Abstract

In open beef feedlot systems, more than 50% of dietary nitrogen (N) is lost as ammonia (NH3). Here we report an effective and economically-viable method to mitigate NH3 emissions by the application of lignite. We constructed two cattle pens (20 × 20 m) to determine the effectiveness of lignite in reducing NH3 emissions. Twenty-four steers were fed identical commercial rations in each pen. The treatment pen surface was dressed with 4.5 kg m−2 lignite dry mass while no lignite was applied in the control pen. We measured volatilised NH3 concentrations using Ecotech EC9842 NH3 analysers in conjunction with a mass balance method to calculate NH3 fluxes. Application of lignite decreased NH3 loss from the pen by approximately 66%. The cumulative NH3 losses were 6.26 and 2.13 kg N head−1 in the control and lignite treatment, respectively. In addition to the environmental benefits of reduced NH3 losses, the value of retained N nutrient in the lignite treated manure is more than $37 AUD head−1 yr−1, based on the current fertiliser cost and estimated cost of lignite application. We show that lignite application is a cost-effective method to reduce NH3 loss from cattle feedlots.

Similar content being viewed by others

Introduction

Ammonia (NH3), a form of reactive nitrogen (N), poses negative effects on ecosystems and biodiversity through its deposition, on human health through secondary particulate matter formation and on emissions of the greenhouse gas nitrous oxide1,2. Globally, livestock industries account for as much as 40% of total NH3 emissions3. Cattle feedlots are large hotspots of NH3 and about 53–65% of the N consumed in feedlot rations is lost as NH34,5. It is suggested that the feedlot pen is the major source of NH3 emissions from cattle feeding operations as faeces and urine are deposited directly to the surface and urinary urea (50 to 90% N in urine6) is rapidly hydrolysed into NH3 and then lost to the atmosphere via volatilization.

Strategies to mitigate NH3 emissions from feedlots have been suggested, which include changing diet formulation7,8 and using additives or management to alter soil and storage conditions of manure to suppress urea hydrolysis9,10,11. However, none of these approaches have been adopted widely by the industry, because of cost and/or difficulties in on-farm implementation of those practices in commercial environments.

Lignite (brown coal) is a low rank, low ash, high moisture content coal12. There are large reserves of lignite in the Latrobe Valley of Victoria, Australia. This lignite is acidic in nature, has a high humic acid content, high cation exchange capacity and contains up to 20% of labile carbon, all of which may suppress NH3 volatilization from manure. It has been reported that NH3 emissions can be significantly reduced with acidifying additives13. For instance, 60–68% NH3 reduction from cattle manure by brown/black humate application was reported by Shi et al.14. The use of lignite in abating NH3 emissions from open feedlot pens is conceptually promising, but has not been previously reported. We conducted an experiment at Dookie (36.39°S, 145.71°E), Victoria, Australia, to quantify the abatement potential of lignite application on NH3 emissions from feedlots. We used two cattle pens each holding 24 black Angus steers and measured NH3 concentrations continuously for 40 days using Ecotech EC9842 NH3 analysers in conjunction with a mass balance method to calculate NH3 fluxes.

Results and Discussion

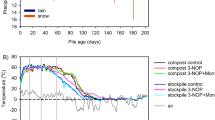

A strong diurnal variation in NH3 emissions from both pens was observed, with the lowest emissions occurring at dawn and the highest occurring at around mid-day (Fig. 1). This pattern in emissions corresponds to the daily temperature variation and has been reported in other studies2,15. Hourly emission rates of NH3 varied from 0.01 to 14.0 g N head−1 hr−1 for lignite treatment and from 0.14 to 29.0 g N head−1 hr−1 for control treatment. Ammonia emissions from the control pen increased significantly after cattle were introduced (9–11 am on 4th November) (Fig. 1), reflecting rapid hydrolysis of urinary-urea16,17. Ammonia volatilization was almost completely suppressed by lignite during the first 10 days compared to the control. After that, the suppression started to decline, but the NH3 emission rates in the lignite treated pen were still about 50% less than that in control pen (Fig. 1) at the end of (40 days) experiment.

