Abstract

The three dimensional (3D) Dirac semimetal is a new quantum state of matter that has attracted much attention recently in physics and material science. Here, we report on the growth of large plate-like single crystals of Cd3As2 in two major orientations by a self-selecting vapor growth (SSVG) method and the optimum growth conditions have been experimentally determined. The crystalline imperfections and electrical properties of the crystals were examined with transmission electron microscopy (TEM), scanning tunneling microscopy (STM) and transport property measurements. This SSVG method makes it possible to control the as-grown crystal compositions with excess Cd or As leading to mobilities near 5–105 cm2V−1s−1. Zn-doping can effectively reduce the carrier density to reach the maximum residual resistivity ratio (RRR ρ300K/ρ5K) of 7.6. A vacuum-cleaved single crystal has been investigated using angle-resolved photoemission spectroscopy (ARPES) to reveal a single Dirac cone near the center of the surface Brillouin zone with a binding energy of approximately 200 meV.

ρ300K/ρ5K) of 7.6. A vacuum-cleaved single crystal has been investigated using angle-resolved photoemission spectroscopy (ARPES) to reveal a single Dirac cone near the center of the surface Brillouin zone with a binding energy of approximately 200 meV.

Similar content being viewed by others

Introduction

Cadmium arsenide (Cd3As2) is a degenerate n-type semiconductor of the II-V family with high mobility, low effective mass and a highly non-parabolic conduction band1. It exhibits an inverted band structure (optical energy gap Eg < 0) comparable to the strained topological insulator HgTe; however, the conduction and valence bands touch at the Dirac nodes in the bulk band structure, giving rise to bulk Dirac fermions featuring robust topologically protected linear dispersion in all three dimensions. These properties are all highly valued for potential applications2 and may provide insight into the formation of other exotic phases such as topological superconductors3 and Weyl semimetals4.

Because of the unusual electrical properties of Cd3As25,6,7,8, namely the high carrier concentration of 2 × 1018 cm−3 coupled with a high mobility of >10,000 cm2/V-s at room temperature9, it has been the subject of many publications concerning its unique transport properties. Additionally, the electron and hole effective masses are  = 0.016 mo and

= 0.016 mo and  = 0.12 mo, giving an estimated exciton Bohr radius of ~47 nm. Thus, this material is expected to show extreme quantum confinement similar to that observed in PbSe (exciton Bohr radius of ∼45 nm)10. Several optical and magneto-optical experiments have also been reported11,12,13,14. For an adequate description of the energy dependent anisotropy of the cyclotron mass and Shubnikov-de Haas (SdH) oscillation period, Bodnar15 proposed a band structure model of Cd3As2, which is consistent with the available experimental data. However, the results of transport and optical measurements have been interpreted within an isotropic Kane-type band model16,17.

= 0.12 mo, giving an estimated exciton Bohr radius of ~47 nm. Thus, this material is expected to show extreme quantum confinement similar to that observed in PbSe (exciton Bohr radius of ∼45 nm)10. Several optical and magneto-optical experiments have also been reported11,12,13,14. For an adequate description of the energy dependent anisotropy of the cyclotron mass and Shubnikov-de Haas (SdH) oscillation period, Bodnar15 proposed a band structure model of Cd3As2, which is consistent with the available experimental data. However, the results of transport and optical measurements have been interpreted within an isotropic Kane-type band model16,17.

Topological insulators (TIs) are new quantum materials characterized by a bulk insulating gap and gapless surface states protected by time reversal symmetry, which is realized by spin-orbit coupling induced band inversion with an odd number of Dirac cones18,19,20. Recently, the topological classification of materials has been extended to higher dimension in the so-called three-dimensional topological Dirac semimetal (TDS) phase21,22. In contrast to TIs, the TDS phase exhibits linear dispersion in all three dimensions and is protected by the crystalline symmetry. A TDS phase was predicted theoretically in Na3Bi and Cd3As2 materials21,22 and confirmed experimentally using angle-resolved photoemission spectroscopy (ARPES)23,24. Note that these TDS phases may be a new type of 3D-Dirac semimetal due to the lack of inversion symmetry, which causes the lifting of the spin degeneracy of certain bands in the vicinity of the Dirac point, thereby raising the possibility of realizing the Weyl semimetal phase21,22.

