Abstract

Width-controlled M-type hexagonal SrFe12O19 nanoribbons were synthesized for the first time via polyvinylpyrrolidone (PVP) sol assisted electrospinning followed by heat treatment in air and their chemical composition, microstructure and magnetic performance were investigated. Results demonstrated that as-obtained SrFe12O19 nanoribbons were well-crystallized with high purity. Each nanoribbon was self-assembled by abundant single-domain SrFe12O19 nanoparticles and was consecutive on structure and uniform on width. PVP in the spinning solution played a significant influence on the microstructure features of SrFe12O19 nanoribbons. With PVP concentration increasing, the ribbon-width was increased but the particle-size was reduced, which distributed on a same ribbon were more intensive and then the ribbon-surface became flat. The room temperature magnetic performance investigation revealed that considerable large saturation magnetization (Ms) and coercivity (Hc) were obtained for all SrFe12O19 nanoribbons and they increased with the ribbon-width broadening. The highest Ms of 67.9 emu·g−1 and Hc of 7.31 kOe were concurrently acquired for SrFe12O19 nanoribbons with the maximum ribbon-width. Finally, the Stoner-Wohlfarth curling model was suggested to dominate the magnetization reverse of SrFe12O19 nanoribbons. It is deeply expected that this work is capable of opening up a new insights into the architectural design of 1D magnetic materials and their further utilization.

Similar content being viewed by others

Introduction

Among various advanced magnetic nanomaterials, M-type hexagonal ferrites with a general formula of MFe12O19 (M = Ba, Sr and Pb) have emerged as multifunctional materials for vast scientific and technological interests due to their unsurpassed properties such as low price, large magneto-crystalline anisotropy, high Curie temperature, considerable saturation magnetization and superior coercivity as well as amazing chemical stability and corrosion resistance1,2,3. Strontium ferrite (SrFe12O19), a classical hard magnetic material discovered in 1950s, has been extensively studied for applications in permanent magnets, microwave devices, modern high-density magnetic memory media used in disk drivers and video recorders and so on2,4,5. Nano-SrFe12O19 also gets the above-mentioned features belonged to M-type ferrites. Nevertheless, a further improvement of its permanent magnetic performance is still of great significance2,6. Plenty of work has indicated theoretically and experimentally that magnetic properties of nanomaterials are highly relevant with their microstructures, dimensions, components and preparation methods2,5,7,8,9,10.

Recently, considerable progress in synthesizing of one-dimensional (1D) magnetic nanostructures, such as nanofibers, nanotubes and nanoribbons, has been inspiring researchers to either investigate their magnetic-domain configurations and magnetization reversals or develop their electromagnetic nanoscale device applications11,12,13,14. As is known to all, 1D magnetic nanostructures possess remarkable geometrical limitations being comparable to the critical magnetic lengths such as exchange length and domain wall width and can effectively overcome the serious aggregation of nanoparticles15,16,17. It means that 1D permanent magnetic nanostructures may get more remarkable magneto-crystalline anisotropy and shape anisotropy18. Hence they are capable of offering more creativity for magnetic media, especially the perpendicular magnetic recording media. Jaya Sarkar has pointed out that nanowire arrays potentially enable generating bit densities in excess of 100 Gbit/in2 in 200719. Furthermore, the theoretical recording density of 500 Gbit/in2 ~ 1 Tbit/in2 may be achieved in the quantum magnetic disks with perpendicular recording pattern20. Thus far, a few techniques containing hydrothermal route21, electrospinning2,22 and template approach23 have been used to synthesize 1D SrFe12O19 nanostructures. What needs to be stressed is that electrospinning technique is more simple and flexible for producing continuous 1D nanostructures of various materials by using a high voltage dc source24,25. The diameter or width of electrospun products can be ranged from tens of nanometers to several micrometers. Hence it has got increased attention for many years in a wide range of biomedical and industrial applications, such as drug delivery26, wound dressing27, air filtration28, water purification29, sensors30 and among others31,32. Out of the numerous 1D nanostructures synthesized via electrospinning, interestingly, nanoribbons are slightly different from others (nanotubes and nanofibers) because the former has a rectangular cross section but the later have a round cross section. Moreover, nanoribbons also could be considered as a development by cutting a finite-width slice from the 2D nanosheets. Therefore, it is urgently expected that SrFe12O19 nanoribbons could perform some more interesting magnetic properties.

For the first time in this content, width-controlled SrFe12O19 nanoribbons were synthesized via a polymer-sol assisted single-spinneret electrospinning route followed by heat treatment in air. Their chemical component, crystalline structure, morphologies and room temperature magnetic properties were investigated in detail. All of the as-synthesized SrFe12O19 nanoribbons have considerable saturation magnetization and superior coercivity. Moreover, it demonstrated that the ribbon-width and particle-size can be availably modulated by the PVP concentration in the spinning solution.

