Abstract

High mobility channel thin-film-transistor (TFT) is crucial for both display and future generation integrated circuit. We report a new metal-oxide TFT that has an ultra-thin 4.5 nm SnO2 thickness for both active channel and source-drain regions, very high 147 cm2/Vs field-effect mobility, high ION/IOFF of 2.3 × 107, small 110 mV/dec sub-threshold slope and a low VD of 2.5 V for low power operation. This mobility is already better than chemical-vapor-deposition grown multi-layers MoS2 TFT. From first principle quantum-mechanical calculation, the high mobility TFT is due to strongly overlapped orbitals.

Similar content being viewed by others

Introduction

The metal-oxide thin-film transistor (TFT)1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20 is a revolutionary technology for displays due to its high mobility and simple process. The high mobility of zinc-oxide (ZnO)-based materials was attributed to the spatially spread metal ns orbitals with isotropic shape, which is possible to overlap the neighboring metal ns orbitals7. However, the high performance ZnO-based TFTs of InGaZnO7, bi-layer InSnO/InGaZnO11, InZnO13 and GaZnON18 compounds usually contain Indium (In) or Gallium (Ga), which are rare elements in earth’s crust. In addition, device performance is sensitive to the moisture degradation and atomic composition of these compound. Alternatively, high mobility, high transistor on-current (ION) and low off-current (IOFF) TFTs are found in two-dimensional metal-chalcogenide21,22,23,24,25,26,27,28. However, chemical vapor deposition (CVD)-grown MoS225,26,27,28 shows a considerably lower mobility compared with peeled-off flakes from crystals21. To further increase the display pixel density and drive organic light-emitting diodes (OLED), higher mobility and ION than those of ZnO-based TFTs are needed. The low DC and switching power consumptions are other technological trends for displays that require a low IOFF and low operation voltage. In this study, a remarkably high field–effect mobility (μFE) of 147 cm2/Vs was demonstrated experimentally in tin-oxide (SnO2) TFT. This TFT also showed a high ION/IOFF of 2.3 × 107, low sub-threshold swing (SS) of 0.11 V/decade, low threshold voltage (VT) of 0.27 V, low drive voltage of 2.5 V for low switching power and ultra-thin layer with a thickness of 4.5 nm. Such ultra-thin thickness is comparable with that of multilayered MoS227 for low DC standby power consumption. Notably, Sn (Group IV) has ns2np2 electron configuration and directive sp3 orbitals, which differ from those of Zn7. According to first principle quantum-mechanical calculations, the considerably high μFE in SnO2 TFT is caused by its overlapped s-orbitals even in an ns2np2 configuration.

Results

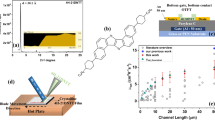

To increase the transistor ION and reduce the operation voltage, a high-dielectric-constant (high-κ) gate insulator12,15 was used for the TFT. Figure 1(a) shows the current-voltage (I-V) and capacitance-voltage (C-V) characteristics of a gate capacitor with top Aluminum (Al) electrode, high-κ hafnium-oxide (HfO2) and bottom n+-Si. In the Al/HfO2/n+-Si capacitor, a small leakage current of 5.7 × 10−7 A/cm2 at 2 V was obtained at a capacitance density of 0.38 μF/cm2. The high capacitance density yielded a low equivalent-oxide-thickness (EOT) of only 9.1 nm, which was due to the high-κ HfO2 with a κ of 17. Figure 1(b) shows the transistor’s drain current versus gate voltage (IDS-VGS) characteristics of the SnO2/HfO2 TFTs with 4.5 ~ 20 nm thick SnO2. The device with thick 20 nm SnO2 failed to show proper pinch off IOFF due to very high conductivity, although the device has very high ION. The device with 4.5 nm thick SnO2 shows the best ION/IOFF performance. Figure 1(c,d) show the transistor’s drain current versus drain voltage (IDS-VDS), IDS-VGS and μFE-VGS characteristics of the SnO2/HfO2 TFT with 4.5 nm thick SnO2, respectively. The device was operated in the enhancement mode of an n-channel metal-oxide-semiconductor field-effect transistor (nMOSFET) at a low operation voltage of 2.5 V. The device also showed a high ION/IOFF of 2.3 × 107, low SS of 110 mV/decade and low VT of 0.27 V. The VT was extracted from the intercept of the linear IDS1/2-VGS curve in a saturation region. A high ION is crucial to drive the OLED and increase the display pixel density, whereas a low IOFF is required to reduce the DC standby power. The low SS with the mean value and standard deviation of 100.2±19.4 mV/decade indicates the good oxide/semiconductor interface to turn on the transistor fast. The ION showed an inversely proportional relation with gate length in a wide gate length TFT, a typical method to extract mobility correctly for Si MOSFET and metal-gate/high-κ MOSFET29,30,31. A remarkably high μFE of 147 cm2/Vs is obtained with the mean value and standard deviation of 141.6 ± 11.5 cm2/Vs, which is higher than that of ZnO-based TFTs3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20 and even higher than that of a CVD-grown multilayered MoS2 MOSFET21,22,23,24. To reach high mobility, epitaxial growth of crystalline MoS2 on a crystal substrate is needed. Unfortunately, the mobility is lower for CVD-grown MoS225,26,27,28 than peeled-off flakes from crystals21,22,23,24,25,26,27,28. The lattice mismatch caused defects are the other major concern for circuit yield. In contrast, high mobility SnO2 TFT is achievable on the amorphous substrate and free from lattice-mismatch defects. Such metal-oxide has already been used to manufacture TFT circuit for display. It is crucial to notice that the mobility of metal-oxide increases with increasing carrier density7. In the 4.5-nm-thick SnO2 TFT, the high mobility is due to the high VG-induced carrier density31 of ~1013 cm−2 to screen out charged defects. This is also supported by the higher mobility with larger VG7, where induced carrier density increases with VG. In the thicker 7 ~ 20 nm SnO2 devices with poor pinch off, the mobility is lowered by extra parallel conduction from non-depleted bulk SnO2. The mobility is lowered in 3.5 nm SnO2 TFT due to stronger roughness scattering from top surface. Here the SnO2 surface roughness is 0.39 nm, close to the HfO2 roughness of 0.41 nm.