The growth and characterization of these semimetals has recently generated much attention. Cd3As2 growth from the vapor phase has been previously reported with limited sizes25,26,27,28, including growth under a hydrogen gas flow29,30. In addition, although Cd3As2 melts at 721 °C, it undergoes a phase change between 578 °C and 615 °C29,30,31,32 and a consequent expansion on cooling. Therefore, growing Cd3As2 from the vapor phase at a temperature below the solid-solid phase transition temperature is desirable to avoid cracking of the crystals on cooling. In this work, we present a detailed report on the self-selecting vapor growth (SSVG) technique [Fig. 1(a)] of crystal growth and characterization of large-size and high quality single crystals of Cd3As2. In particular, we have successfully generated crystals containing two types of self-selected large facets, namely the (112) and (even 00) orientations [Fig. 1(b)]. Our study will be useful toward achieving the stable electronic phase and the Weyl semimetal phases in TDS.

(a) Cross-sectional side view of an alumina furnace used for self-selecting vapor growth of a Cd3As2 single crystal. The positions of the ampoule in which transport takes place and the temperature profile of the furnace for Cd3As2 growth are shown. (b) Cd3As2 single crystals grown by the self-selecting vapor growth (SSVG) method. The larger facets are (112) and (even 0 0) planes, respectively.

Results and Discussions

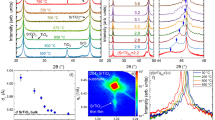

The x-ray diffraction patterns were analyzed using the General Structure Analysis System (GSAS) program following the Rietveld profile refining method33. Figure 2 shows the x-ray diffraction (XRD) pattern of the as-grown sample and the refined synchrotron x-ray diffraction pattern following the Rietveld profile method. It can be seen that all of the diffraction peaks can be indexed with the I41cd space group which is in agreement with recent reports by H. Yi et al.34 The Rietveld refinement on the XRD pattern yields lattice constants of a = 12.6512(3) Å and c = 25.4435(4) Å. The refined structural parameters of the Cd3As2 with I41cd space group obtained at 300 K by synchrotron x-ray diffraction analysis are summarized in Table 1. In addition, the detailed characterization of Cd3As2 single crystal with I41/acd space group as described in the supplementary section from Figures S1-S5. The crystal structure of Cd3As2 has been shown to be complex, depending strongly on the growth temperature and quenching rate35. The published phase diagram indicates that more than four different symmetries can be identified as the sample is quenched or slowly cooled from different temperature ranges, from the high symmetry fcc structure of space group Fm  m (No. 225) quenched above 721 °C, to the low symmetry tetragonal structure of space group I41cd (No. 110) after slow cooling. Cd3As2 can be viewed as a large stacked fluorite-type unit cell with ordered Cd vacancies.

m (No. 225) quenched above 721 °C, to the low symmetry tetragonal structure of space group I41cd (No. 110) after slow cooling. Cd3As2 can be viewed as a large stacked fluorite-type unit cell with ordered Cd vacancies.

Depending on the growth conditions, there have been two different space groups assigned to the crystals obtained from slow cooling: the noncentrosymmetric I41cd and the I41/acd with centrosymmery36,37. The I41cd and I41/acd symmetry difference is a reflection of the different ordering types of CdAs4 tetrahedral unit packed in a large unit cell of stacked fluorite-like structure with vacancies. The crystal of I41/acd space group has a morphology of needle-shape [Figs S1 and S2] along the <110> direction37,38, which is grown mostly near the high temperature 575 °C region of sharper thermal gradient in whisker-like growth. As a result, needle crystal of I41/acd symmetry is expected to show much less defect comparing to that of I41cd symmetry with large (112) area of plate-like morphology. On the other hand, because the needle crystal of I41/acd (No. 142) space group has an unexpected high symmetry, even higher than the intermediate temperature quenched phase of P42/nmc (No. 137)37, the unique morphology of needle growth could be responsible for the sustaining I41/acd space group with centrosymmetry. The stable growth of large crystal of space group I41cd allows the plate-like growth morphology [Fig. 1(b)] of (112) plane as a result of preferable pseudo-hexagonal close packing when c ~ 2a, which could be the reason why noncentrosymmetry is tolerated. The Cd3As2 crystal structure studied in this report can be satisfactorily indexed with the I41cd space group. Figure 3 shows the I41cd crystal structure with two different planes highlighted in red. The (112) plane, shown in panel (a), exhibits pseudo-hexagonal close-packing because c ~ 2a in the large tetragonal unit cell and the (even 0 0) plane is shown in rectangular shape in panel (b).

