Abstract

This paper introduced a process to prepare the carbon nanosphere (CNS)/NiCo2O4 core-shell sub-microspheres. That is: 1) CNSs were firstly prepared via a simple hydrothermal method; 2) a layer of NiCo2O4 precursor was coated on the CNS surface; 3) finally the composite was annealed at 350 °C for 2 hours in the air and the CNS/NiCo2O4 core-shell sub-microspheres were obtained. This core-shell sub-microsphere was prepared with a simple, economical and environmental-friendly hydrothermal method and was suitable for large-scale production, which expects a promising electrode candidate for high performance energy storage applications. Electrochemical experiments revealed that the composite exhibited remarkable electrochemical performances with high capacitance and desirable cycle life at high rates, such as: 1) the maximum specific capacitance was up to 1420 F/g at 1 A/g; 2) about 98.5% of the capacitance retained after 3000 charge-discharge cycles; 3) the capacitance retention was about 72% as the current density increase from 1 A/g to 10 A/g.

Similar content being viewed by others

Introduction

In the past few years, supercapacitors (SCs) have attracted considerable attention due to their high power density, long life cycle and fast recharge capability. In general, the electrode materials for supercapacitors can be divided into two categories on the basis of the energy storage mechanism: electrical double layer capacitors (EDLCs) and pseudo-capacitors1. However, pseudo-capacitors exhibit much larger capacitance values and energy density than EDLCs due to that the pseudo-capacitive materials taking full advantages of the fast and reversible redox reactions of the electrochemically active electrode materials2,3.

It is well-known that transition metal oxides are of ultra high pseudoactive capacitance4,5,6. Recently, mixed transition-metal oxides (MTMOs), such as single-phase ternary metal oxides with two different metal cations, typically in a spinel structure AxB3-xO4 (A, B = Co, Ni, Zn, Mn, Fe and so on), have captured much attentions as promising electrode materials in electrochemical energy conversion and storage systems7,8,9. Due to complex chemical compositions and relatively low activation energy for electron transfer between cations, MTMOs exhibit the higher electrochemical activity and electrical conductivity than the simple transition-metal oxides7,9.

Among the MTMOs, the spinel nickel cobaltite (NiCo2O4) is one of the promising electrode material, which shows many outstanding advantages including high theoretical capacitance (higher than 3000 F/g), low cost, natural abundance and environmental-friendly10,11. NiCo2O4 holds great promise as a supercapacitor electrode material owing to its high specific capacitance and rate capabilities12,13. However, due to relatively poor conductivity and limited specific area, the practical capacitance of NiCo2O4 is much lower than the theoretical capacitance value2.

In order to overcome these disadvantages, many studies have been done to optimization of morphology and incorporating NiCo2O4 with conductive materials for obtaining a high specific capacitance2,4,14,15,16,17. Cai et al.2 prepared the CNT@NiCo2O4 core-shell structural nanocable by a facile chemical co-deposition route and the as-prepared CNT@NiCo2O4 nanocables exhibited a high capacitance of 1038 F/g at a current density of 0.5 A/g. Deng et al.4 synthesized ultrathin mesoporous NiCo2O4 nanosheets on carbon fiber paper, which showed a high specific capacitance and desirable cycling stability, due to the contributions involving high porosity and good electric conductivity of the CFP substrate. Luo et al.15 fabricated irregular porous network-like NiCo2O4-reduced graphene oxide (rGO) nanocomposite and the rGO served as a conductive network to facilitate the collection and transportation of electrons during the cycling.

As many kinds of carbon materials have been proven to be excellent electrode materials, including graphene, carbon nanotubes, porous carbon and so on18,19,20,21, carbon materials usually are used for improving the electrochemistry performance of metal oxides. In this paper, we reported a novel route to synthesis CNS/NiCo2O4 core-shell structural sub-microspheres, in which the CNS act as a core and NiCo2O4 coated on the CNS surface, which exhibited a high specific capacitance and excellent cycling stabilities at high current density. It is of advantages including simple, economical, environmental-friendly and mass production, which exhibits a potential industrial application for high performance supercapacitors as an electrode material.