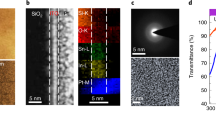

The high mobility SnO2 TFT was further investigated using material analysis. Figure 2(a) shows the X-ray photoelectron spectroscopy (XPS) spectra from the Sn 3d and O 1s core level of the SnO2 thin film. The Sn 3d peak corresponded to the oxidation state of Sn4+ and the O 1s peak was attributed to the O-Sn and O-H bonds. Thus, the chemical composition was determined to be Sn4+O22−. The X-ray diffraction spectroscopy (XRD) pattern in Fig. 2(b) reveals the presence of a rutile phase in SnO2. An average grain size of 7.9 nm was obtained using the Scherrer’s equation. Figure 2(c) shows the cross-sectional transmission electron microscopy (TEM) image of the SnO2/HfO2 stack. A relatively uniform SnO2 layer with an ultra-thin thickness of 4.5 nm was observed.

To thoroughly understand the cause of the high mobility in SnO2 TFT, first principle quantum-mechanical calculations were used to investigate the electronic structures of SnO2 and ZnO; ZnO has been extensively studied using the localized density functional theory (DFT) to reveal the mechanism that leads to its high mobility. The structures of both SnO2 and ZnO semiconductors were successfully obtained using local density approximation plus U (LDA+U) method with appropriate Up and Ud value. The LDA+U method compensates for the underestimation of the bandgap caused by a strong self-interaction by the DFT. The bandgaps of SnO2 and ZnO were calculated to be 3.68 and 3.39 eV (Figure S1(a) and S1(b)), respectively, which are consistent with the experimental values of 3.6 and 3.4 eV, respectively. The contribution of each orbital in the conduction band minimum (CBM) of SnO2 was investigated using density of state (DOS) analysis. The energy of valence band minimum was set to zero for convenience. As shown in Fig. 3(a), the upmost valence band was predominated by the O 2p orbitals and the contribution from Sn was mostly from 5p orbitals. The lower conduction states near CBM were mostly derived from Sn 5s orbitals, whereas the O 2p orbitals contributed only in higher energy states. The Sn 4d orbitals did not give rise to the electron conducting property of SnO2 because the antibonding interaction between Sn 4d and O 2p orbitals led only to the slight mixing of states at a deep valence band level. The DOS results of ZnO (Fig. 3(b)) were similar to those of SnO2. The major difference between the valence bands of SnO2 and ZnO is the contribution of d orbitals. The upper valence bands (from −6 to 0 eV) were composed of primarily of O 2p orbitals and slight mixing states from Zn 4s, 4p and 3d, whereas Zn 3d orbitals dominated in deeper states. In conduction band, Zn 4s was the major component near CBM while O 2p orbitals had little contribution at levels lower than 5 eV. Therefore, the high mobility of SnO2 was attributed to the overlapping of s-orbitals, as with ZnO, although it had ns2np2 configuration. This is further supported by the charge density distribution of SnO2 shown in Figure S2(a), which has highly overlapped orbitals similar with those of ZnO in Figure S2(b). The highly overlapped orbitals of SnO2 is related to large atomic radius, one row below Zn in the periodic table. From the results of DOS and charge density distribution, the higher mobility than the state-of-the-art ZnO TFTs32,33 is attributed to the highly overlapped s-orbitals of SnO2.

