Abstract

Photosplitting water for H2 production is a promising, sustainable approach for solar-to-chemical energy conversion. However, developing low-cost, high efficient and stable photocatalysts remains the major challenge. Here we report a composite photocatalyst consisting of FeP nanoparticles and CdS nanocrystals (FeP/CdS) for photogenerating H2 in aqueous lactic acid solution under visible light irradiation. Experimental results demonstrate that the photocatalyst is highly active with a H2-evolution rate of 202000 μmol h−1 g−1 for the first 5 h (106000 μmol h−1 g−1 under natural solar irradiation), which is the best H2 evolution activity, even 3-fold higher than the control in situ photo-deposited Pt/CdS system and the corresponding to an apparent quantum efficiency of over 35% at 520 nm. More important, we found that the system exhibited excellent stability and remained effective after more than 100 h in optimal conditions under visible light irradiation. A wide-ranging analysis verified that FeP effectively separates the photoexcited charge from CdS and showed that the dual active sites in FeP enhance the activity of FeP/CdS photocatalysts.

Similar content being viewed by others

Introduction

The production of chemical fuels using sunlight is an attractive and sustainable solution to global energy and environmental problems1,2. Since the 1970s, splitting water using solar energy has received much attention as a possible means for converting solar energy to chemical energy by creating clean and renewable hydrogen fuel3,4. Molecular hydrogen (H2) production using semiconductor photocatalysts is one of the most promising strategies for light-driven proton reduction5,6,7. However, most semiconductors cannot produce H2 without a co-catalyst, even in the presence of sacrificial electron donor. This is attributed to the quick recombination of electron and hole pairs while migrating to the surface and the surface reaction being too slow to efficiently consume these charges3. Generally, to prevent the recombination of electron and hole pairs, co-catalysts (such as metals and especially noble metals) are used to serve as electron sinks and provide effective proton-reduction reaction sites8. Platinum (Pt) is the most widely used co-catalyst for the photocatalytic production of H2 from water because of its high activity and stability under the often harsh operational conditions. However, noble metals like Pt are expensive and scarce. It is therefore useful to develop high efficiency, low-cost, noble-metal-free co-catalysts to further facilitate the development of H2 photogeneration. Several new earth-abundant metal compounds have emerged and can be good candidates for co-catalysts, including MoS29,10,11,12, NiS13,14, NiSx15, CuS16, Cu(OH)217, Co(OH)218 and other related materials19. However, these co-catalysts also have the drawback of instability during the photocatalytic reaction. Very recently, metal phosphides, such as Ni2P20, CoP21,22, CuP23, MoP24 and FeP25,26,27,28 have been found to have the high electrochemical catalysis activity and good stability for the hydrogen evolution reaction (HER) in acid or alkali solutions. Transition metal phosphides, which involve the alloying of metals and phosphorus (P), have demonstrated high activity for the HER and hydrodesulfurization reactions because of their ability to reversibly bind hydrogen. However, the photocatalytic activity of these metal phosphides as the co-catalyst for H2 production has not yet been fully explored. We recently reported that a colloidal metal phosphide (Ni2P or Co2P) catalyst combined with colloidal CdS nanorod photosensitizers displayed good photocatalytic H2 evolution activity in an aqueous lactic acid solution, revealing the co-catalyst potential of metal phosphides29,30. Iron-based alternatives are especially attractive because Fe is the most abundant transition metal and its price is typically at least two orders of magnitude less than that of other highly abundant and catalytically relevant metals, including Ni and Co25. Iron phosphide (FeP) nanoparticles (NPs) as co-catalysts deposited on TiO2 have been shown to be exceptionally active for sustained H2 production in either acidic or neutral-pH aqueous solutions under UV light irradiation25. However, highly active photocatalysts composed of high-quality, iron-based nanoparticulate materials under visible light irradiation are among the most desired because of their low cost, abundance and ease of processing.

Herein we performed a noble-metal-free system of visible-light driven H2 production with the best activity and significant longevity. The system includes the semiconductor CdS and a FeP composite photocatalyst that together exhibit high activity and good photochemical stability under artificial and natural irradiation. The essence of the thermodynamic relationship between CdS and FeP is elucidated and the mechanism of effective charge separation based on the band alignment in such system is also studied in depth. This information will be useful for providing insight for the design and preparation of efficient semiconductor-based photocatalysts.

Results

Characterization of FeP samples

FeP nanoparticles were prepared by chemical conversion from Fe3O4 nanoparticles precursor (Figs S1–S3) via the low-temperature phosphidation reaction under Ar atmosphere. FeP adopted a hexagonal structure (Fig. S4a) and is a well-known electrochemical hydrogen evolution catalyst25,28,31. The structure of the FeP (103) surface results in Fe and P sites being simultaneously exposed (Fig. S4b). This resulted in an ensemble effect, whereby proton-acceptor and hydride-acceptor centres are both present to facilitate catalysis of the HER20.