Figure 4(a–c) shows a series of selected area electron diffraction (SAED) patterns taken on a Cd3As2 single crystal. Tetragonal lattice of space group I41cd is used to index all diffraction spots in Fig. 4a. The observation of ( 10) spots (yellow circle in Fig. 4a), which are symmetry-forbidden reflections to the I41/acd (extinction condition of hk0: h and k both even) space group, gives a direct evidence for the satisfactory assignment of I41cd space group. Notably, Cd3As2 was sensitive to the beam irradiation and all patterns were taken with only a relatively low exposure to the electron beam.

10) spots (yellow circle in Fig. 4a), which are symmetry-forbidden reflections to the I41/acd (extinction condition of hk0: h and k both even) space group, gives a direct evidence for the satisfactory assignment of I41cd space group. Notably, Cd3As2 was sensitive to the beam irradiation and all patterns were taken with only a relatively low exposure to the electron beam.

The SAED patterns of the Cd3As2 crystal taken along the zone axes of (a) [111], (b) [100] and (c) [201] indexed with the I41cd space group. Note that the appearance of symmetry-forbidden spots, 00l with l = 2n (n odd) in Fig. 4b can be understood as a result of electron multiple scattering. The yellow arrows denote the multiple scattering paths for the (00 ) reflection.

) reflection.

ARPES measurements for the low-energy electronic structure investigation were performed at Beam Line 4.0.3 at the Advanced Light Source in Berkeley, California, which is equipped with a high-efficiency R8000 electron analyzer. The energy and momentum resolutions were better than 40 meV and 1% of the surface BZ, respectively. The samples were cleaved in situ and measured at 10–80 K in a vacuum better than 10−10 torr. The crystals were found to be very stable and exhibited no degradation for the typical measurement period of 20 h. Figure 5(a) shows the core level spectroscopic measurement of the Cd3As2 sample. Sharp XPS peaks at binding energies of EB ~ 11 eV and 41 eV that correspond to the cadmium 4d and the arsenic 3d core levels were observed, confirming the correct chemical composition of our samples. Figure 5(b) shows an ARPES dispersion map in the 800 meV binding energy window, where the dispersion of several bands can be identified. Remarkably, a low-lying small feature that crosses the Fermi level is observed, which corresponds to the surface bands of Cd3As222,23. It is important to note that the linearly dispersive upper Dirac cone is located at the surface Brillouin zone center and that the Dirac point is found at a binding energy of 200 meV, consistent with earlier reports23,39,40. Our spectroscopic sample characterization shows a linear dispersive band, thus confirming the high quality of the sample used in our measurements.

STM topographies acquired from the vacuum-cleaved Cd3As2 surface exhibit a clean step-terrace morphology, as demonstrated in Fig. 6(a). The corresponding height profile is shown in Fig. 6(b). The zoomed-in image on one of the terraces, shown in Fig. 6(c), reveals an atomic surface lattice, which has a clear surface reconstruction37,38 as shown by the 2D Fourier transform displayed in Fig. 6(d), consistent with that observed by Jeon et al.38. The observed pseudo-hexagonal nearest-neighbor lattice spacing of dn-n = 0.435 (±0.02) nm is close to that expected for the (112) surface. With this in mind, we interpret the step-height of 0.718 nm observed in the large-scale topography map as corresponding to approximately twice the As-As interlayer spacing perpendicular to the (112) plane (two times √(2/3) x dn-n). Tunneling spectroscopy was subsequently performed on this (112) surface, as shown in Fig. 6(e). The results reveal a conductance minimum at approximately 200 meV below the Fermi level, consistent with the energy of the Dirac point observed in the ARPES data. The approximately linear increase in conductance above this point is also consistent with the linearly dispersive upper Dirac cone observed using ARPES.