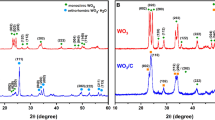

The phase structures of the samples were studied by powder X-ray diffraction (XRD). Figure 1a illustrates the XRD patterns of the CNS, NiCo2O4 and CNS/NiCo2O4. The diffraction peaks at 2 theta = 18.91°, 31.12°, 36.71°, 38.41°, 44.57°, 55.52°, 59.20° and 64.92° are indexed as the crystal planes (111), (220), (331), (222), (400), (422), (511) and (440) of NiCo2O4. The crystallite size of NiCo2O4 is estimated base on XRD pattern. According to the Scherrer equation, the average crystallite size of NiCo2O4 is about 17.9 nm. In the XRD pattern of CNS/NiCo2O4, in addition to the pronounced peaks of spinel phase NiCo2O4, the diffraction peak of CNSs can not be identified clearly due to the mass ratio of CNSs in the composite was too low. Actually the mass ratio of CNS in the composite is roughly about 5.3% (as shown in Fig. S1 in Supplementary information).

However, the existence of CNS can be proven by Raman spectroscopy. As shown in Fig. 1b, the peaks at 151.8, 457.8, 455.2, 505.7, 656.7 and 1096.7 cm−1 correspond to the F2g, Eg, LO, A1g and 2LO modes of NiCo2O4, respectively, while the peaks at 1368.5 and 1593.3 cm−1 correspond to the D and G band of carbon. These results are well consistent with previously reported literatures22,23.

The species and chemical states of elements in the surface of the composite materials were analysis by XPS. Obviously, the CNS/NiCo2O4 composite had predominant C1s, O1s, Ni2p and Co2p peaks (as shown in Fig. S2 in supplementary information). Figure 2 illustrates the XPS spectra of the CNS/NiCo2O4 composite. The following messages were obtained: 1) Figure 2a shows two main peaks, which correspond to the SP2 carbon (C1, ~284.8 eV) and C-OH (C2, ~285.6 eV)18,20,24,25. While the weak fitting peak at binding energy of 287.2 eV (C3) was ascribed to C-O bond18. 2) As shown in Fig. 2b, O1s peak also could be divided into three different peaks (marked as O1, O2 and O3), which corresponded to the metal oxygen bonds (O1, ~529.5 eV), oxygen ions (O2, ~531.2 eV) and physic or chemisorbed water at or within the surface (O3, ~533.1 eV)26,27,28,29. O 1s spectra at binding energies of 529.5 and 531.2 eV were ascribed to O2− species in NiCo2O4; 3) By using Gaussian fitting, the Ni 2p spectrum (Fig. 2c) is fitted considering two spin-orbit doublets characteristic of Ni2+ and Ni3+ and two shakeup satellites26,29. According to the fitting data, the fitting peaks at binding energy of 855.7 and 873.7 eV are indexed to Ni2+, while the fitting peaks at binding energy of 854.1 and 872.0 eV are ascribed to Ni3+, respectively; 4) In Co 2p spectrum(Fig. 2d), two kinds of Co species are also observed. The fitting peaks at binding energies of 781.4 eV and 796.2 eV are indexed to Co2+, while the other two fitting peaks at binding energies of 779.7 eV and 794.7 eV belong to Co3+. Also, the Co3+/Co2+ were also coexisting in the core-shell composite. These results were consistent with the previous reports for NiCo2O429,30 and further confirmed the coexistence of CNS and NiCo2O4 in the composite. In addition, the existence of cations Co3+/Co2+ and Ni3+/Ni2+ in the CNS/NiCo2O4 composite provided abundant active sites for energy storage.