The average daily NH3 emission rates were 53.2 ± 6.4 and 156.4 ± 10.7 g N head−1 d−1 for lignite and control pens, respectively (Table 1). The NH3 emission rate from the control pen was comparable to those observed in other feedlot studies (100−200 g N head−1 d−1)15,18. Nitrogen excretion from the cattle was estimated to be approximately 350 g head−1 d−1 (using NRC19 estimates). Nitrogen loss through NH3 volatilization from pen surface accounted for approximately 15 and 45% of N in cattle excretion, for lignite and control pens, respectively. The application of lignite reduced NH3 emission by 103.2 g N head−1 d−1 or 66.0% compared to the control. The cumulative NH3 emissions were 2.13 ± 0.11 and 6.26 ± 0.31 kg N head−1, for lignite and control pens, respectively (Table 1 and Fig. 2). When collected from pens after 40 days, manure treated with lignite had a higher N content (2.4%) than that of the control pen (1.7%). The amount of N retained in manure was 9.9 and 5.3 kg head−1 for lignite and control pen, respectively.

Our results show that application of lignite is more effective, practical and longer lasting than applying the urease inhibitor NBPT (47–49%17 or 64–66%14 reduction of ammonia loss, last less than a week17 and not tested for continuous excretion-N input at feedlots), humate14 (60–68% reduction of ammonia loss, high application rate and not cost effective) or acidifying additives11 (normally require complex application systems). Lignite abates NH3 emissions through its strong acidity13,20 (pH 3.69), strong adsorption capacity of ammonium20 (cation exchange capacity 96.8 cmol(+) kg−1) as well as biological immobilisation due to the high content of labile carbon21,22 (20.1%). The humic acid content of the lignite may also indirectly inhibit urea hydrolysis23. However, these effects will decline when the acidity is neutralised and the cation exchange capacity reduced through the accumulation of manure in the feedlot. After routine manure removal from pens, lignite needs to be reapplied to optimise the reduction of NH3 emissions.

It has been widely reported that the application of feedlot manure to crop land can increase crop yield, maintain soil organic matter content and improve soil physical condition24,25. Feedlot manure with higher N content can practically reduce the total application amount, resulting in less environmental risks related to other nutrients in manure, such as leaching of phosphorus26. When extrapolating to an annual basis, the addition of lignite decreased NH3 volatilization by approximately 38 kg N head−1 yr−1. Given the market price for urea fertiliser (46% N) of $600 AUD tonne−1, the N nutrient retained in the manure by lignite is equivalent to approximately $49 AUD head−1 yr−1. We estimate the cost of lignite application at a commercial feedlot, including cost of purchase, transportation of 500 km from source and feedlot surface dressing of 4.5 kg dry mass applied every 40 days, to be $11.7 AUD head−1 yr−1.

The emitted NH3 from intensive sources may have substantial local impacts on the surrounding ecosystems27,28. A study of NH3 deposition near a feedlot in Canada revealed that a large portion (19%) of emitted NH3 was deposited within 1.7 km of the source29. Therefore, reducing emissions from the local hot spots such as feedlots will also achieve local environmental benefits. In summary, the addition of lignite is a cost-effective method for mitigating NH3 emissions, reducing environmental impacts and improving N use efficiency of these intensive animal production systems. These findings have major economic and environmental implications for effective N management in agriculture, especially in feedlots.