STM topography measurements performed on the cleaved Cd3As2 (112) surface.

(a) Large-scale topography map (Vbias = 2 V, Iset = 0.1 nA) showing a step-terrace morphology and (b) the topographic profile, taken along the dashed line shown in panel (a) with a step height of 0.718 nm, corresponding to approximately twice the As-As inter-layer distance perpendicular to the (112) plane. (c) Atomically resolved topography (Vbias = −100 mV, Iset = 1 nA) taken on a terrace, revealing a clear surface re-construction and (d) the corresponding 2D-FFT pattern showing peaks for the atomic surface lattice (circled in blue) of nearest- neighbor distance 0.435 (±0.02) nm and for the reconstruction (circled in red). (e) Tunneling spectroscopy measurements on the cleaved Cd3As2 (112) surface. An averaged dI/dV spectrum was acquired with a set-point of Vbias = −100 mV, Iset = 1 nA from the area shown in the topography image on the left (also taken with Vbias = −100 mV, Iset = 1 nA). The minimum in the dI/dV curve corresponds to the Dirac point (DP).

The resistivity data were measured using a standard four-probe method. The temperature dependence of the resistivity is shown in Fig. 7(a), which shows that metallic behavior is observed in both the pure and doped Cd3As2 crystals under investigation. The resistivity is nearly temperature independent below T = 5 K, giving a residual resistivity in the range of approximately 0.2–0.4 mΩ-cm. The Hall resistivity is practically linear under a magnetic field of up to 15 Tesla, as shown in Fig. 7(b), with the Shubnikov-de Haas oscillation appearing in higher fields. From the Hall data at T = 2 K, the carrier density equals n = 1.4 × 1018cm−3 in Cd2.9Zn0.1As2 giving a Hall mobility of μ = 105 cm2/V-s. The 105 order of mobility in Cd3As2 has also been reported recently by Liang et al.41,42,43 For pure Cd3As2 and Cd2.9Sn0.1As2, the carrier densities are higher in the range of n = 2.6–5.2 × 1018 cm−3. We note that Zn-doping can effectively reduce the carrier density in Cd3As2, which gives the lowest carrier density and the highest residual resistivity ratio (RRR ρ300K/ρ5K) of approximately 7.6 among the crystals we have studied.

ρ300K/ρ5K) of approximately 7.6 among the crystals we have studied.

Conclusions

In summary, large plate-like high quality single crystals of Cd3As2 with large facets of (112) and (even 0 0) planes have been grown by a self-selecting vapor growth (SSVG) method. The observation of sharp and clean diffraction spots in the SAED patterns indicate the good crystallinity of the single crystals grown and the symmetry is indexed satisfactorily with the I41cd space group. Tunneling spectroscopy measurements performed using STM on the cleaved (112) surface confirms a conductance minimum at approximately 200 meV below the Fermi level. This is consistent with the energy of the Dirac point, as observed using ARPES. The approximately linear increase in the conductance above this point is also consistent with the linearly dispersive upper Dirac cone observed using ARPES. Cd3As2 single crystals show a large resistivity anisotropy in the different planes. Zn-doping can effectively reduce the carrier density of Cd3As2, which gives the lowest carrier density and the highest residual resistivity ratio (RRR  ρ300K/ρ5K) of approximately 7.6 among the crystals we have studied.

ρ300K/ρ5K) of approximately 7.6 among the crystals we have studied.

Experimental Section

Self- selecting vapor growth of Cd3As2 single crystals

We have applied self-selecting vapor growth (SSVG) method on the growth of Cd3As2 single crystals. In this SSVG technique, there is no transport agent used. A selected single crystal orientation can be grown using this SSVG technique. To prepare the source materials, the binary compounds were first synthesized by reacting the 99.9999% pure elemental forms of Cd and As. The nominally stoichiometric proportions were sealed in evacuated ampoules, heated to 50 °C above the melting points of the corresponding compounds for 4 hours and quenched in water. The pure Cd3As2 and Sn/Zn-doped Cd3As2 were purified by an evacuated closed-tube sublimation process, in which sample ingots were held at a temperature near 800 °C to allow vapor deposition on the inner wall of the cold end extending out of the tube furnace.