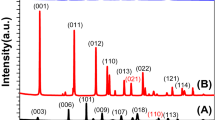

The intense grinding of the various ratios of FeP and CdS ensured the formation of a robust solid-solid interface between the FeP NPs and the CdS supports. Figure 1a shows transmission electron microscope (TEM) images of 5 wt% FeP/CdS photocatalysts. A high-resolution TEM (HRTEM) image clearly reveals the interaction between the NPs of FeP and CdS (Fig. 1b). The well-resolved lattice fringes with distances of 1.8 and 3.22 Å correspond to the (103) and (101) planes for FeP and CdS, respectively. X-ray diffraction (XRD) results showed no clear FeP peaks after loading 5 wt% and 10 wt% FeP on the CdS (Fig. 1c). This lack of peaks may be attributed to effective dispersion and a lack of crystallization of FeP, which together may have led to a relatively low diffraction intensity of the FeP on the CdS32,33,34. Figure 1d shows the UV-vis diffuse reflectance spectra of samples of pure CdS and those when loaded with different amounts of FeP co-catalyst. Pure CdS absorbed visible light with wavelengths around 557 nm and a corresponding band gap of 2.2 eV. CdS samples gradually increased their visible light absorption as the amount of FeP co-catalysts increased. This is attributed to FeP’s deep black colour being beneficial to photocatalytic activity.

Characterization of FeP/CdS samples.

(a) TEM image of 5wt% FeP/CdS composite photocatalysts. (b) HRTEM image taken from the area marked with a red rectangle in (a). (c) XRD patterns for samples of pure CdS and for those with various amounts of FeP co-catalysts. (d) UV-vis spectra of pure CdS samples and for those with various amounts of FeP co-catalysts.

Photocatalytic activity

CdS has demonstrated that is an important photocatalyst for the photocatalytic HER because of its wide light-response range (with a direct bandgap of around 2.4 eV) and its high flat-band potential (−0.9 V vs. a normal hydrogen electrode)9,35,36,37. However, bare CdS is unstable during the photocatalytic reaction because of photocorrosion, where S2− in CdS is oxidized by photogenerated holes accompanied with the elution of Cd2+ 38, which restricts its usefulness. To overcome this drawback, co-catalysts were generally loaded onto CdS to promote the rapid surface transfer of photogenerated electrons and holes from CdS3,39,40. Herein, in a typical experiment, we performed H2 evolution upon irradiation of a lactic acid solution (10% v/v, pH 2.0) containing the 5 wt% FeP/CdS photocatalysts (5 mg). The system continued to produce H2 at a constant rate for over 50 h (Fig. 2a), later the hydrogen evolution will become gently and there is still hydrogen evolution after 100 h irradiation. A control experiment with no FeP yielded no substantial H2 production (Fig. 2a). Cycle tests also demonstrated that the FeP/CdS composite photocatalysts had good stability after four cycles of photocatalysis under visible light irradiation (Fig. S5). This longevity may be attributed to the effective separation of photoexcited electrons and holes on CdS photocatalysts, decreasing the amount of photocorrosion. The decreasing rate of HER after 50 h of irradiation may be attributed to increasingly bare CdS photo-corrosion caused by the detachment of CdS and FeP. XRD analysis of 5 wt% FeP/CdS before and after photocatalysis for 100 h demonstrated that the crystallization of CdS clearly decreased after long periods of photocatalytic H2 evolution (Fig. S6).

Photocatalytical activity comparison.

(a) Photocatalytic activity of H2 evolution over time from 5 wt% FeP under visible light irradiation at pH 2.0 solution. (b) Photocatalytic activity of CdS (5 mg) loaded with 1 wt % of Pt, Au, Ru, Pd, MoS2 and 5 wt% FeP for 5 h under visible light irradiation. (c) FeP/CdS composite photocatalysts (1 mg) with different amounts of FeP over 5 h under visible light irradiation. (d) H2 evolution rates from a physical mixture of FeP and CdS (FeP + CdS) without grinding, CdS, FeP and 1 mg of Fe3O4/CdS (with long term grinding) photocatalysts. Light resource: λ > 420 nm, LED: 30 × 3 W, 28 mW cm−2. Solution: lactic solution (10 mL, 10% v/v).

To further verify the photocatalytic activity of FeP/CdS composite photocatalysts, some well-known co-catalysts such as MoS2, Pt, Pd, Ru and Au were synthesized or in situ photo-deposited on the CdS surface and their activities were compared (in Fig. 2b). The results verified that compared to the other famous co-catalysts loaded with 1% on CdS, FeP/CdS shows the best H2 evolution activity, even 3 fold higher than in situ photo-deposited Pt-CdS photocatalysts. In addition, as we know, for Pt/CdS system, the hydrogen generation rate will clearly decrease after several hours irradiation because the noble Pt is easy poisoned by the – CO group from the degradation of lactic acid and lead to the deactivation of Pt2,41. However, FeP doesn’t display the poisoning phenomenon and FeP catalyst has demonstrated the excellent stability in strong acid solution25,28,31,42, which also supports the high activity and excellent stability of FeP.

Varying the amount of FeP in the present system clearly affected the photocatalytic activity of FeP/CdS composites. Figures 2c and S7 shows that 5 wt% FeP/CdS photocatalysts were the most active. The H2 evolution rate reached 202000 μmol h−1 g−1 after 5 h of irradiation, this corresponded to an apparent quantum efficiency (AQE) of over 35% upon excitation at 520 nm, more than 67 times the rate observed for pure CdS (3000 μmol h−1 g−1) which remained low because of the easy recombination of photoexcited electron-hole pairs. Evolution of H2 from the solution was very robust when using visible light irradiation (see supporting Movie 1). To the best of our knowledge, these are among the highest evolution activity and efficiency rates achieved over powdered photocatalysts for visible-light driven H2 production using non-noble metal, acid-stable HER catalysts (Table S1). The H2 evolution rates of 10 and 15 wt% FeP/CdS composite photocatalysts also showed rates of 180000 and 150000 μmol h−1 g−1, respectively. This trend indicates that after a peak FeP content the H2 evolution rate decreases, which may be attributed to overloading of black FeP particles would block the transition of photons43, in addition because the alone FeP can’t generate the H2, which is possible that the that FeP absorption in higher loaded samples provides parasitic absorption and could account for decreased performance.