Experimental Section

Materials

Polyvinylpyrrolidone (PVP, Mw = 1,300,000, Alfa Aesar, USA), strontium nitrate (Sr(NO3)2, 99.5% purity, Sinopharm Chemcial Reagent Co., Ltd, China), iron nitrate nonahydrate (Fe(NO3)3·9H2O, 98.5% purity, Tianjin Kaixin Chemical Industry Co., Ltd, China) and absolute ethanol (C2H5OH, 99.7% purity, Rionlon Bohua Medical Chemistry Co., Ltd, Tianjin, China) were analytical grade and used as the raw reagents in this work.

Preparation of SrFe12O19 nanoribbons

SrFe12O19 nanoribbons were synthesized via a polymer-sol assisted single-spinneret electrospinning route followed by heat treatment. A typical preparation is as below. Firstly, 0.018 g of anhydrous strontium nitrate (Sr(NO3)2) and 0.368 g of iron nitrate nonahydrate (Fe(NO3)3·9H2O) were quickly dissolved in 1.5 g of deionized water. Subsequently, a certain amount of PVP powders (0.4 g, 0.5 g and 0.6 g as needed) and 2.4 g C2H5OH were added together into the above red nitrate solution under vigorous stirring and equilibrated for overnight to acquire a homogenous viscous solution. Of which, the PVP concentrations of these obtained solutions were about 8.5%, 10.4% and 12.3%, respectively. Secondly, right amount of the obtained spinning solution was transformed to a glass syringe equipped with an ordinary stainless needle (the tip was flat and the inner diameter was about 0.4 mm) for electrospinning. The needle was connected with a positive voltage of 15 kV and the aluminum collector was grounded. The vertical distance between the tip of needle and the collector plane was controlled at about 20 cm. Moreover, the spinning solution was withdrawn at a rate of 0.3 mL/h by a micro-injection pump. The whole electrospinning process was conducted at room temperature (about 25 °C) in air. Thirdly, the collected precursor PVP/SrFe12O19 nanoribbons were kept in a drying oven for several hours and then were subjected to annealing at 800 °C for 2 h in a muffle furnace in air, respectively. Then SrFe12O19 nanoribbons were obtained. The heating and cooling rates were both 1 °C/min. For simplicity, we use the S1, S2 and S3 to label the as-obtained SrFe12O19 nanoribbons resulted from the spinning solutions with PVP concentrations of 8.5%, 10.4% and 12.3%, respectively.

Characterization

The morphological and microstructural characterizations of the as-prepared SrFe12O19 nanoribbons were performed by applying field emission scanning electron microscopy (FESEM, Hitachi S-4800) and transmission electron microscopy (TEM, TecnaiTM G2 F30, FEI) equipped with an energy dispersive X-ray spectroscopy (EDX). The element and phase component and crystalline structure were determined using powdered X-ray diffraction (XRD, Analytical X’Pert Pro) with Cu-Kα radiation (λ = 0.15406 nm) and high-resolution transmission electron microscopy (HRTEM). Room temperature magnetic properties of the SrFe12O19 nanoribbons were investigated by using a vibrating sample magnetometer (VSM, Lakeshore 7403, USA).

Results and Discussion

The composition and microstructure of the prepared SrFe12O19 nanoribbons

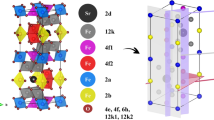

The element and phase component, crystalline structure of as-annealed samples (S1–S3) correspondingly originated from their spinning solutions have been demonstrated by carrying out EDX and XRD analysis. Figure 1a displays their EDX patterns. Targeted elements of Sr, Fe and O are simultaneously detected for all samples. The calculated mole ratios of Sr: Fe are basically equivalent to the stoichiometric ratio of SrFe12O19. The detected C and Cu elements should be ascribed to the carbon-coated copper grids used for the TEM measurement. Figure 1b shows their XRD patterns. All labeled diffraction peaks in the range of 20o ~ 70o could be well-indexed as (110), (008), (107), (114) crystallographic planes and etc., respectively and definitely confirm the formation of hexagonal SrFe12O19 (PDF#33-1340) crystallites with a space group of P63/mmc2. It means that all samples are well crystallized into SrFe12O19 but polycrystalline. No peaks of other additional phases are detected, indicating that these SrFe12O19 samples are highly purified. Based on these diffraction peaks, the lattice parameters (a, c and V) of S1–S3 are calculated (Table 1) by using the follow equations for the hexagonal crystal system33:

where θ is the diffraction angle, λ ≈ 1.5406 Å is X-ray wavelength, h, k and l are Miller indexes. The calculated values are basically similar to the cell parameters (a = 5. 869 Å, c = 23.007 Å and V = 686.307 Å3) of SrFe12O19 nanoparticles reported by R. K. Sahu33. It is also observed that there is a slight line broadening of some characteristic peaks from S1 to S3, which indicates a reduction in grain size. Using Debye-Scherrer formula34:

where K = 0.9 is a constant, λ ≈ 1.5406 Å is X-ray wavelength and β is full-width at half-maximum of diffraction peak at 2θ, the average crystallite sizes of S1–S3 were also given in Table 1. It suggests that PVP has an influence on crystallization and growth of SrFe12O19 crystallites in the resultant nanoribbons.