The next step in preparing the growth precursors is to refine the binary compounds with small amounts of excess metal or chalcogen elements in another evacuated closed ampoule. The precursors were melted at 50 °C above the liquidus temperature for 4 hours and then water-quenched. The quenched ingot was iso-thermally annealed at 700 °C for 3 days and then air-cooled. As illustrated in Fig. 1(a), the SSVG technique requires the heating of a sealed evacuated double quartz ampoule with an outer tube (30 cm length × 1.8 cm inner diameter) and an inner tube (20 cm length × 1.4 cm inner diameter) that contains approximately 20 g of uniformly distributed coarsely powdered source material in a horizontal three-zone furnace (100 cm long × 15 cm bore diameter). Before the ampoule is loaded, it is degreased and etched with aqua regia, rinsed and heated overnight at 1,000 °C under high vacuum. The furnace is heated to the growth temperature with the designated temperature profile before inserting the ampoule. The growth ampoule rests on the furnace core and near the center of the furnace. The horizontal and vertical temperature gradients measured in the furnace without the ampoule in place are ~0.1–0.2 °C/cm and 1.0–1.4 °C/cm, respectively.

In the final step of the SSVG method, the ingot was crushed with an agate mortar and pestle, sieved to obtain the proper range of particle sizes (0.1–0. 3 mm diameter) and placed in the growth ampoule. The growth temperature profiles used were approximately 675–575–500 °C for Cd3As2 and 700–650–600 °C for Sn/Zn-doped Cd3As2, respectively. The typical growth time used was 10 days. It was found that longer growth time had little effect on both the number and size of the crystals. Crystals with lower dislocation densities can be obtained by leaving the ampoule in the furnace and turning off the power directly. A successful growth exhibits few well separated plate like crystals, as displayed in Fig. 2. These crystals have individual facets of up to 0.7 cm2 in area. The facets are typically (112) oriented, although occasionally crystals with large facets of (even 0 0) orientation are present in the middle region. No obvious crystal morphology change in Cd3As2 is detected with the addition of Zn or Sn.

Material Characterization

Initial phase characterization was carried out using Bruker-AXS D8 ADVANCE x-ray diffractometer that is equipped with a diffracted beam monochromator set for Cu Kα1 radiation (λ = 1.54056 Å) and further crystal structure analysis was conducted using synchrotron x-ray powder diffraction (SXRD). The SXRD patterns were collected at room temperature with crushed crystals at the beam line in the National Synchrotron Radiation Research Center (NSRRC), Taiwan with energy of 20 keV, which corresponds to a wavelength of 0.6199 Å. The structural refinement was performed using data obtained from the synchrotron X-ray source facility in NSRRC-Taiwan. The transport properties for the Cd3As2 crystals were measured using a four-probe method for the in-plane resistivity as a function of temperature. Two types of specimens with crystalline (112) and (even 00) planes were prepared for investigation. The structural characteristics of Cd3As2 in three-dimensional reciprocal space were also investigated by electron diffraction using a transmission electron microscope TEM (JEOL 2000FX) operated at 200 kV. The electron diffraction measurements were performed on thin regions of freshly crushed single crystals dispersed in a Cu grid. Cleavage of Cd3As2 crystals for investigation by STM was performed in a preparation chamber with a base pressure lower than 5 × 10−11 mbar. The crystals were cleaved on a L-He cooled cryostat, allowing for a cleavage temperature of approximately 8 K. All of the STM measurements were performed at 4.5 K in an Omicron low temperature STM using a chemically etched tungsten tip. dI/dV(V) spectroscopy was performed using a lock-in amplifier with a bias modulation of 30 mV at a frequency of 5.9 kHz.

Additional Information

How to cite this article: Sankar, R. et al. Large single crystal growth, transport property and spectroscopic characterizations of three-dimensional Dirac semimetal Cd3As2. Sci. Rep. 5, 12966; doi: 10.1038/srep12966 (2015).

References

Sieranski, K., Szatkowsky, J. & Misievicz, J. Semiempirical tight-binding band structure of II3V2 semiconductors: Cd3P2, Zn3P2, Cd3As2 and Zn3As2 . Phys. Rev. B 50, 7331 (1994).