Figure 2d shows the rate of H2 evolution from FeP/CdS, a physical mixture of FeP and CdS (FeP + CdS), CdS, FeP and Fe3O4/CdS photocatalysts. The 5 wt% FeP/CdS photocatalysts exhibited the highest activity among the catalysts, with a rate that was more than 17 times greater than the rate for the physical mixture of 5 wt% FeP and CdS. This indicates that the intimate contact between FeP and CdS was crucial for the inter-electron transfer between the two components. Without FeP, CdS alone exhibited a very low H2 evolution rate, more than 67 times less than that of the 5 wt% FeP/CdS photocatalyst. Without photosensitizer CdS, FeP alone did not exhibit any photocatalytic activity. The 5 wt% Fe3O4/CdS exhibited activity levels that were slightly less than those for pure CdS, demonstrating that Fe3O4 is not a co-catalyst for H2 evolution in this CdS system. The control experiments results suggest that the strong and repeated grinding action effectively combined the materials and ensured the formation of a solid–solid interface between the FeP nanoparticles and the CdS support, contributing to the enhanced photocatalytic activity observed.

It was worth noting that the photocatalytic activity of the FeP/CdS system strongly depended on the pH of the lactic acid solution that acted as the proton source (Fig. S8). Therefore, we adjusted the pH value of solution using HCl and NaOH prior to irradiation to ensure the same concentration of protons from the lactic acid. The maximal H2 evolution rate was achieved at pH 2.0 although significant amounts of H2 were also obtained at both lower and higher pH values, similar to results observed in other systems44,45. This pH-dependency is related to the concentration of various ions at the catalyst surface, the dissociation equilibrium of lactic acid (HL ↔ H+ + L−) and the stability of CdS among other factors. For example, at higher pH values the unfavourable protonation of the reduced FeP will decrease the H2 evolution rate44. Conversely, at lower pH values the dissociation equilibrium is suppressed, decreasing the ability of lactic acid to function as a sacrificial electron donor and the stability of CdS is decreased.

In order to further verify the activity of FeP/CdS photocatalysts, we also performed the photocatalytic hydrogen under irradiation by direct sunlight (Fig. 3). Here, a dramatic bubble was clearly generated when the quartz tube containing the catalysts and reactive solution was irradiated (as shown in the insert Figures). The robust photocatalytic activity of FeP/CdS photocatalyst was further demonstrated by a H2 evolution rate of 106000 μmol h−1 g−1 at midday on the first day of testing. In the natural sun irradiation movie in the air condition demonstrates also the continuous and robust hydrogen bubbles were generated using the composites catalysts (as shown in supporting Movie 2), which also shows the stability of catalysts under aerobic conditions.

Photocatalytic activity under Sun light irradiation.

Time courses of visible sola-light (glass filter) irradiation in laboratory using 5 wt% FeP/CdS photocatalyst (1 mg) at pH 2.0 in 10 mL H2O solution containing lactic acid (1 mL, 10% v/v). The light source was sunlight at December, 2014, in Beijing, China.

Photocatalytic mechanism

To further explain the above experimental results, we carried out a preliminary density functional theory (DFT) calculation using the ultrasoft pseudopotential plane wave method implemented in the Cambridge Serial Total Energy Package (CASTEP) code46. The calculation model for the heterojunction metal-semiconductor structure of CdS (101)/FeP (103) is shown in Fig. 4a with the calculated energy band diagram illustrated in Fig. 4b. In the case of an isolated surface model (where FeP and CdS were not in contact with each other), the work functions of the metal FeP (103) and CdS (101) surfaces were 6.454 and 5.386 eV, respectively. Thus, when the heterojunction was formed by intense grinding, the contact of FeP and CdS creates an inherent electric field at the interface. This causes the energy band edges of CdS to be shifted downwards while the Fermi energy of FeP is shifted upwards (also known as band bending). After the heterojunction system reached equilibrium, the unified work function was observed to be 5.231 eV with the CB energy levels of CdS approximately equal to 3.57 eV, close to the experimental measurement of 3.49 eV37,47. Thus, the presence of the band bending can significantly depress the electron-hole pair recombination rate, consequently can promote more electrons to transfer out of the space-charge region at the interface to flow from the CdS layer to the FeP layer48,49. Also, the presence of the Schottky barrier means that the flow of electrons requires a larger amount of energy, which allows the photogenerated electron–hole pairs to be spatially separated by the FeP/CdS interface. Eventually, the oxidation reaction may occur on the CdS (101) surface with the separated holes, while the reduction reaction may occur on the FeP (103) surface with the separated electrons. In this way FeP loading can suppress the recombination of photogenerated electron–hole pairs, acting as an electron-acceptor in the composite photocatalyst system. Based on this theory, it is clear that H2 production by photocatalytic water splitting is possible, confirming the experimental observations above.