Figure 3 shows the SEM morphologies of the CNS/NiCo2O4 composite. It could be seen that the CNS/NiCo2O4 composite was in typically spheres with rough surface and the diameters were in a range of 250 ~ 300 nm. Figure 4a,b shows the HRTEM image of the CNS/NiCo2O4 spheres. Clearly, a core-shell structure was observed, which showed a CNS was a core and NiCo2O4 was coated on the surface. The lattice fringe of the coated layer revealed that with interplanar distance of 0.47 nm corresponded to the (111) planes of spinel-structured NiCo2O4. However, the crystalline structure of the CNSs could not be directly observed due to the NiCo2O4 coated layer.

According to TEM observations, the shell was composed of numerous NiCo2O4 nanoparticles with controlled size and compositions. This kind of structure shows advantages in facile penetration of liquid electrolyte and effective buffering of large volume changes during charge/discharge process31. The corresponding Fast Fourier Transformation (FFT) image was shown in Fig. 4d, which demonstrates polycrystalline of the sub-microspheres.

Figure 4f,e shows the EDS elemental maps of the CNS/NiCo2O4 core-shell sub-microspheres. Clearly, the elements oxygen (O), nickel (Ni), cobalt (Co) and carbon(C) were well distributed in the core-shell sub-microspheres.

The electrochemical properties of the CNS/NiCo2O4 core-shell sub-microspheres were measured by using various techniques involving cyclic voltammetry (CV), galvanostatic charge/discharge (GCD) curves and EIS in a three electrode system. Figure 5a illustrates the CV curves with variant scanning rates ranging from 5 to 100 mV/s. According to experimental results, a pair of redox current peaks was existed in all CV curves. Generally, the redox couples correspond to the reversible reactions of M-O/M-O-OH (M represent Ni or Co)8. With the sweep rate rising from 5 mV to 100 mV, the position of the cathodic peak shifted from 0.26 V to 0.107 V, which indicated a low resistance of the electrodes4.

Figure 5b gives the GCD curves at different current densities of the CNS/NiCo2O4 core-shell sub-microspheres. Because the redox reaction between Ni/Co cations and OH anions is a diffusion-controlled process through electrode grain boundaries32, therefore, the specific capacitance decreases as the current density increases. Figure 5c is the corresponding specific capacitance as a function of current density. That is to say, when the discharge current densities were at 1 A/g and 10 A/g, the specific capacitances were 1420 F/g and 1018 F/g, respectively. Over the current density range, the specific capacitance decreased to 71.7% of its initial value. Comparing with reported data10,33, the present results exhibited the same or better rate performance. This might attributed to the unique hierarchical core-shell structure, which provided massive electroactive sites34 and the CNSs facilitated the electron transport during electrochemical reaction. Moreover, in addition to the conductivity, CNSs could also effectively prevent the agglomeration of NiCo2O4 and ensured the full utilization of electroactive materials.

The cyclability of the CNS/NiCo2O4 core-shell sub-microspheres electrode was evaluated by the repeated GCD measurement at current density of 10 A/g, as shown in Fig. 5d. Obviously, the specific capacitance of the CNS/NiCo2O4 core-shell sub-microspheres slightly decrease to 98.5% for the first cycle after 3000 time’s test, which indicated its excellent cycling stability.

In general, EIS was usually used to investigate the performance of electrochemical capacitors, such as internal resistance, capacity, etc. The EIS data were analyzed by using Nyquist plots, which showed the frequency response of the electrode/electrolyte system and were the plots of the imaginary component (Z”) of the impedance against the real component (Z’)35. As shown in Fig. 6, the Nyquist plot of the CNS/NiCo2O4 electrode is presented with the equivalent circuit inset. In the high frequency region, the CNS/NiCo2O4 core-shell sub-microspheres showed inconspicuous loop from an expanded view, which indicated a minimal charge-transfer resistance between the electroactive materials and the electrolyte interface. The curve of the lower frequency showed the impedance of the electroactive materials, which was mostly caused by the ion diffusion within the electroactive materials36. At high frequency, the intercept on real axis represents a combined resistance (Rs) containing intrinsic resistance of electrode materials, ionic resistance of electrolyte and contact resistance between electrode and current collector. The EIS plot exhibits identical Rs value about 3.25 Ω and 3.54 Ω before and after 3000 cycles of the charging/discharging experiments. Obviously, a quasi-semicircle was observed at higher frequency range and its diameter corresponded to the charge transfer resistance (Rct) caused by Faradic reactions. The fitted value of Rct obtained for electrode was about 4.01 Ω and 4.05 Ω before and after 3000 cycles of the charging/discharging experiments. However, a minimal slope differences was observed from the vertical diffusion lines, indicating the excellent capacitive performance of the electrode before and after 3000 cycles of the charging/discharging experiments. These results revealed good stability of the CNS/NiCo2O4 core-shell sub-microspheres.