Methods

The experimental site was topographically flat and underlain by a clay soil. The prevailing winds during the experiment period were SSW, with the minimum daily temperature 6 °C and the maximum 39 °C (Fig. 1). Two cattle pens (20 × 20 m, 180 m apart) were constructed to mimic the environment of cattle feedlots. Prior to introducing animals, lignite, at a rate of 4.5 kg m−2, was spread uniformly within the treatment pen. The lignite, Yallourn Brown Coal, had a pH of 3.69, a cation exchange capacity of 96.75 cmol(+) kg−1, a labile carbon content of 20.13% and a water content of 65%. No lignite was applied in the control pen. Twenty-four Angus steers (Bos taurus; 12 months of age, with initial average live weight of 486 ± 33 kg) were put into each pen. Ammonia flux measurements were conducted from 4th November (cattle moved in around 9–11 am) to 13th December 2013 (cattle moved out around 1–3 pm) for 40 days. During this period the cattle were fed twice a day with a diet of 50% grain and 50% hay (17% crude protein, 27.2 g N kg−1 dry matter). Live weight of cattle and the weight of accumulated manure were recorded at the end of the measurement period. These data were used to estimate N excretion of urine and faeces using NRC19. All experiments were approved by the University of Melbourne Animal Ethics Committee under licence 1312794.1 and conducted in accordance with guidelines and regulations of this committee.

An NH3 chemiluminescence analyser (EC9842, Ecotech Pty Ltd, Australia) was used to measure NH3 concentrations at each pen. The analysers were housed in air-conditioned trailers and placed approximately 30 m away from the pens. Analysers were calibrated against an NH3 target tank every two weeks. Air was transferred to the NH3 analysers through ¼ inch OD Teflon tubing from a sampling mast in the centre of each pen. There were 5 sampling inlets at heights of 0.25, 1, 2, 3 and 4 m. Sampling lines were constantly pumped and samples were delivered to the analysers via an automated manifold with a sequenced switching program. Every inlet was sampled for 6 minutes, resulting in a half-hour cycle of the five inlets. A custom-made hot water sleeve system was used to maintain temperatures of sampling lines at 45 °C to prevent NH3 condensation or build-up in the sampling lines. A two-dimensional sonic anemometer (WindSonic, Gill Instruments Ltd, UK) was mounted at each sampling height to record horizontal wind speed and direction.

Ammonia emission rates were calculated using a mass balance approach, the integrated horizontal flux (IHF) method30,31. The method is well-suited for small and well-defined experimental areas and requires no corrections for atmospheric stability or the shape of the wind profile32. The emission rate, which is the vertical flux, was calculated by integrating the horizontal flux density across the vertical profile:

where X is the mean fetch (distance from edge of pen along the line of the mean wind direction to the centre mast) for the calculated period, u is the horizontal wind speed at height z and ρN is the concentration of NH3 at height z. It is assumed that the horizontal flux is zero at the ground because the wind speed goes to zero there. The background concentrations at the height of 4 m are subtracted from the measured concentrations to get the ρN in the calculation. We reduced the calculated flux by 15%, based on empirical evidence from previous studies that the IHF method overestimates the true flux by 10–15%33,34.

Ammonia data was not available from 27th November to 6th December when the EC9842 analyser at the lignite pen malfunctioned. Following Junninen et al.35. We applied linear regression to compute cumulative NH3 fluxes for the period had missing data based on the data obtained 7 days prior to and 7 days after this period (Fig. 2). Similarly, there was some intermittent data lost (2nd, 3rd, 5th and 6th December) from the control pen. The diel pattern of NH3 emission was used to interpolate the daily fluxes of the four days that had missing hourly data points for the control pen.

According to the manufacturer36, the EC9842 analysers have a random error (precision) of 1% and a systematic error of 5% for measurements taken at a 5-minute interval. We calculated the total errors for the cumulative fluxes based on the nominal errors defined by the manufacturer using the approach of Moncrieff et al.37 (Fig. 2). Random errors had a minimal impact (accounting for approximately 1‰) on the cumulative flux37. In addition, we allowed a 20% systematic error in a sensitivity analysis as shown in Fig. 2, which still shows a significant difference between lignite and control treatments.

Additional Information

How to cite this article: Chen, D. et al. A new cost-effective method to mitigate ammonia loss from intensive cattle feedlots: application of lignite. Sci. Rep. 5, 16689; doi: 10.1038/srep16689 (2015).

References

Dean, S. L. et al. Nitrogen deposition alters plant-fungal relationships: linking belowground dynamics to aboveground vegetation change. Mol Ecol 23, 1364–1378 (2014).