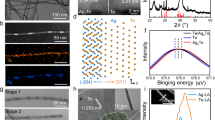

Figure 2 displays the representative SEM, TEM and HRTEM images of the as-prepared SrFe12O19 nanoribbons (S1–S3). Clearly, as revealed by the low-magnification SEM images (Fig. 2a,e,i), all samples present a novel ribbon-like structure constructed by a large number of interconnecting SrFe12O19 nanoparticles, which will be further confirmed later. Each nanoribbon is uniform on width and continuous on structure with several micrometers along the long-axis direction. By counting all nanoribbons in the whole SEM image area, the average widths (W) are estimated to be about 484 ± 15, 812 ± 10 and 1099 ± 18 nm for S1, S2 and S3 in sequence, indicating that the ribbon-width broadens with PVP concentration increasing in their spinning solutions. Figure 2b,f,j show the large-magnification SEM images of several typical nanoribbons selected from S1–S3. Some pores can be observed obviously between SrFe12O19 nanoparticles on nanoribbons. It is easy to deduce that these pores are caused by PVP decomposition and SrFe12O19 nanoparticles crystallization during the heat treatment. For a nanoribbon from S1 to S3, however, these pores shrink gradually and the reduced SrFe12O19 nanoparticles distribute more and more densely, which make the ribbon-surface smooth and neat. Observation from the typical TEM images for S1–S3 (Fig. 2c,g,k), although these SrFe12O19 nanoparticles located in the same nanoribbon are not of uniform on size, they have remarkable polyhedron sections. This indicates that all samples have a good crystallinity being in accordance with the XRD results. The average sizes (d) of SrFe12O19 nanoparticles are also estimated to be about 131 ± 3 nm for S1, 94 ± 2 nm for S2 and 76 nm ± 3 for S3, respectively. Figure 2d,h and m show the HRTEM images to further confirm the aforementioned SrFe12O19 nanoparticles. Of which, lattice fringe distances of about 0.290 nm and about 0.261 nm are severally indexed to the (008) and (114) planes of SrFe12O19 for S1 (Fig. 2d); lattice fringe distances of about 0.228 nm and 0.277 nm are severally indexed to (0010) and (107) planes of SrFe12O19 for S2 (Fig. 2h); lattice fringe distances of about 0.272 nm and 0.248 nm are severally indexed to (107) and (202) planes of SrFe12O19 for S3 (Fig. 2m). Therefore, it is concluded that these novel SrFe12O19 nanoribbons are self-assembled by abundant SrFe12O19 nanoparticles and that PVP concentration in the spinning solutions plays a significant role in controlling their ribbon-width and particle-size.

The formation mechanism and ribbon-width controlling of the prepared SrFe12O19 nanoribbons

To obtain a visual understanding for the formation mechanism of SrFe12O19 nanoribbons, a possible schematic diagram is displayed in Fig. 3. The whole preparation can be segmented into electrospinning and heat treatment. Based on the earlier researches, one can be summarized that the novel ribbon-like structure of SrFe12O19 nanoribbons is produced during electrospinning process25,35,36,37,38. When the spinning solution arrived up to the spinneret tip, a Taylor-cone shape colloidal droplet (Fig. 3a) formed under the coaction of electrostatic field force and surface tension. With the accumulation of surface charges, the electrostatic field force eventually overcomes the surface tension and a columnar flow-jet (Fig. 3b) with a circular cross section (Fig. 3c) is ejected from the Taylor-cone. Some works have pointed out that the solvents evaporation starts rapidly from the jet surface and causes the jet to become extremely unstable39,40. So, the PVP concentration of jet surface sol increases sharply and is much larger than that of jet internal sol. If the PVP concentration of the surface sol is increased to a coagulated critical value at a relatively earlier stage, in which the jet travels steadily and extends along a single straight line41, the PVP-sol transforms to PVP-gel. Namely, the viscous PVP sol shell begins to freeze and transforms to an elastic skin38,41. But the internal sol is still viscous flow. Once the elastic behavior of skin overcomes viscous behavior of internal sol, the columnar flow-jet is immediately buckled into a flattened flow-jet (Fig. 3d) with approximately rectangular cross section (Fig. 3e)38,42. Subsequently, the jet is subjected an unstable stage with a series of bending instabilities and anisotropic shrinkage and is finally elongated with or without branching/splitting39,40,43 and solidified to PVP/SrFe12O19 composite precursor nanoribbons (Fig. 3f). Figure 3g shows the SEM image of the collected PVP/SrFe12O19 composite precursor nanoribbons for S1. When electrospinning is finished, the as-spun PVP/SrFe12O19 precursor nanoribbons are annealed at the temperature of 800 °C in air, the PVP is degraded completely and the Sr2+ and Fe3+ ions are compounded to SrFe12O19. Finally, the SrFe12O19 nanoribbons (Fig. 3h,i) are constructed by crystalline SrFe12O19 nanoparticles.