In summary, compared to single component NiO and Co3O4, NiCo2O4 is a promising electrode material, due to its outstanding advantages including high theoretical capacitance, low cost, natural abundance and environmental-friendly. However, its relatively poor conductivity and small specific area limited its practical capacitance much lower than the theoretical value. In this work, CNS/NiCo2O4 core-shell sub-microspheres were successfully prepared via a facile and simple hydrothermal process.

The experimental results revealed that this composite exhibited a remarkable capacitance performance, when it was used as an electrode material. The reason is as follows: 1) the conductive CNSs facilitate the electron transport; 2) the unique hierarchical core-shell structure provides massive electroactive sites; 3) CNSs effectively prevent the NiCo2O4 agglomeration and ensure the full utilization of the electroactive materials. The CNS/NiCo2O4 core-shell sub-microspheres is suitable for large-scale synthesis with a simple, economical and environmental-friendly hydrothermal method, which shows a potential applications in area of supercapacitors, Li-ion battery, etc.

Methods

Carbon nanospheres (CNSs) were prepared via a simple hydrothermal method, i.e., 1) 0.5 g glucose was added into 20 ml deionized water and transferred to a 25 ml Teflon-lined stainless autoclave; 2) The autoclave heated with hydrothermal condition of 200 °C for 24 hours; 3) After it was cooled down to room temperature, the products were cleaned for several times with DI water and ethanol and finally dried at 60 °C for 4 hours. In order to acknowledge high crystallization CNSs, the producte was annealed at 400 °C for 4 hours in Ar.

The CNS/NiCo2O4 core-shell sub-microspheres were prepared according to the process: 1) 10 mg CNSs was mixed with 10 mg/ml sodium oleate methanol solution; 2) After the CNSs were uniformly dispersed by ultrasonication for 1 hour, the resultant solution was mixed with 1 g urea, 2 mmol Co(NO3)2·6 H2O and 1 mmol Ni(NO3)2·6 H2O; 3) The solution was stirred for 2 hours at 60 °C to form a uniform solution; 4) The solution was transferred into a Teflon-lined stainless autoclave and maintained at 180 °C for 12 hours; 5) As the autoclave cooled down to room temperature, the products were cleaned for several times with DI water and ethanol and dried at 60 °C for 4 hours under vacuum; 6) The hybrid precursor was annealed at 350 °C for 2 h in order to obtain the CNS/NiCo2O4 core-shell sub-microspheres.

The phase structures of the samples were characterized by X-ray diffraction spectrometer (XRD) (D8 Advanced XRD; Bruker AXS, Karlsruhe, Germany) with Cu Ka radiation. Raman spectra were carried out by using a Raman spectroscopy (HORIBA Jobin Yvon LabRAM HR). The morphologies of the samples were observed by using a scanning electron microscope (SEM,S-4800; Hitachi High-Technologies Corporation, Japan), a transmission electron microscope (TEM, JEM−2010, JEOL, Japan) and a high resolution transmission electron microscope (HRTEM, JEM 2010FEF, JEOL, Japan). Field emission gun scanning electron microscopy (FEG-SEM) (SEM, Sirion, FEI, Netherlands) with an energy-dispersive X-ray spectrometer (EDS) was employed to characterize the chemical compositions. The surface chemical species of the samples were examined on a X-ray photoelectron spectroscope (XPS, ESCALAB 250Xi, Thermo Fisher Scientific, USA) using Al Ka radiation of 1486.6 eV as the excitation source.