The carrier effective mass is a major factor that may explain the higher mobility of SnO2 than that of ZnO. The high electron mobility of n-type materials is caused by a deep curvature in CBM of band structure shown in Figure S1(a) and S1(b), which leads to a low effective mass of electrons. The calculated electron effective mass of SnO2 was approximately 20% lighter than that of ZnO, indicating a faster electron transport in the SnO2 conduction band.

In conclusion, this SnO2 TFT device had a considerably high mobility, high ION/IOFF, low SS, low operation voltage and ultra-thin thickness. The low operation voltage is due to the high-κ gate dielectric with a high capacitance density. The low SS indicates the good gate dielectric and SnO2 interface. The high ION/IOFF is related to the high mobility to increase ION and the ultra-thin thickness to decrease IOFF, where the high mobility is caused by strongly overlapped s-orbitals.

Methods

The SnO2 TFTs were fabricated on a heavily doped n-type silicon (100) substrate. The 40-nm-thick high-κ gate HfO2 and 20 ~ 3.5-nm-thick SnO2 films were deposited by physical vapor deposition. Thicker 20 nm SnO2 film was also deposited for X-ray photoelectron spectroscopy (XPS) and X-ray diffraction (XRD) pattern analysis. Then the high-κ layer and SnO2 film was annealed at 400oC. Finally, the Al source-drain electrodes were thermally evaporated and patterned. The gate length and width are 50 ~ 150 μm and 500 μm, respectively. Therefore, the maximum process temperature for this device is 400oC. The fabricated devices were characterized by XPS, XRD, TEM, C-V and I-V measurements. All quantum-mechanical calculations were performed by Cambridge Sequential Total Energy Package (CASTEP) code. Structural optimization was performed on each model prior to calculating their electrical properties. The LDA+U method is known to correct the strong correlation of metal oxides and is proven to be quite effective for ZnO. The calculations were carried out by using generalized gradient approximation (GGA) with LDA+U.

Additional Information

How to cite this article: Wei Shih, C. et al. Remarkably high mobility ultra-thin-film metal-oxide transistor with strongly overlapped orbitals. Sci. Rep. 6, 19023; doi: 10.1038/srep19023 (2016).

References

Boesen, G. F. & Jacobs, J. E. Comparison between the oscillating limiter and the first-order phase-locked loop. Proceedings of IEEE 12, 2094 (1968).

Prins, M. W. J. et al. A ferroelectric transparent thin‐film transistor. Appl. Phys. Lett. 68, 3650 (1996).

Nomura, K. et al. Thin-film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 300, 1269 (2003).

Hoffman, R. L., Norris, B. J. & Wager, J. F. ZnO-based transparent thin-film transistors. Appl. Phys. Lett. 82, 733 (2003).

Carcia, P. F., McLean, R. S., Reilly, M. H. & Nunes, G. Transparent ZnO thin-film transistor fabricated by rf magnetron sputtering. Appl. Phys. Lett. 82, 1117 (2003).

Masuda, S. et al. Transparent thin film transistors using ZnO as an active channel layer and their electrical properties. J. Appl. Phys. 93, 1624 (2003).

Nomura, K. et al. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 432, 488 (2004).

Presley, R. E. et al. Tin oxide transparent thin-film transistors. J. Phys. D-Appl. Phys. 37, 2810 (2004).

Fortunato, E. M. C. et al. Fully transparent ZnO thin-film transistor produced at room temperature. Adv. Mater. 17, 590 (2005).

Iwasaki, T. et al. Combinatorial approach to thin-film transistors using multicomponent semiconductor channels: An application to amorphous oxide semiconductors in In–Ga–Zn–O system. Appl. Phys. Lett. 90, 242114 (2007).

Kim, S. I. et al. High performance oxide thin film transistors with double active layers. IEDM Tech. Dig. 73 (2008).

Su, N. C., Wang, S. J. & Chin, A. High-performance InGaZnO thin-film transistors using HfLaO gate dielectric. IEEE Electron Device Lett. 30, 1317 (2009).

Park, J. C. et al. High performance amorphous oxide thin film transistors with self-aligned top-gate structure. IEDM Tech. Dig. 191 (2009).

Kamiya, T., Nomura, K. & Hosono, H. Present status of amorphous In–Ga–Zn–O thin-film transistors. Sci. Technol. Adv. Mater. 11, 044305 (2010).