Figure 4a,d,g show the digital photographs grabbed at several stable moments in the spinning process of PVP/SrFe12O19 precursor nanoribbons for S1–S3, which can be utilized to explore vividly the reason why the SrFe12O19 nanoribbon width is controlled by PVP concentration in the spinning solutions. Earlier literature has figured out that the electrospun nanofiber diameter mainly depends on the spinneret aperture, polymer (PVP) solution viscosity, feeding rate and voltage supplied44. In our work, the unified parameters (a spinneret with an internal diameter of ~0.4 mm, a rate of ~0.3 mL/h and a voltage of ~15 kV) were applied in the electrospinning except the solution viscosity. Hence a higher spinning solution viscosity results in a larger nanoribbon width. When a polymer is dissolved in the mixed solvents of water and ethanol, the solution viscosity is proportional to the polymer concentration45. Thus the width of SrFe12O19 nanoribbons ultimately depends upon the PVP concentration. It should be noted that PVP concentration has a significant influence on the stable stage of electrospinning. Based on the above analysis, besides, the PVP/SrFe12O19 precursor nanoribbons (Fig. 4b,e,h) are formed at the stable stage of jet traveling and then elongated and narrowed at the unstable stage. Herein, we named a “transition point” at the junction of the stable and unstable stages. For S1–S3, their own “transition points (I, II and III)” are respectively marked by cyan, green and yellow circles. It is observed that the jet directions for S1–S3 at their stable stages were respectively deviated a certain angle (φ) from the horizontal direction and they are measured to be small but noticeable change on the PVP concentration increased from S1 to S3, as revealed in Fig. 4j. During the electrospinning, these drift angles should be ascribed to disturbance resulted from the breakage of equilibrium between the surface intension and electric field force. Of which, the surface intension is always used to overcome the electric field force to maintain the equilibrium of flow-jet. If the PVP concentration is bigger, the surface intension is increased and the equilibrium resisting ability of jet is enhanced and then the drift angle is reduced. In our case, the difference between the largest φ for S1 and the smallest φ for S3 is about 6o, which can cause a difference between the total jet traveling distances of S1–S3. But the difference is small and could be ignored briefly because the actual motion of jet is very complete. Thus we could assume that the jets for S1–S3 can travel an approximately equivalent distance (L) from the tip to collector. For simplicity sake, the L can be considered as the sum of lengths of the stable (Ls) and unstable (Lus) stages, i.e., L = Ls + Lus. For S1–S3 with PVP concentration in the jet of about 8.5%, 10.4% and 12.3 wt%, the “transition point” shift gradually towards to collector and their lengths Ls are measured to be about 2.7, 5.5 and 8.9 cm, respectively. Therefore, Ls is increased with PVP concentration increasing from S1 to S3 (Fig. 4k), i.e., Ls-S1 < Ls-S2 < Ls-S3. In contrast, the length Lus of unstable stage is reduced correspondingly, i.e., Lus-S1 > Lus-S2 > Lus-S3. Namely, the distance of ribbon elongation and narrowing is reduced from S1 to S3. As a result, the average width of as-spun PVP/SrFe12O19 precursor nanoribbons (Fig. 4b,e,h) for S1–S3 increases gradually as well as that of the final SrFe12O19 nanoribbons (Fig. 4c,f,i). For the polymer-sol assisted electrospinning technique, furthermore, polymer PVP molecular chains construct the main frame of the as-spun precursor nanoribbons. And then the metal ions (Sr2+ and Fe3+ ions) locate in the interspaces among the PVP frame. That is, the PVP frame acts as a stabilizer or a capping for metal ions. When the PVP concentration reaches a certain value, its frame can effectively enable restraining the growth of SrFe12O19 nanoparticles during annealing45. To understand visually, we consider the interspaces between PVP molecular chains as cells for metal ions. A cell is defined as a unit. If the PVP content or concentration is larger, the units for metal ions anchoring are more but smaller and denser (Fig. 4b,e,h). And the nucleation of SrFe12O19 grains is then more sufficient during annealing. Although these SrFe12O19 grains are tighter, they can’t excessively swallow each other following as the Ostwald-ripening theory46 because of the PVP restraining effect. Therefore, the resultant SrFe12O19 nanoparticle on a nanoribbon originated from the spinning solution with higher PVP concentration are smaller but distribute intensively, which is just like S3.

Digital photographs for moments during electrospinning, simulated diagrams for PVP/SrFe12O19 precursor nanofibers and SEM images of SrFe12O19 nanoribbons: (a–c) for S1, (d–f) for S2 and (g–i) for S3.