The electrochemical tests were carried out in a 6 M KOH aqueous electrolyte solution at room temperature. The electrochemical properties of the samples were evaluated by using a CHI660D Electrochemical Working Station. All electrochemical measurements were carried out in a three-electrode system, wherein the sample modified nickel foam as the working electrode (WE), platinum as the counter electrode and saturated calomel electrode (SCE) electrode as the reference electrode. The WE was prepared by mixturing CNS/NiCo2O4, conductive carbon black and PVDF with a mass ratio of 8:1:1. Then adding appropriate amount of DMF and grinding for one hour to obtain the homogeneous solution. The solution was then casted on nickel foam to obtain an electrode. The assembled electrode pressed at 10 MPa for one minute and dried in a vacuum oven at 60 °C for 12 hours. The mass of active materials coated on each WE is about 1.5 mg.

The specific capacitance (C) was calculated from the slope of each discharge curve, according to the equation C = (I × Δt)/(ΔV × m), where I is the constant discharge current, Δt is the discharge time, ΔV is the voltage difference in discharge and m is the mass of active materials coated on each WE37,38. Electrochemical impedance spectroscopy (EIS) measurements were made in the frequency range of 0.1–100,000 Hz by applying an AC voltage with 5 mV perturbation.

Additional Information

How to cite this article: Li, D. et al. Facile Synthesis of Carbon Nanosphere/NiCo2O4 Core-shell Sub-microspheres for High Performance Supercapacitor. Sci. Rep. 5, 12903; doi: 10.1038/srep12903 (2015).

References

Zhang, L. L. & Zhao, X. S. Carbon-based materials as supercapacitor electrodes. Zhao, Chem. Soc. Rev., 38: 2520–2531 (2009).

Cai, F. et al. Hierarchical CNT@NiCo2O4 core-shell hybrid nanostructure for high-performance supercapacitors. J. Mater. Chem. A, 2, 11509–11515 (2014).

Chen, X. Y. et al. MWCNT/V2O5 core/shell sponge for high areal capacity and power density li-ion cathodes. Acs Nano, 6, 7948–7955 (2012).

Deng, F. Z. et al. Synthesis of ultrathin mesoporous NiCo2O4 nanosheets on carbon fiber paper as integrated high-performance electrodes for supercapacitors. J. Power Sources, 251, 202–207 (2014).

Cheng, J. B. et al. Hierarchical multi-villous nickel–cobalt oxide nanocyclobenzene arrays: morphology control and electrochemical supercapacitive behaviors. CrystEngComm, 16, 9735–9742 (2014).

Qiu, K. W. et al. Mesoporous, hierarchical core/shell structured ZnCo2O4/MnO2 nanocone forests for high performance supercapacitors. Nano Energy, 11, 687–696 (2015).

Hwang, S. M. et al. Electrospun manganese–cobalt oxide hollow nanofibres synthesized via combustion reactions and their lithium storage performance. Nanoscale, 7, 8351–8355 (2015).

Jung, K. N. et al. One-dimensional manganese-cobalt oxide nanofibres as bi-functional cathode catalysts for rechargeable metal-air batteries. Sci. Rep.-UK, 5, 7665 (2014).

Yuan, C. Z. et al. Mixed transition-metal oxides: design, synthesis and energy-related applications. Angew. Chem. Int. Ed., 53, 1488–1504 (2014).

Hou, Y. et al. Design and synthesis of hierarchical MnO2 nanospheres/carbon nanotubes/conducting polymer ternary composite for high performance electrochemical electrodes. Nano lett., 2010, 10, 2727–2733 (2010).

Dumitrescu, I., Unwin P. R. & Macpherson, J. V. Electrochemistry at carbon nanotubes: perspective and issues. Chem Commun, 45: 6886–6901 (2009).

Tang, Z., Tang, C. H. & Gong, H. Electrochemistry at carbon nanotubes: perspective and issues. Adv. Funct. Mater., 22, 1272–1278 (2012).