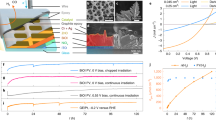

The photocurrent-voltage and the photocurrent-generated response experiments of FeP loaded onto CdS composites, were also used to verify that FeP served as an acceptor of CdS generated electrons and effectively suppressed charge recombination thereby lengthening the lifetime of the charge carriers (as shown in Fig. 5a,b). Figure 5a shows the I–V curve of the variously proportioned FeP co-catalysts in a 0.5 M Na2SO4 solution. All of the photocatalysts displayed the exhibited prompt andreproducible photocurrent, whereas without FeP, CdS generated a very low photoresponse. This indicates that loading FeP onto CdS can improve the charge transport from CdS to FeP, with the charge then passed onto the working electrode surface. The 5 wt% FeP loaded onto CdS exhibited the highest photocurrent density of all tested FeP photocatalysts, which is consistent with the photocatalytic activity results and again verifies that the 5 wt% FeP sample was the optimal content for photocatalytic H2 production. Importantly, we also compared the photoelectrochemical activity of 1 wt% Pt and 5 wt% FeP on CdS with the latter being found to have a much larger photocurrent density, indicating that FeP is excellent at assimilating electrons. Figure 5b shows the evolution of the photocurrent response over time with the 5 wt% FeP loaded on CdS, again displaying higher photocurrent densities than the other FeP co-catalysts and the 1wt% Pt on CdS.

Photoelctrochemical characterization and Scheme of electron transfer.

(a) I–V curve of various FeP co-catalysts and 1wt% Pt on CdS under visible irradiation in chopping mode in a 0.5 M Na2SO4 solution. (b) The unbiased On-Off photocurrent (I–t) of photoanodes including various FeP co-catalysts and 1 wt%Pt on CdS. A 300 W xenon arc lamp was used as the light source with a long-pass cut filter (λ > 420 nm). Mott–Schottky plot of (c) CdS nanoparticles and (d) FeP nanoparticles. (e) Energy level diagram to illustrate photocatalytic H2 evolution using FeP/CdS hybrid as a photocatalyst.

As a typical “transition metal–metalloid” binary alloy, band gap theory also demonstrates through the Mott–Schottky curve50,51 that the conduction band of FeP is more negative than the energy level for H2 evolution (−0.059 V versus NHE, pH 1.0) and is more positive than the conduction band of CdS (as shown in Fig. 5c,d). Thus, the photogenerated electron from CdS can transfer to the conduction band of FeP, where it can be used in H2 production (Fig. 5e).

The work function, energy band gap theory and photoelectrochemical results verified that FeP can effectively separate the photoexcited charge from CdS. It should be mentioned that not all long-lived charge carriers at the surface of FeP can contribute to the course of the photocatalytic reaction, because the active sites on surface of FeP will decide the surface reactions. Fortunately, much more active sites on the surface of FeP because of the binary alloy capability will further increase the hydrogen evolution reaction. Work focusing on the electrochemical H2 generation by transition metal phosphides has demonstrated that both the metal centre (Fe) and the pendant base (P) are active sites for H2 production22,23,28,31,52. We performed the x-ray photoelectron spectroscopy (XPS) results showed that Fe and P in FeP NPs carry a partial positive charge (δ+) and a partial negative charge (δ−), respectively (Fig. S9). This implies electron transfer from Fe to P in FeP28,53,54. Metal Fe exhibits strong binding to H and acts as the hydride acceptor. Meanwhile, P sites play a crucial role by acting as a proton acceptor or the delivery site for H, allowing P to facilitate the formation of iron hydride to be used in subsequent H2 evolution55. This is similar to the situation observed with the [FeFe] or [NiFe] hydrogenase where the active sites feature pendant bases proximate to their metal centres. Metal-complex HER catalysts also incorporate proton relays from pendant acid/base groups positioned close to the metal centre where H2 evolution occurs56,57.

Discussion

As a typical “transition metal-metalloid” binary alloy, FeP displayed some capabilities common among alloys. For example, a number of electrochemical analyses confirmed that both the metal centre (Fe) and the pendant base (P) are active sites for H2 generation. The FeP nanoparticles also combined the merits of both metallic nanoparticles and metal complexes while simultaneously avoiding the decomposition associated with molecular catalysts, which together enabled highly efficient and robust photocatalytic H2-production. However, another band gap theory that illustrates how FeP functions as a semiconductor remained outstanding catalytic activity. In order to further study the properties, we also calculated the band structure of FeP (Figure S10). In the band structure of FeP, one can see that the highest occupied states and the lowest unoccupied states are contacted together near the k-point of G/S and the k-line of U-R, implying the zero band gap (i.e. presents conducting feature) along these wave vector directions. On the other hand, on the k-lines of Z-T and T-Y, there is an obvious band gap (about 1 eV), indicating that the semiconducting feature. This calculated result shown the anisotropy property for electronic structure of FeP, resulting in the semiconducting feature. Furthermore, in the partial density of states of FeP, one can see that Fe-3d states continuously fill the energy region near the EF level, which is the origin of the conducting feature of FeP; while above/below the EF level, there are hybridized states between Fe-3d states and P-3p states, which is the origin of the semi-conducting feature of FeP. Therefore, we combined the experimental analysis and DFT calculations both from the alloy and the semiconductor to demonstrate the mechanism that explains how using FeP as a co-catalyst enhanced the H2 generation activity of CdS.

In summary, a low-cost yet highly efficient and stable semiconductor FeP/CdS photocatalytic system was successfully established using lactic acid as the electron donor. The robust photocatalytic activity was demonstrated by an especially high H2 evolution rate of 202000 μmol h−1 g−1 for a FeP/CdS sample during 5 h of visible lightirradiation and the activity showed an AQE of over 35% at 520 nm, considerably better than that of more common co-catalysts—such as Pt, Ru and MoS2,—and 3-fold higher than that of the control in situ photodepositedPt/CdS system under the same experimental conditions. The system also performed well under solar irradiation with a rate of 106000 μmol h−1 g−1 at midday on the first day of testing. More importantly, FeP/CdS photocatalysts showed impressive photochemical stability even after 100 h of irradiation. The essential thermodynamic relationship and the mechanism of effective charge separation based on the band alignment between the CdS and FeP was elucidated, which will be useful in providing insight for the design and preparation of efficient semiconductor-based, water-based, artificial H2-generating photocatalysts that function under visible light irradiation.