The dependences of PVP concentration on the drift angle φ between jet initial directions and horizontal direction and length of stable stage Ls during electrospinning for S1–S3 are shown in (j) and (k), respectively. The variations of average ribbon width W and average particle diameter d with PVP concentration are shown in (m).

The room temperature magnetic performance of the prepared SrFe12O19 nanoribbons

Figure 5 shows the M-H hysteresis loops recorded at room temperature (RT) to investigate the basic magnetic parameters, such as saturation magnetization (Ms), remanent magnetization (Mr) and coercivity (Hc), of the all SrFe12O19 nanoribbons (S1–S3). All samples present a typical ferromagnetic behavior. Their calculated Ms, Mr and Hc are displayed in Table 2. Of which, the highest Ms of 67.9 emu·g−1 or 346.29 emu·cm−3 (ρ ≈ 5.1 g·cm−3) and Hc of 7.31 kOe for S3 are slightly smaller than the values of 74.3 emu·g−1 and 7.4 kOe for theoretical limits predicted by Stoner–Wohlfarth5, respectively. Moreover, they are larger than the corresponding reported values of all 1D2,21,22,23, several typical 0D7,47,48,49,50,51 and 2D9,10,52,53 nanostructures of pure SrFe12O19 in recent years (Table 2). Their remanence ratios (Mr/Ms) are basically equivalent and approximately equal to 0.55. Earlier studies have indicated that the single-domain critical size (Dc) for a SrFe12O19 nanoparticle is about 650 nm4, which is much larger than the average sizes (131 ± 3 nm for S1, 94 ± 2 nm for S2 and 76 ± 2.8 nm for S3) of the SrFe12O19 nanoparticles contained in nanoribbons. Therefore, all nanoribbons consist of abundant single-domain SrFe12O19 nanoparticles, in which the absence of domain walls and high magneto-crystalline anisotropy result in the magnetization reverse difficulty. And then these SrFe12O19 nanoribbons have a high Hc. Of course, the unique shape anisotropy also contributes to their Hc as well as the strong exchange-interaction between SrFe12O19 nanoparticles and between nanoribbons. Additionally, it is clearly discovered that there is a progressive increase of Ms, Mr and Hc from S1 to S3. Just like what has been mentioned in the introduction, although the magnetic properties of assembly nanostructures depend on the particle size and shape of nanoparticles, they are also strongly influenced by the inter-particle interactions54. In our case, particularly, the SEM and TEM characterizations have revealed that SrFe12O19 nanoparticles distribute more and more intensively on nanoribbons from S1 to S3. Thus the amount of magnetic moment per unit volume is increased and then Ms is increased. Moreover, the exchange-interaction of SrFe12O19 nanoparticles are increased and then Mr and Hc are increased, too54,55.

The understanding of magnetization reverse is very important to magnetic materials for their technic applications56. According to Stoner-Wohlfarth nucleation modes of the micro-magnetism theory, the magnetization reverse mechanism of a nano- or micro-scale system is depended on the coherent radius Rcoh. For 1D and 0D magnetic structures, Rcoh = 3.655Lex and 5.099Lex, respectively. For R < Rcoh, the magnetization reverse behavior is realized by coherent rotation, whereas for R > Rcoh, that is realized by curing1,57. For a ferromagnetic material such as SrFe12O19, Lex is the exchange length following the equation17,58:

where A and K1 denote the exchange stiffness and the effective anisotropy constant. For SrFe12O19, A = 6.6 × 10−12 J·m−1 and K1 = 3.6 × 105 J·m−3 59. Value of about 4.28 nm is calculated for Lex and of about 21.82 nm is calculated for Rcoh for a SrFe12O19 spherical nanoparticle. In our case, all nanoribbons (S1–S3) are assembled by single-domain SrFe12O19 nanoparticles, which can be approximately considered as spheres. From the TEM observation, the average radiuses R of SrFe12O19 spheres are estimated to be about 65.5 nm for S1, 47 nm for S2 and 38 nm for S3, respectively, which are larger than the coherent radius Rcoh. Consequently, the magnetization reversal is dominated by the curling model.

Conclusion

Herein, novel SrFe12O19 nanoribbons with high crystallinity and purity were successfully synthesized for the first time by using PVP sol-gel assisted electrospinning followed by heat treatment and they were characterized by EDX, XRD, FESEM, TEM and VSM in detail. Each nanoribbon has been demonstrated to be structural continuous and width uniform and be assembled-well by abundant single-domain SrFe12O19 nanoparticles along the long-axis direction. Besides, it was revealed that the PVP concentration in the spinning solution has a significant influence on the ribbon-width, surface-flatness and particle-size of SrFe12O19 nanoribbons and the potential mechanism was explored systematically. The recorded M-H curves at room temperature showed that large values of Ms, Mr and Hc were obtained for all SrFe12O19 nanoribbons and they were increased with broadening of ribbon-width. Particularly, the highest Ms and Hc of about 67.9 emu·g−1 and about 7.31 kOe were simultaneously obtained for SrFe12O19 nanoribbons with the maximum ribbon-width. The high Hc values are mainly attributed to their single-domain particles, high magneto-crystalline anisotropy and the unique shape anisotropy as well as the exchange-interactions between SrFe12O19 nanoparticles and between nanoribbons. Finally, the curling model can be proposed to guide the magnetization reverse of SrFe12O19 nanoribbons.