Denmead, O. T. et al. Gaseous nitrogen emissions from Australian cattle feedlots. In: Nitrogen Deposition, Critical Loads and Biodiversity (eds Sutton, M. A., Mason, K. E., Sheppard, L. J., Sverdrup, H., Haeuber, R. & Hicks, W. K. ). Springer: Netherlands, (2014).

Bouwman, A. F. et al. A global high-resolution emission inventory for ammonia. Global Biogeochem Cycles 11, 561–587 (1997).

Flesch, T. K. et al. Determining ammonia emissions from a cattle feedlot with an inverse dispersion technique. Agr Forest Meteorol 144, 139–155 (2007).

Todd, R. W. et al. Ammonia emissions from a beef cattle feedyard on the southern High Plains. Atmos Environ 42, 6797–6805 (2008).

Dijkstra, J. et al. Diet effects on urine composition of cattle and N2O emissions. Animal 7, 292–302 (2013).

Guo, J. & Zhou, C. Greenhouse gas emissions and mitigation measures in Chinese agroecosystems. Agr Forest Meteorol 142, 270–277 (2007).

Carew, R. Ammonia emissions from livestock industries in Canada: Feasibility of abatement strategies. Environ Pollut 158, 2618–2626 (2010).

Kithome, M., Paul, J. W. & Bomke, A. A. Reducing nitrogen losses during simulated composting of poultry manure using adsorbents or chemical amendments. J Environ Qual 28, 194–201 (1999).

Petersen, S. O., Andersen, A. J. & Eriksen, J. Effects of cattle slurry acidification on ammonia and methane evolution during storage. J Environ Qual 41, 88–94 (2012).

McCrory, D. F. & Hobbs, P. J. Additives to Reduce Ammonia and Odor Emissions from Livestock Wastes. J Environ Qual 30, 345–355 (2001).

Li, N., Ma, Z. & Zhu, Y. Experimental study on drying and agglomerating moulding on lignite. Adv Mat Res 158, 64–70 (2011).

Husted, S., Jensen, L. S. & Jørgensen, S. S. Reducing ammonia loss from cattle slurry by the use of acidifying additives: The role of the buffer system. J Sci Food Agric 57, 335–349 (1991).

Shi, Y. et al. Surface amendments to minimize ammonia emissions from beef cattle feedlots. Trans ASAE 44, 677–682 (2001).

Denmead, O. T. et al. Emissions of the indirect greenhouse gases NH3 and NOx from Australian beef cattle feedlots. Aust J Exp Agr 48, 213–218 (2008).

Laubach, J. et al. Ammonia emissions from cattle urine and dung excreted on pasture. Biogeosciences 10, 327–338 (2013).

Pereira, J. et al. Effects of a urease inhibitor and aluminium chloride alone or combined with a nitrification inhibitor on gaseous N emissions following soil application of cattle urine. Biosys Eng 115, 396–407 (2013).

Loh, Z. et al. Measurement of greenhouse gas emissions from Australian feedlot beef production using open-path spectroscopy and atmospheric dispersion modelling. Aust J Exp Agr 48, 244–247 (2008).

National Research Council. Nutrient requirements of beef cattle. National Academy Press Washington, DC (1996).

Sommer, S. G. et al. Processes controlling ammonia emission from livestock slurry in the field. Eur J Agron 19, 465–486 (2003).

Manzoni, S. & Porporato, A. Soil carbon and nitrogen mineralization: Theory and models across scales. Soil Biol Biochem 41, 1355–1379 (2009).

He, Z. L. et al. Clinoptilolite zeolite and cellulose amendments to reduce ammonia volatilization in a calcareous sandy soil. Plant Soil 247, 253–260 (2002).

Dong, L. et al. Humic acids buffer the effects of urea on soil ammonia oxidizers and potential nitrification. Soil Biol Biochem 41, 1612–1621 (2009).