Methods

Preparation of Fe3O4 NPs

All materials were of analytical grade and used as received without further purification. Fe3O4 NPs were prepared using the modified hydrothermal method reported by Li et al.58 (see Figs S1–S3). Principally, 1.35 g of FeCl3·6H2O was added to 25 mL of ethylene glycol. The solution was vigorously stirred until it became transparent. Then, 2.70 g of sodium acetate and 1.0 g of sodium citrate were dissolved into the solution while stirring. The transparent solution was poured into a 50 mL Teflon-lined autoclave and heated at 200 °C for 10 h. The product was then centrifuged and washed several times with deionized water and ethanol. The product was then dried at 80 °C for 12 h in a vacuum oven. The black powder obtained was Fe3O4 NPs.

Preparation of FeP NPs

Fe3O4 (100 mg) and NaH2PO2 (500 mg) were ground using an agate mortar. The mixture was then transferred into a porcelain boat and calcined in a tubular furnace under a flow of Ar gas for 3 h with a heating rate of 2 °C min−1 up to 400 °C to obtain the FeP NPs. The NPs were washed with deionized water and ethanol several times and then dried in a vacuum oven at 40 °C for 8 h to yield the black, solid FeP NPs.

Synthesis of the CdS NPs

In a typical synthesis, Na2S solution was added dropwise into a CdCl2 solution to yield a molar ratio of Cd:S of 1:1.2. The mixed solution was strongly stirred for 24 h and then left to stand for another 24 h. The product was centrifuged and washed with deionized water several times before undergoing ultrasonic treatment with water and being put into a 100 mL Teflon-lined autoclave. The product was then heated at 200 °C for 24 h, filtered and washed by deionized water and ethanol several times before being dried at 80 °C for 10 h to obtain the CdS NPs.

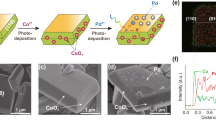

Various proportions of FeP and CdS NPs were combined by strongly grinding them together in the agate mortar for a long period (40 min) to ensure the formation of a robust solid–solid interface between the FeP NPs and the CdS supports. MoS2 NPs and MoS2-CdS composites were synthesized by modifying the existing literature2. Typically, a mixture of 0.25 g of Na2MoO4 and 0.2 g of L-cysteine was dissolved in 40 mL of deionized water which was then transferred into a 50 mL Teflon-lined stainless steel autoclave and heated at 180 °C for 24 h. After cooling naturally, the precipitates were collected by centrifuge, washed and dried in a vacuum oven. To prepare the 1% MoS2-CdS composite, CdCl2 and as-prepared MoS2 were dispersed in water with polyvinylpyrrolidone under an Ar atmosphere. Thioglycolic acid was then added to the solution which was stirred for 2 h before 0.05 M Na2S·9H2O was added. This mixture was then continuously stirred for 2 days. Finally, the products were washed and annealed at 300 °C for 2 h in an Ar atmosphere.

Noble metals including Pt, Ru, Pd and Au were loaded on CdS using in situ the photoreduction method with aqueous solutions of H2PtCl6, RuCl3, PdCl2 and HAuCl4, respectively.

Sample characterization

The crystalline structures of the samples were determined by XRD (Bruker D8 Focus) with Cu-Kα radiation (λ = 1.54056 Å). The morphologies were obtained from a TEM (JEM 2100F) that was operated at an accelerating voltage of 200 kV. The scanning electron microscope (SEM) images and the energy dispersive X-ray spectrometry (EDX) analyses were carried out by a field emission SEM (S-4800, Hitachi) operating at 5 kV. XPS data were obtained with an electron spectrometer (ESCALab220i-XL, VG Scientific) using 300 W Al Kα radiation. The base pressure was approximately 3 × 10−9 mbar. The binding energies were referenced to the C1s line at 284.8 eV from adventitious carbon. The UV-vis absorption spectrum was investigated on a spectrophotometer (U-3010, Hitachi).

Photocatalytic H2 generation

H2 production was carried out in a 50 mL quartz cuvette containing 1 mg of FeP/CdS photocatalyst in a 10 mL aqueous solution containing lactic acid (1 mL, 10% v/v) in a quartz cuvette reaction cell. The cuvette was sealed with a rubber septum and degassed by bubbling Ar through the solution for 40 min at atmospheric pressure. Then, the mixture was irradiated using LEDs (λ > 420 nm, LED: 30 × 3 W, 16 mW/cm2) while stirring. All of the experiments were conducted at room temperature with distilled water. A 0.6 mL gas was intermittently sampled through the septum and was analyzed by a TCD for the quantification of H2 using a gas chromatograph (GC-14C, Shimadzu Co.) equipped with a column (3 m × 2 mm) of 5 Å molecular sieves, a thermal conductivity detector and Ar as the carrier gas. The amount of H2 evolved was calculated relative to the amount of photocatalyst in the system. White LED light source (30 × 3W, λ > 420 nm) were used as the irradiation light sources.