Additional Information

How to cite this article: Jing, P. et al. Width-controlled M-type hexagonal strontium ferrite (SrFe12O19) nanoribbons with high saturation magnetization and superior coercivity synthesized by electrospinning. Sci. Rep. 5, 15089; doi: 10.1038/srep15089 (2015).

References

Zhang, J. L. et al. BaFe12O19 Single-Particle-Chain Nanofibers: Preparation, Characterization, Formation, Principle and Magnetization Reversal Mechanism. ACS Nano 6, 2273–2280 (2012).

Gu, F. M., Pan, W. W., Liu, Q. F. & Wang, J. B. Electrospun magnetic SrFe12O19 nanofibres with improved hard magnetism. J. Phys. D: Appl. Phys. 46, 445003–445009 (2013).

Yang, N., Yang, H., Jia, J. J. & Pang, X. F. Formation and magnetic properties of nanosized PbFe12O19 particles synthesized by citrate precursor technique. J. Alloy. Compd. 438, 263–267 (2007).

Zi, Z. F. et al. Structural and magnetic properties of SrFe12O19 hexaferrite synthesized by a modified chemical co-precipitation method. J. Magn. Magn. Mater. 320, 2746–2751 (2008).

Vijayalakshmi, A. & Gajbhiye, N. S. Magnetic properties of single-domain SrFe12O19 particles synthesized by citrate precursor technique. J. Appl. Phys. 83, 400–406 (1998).

Park, J. et al. Maximum energy product at elevated temperatures for hexagonal strontium ferrite (SrFe12O19) magnet. J. Magn. Magn. Mater. 355, 1–6 (2014).

Kushnir, S. E. et al. Synthesis of colloidal solutions of SrFe12O19 plate-like nanoparticles featuring extraordinary magnetic-field-dependent optical transmission. J. Mater. Chem. 22, 18893–18901 (2012).

Rai, B. K., Mishra, S. R., Nguyen V. V. & Liu, J. P. Synthesis and characterization of high coercivity rare-earth ion doped Sr0.9RE0.1Fe10Al2O19 (RE: Y, La, Ce, Pr, Nd, Sm and Gd). J. Alloy. Compd. 550, 198–203 (2013).

Masoudpanah, S. M. & Ebrahimi, S. A. S. Influence of metal precursor on the synthesis and magnetic properties of nanocrystalline SrFe12O19 thin films. J. Magn. Magn. Mater. 343, 276–280 (2013).

Masoudpanah, S. M. & Ebrahimi, S. A. S. Structure and magnetic properties of nanocrystalline SrFe12O19 thin films synthesized by the Pechini method. J. Magn. Magn. Mater. 342, 128–133 (2013).

Henry, Y. et al. Magnetic anisotropy and domain patterns in electrodeposited cobalt nanowires. Eur. Phys. J. B 20, 35–54 (2001).

Adeyeye, A. O., Jain, S. & Ren, Y. Magnetic anisotropy and domain patterns in electrodeposited cobalt nanowires. IEEE T. Magn. 47, 1639–1643 (2011).

Arshad, A. S. et al. Effect of magnetocrystalline anisotropy on the magnetic properties of electrodeposited Co-Pt nanowires. J. Nanopart. Res. 16, 2688–2707 (2014).

Xia, Y. N. et al. One-dimensional nanostructures: synthesis, characterization and application. Adv. Mater. 15, 353–389 (2003).

Han, R. et al. 1D Magnetic materials of Fe3O4 and Fe with high performance of microwave absorption fabricated by electrospinning method. Sci. Rep. 4, 7493–7496 (2014).

Jing, P. P., Pan, L. N., Du, J. L., Wang J. B. & Liu, Q. F. Robust SiO2-modified CoFe2O4 hollow nanofibers with flexible room temperature magnetic performance. Phys. Chem. Chem. Phys. 17, 12841 (2015).

Song, F., Shen, X., Liu M. & Xiang, J. Microstructure, magnetic properties and exchange–coupling interactions for one-dimensional hard/soft ferrite nanofibers. J. Solid State Chem. 185, 31–36 (2012).

Sun, H. L., Shi, H., Zhao, F., Qi, L. & Gao, S. Shape-dependent magnetic properties of low-dimensional nanoscale Prussian blue (PB) analogue SmFe(CN)6·4H2O. Chem. Commun. 4339–4341 (2005), 10.1039/b507240a.

Sarkar, J., Khan G. G. & Basumallick, A. Nanowires: properties, applications and synthesis via porous anodic aluminium oxide template. Bull. Mater. Sci. 30, 271–290 (2007).