Kharzeev, D. E. & Yee, H.-U. Anomaly induced chiral magnetic current in a Weyl semimetal: Chiral electronics. Phys. Rev. B 88, 115119 (2013).

Wang, H. et al. Observation of superconductivity in 3D Dirac semimetal Cd3As2 crystal. arXiv 1501. 00418.

Qi, X.-L. & Zhang, S.-C. Topological insulators and superconductors. Rev. Mod. Phys. 83, 1057 (2011).

Zdanowicz, W. Electric Properties of Copper-doped Cadmium Arsenide. Acta Phys. Pol. 21, 541 (1962).

Rosenman, I. Quantum transport effects in cadmium arsenide, effective mass tensor and band structure. Phys. Lett. 21, 148 (1966).

Aubin, M., Brizardand, R. & Messa, J. P. Une deuxième bande de conduction dans Cd3As2 . Can. J.Phys. 48 (19), 2215 (1970).

Blom, F. A. P. & Gelten, M. J. Proceedings of the International Conference on the Physics of Marrow Gap Semiconductors, Warsaw, p. 257 (1977). Polish Scientific Publishers (1978).

Dowgiazzo-Plenkiewicz, B. & Plenkiewicz, P. Inverted band structure of Cd3As2 . Phys. Status Solidi (b) 94, K57 (1979).

Wise, F. W. Lead Salt Quantum Dots: the Limit of Strong Quantum Confinement. Acc. Chem. Res. 33, 773 (2000).

Turner, W. J., Fischler, A. S. & Reese, W. E. Electrical and Optical Properties of the II–V Compounds. J. Appl. Phys. 32, 2241 (1961).

Turner, W. J., Fischler, A. S. & Reese . Physical properties of several II-V semiconductors. Phys. Rev. 121, 759 (1961).

Wagner, R. J., Palik, E. D. & Swiggard, E. M. Interband Magneto absorption in CdxZn3-xAs2 and Cd3AsxP2-x . J. Phys. Chem. Solids, Suppl. 1, 471 (1971).

Aubin, M. J. & Cloutier, J. P. La thermoréflectance des alliages Cd3−xZnxAs2 . Can. J. Phys. 53, 1642 (1975).

Blom, F. A. P. Narrow Gap Semiconductors Physics and Applications. Proceedings of the International Summer School Held in Nimes, France, September 3-15, 1979. Lectures Notes in Physics 133, 191 (1980).

Blom, F. A. P. & Gelten M. J. Temperature dependence of electron concentration in cadmium arsenide. Phys. Rev. B 19, 2411 (1979).

Gelten, M. J., Van Es, C. M., Blom, F. A. P. & Jonganeelen, J. W. F. Optical verification of the valence band structure of cadmium arsenide. Solid State Commun. 33, 833 (1980).

Hasan, M. Z. & Kane, C. L. Colloquium: Topological insulators. Rev. Mod. Phys. 82, 3045 (2010).

Qi, X. L. & Zhang, S.-C. Topological insulators and superconductors. Rev. Mod. Phys. 83, 1057 (2011).

Moore, J. E. The birth of topological insulators. Nature 464, 194 (2010).

Wang, Z. et al. Dirac semimetal and topological phase transitions in A3Bi (A = Na, K, Rb). Phys. Rev. B, 85, 195320 (2012).

Wang, Z., Weng, H., Wu, Q., Dai, Xi & Fang, Z. Three-dimensional Dirac semimetal and quantum transport in Cd3As2 . Phy. Rev. B 88, 125427 (2013).

Neupane, M. et al. Observation of a three-dimensional topological Dirac semimetal phase in high-mobility Cd3As2 . Nat. Commun. 5, 4786 (2014).

Liu, Z. K. et al. Discovery of a Three-Dimensional Topological Dirac Semimetal, Na3Bi. Science 343, 864 (2014).

Koltirine, B. & Chaumereuil, M. Formation de monocristaux d’arseniure de cadmium. Phys. Stat. Sol. 13, K1 (1966).

Sexer, M. J. Sur quelques propriétés de Cd3As2 . Phys. Radium 22, 807 (1961).