The AQE was measured by the similar method, just applying a Xe lamp (300 W) with a 520 nm bandpass filter (MIF-W, Ceaulight Co., China) as the irradiation light. The number of incident photons was measured using a radiant power energy meter. The total intensity of irradiation was estimated by averaging 20 points of the irradiation area. The AQE was calculated using the following equation:

The film electrodes of different photocatalysts for the photoelectrochemical response measurements were firstly fabricated. The powders and ethanol were mixed homogeneously (150 mg mL−1) and the obtained paste was then spread on the conducting fluorine-doped SnO2 glass substrate (FTO, 15 U per square) with a glass rod, using adhesive tapes as spacers. The resulting films have ca. 4.0 mm thickness and 1.0 cm2 active area.

Photoelectrochemical activity measurements were performed with a CHI electrochemical analyser (Chenhua electrochemical workstation) in a standard three-electrode system using the prepared samples as the working electrodes with an active area of approximately 1.0 cm2, a Pt sheet as the counter electrode and a saturated calomel electrode (SCE) as a reference electrode. A 300 W Xe lamp with a monochromator and a cutoff filter was used as the light source.

DFT calculations

The DFT calculations were carried out by the Cambridge Serial Total Energy Package (CASTEP) codes. The ultrasoft pseudopotential was chosen to deal with the interaction between the ion core and valence electrons. The exchange and correlation effects among valence electrons were described by the Perdew–Burke–Ernzerhof version of the generalized gradient approximation. The Kohn–Sham wave functions of the valence electrons were expanded using a plane-wave basis set within a specified energy cutoff chosen at 340 eV. Using the periodic slab model and self-consistent dipole correction, the averaging electrostatic potential in the planes perpendicular to the slab normal could be obtained. Thus, the change in electrostatic potential through the slab could be plotted. Furthermore, the plot of electrostatic potential also contained the value of work function calculated as the difference between the potential level in a vacuum and the Fermi energy.

Additional Information

How to cite this article: Cheng, H. et al. Robustly photogenerating H2 in water using FeP/CdS catalyst under solar irradiation. Sci. Rep. 6, 19846; doi: 10.1038/srep19846 (2016).

References

Hou, Y. et al. Bioinspired molecular co-catalysts bonded to a silicon photocathode for solar hydrogen evolution. Nat. Mater. 10, 434–438 (2011).

Chang, K. et al. MoS2/graphene co–catalyst for efficient photocatalytic H2 evolution under visible light irradiation. ACS Nano 8, 7078–7087 (2014).

Yang, J., Wang, D., Han, H. & Li, C. Roles of co-catalysts in photocatalysis and photoelectrocatalysis. Acc. Chem. Res. 46, 1900–1909 (2013).

Tong, H. et al. Nano-photocatalytic materials: possibilities and challenges. Adv. Mater. 24, 229–251 (2012).

Kubacka, A., Fernández-García, M. & Colón, G. Advanced nanoarchitectures for solar photocatalytic applications. Chem. Rev. 112, 1555–1614 (2012).

Chen, X., Shen, S., Guo, L. & Mao, S. S. Semiconductor-based photocatalytic hydrogen generation. Chem. Rev. 110, 6503–6570 (2010).

Ghosh Chaudhuri, R. & Paria, S. Core/Shell nanoparticles: classes, properties, synthesis mechanisms, characterization and applications. Chem. Rev. 112, 2373–2433 (2012).

Maeda, K., Teramura, K., Saito, N., Inoue, Y. & Domen, K. Improvement of photocatalytic activity of (Ga1−xZnx)(N1−xOx) solid solution for overall water splitting by co-loading Cr and another transition metal. J. Catal. 243, 303–308 (2006).

Zong, X. et al. Enhancement of photocatalytic H2 evolution on CdS by loading MoS2 as co-catalyst under visible light irradiation. J. Am. Chem. Soc. 130, 7176–7177 (2008).

Jia, T. et al. A graphene dispersed CdS-MoS2 nanocrystal ensemble for cooperative photocatalytic hydrogen production from water. Chem. Commun. 50, 1185–1188 (2014).

Laursen, A. B., Kegnæs, S., Dahl, S. & Chorkendorff, I. Molybdenum sulfides-efficient and viable materials for electro - and photoelectrocatalytic hydrogen evolution. Energy Environ. Sci. 5, 5577–5591 (2012).

Xiang, Q., Yu, J. & Jaroniec, M. Synergetic effect of MoS2 and graphene as co-catalysts for enhanced photocatalytic H2 production activity of TiO2 nanoparticles. J. Am. Chem. Soc. 134, 6575–6578 (2012).

Hong, J., Wang, Y., Wang, Y., Zhang, W. & Xu, R. Noble-metal-free NiS/C3N4 for efficient photocatalytic hydrogen evolution from water. ChemSusChem 6, 2263–2268 (2013).

Zhang, J., Qi, L., Ran, J., Yu, J. & Qiao, S. Z. Ternary NiS/ZnxCd1-xS/reduced graphene oxide nanocomposites for enhanced solar photocatalytic H2-production activity. Adv. Energy Mater. 4, 1301925 (2014).

Kong, C., Min, S. & Lu, G. Dye-Sensitized NiSx Catalyst Decorated on Graphene for Highly Efficient Reduction of Water to Hydrogen under Visible Light Irradiation. ACS Catal. 4, 2763–2769 (2014).

Zhang, J., Yu, J., Zhang, Y., Li, Q. & Gong, J. R. Visible light photocatalytic H2-production activity of CuS/ZnS porous nanosheets based on photoinduced interfacial charge transfer. Nano Lett. 11, 4774–4779 (2011).

Yu, J. & Ran, J. Facile preparation and enhanced photocatalytic H2-production activity of Cu(OH)2 cluster modified TiO2 . Energy Environ. Sci. 4, 1364–1371 (2011).