Chen, J., Wang, Y. & Deng, Y. Highly ordered CoFe2O4 nanowires array prepared via a modified sol–gel templated approach and its optical and magnetic properties. J. Alloy Compd. 552, 65–69 (2013).

Wang, J. & Zeng, C. Growth of SrFe12O19 nanowires under an induced Magnetic field. J. Cryst. Growth 270, 729–733 (2004).

Shen, X., Liu, M., Song F. & Meng, X. Structural evolution and magnetic properties of SrFe12O19 nanofibers by electrospinning. J. Sol-Gel Sci. Techn. 53, 448–453 (2009).

Li, C. J. & Xu, G. R. Template preparation of strontium hexaferrite (SrFe12O19) micro/nanostructures: characterization, synthesis mechanism and magnetic properties. Mater. Res. Bull. 46, 119–123 (2011).

Wang, X., Ding, B. & Li, B. Biomimetic electrospun nanofibrous structures for tissue engineering. Mater. Today 16, 229–241 (2013).

Wang, Z. L. et al. Preparation of ferrite MFe2O4 (M = Co, Ni) ribbons with nanoporous structure and their magnetic properties. J. Phys. Chem. B 112, 11292–11297 (2008).

Hu, X. L. et al. Electrospinning of polymeric nanofibers for drug delivery applications. J. Controll. Release 185, 12–21 (2014).

Lu, B. A. et al. Graphene-based composite materials beneficial to wound healing. Nanoscale 4, 2978–2982 (2012).

Liu, C. et al. Transparent air filter for high-efficiency PM2.5 Capture. Nat. Commun. 6, 6205–6213 (2015).

Jing, P. P. et al. Efficient photocatalytic degradation of acid fuchsin in aqueoussolution using separate porous tetragonal-CuFe2O4 nanotubes. J. Hazard. Mater. 284, 163–170 (2015).

Zhao, C. H. et al. Effects of SnO2 additives on nanostructure and gas-sensing properties of γ-Fe2O3 nanotubes. Sensor. Actuat. B: Chem. 195, 486–493 (2014).

Kim, Y. J., Ebara, M. & Aoyagi, T. A smart hyperthermia nanofiber with switchable drug release for inducing cancer apoptosis. Adv. Funct. Mate. 23, 5753–5761 (2013).

Dong, Z., Kennedy, S. J. & Wu, Y. Electrospinning materials for energy-related applications and devices. J. Power Sources 196, 4886–4904 (2011).

Sahu, R. K., Mohanta, O. & Pramanik, A. K. XPS study on the correlation of magnetic properties and site occupancy of Al doped SrFe12O19 . J. Alloy Compd. 532, 114–120 (2012).

Holzwarth, U. & Gibson, N. The Scherrer equation versus the ‘Debye–Scherrer equation’. Nat. Nanotechnology 6, 534 (2011).

Su, Y. R. et al. Temperature effect on electrospinning of nanobelts: the case of hafnium oxide. Nanotechnology 22, 285609–285614 (2011).

Fan, H., Zhang, T., Xu, X. & Lv, N. Fabrication of N-type Fe2O3 and P-type LaFeO3 nanobelts by electrospinning and determina-tion of gas-sensing properties. Sensor. Actuat. B: Chem. 153, 83–88 (2011).

Koombhongse, S., Liu, W. & Reneker, D. H. Flat polymer ribbons and other shapes by electrospinning. J. Polym. Sci. Part B: Polym. Phy. 39, 2598–2606 (2001).

Li, Z., Fan, Y. & Zhan, J. In2O3 nanofibers and nanoribbons: preparation by electrospinning and their formaldehyde gas-sensing properties. Eur. J. Inorg. Chem. 2010, 3348–3353 (2010).

Lu, B. A. et al. Direct preparation of carbon nanotubes and nanobelts from polymer. Nanoscale 3, 2145–2149 (2011).

Lu, B. A. Zhu, C. Q., Zhang, Z., Lan, W. & Xie, E. Q. Preparation of highly porous TiO2 nanotubes and their catalytic applications. J. Mater. Chem. 22, 1375–1379 (2012).

Garg, K. & Bowlin, G. L. Electrospinning jets and nanofibrous structures. Biomicrofluidics 5, 13403–13421 (2011).

Tsapis, N. et al. Onset of buckling in drying droplets of colloidal suspensions. Phy. Rev. Lett. 94, 018302–018305 (2005).

Huang, Z. M., Zhang, Y. Z., Kotaki, M. & Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 63, 2223–2253 (2003).

Beachley, V. & Wen, X. Effect of electrospinning parameters on the nanofiber diameter and length. Mat. Sci. Eng. C: Mater. 29, 663–668 (2009).

Suwanboon, S. Structural and optical properties of nanocrystalline ZnO powder from sol-gel method. ScienceAsia 34, 031–034 (2008).