Su, N. C. et al. Low-voltage-driven flexible InGaZnO thin-film transistor with small subthreshold swing. IEEE Electron Device Lett. 31, 680 (2010).

Zan, H. W., Tsai, W.-W., Chen, C.-H. & Tsai, C.-C. Effective mobility enhancement by using nanometer dot doping in amorphous IGZO thin-film transistors. Adv. Mater. 23, 4237 (2011).

Fortunato, E., Barquinha, P. & Martins, R. Oxide semiconductor thin-film transistors: A review of recent advances. Adv. Mater. 24, 2945 (2012).

Kim, T. S. et al. High performance gallium-zinc oxynitride thin film transistors for next-generation display applications. IEDM Tech. Dig. 660 (2013).

Lee, E. et al. Nanocrystalline ZnON; High mobility and low band gap semiconductor material for high performance switch transistor and image sensor application. Scientific Reports 4, 4948 (2014).

Bak, J. Y. et al. Origin of degradation phenomenon under drain bias stress for oxide thin film transistors using IGZO and IGO channel layers. Scientific Reports 5, 7884 (2015).

Radisavljevic, B., Radenovic, A., Brivio, J., Giacometti, V. & Kis, A. Single-layer MoS2 transistors. Nature Nanotech. 6, 147 (2011).

Kim, S. et al. High-mobility and low-power thin-film transistors based on multilayer MoS2 crystals. Nature Commun. 3, 1011 (2012).

Das, S., Chen, H. Y., Penumatcha, A. V. & Appenzeller, J. High performance multilayer MoS2 transistors with scandium contacts. Nano Lett. 13, 100 (2013).

Ganatra, R. & Zhang, Q. Few-layer MoS2: A promising layered semiconductor. ACS Nano 8, 4074 (2014).

Lee, Y. H. et al. Synthesis of large-area MoS2 atomic layers with chemical vapor deposition. Adv. Mater. 24, 2320 (2012).

Wu, W. et al. High mobility and high on/off ratio field-effect transistors based on chemical vapor deposited single-crystal MoS2 grains. Appl. Phys. Lett. 102, 142106 (2013).

Chen, M. C. et al. Hybrid Si/TMD 2D electronic double channels fabricated using solid CVD few-layer-MoS2 stacking for Vth matching and CMOS-compatible 3DFETs. IEDM Tech. Dig. 808 (2014).

Kang, K. et al. High-mobility three-atom-thick semiconducting films with wafer-scale homogeneity. Nature 520, 656 (2015).

Sun, S. C. & Plummer, J. D. Electron mobility in inversion and accumulation layers on thermally oxidized silicon surfaces. IEEE Trans. Electron Devices 8, 1497 (1980).

Cheng, C. F. et al. Very low Vt [Ir-Hf]/HfLaO CMOS using novel self-aligned low temperature shallow junctions. IEDM Tech. Dig. 333 (2007).

Liao, C. C. et al. Metal-gate/high-κ/Ge nMOS at small CET with higher mobility than SiO2/Si at wide range carrier densities, IEEE Electron Device Lett. 34, 163 (2013).

Chang, S. J. et al. Mobility behavior and models for fully depleted nanocrystalline ZnO thin film transistors. Solid State Electronics 90, 134 (2013).

Bayraktaroglu, B. & Leedy, K. Self-assembled nanocrystalline ZnO thin film transistor performance optimization for high speed applications. Turk J Phys 38, 375 (2014).

Acknowledgements

This paper’s publication was supported in part by Ministry of Science and Technology of Taiwan. We would like to thank the computing time support from National Taiwan University of Science & Technology and National Center for High-performance Computing.

Author information

Authors and Affiliations

Contributions

C.W.S. did the experiments; A.C. supervised the experiments and wrote the main manuscript text; C.F.L. and W.F.S. did the quantum-mechanical calculations. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wei Shih, C., Chin, A., Fu Lu, C. et al. Remarkably high mobility ultra-thin-film metal-oxide transistor with strongly overlapped orbitals. Sci Rep 6, 19023 (2016). https://doi.org/10.1038/srep19023

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep19023

This article is cited by

-

Large mobility modulation in ultrathin amorphous titanium oxide transistors

Communications Materials (2020)

-

High mobility approaching the intrinsic limit in Ta-doped SnO2 films epitaxially grown on TiO2 (001) substrates

Scientific Reports (2020)

-

All-inkjet-printed high-performance flexible MoS2 and MoS2-reduced graphene oxide field-effect transistors

Journal of Materials Science (2020)

-

Ultrathin channels make transistors go faster

Nature Materials (2019)

-

Remarkably High Hole Mobility Metal-Oxide Thin-Film Transistors

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.