Dang, H., Dong, X., Dong, Y., Fan, H. & Qiu, Y. Facile synthesis of Co(OH)2 modified TiO2 nanocomposites with enhanced photocatalytic H2 evolution activity. Mater. Lett. 138, 56–59 (2015).

Du, P. & Eisenberg, R. Catalysts made of earth-abundant elements (Co, Ni, Fe) for water splitting: Recent progress and future challenges. Energy Environ. Sci. 5, 6012–6021 (2012).

Popczun, E. J. et al. Nanostructured nickel phosphide as an electrocatalyst for the hydrogen evolution reaction. J. Am. Chem. Soc. 135, 9267–9270 (2013).

Popczun, E. J., Read, C. G., Roske, C. W., Lewis, N. S. & Schaak, R. E. Highly active electrocatalysis of the hydrogen evolution reaction by cobalt phosphide nanoparticles. Angew. Chem. Int. Ed. 53, 5427–5430 (2014).

Liu, Q. et al. Carbon nanotubes decorated with CoP nanocrystals: a highly active non-noble-metal nanohybrid electrocatalyst for hydrogen evolution. Angew. Chem. Int. Ed. 53, 6710–6714 (2014).

Tian, J., Liu, Q., Cheng, N., Asiri, A. M. & Sun, X. Self-supported CuP nanowire arrays as an integrated high-performance three-dimensional cathode for generating hydrogen from water. Angew. Chem. Int. Ed. 53, 9577–9581 (2014).

Kibsgaard, J. & Jaramillo, T. F. Molybdenum phosphosulfide: an Active, acid-stable, earth-abundant catalyst for the hydrogen evolution reaction. Angew. Chem. Int. Ed. 53, 14433–14437 (2014).

Callejas, J. F. et al. Electrocatalytic and photocatalytic hydrogen production from acidic and neutral-pH aqueous solutions using iron phosphide nanoparticles. ACS Nano 8, 11101–11107 (2014).

Xu, Y., Wu, R., Zhang, J., Shi, Y. & Zhang, B. Anion-exchange synthesis of nanoporous FeP nanosheets as electrocatalysts for hydrogen evolution reaction. Chem. Commun. 49, 6656–6658 (2013).

Zhang, Z., Lu, B., Hao, J., Yang, W. & Tang, J. FeP nanoparticles grown on graphene sheets as highly active non-precious-metal electrocatalysts for hydrogen evolution reaction. Chem. Commun. 50, 11554–11557 (2014).

Jiang, P. et al. A cost-effective 3D hydrogen evolution cathode with high catalytic activity: FeP nanowire array as the active phase. Angew. Chem. Int. Ed. 53, 12855–12859 (2014).

Cao, S., Chen, Y., Wang, C. J., He, P. & Fu, W. F. Highly efficient photocatalytic hydrogen evolution by nickel phosphide nanoparticles from aqueous solution. Chem. Commun. 50, 10427–10429 (2014).

Cao, S., Chen, Y., Hou, C. C., Lv, X. J. & Fu, W. F. Cobalt phosphide as a highly active non-precious-metal co-catalyst for photocatalytic hydrogen production under visible light irradiation. J. Mater. Chem. A 3, 6069–6101 (2015).

Liang, Y., Liu, Q., Asiri, A. M., Sun, X. & Luo, Y. Self-supported FeP nanorod arrays: a cost-effective 3D hydrogen evolution cathode with high catalytic activity. ACS Catal. 4, 4065–4069 (2014).

Radha, Thomas, G. S., Kamath, P. V. & Shivakumara, C. Suppression of spinel formation to induce reversible thermal behavior in the layered double hydroxides (LDHs) of Co with Al, Fe, Ga and In. J. Phys. Chem. B 111, 3384–3390 (2007).

Lv, X. J. et al. Synergetic effect of Cu and graphene as co-catalyst on TiO2 for enhanced photocatalytic hydrogen evolution from solar water splitting. J. Mater. Chem. 22, 18542–18549 (2012).

Zhang, H., Lv, X., Li, Y., Wang, Y. & Li, J. P25-graphene composite as a high performance photocatalyst. ACS Nano 4, 380–386 (2009).

Li, Q. et al. Highly efficient visible-light-driven photocatalytic hydrogen production of CdS-cluster-decorated graphene nanosheets. J. Am. Chem. Soc. 133, 10878–10884 (2011).

Xie, Y. P., Yu, Z. B., Liu, G., Ma, X. L. & Cheng, H. M. CdS–mesoporous ZnS core–shell particles for efficient and stable photocatalytic hydrogen evolution under visible light. Energy Environ. Sci. 7, 1895–1901 (2014).

Kim, Y. K. & Park, H. Light-harvesting multi-walled carbon nanotubes and CdS hybrids: Application to photocatalytic hydrogen production from water. Energy Environ. Sci. 4, 685–694 (2011).

Kudo, A. & Miseki, Y. Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 38, 253–278 (2009).

Yang, J. et al. Roles of co-catalysts in Pt–PdS/CdS with exceptionally high quantum efficiency for photocatalytic hydrogen production. J. Catal. 290, 151–157 (2012).

Cao, S., Wang, C. J., Lv, X. J., Chen, Y. & Fu, W. F. A highly efficient photocatalytic H2 evolution system using colloidal CdS nanorods and nickel nanoparticles in water under visible light irradiation. Appl. Catal. B: Environ. 162, 381–391 (2015).