Rosenman, I. Effet Shubnikov de Haas dans Cd3As2: Forme de la surface de Fermi et modele non parabolique de la bande de conduction. J. Phys. Chem. Solids 30, 1385 (1969).

Hrubý, A. & Petrová J. Preparation of Cd3As2 and CdAs2 crystals by transport reaction in vapour phase. Czech. J. Phys. B 21, 890 (1971).

Sillvey, G. A., Lyons, V. J. & Silvestri, V. J. The Preparation and Properties of Some II – V Semiconducting Compounds. J. Electrochem. Soc. 108, 653 (1961).

Fiansen, M. & Anderko, K. Constitution of the Binary Alloys, McGraw-Hill, Maidenhead, p. 157 (1958).

Jayaraman, A., Aanatharaman, T. & Klement, W. Melting and polymorphism of Zn3As2 and Cd3As2 at high pressures. J. Phys. Chem. Solids 27, 1605 (1966).

Hiscocks, S. E. R. The Cd3As2-NiAs pseudobinary eutectic. J. Mater. Sci. 4, 773 (1969).

Larson, A. C. & Von Dreele, A. C. Los Alamos National Laboratory Report No. LAUR086-748 (2000).

Yi, H. et al. Evidence of Topological Surface State in Three-Dimensional Dirac Semimetal Cd3As2 . Sci. Rep. 4, 6106 (2014).

Arushanov, E. K. II3V2 compounds and alloys. Prog. Cryst. Growth Charact. Mater. 25, 131 (1992).

Steigmann, G. & Goodyear, J. The crystal structure of Cd3As2 . Acta Crystallogr.,Sect. B: Struct. Crystallogr. Cryst. Chem. 24, 1062 (1968).

Ali, M. N. et al. The Crystal and Electronic Structures of Cd3As2, the Three-Dimensional Electronic Analogue of Graphene. Inorganic Chemistry 53(8), 4062 (2014).

Jeon, S. et al. Landau quantization and quasiparticle interference in the three-dimensional Dirac semimetal Cd3As2 . Nature Materials 13, 851 (2014).

Liu, Z. K. et al. A stable three-dimensional topological Dirac semimetal Cd3As2 . Nature Materials 13, 677 (2014).

Borisenko, S. et al. Experimental Realization of a Three-Dimensional Dirac Semimetal. Phys. Rev. Lett. 113, 027603 (2014).

Liang, T. et al. Ultrahigh mobility and giant magnetoresistance in the Dirac semimetal Cd3As2 . Nat. Mater. 10.1038/ nmat 4143 (2014).

He, L. P. et al. Quantum Transport Evidence for the Three-Dimensional Dirac Semimetal Phase in Cd3As2 . Phys. Rev. Lett. 113, 246402 (2014).

Zhao, Y. et al. Anisotropic Fermi Surface and Quantum Limit Transport in High Mobility 3D Dirac Semimetal Cd3As2. arXiv:1412.0330.

Acknowledgements

FCC acknowledges the support provided by the Ministry of Science and Technology in Taiwan under project number MOST-102-2119-M-002-004. RS and F.C.C acknowledges the support provided by the Academia Sinica research program on nanoscience and nanotechnology project number NM004. V. M. gratefully acknowledges funding from the US Department of Energy, Scanned Probe Division under Award Number DE-FG02-12ER46880.

Author information

Authors and Affiliations

Contributions

R.S. and F.C.C. designed the study; R.S. synthesized the sample; M.N. and M.Z.H. performed ARPES the measurements; I.P.M., S.-T. Guo and W.L.L. performed resistivity measurements, S.K. and R.J. performed structural analyses, performed the STM measurements C.J.B., I.Z., V.M. and M.T. F.T. and M.W. performed the TEM measurements; all of the authors discussed the results and discussion; R.S. and F.C.C. wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Sankar, R., Neupane, M., Xu, SY. et al. Large single crystal growth, transport property and spectroscopic characterizations of three-dimensional Dirac semimetal Cd3As2. Sci Rep 5, 12966 (2015). https://doi.org/10.1038/srep12966

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep12966

This article is cited by

-

Large transverse Hall-like signal in topological Dirac semimetal Cd3As2

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.