochemical wastewater: COD removal mechanism and floc formation. Ind. Eng. Chem. Res. 50, 5352–5359 (2011).

Kleerebezem, R., Beckers, J., Hulshoff Pol, L. W. & Lettinga, G. High rate treatment of terephthalic acid production wastewater in a two‐stage anaerobic bioreactor. Biotechnol. Bioeng. 91(2), 169–179 (2005).

Cocero, M. J. et al. Supercritical water oxidation (SCWO) for poly (ethylene terephthalate)(PET) industry effluents. Ind. Eng. Chem. Res. 39, 4652–4657 (2000).

Hu, L.-C., Oku, A. & Yamada, E. Alkali-catalyzed methanolysis of polycarbonate. A study on recycling of bisphenol A and dimethyl carbonate. Polymer. 39, 3841–3845 (1998).

Yim, K.-J. et al. Selective, high efficiency reduction of CO2 in a non-diaphragm-based electrochemical system at low applied voltage. RSC. Adv. 5, 9278–9282 (2015).

Kao, C.-Y., Wan, B.-Z. & Cheng, W.-H. Kinetics of hydrolytic depolymerization of melt poly (ethylene terephthalate). Ind. Eng. Chem. Res. 37, 1228–1234 (1998).

Butkovskyi, A. et al. Electrochemical conversion of micropollutants in gray water. Environ. Sci. Technol. 48, 1893−1901 (2014).

Ren, D. et al. Selective Electrochemical Reduction of Carbon Dioxide to Ethylene and Ethanol on Copper (I) Oxide Catalysts. ACS Catal. 5, 2814−2821 (2015).

Nakata, K., Ozaki, T., Terashima, C., Fujishima, A. & Einaga, Y. High‐Yield Electrochemical Production of Formaldehyde from CO2 and Seawater. Angew. Chem. 126, 890–893 (2014).

Collins, M. J. & Zeronian, S. H. The molecular weight distribution and oligomers of sodium hydroxide hydrolyzed poly (ethylene terephthalate). J. Appl. Polym. Sci. 45, 797–804 (1992).

Liang, B., Long, Z. Y., Qing, H. Y., Bing, Z. & Yi, P. S. Safe and convenient procedure for solvent purification. J. Nat. Gas Chem. 5, 3 (1996).

Berkes, B. B., Inzelt, G., Schuhmann, W. & Bondarenko, A. S. Influence of Cs+ and Na+ on specific adsorption of *OH, *O and *H at platinum in acidic sulfuric med ia. J. Phys. Chem. C. 116, 10995–11003 (2012).

Gu, J. et al. p-Type CuRhO2 as a Self-Healing Photoelectrode for Water Reduction under Visible Light. J. Am. Chem. Soc. 136, 830−833 (2014).

Ma, F. & Hanna, M. A. Biodiesel production: a review. Bioresour. Technol. 70, 1–15 (1999).

Bai, L., Zhao, Y.-L., Hu, Y.-Q., Zhong, B. & Peng, S.-Y. The natural selection of the chemical elements. J. Nat. Gas Chem. 5(3), 229–236 (1996).

Jeon, I.-Y. et al. Direct nitrogen fixation at the edges of graphene nanoplatelets as efficient electrocatalysts for energy conversion. Sci. Rep. 3, 2260 (2013).

Qiao, J. et al. Effect of KOH Concentration on the Oxygen Reduction Kinetics Catalyzed by Heat-Treated Co-Pyridine/C Electrocatalysts. Int. J. Electrochem. Sci. 8, 1189–1208 (2013).

Wu, L. et al. Automatic Release of Silicon Nanowire Arrays with a High Integrity for Flexible Electronic Devices. Sci. Rep. 4, 3940 (2014).

Fu, Q., Mabilat, C., Zahid, M., Brissea, A. & Gautiera, L. Syngas production via high-temperature steam/CO2 co-electrolysis: an economic assessment. Energy Environ. Sci. 3, 1382–1397 (2010).

Kang, P., Chen, Z., Nayak, A., Zhang, S. & Meyer, T. J. Single catalyst electrocatalytic reduction of CO2 in water to H2+CO syngas mixtures with water oxidation to O 2. Energy Environ. Sci. 7, 4007–4012 (2014).

Varcoe, J. R. et al. Anion-exchange membranes in electrochemical energy systems. Energy Environ. Sci. 7, 3135–3191 (2014).

Page, S.-E., Arnold, W. A. & McNeill, K. Terephthalate as a probe for photochemically generated hydroxyl radical. J. Environ. Monit. 12, 1658–1665 (2010).

Razavi, B., Abdelmelek, S. B., Song, W. & O’Shea, K. E. Photochemical fate of atorvastatin (lipitor) in simulated natural waters. J. Water Research. 45, 625–631 (2011).

Xu, H., Cooper, W. J., Jung, J. & Song, W. Photosensitized degradation of amoxicillin in natural organic matter isolate solutions. J. Water Research. 45, 632–638 (2011).

Luo, X., Zheng, Z., Greaves, J. & Cooper, W. J. Trimethoprim: Kinetic and mechanistic considerations in photochemical environmental fate and AOP treatment. J. Water Research. 46, 1327–1336 (2012).

Koper, M. T. M. et al. A new mechanism for the selectivity to C1 and C2 species in the electrochemical reduction of carbon dioxide on copper electrodes. Chem. Sci. 2, 1902 (2011).

Norskov, J. K. et al. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 3, 1311–1315 (2010).

Koper, Marc. T. M., Gallent, E. P. G. & Schouten, K. J. P. Structure Sensitivity of the Electrochemical Reduction of Carbon Monoxide on Copper Single Crystals. ACS Catal. 3, 1292−1295 (2013).

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) grant, funded by the Korean Government (NRF-2013R1A1A2008882).

Author information

Authors and Affiliations

Contributions

N.-G.K., K.-J.Y. wrote the main manuscript text and M.-H.H., Y.-H.K. prepared Figures 1–8. C.-S.K., D.-K.S. and K.O., S.-E.L. and T.-O.K. reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kim, NG., Yim, KJ., Kim, CS. et al. High production of CH4 and H2 by reducing PET waste water using a non-diaphragm-based electrochemical method. Sci Rep 6, 20512 (2016). https://doi.org/10.1038/srep20512

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep20512

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.