Kang, Y. et al. Highly active Pt3Pb and core–shell Pt3Pb–Pt electrocatalysts for formic acid oxidation. ACS Nano 6, 2818–2825 (2012).

Tian, J. et al. FeP nanoparticles film grown on carbon cloth: an ultrahighly active 3D hydrogen evolution cathode in both acidic and neutral solutions. ACS Appl. Mater. Interfaces 6, 20579–20584 (2014).

Shown, I. et al. Highly efficient visible light photocatalytic reduction of CO2 to hydrocarbon fuels by Cu-nanoparticle decorated graphene oxide. Nano Lett. 14, 6097–6103 (2014).

Wang, F. et al. A highly efficient photocatalytic system for hydrogen production by a robust hydrogenase mimic in an aqueous solution. Angew. Chem. Int. Ed. 50, 3193–3197 (2011).

Li, Z. J. et al. A robust “artificial catalyst” in situ formed from CdTe QDs and inorganic cobalt salts for photocatalytic hydrogen evolution. Energy Environ. Sci. 6, 465–469 (2013).

Clark, S. J. et al. First principles methods using CASTEP. Z. Kristallogr. 220, 567–570 (2005).

Robel, I., Bunker, B. A. & Kamat, P. V. Single-walled carbon nanotube–CdS nanocomposites as light-harvesting Assemblies: Photoinduced Charge-Transfer Interactions. Adv. Mater. 17, 2458–2463 (2005).

Zhang Z. & Yates J. T., Jr. Band bending in semiconductors: chemical and physical consequences at surfaces and interfaces, Chem. Rev. 112, 5520−5551 (2012).

Gerischer, H. J. Phys. Chem. 88, 6096–6907 (1984).

Shabanova, I. N., Kormilets, V. I. & Terebova, N. S. XPS-studies of the electronic structure of Fe–X (X = Al, Si, P, Ge, Sn) systems. J. Electron. Spectrosc. Relat. Phenom. 114–116, 609–614 (2001).

Tian, J., Cheng, N., Liu, Q., Xing, W. & Sun, X. Cobalt phosphide nanowires: efficient nanostructures for fluorescence sensing of biomolecules and photocatalytic evolution of dihydrogen from water under visible light. Angew. Chem. Int. Ed. 54, 5493–5497 (2015).

Tian, J., Liu, Q., Asiri, A. M. & Sun, X. Self-supported nanoporous cobalt phosphide nanowire arrays: an efficient 3D hydrogen-evolving cathode over the wide range of pH 0–14. J. Am. Chem. Soc. 136, 7587–7590 (2014).

Li, L., Chen, C., Chen, L., Zhu, Z. & Hu, J. Catalytic decomposition of toxic chemicals over iron group metals supported on carbon nanotubes. Environ Sci. Technol. 48, 3372–3377 (2014).

Grosvenor, A. P., Wik, S. D., Cavell, R. G. & Mar, A. Examination of the bonding in binary transition-metal monophosphides MP (M = Cr, Mn, Fe, Co) by X-ray photoelectron spectroscopy. Inorg. Chem. 44, 8988–8998 (2005).

Zhang, W. et al. Nickel-thiolate complex catalyst assembled in one step in water for solar H2 production. J. Am. Chem. Soc. 133, 20680–20683 (2011).

Liu, P. & Rodriguez, J. A. Catalysts for hydrogen evolution from the [NiFe] hydrogenase to the Ni2P(001) surface: the importance of ensemble effect. J. Am. Chem. Soc. 127, 14871–14878 (2005).

Nicolet, Y. et al. Crystallographic and FTIR spectroscopic evidence of changes in Fe coordination upon reduction of the active site of the Fe-only hydrogenase from desulfovibrio desulfuricans. J. Am. Chem. Soc. 123, 1596–1601 (2001).

Deng, H. et al. Monodisperse magnetic single-crystal ferrite microspheres. Angew. Chem. Int. Ed. 44, 2782–2785 (2005).

Acknowledgements

Research Program of China (973 Program 2013CB834804, 2013CB632403) and the Ministry of Science and Technology (2012DFH40090). We thank the Natural Science Foundation of China (21273257, 21477136, 21471155) and the Beijing Natural Science Foundation (2132057) for financial support.

Author information

Authors and Affiliations

Contributions

X.-J.L. designed research; H.-Q.C. performed research; S.C. assisted with the experiments and characterizations; X.-J.L., Y.C. and W.-F.F. analysed data; Z.-Y.Z. performed the DFT calculations; X.-J.L. and W.-F.F. wrote the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Cheng, H., Lv, XJ., Cao, S. et al. Robustly photogenerating H2 in water using FeP/CdS catalyst under solar irradiation. Sci Rep 6, 19846 (2016). https://doi.org/10.1038/srep19846

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep19846

This article is cited by

-

A revisiting of transition metal phosphide (Cu3P and FeP) nanozymes for two sugar-related reactions

Nano Research (2023)

-

Three-dimensional ordered macroporous g-C3N4-Cu2O-TiO2 heterojunction for enhanced hydrogen production

Science China Materials (2022)

-

Synthesis of layered compound from walnut shell by template method TiO2/CdS/CoP application of photocatalyst in efficient hydrogen productions

Applied Physics A (2021)

-

Efficient Improved Charge Separation of FeP Decorated Worm-Like Nanoporous BiVO4 Photoanodes for Solar-Driven Water Splitting

Catalysis Letters (2021)

-

Photocatalytic degradation of metronidazole and methylene blue by PVA-assisted Bi2WO6–CdS nanocomposite film under visible light irradiation

Applied Nanoscience (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.