Chang, C., Sommerfeldt, T. & Entz, T. Soil chemistry after eleven annual applications of cattle feedlot manure. J Environ Qual 20, 475–480 (1991).

Sommerfeldt, T. G. & Chang, C. Changes in Soil Properties Under Annual Applications of Feedlot Manure and Different Tillage Practices. Soil Sci Soc Am J 49, 983–987 (1985).

Whalen, J. K. & Chang, C. Phosphorus accumulation in cultivated soils from long-term annual applications of cattle feedlot manure. J Environ Qual 30, 229–237 (2001).

Sommer, S. G. et al. Validation of model calculation of ammonia deposition in the neighbourhood of a poultry farm using measured NH3 concentrations and N deposition. Atmos Environ 43, 915–920 (2009).

Sutton, M. A., Erisman, J. W., Dentener, F. & Möller, D. Ammonia in the environment: From ancient times to the present. Environ Pollut 156, 583–604 (2008).

Hao, X. et al. Sorption of Atmospheric Ammonia by Soil and Perennial Grass Downwind From Two Large Cattle Feedlots. J Environ Qual 35, 1960–1965 (2006).

Denmead, O. T. Novel meteorological methods for measuring trace gas fluxes. Philos Transact A Math Phys Eng Sci 351, 383–396 (1995).

Beauchamp, E. G., Kidd, G. E. & Thurtell, G. Ammonia volatilization from sewage sludge applied in the field. J Environ Qual 7, 141–146 (1978).

Denmead, O. T. Approaches to measuring fluxes of methane and nitrous oxide between landscapes and the atmosphere. Plant Soil 309, 5–24 (2008).

Denmead, O. T. et al. A mass balance method for non-intrusive measurements of surface-air trace gas exchange. Atmos Environ 32, 3679–3688 (1998).

Leuning, R., Freney, J. R., Denmead, O. T. & Simpson, J. R. A sampler for measuring atmospheric ammonia flux. Atmos Environ 19, 1117–1124 (1985).

Junninen, H. et al. Methods for imputation of missing values in air quality data sets. Atmos Environ 38, 2895–2907 (2004).

Ecotech Pty Ltd. EC9842 nitrogen oxides/ammonia analyser operation and service manuals. (2007).

Moncrieff, J., Malhi, Y. & Leuning, R. The propagation of errors in long‐term measurements of land‐atmosphere fluxes of carbon and water. Global Change Biol 2, 231–240 (1996).

Acknowledgements

The authors thank the Meat and Livestock Australia for financial support. We thank Mr. Trevor Coates, Dr. Marcelo Benvenutti and Ms. Piumika Abesekara for technical support. We acknowledge Dr. Sean McGinn, Dr. Thomas Flesch, Dr. Arvin Mosier, Dr. Shu Kee Lam and Dr. Michael Thomas for providing useful comments on this manuscript.

Author information

Authors and Affiliations

Contributions

D.C. & J.H. designed the investigation. D.C. & K.B supervised the whole project. K.B, J.S. & M.B. conducted the field experiment. D.C., J.S., T.D. and M.B. interpreted the data. All authors were involved in writing the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Chen, D., Sun, J., Bai, M. et al. A new cost-effective method to mitigate ammonia loss from intensive cattle feedlots: application of lignite. Sci Rep 5, 16689 (2015). https://doi.org/10.1038/srep16689

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep16689

This article is cited by

-

High Carbon Amendments Increase Nitrogen Retention in Soil After Slurry Application—an Incubation Study with Silty Loam Soil

Journal of Soil Science and Plant Nutrition (2022)

-

Nitrogen Dynamics in Soil Fertilized with Slow Release Brown Coal-Urea Fertilizers

Scientific Reports (2018)

-

Nitrogen budget estimated for 908 cow-calf, backgrounding and finishing beef operations across Canada

Nutrient Cycling in Agroecosystems (2018)

-

Ammonia deposition in the neighbourhood of an intensive cattle feedlot in Victoria, Australia

Scientific Reports (2016)

-

Beef and coal are key drivers of Australia’s high nitrogen footprint

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.