Cavalcante, L. S., Sczancoski, J. C., Li, M. S., Longo, E. & Varela, J. A. β-ZnMoO4 microcrystals synthesized by the surfactant-assisted hydrothermal method: Growth process and photoluminescence properties. Colloid. Surface. A 396, 346–351 (2012).

Wang, Z. et al. Microwave-assisted synthesis of SrFe12O19 hexaferrites. J. Magn. Magn. Mater. 322, 2782–2785 (2010).

Kiani, E., Rozatian, A. S. H. & Yousefi, M. H. Synthesis and characterization of SrFe12O19 nanoparticles produced by a low-temperature solid-state reaction method. J. Mater. Sci.: Mater. El. 24, 2485–2492 (2013).

Baykal, A., Toprak, M. S., Durmus, Z. & Sozeri, H. Hydrothermal synthesis of SrFe12O19 and its characterization. J. Supercond. Nov. Magn. 25, 2081–2085 (2012).

Sánchez-De Jesús, F., Bolarín-Miró, A. M., Cortés-Escobedo, C. A., Valenzuela, R. & Ammar, S. Mechano synthesis, crystal structure and magnetic characterization of M-type SrFe12O19 . Ceram. Int. 40, 4033–4038 (2014).

Nga, T. T., Duong, V. N. P., Loan, T. T. & Hien, T. D. Key step in the synthesis of ultrafine strontium ferrite powders (SrFe12O19) by sol–gel method J. Alloy Compd. 610, 630–634 (2014).

Masoudpanah, S. M. & Ebrahimi, S. A. S. Effect of pH value on the structural and magnetic properties of nanocrystalline strontium hexaferrite thin films. J. Magn. Magn. Mater. 323, 2643–2647 (2011).

Masoudpanah, S. M., Ebrahimi, S. A. S. & Ong, C. K. Effect of oxygen pressure on microstructure and magnetic properties of strontium hexaferrite (SrFe12O19) film prepared by pulsed laser deposition. J. Magn. Magn. Mater. 324, 1440–1443 (2012).

Zhou, L., Fu, Q., Zhou, D., Xue, F. & Tian Y. Solvothermal synthesis of CoFe2O4 submicron compact spheres and tunable coercivity induced via low-temperature thermal treament. J. Magn. Magn. Mater. 392, 22–26 (2015).

Jeun, M. et al. Effects of particle dipole interaction on the ac magnetically induced heating characteristics of ferrite nanoparticles for hyperthermia. Appl. Phys. Lett. 95, 082501–082503 (2009).

Sokolov, A., Sabirianov, R., Wernsdorfer, W. & Doudin, B. Effects of particle dipole interaction on the ac magnetically induced heating characteristics of ferrite nanoparticles for hyperthermia. J. Appl. Phys. 91, 7059–7061 (2002).

Skomski, R. Nanomagnetics. J. Phys.: Condens. Matt. 15, R841–R896 (2003).

Herzer, Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. G. IEEE T. Magn. 26, 1397–1402 (1990).

Xia, A. et al. Magnetic properties, exchange coupling and novel stripe domains in bulk SrFe12O19/(Ni,Zn)Fe2O4 composites. J. Phys. D: Appl. Phys. 47, 415004–4150014 (2014).

Acknowledgements

This work is supported by the National Science Fund of China (51171075, 51371092) and the National Basic Program of China (2012CB933101).

Author information

Authors and Affiliations

Contributions

P.P.J. prepared the nanoribbons and wrote the main manuscript text, J.L.D., L.N.P. and J.N.L. processed data, J.B.W., J.W.W. and Q.F.L. discussed the synthesis mechanism and magnetic properties of SrFe12O19 nanoribbons. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Jing, P., Du, J., Wang, J. et al. Width-controlled M-type hexagonal strontium ferrite (SrFe12O19) nanoribbons with high saturation magnetization and superior coercivity synthesized by electrospinning. Sci Rep 5, 15089 (2015). https://doi.org/10.1038/srep15089

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep15089

This article is cited by

-

Magnetic Properties and Exchange Coupling Effects of SrFe12O19@MFe2O4 (M = Co, Ni, Zn) as Hard-Soft Magnetic Ferrite Core–Shell Nanofibers

Journal of Superconductivity and Novel Magnetism (2023)

-

β-NaFeO2@SrFe12O19 magnetic nanocomposite: synthesis, characterization, magnetic properties and antibacterial activity

Journal of Materials Science: Materials in Electronics (2022)

-

RETRACTED ARTICLE: Magnetic CeO2/SrFe12O19 Nanocomposite: Synthesis, Characterization and Photocatalytic Degradation of Methyl Orange

Arabian Journal for Science and Engineering (2022)

-

Features of structure, magnetic state and electrodynamic performance of SrFe12−xInxO19

Scientific Reports (2021)

-

Structural, Magnetic, and Dielectric properties of Sr4Fe6O13 ferrite prepared of small crystallites

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.