Wang, H. L. et al. Facile approach to prepare nickel cobaltite nanowire materials for supercapacitors. Small, 7, 2454–2459 (2011).

Xu, K. B. et al. Hierarchical mesoporous NiCo2O4@MnO2 core-shell nanowire arrays on nickel foam for aqueous asymmetric supercapacitors. J. Mater. Chem. A, 2, 4795–4802 (2014).

Luo, Y. Z. et al. Porous NiCo2O4-reduced graphene oxide (rGO) composite with superior capacitance retention for supercapacitors. Electrochim. Acta, 132, 332–337 (2014).

Wang, Z. Y. et al. Hierarchical porous NiCo2O4 nanograss arrays grown on Ni foam as electrode material for high-performance supercapacitors. Rsc Adv., 4, 20234–20238 (2014).

Padmanathan, N. & Selladurai, S. Controlled growth of spinel NiCo2O4 nanostructures on carbon cloth as a superior electrode for supercapacitors. Rsc Adv., 4, 8341–8349 (2014).

Zhang, L. et al. Electronic structure and chemical bonding of a graphene oxide–sulfur nanocomposite for use in superior performance lithium–sulfur cells. Phys. Chem. Chem, Phys., 14, 13670–13675 (2012).

Chen, X. Y. et al. Structure and electrochemical performance of highly nanoporous carbons from benzoate–metal complexes by a template carbonization method for supercapacitor application. Carbon, 72, 410–420 (2014).

Gutiérrez, M. C. et al. PPO15-PEO22-PPO15 block copolymer assisted synthesis of monolithic macro- and microporous carbon aerogels exhibiting high conductivity and remarkable capacitance. J. Mater. Chem., 19, 1236–1240 (2009).

Torad, N. L. et al. Electric double-layer capacitors based on highly graphitized nanoporous carbons derived from ZIF-67. Chem Eur. J., 20, 7895–7900 (2014).

Babu, G. A. et al. Microwave synthesis and effect of CTAB on ferromagnetic properties of NiO, Co3O4 and NiCo2O4 nanostructures. Appl. Phys. A, 119, 219–232 (2015).

Tang, J. et al. Synthesis and electrochemical characterization of N-Doped partially graphitized ordered mesoporous carbon−Co composite. J. Phys. Chem. C, 117, 16896–16906 (2013).

Ganguly, A. et al. Probing the Thermal Deoxygenation of Graphene Oxide Using High-Resolution In Situ X-ray-Based Spectroscopies. J. Phys. Chem. C, 115, 17009–17019 (2011).

Okpalugo, T. I. T. et al. High resolution XPS characterization of chemical functionalised MWCNTs and SWCNTs. Carbon, 43, 153–161 (2005).

Gu, L. et al. Microwave-assisted synthesis of nanosphere-like NiCo2O4 consisting of porous nanosheets and its application in electro-catalytic oxidation of methanol. J. Power Sources, 261, 317–323 (2014).

Tian, X. Q. et al. Microwave-assisted non-aqueous homogenous precipitation of nanoball-like mesoporous α-Ni(OH)2 as a precursor for NiOx and its application as a pseudocapacitor. J. Mater. Chem., 22, 8029 (2012).

Marco, J. F. et al. Characterization of the nickel cobaltite, NiCo2O4 prepared by several methods: An XRD, XANES, EXAFS and XPS study. J. Solid State Chem., 153, 74–81 (2000).

Lei,Y. et al. Rapid Microwave-Assisted Green Synthesis of 3D Hierarchical Flower-Shaped NiCo2O4 Microsphere for High-Performance Supercapacitor. Acs Appl. Mater. Interfaces, 6, 1773–1780 (2014).

Liu, M. C. et al. A Sol-Gel Process for fabrication of NiO/NiCo2O4/Co3O4 composite with improved electrochemical behavior for electrochemical capacitors. Acs Appl. Mater. Interfaces, 4, 4631–4636 (2012).

Hwang, S. M. et al. A case study on fibrous porous SnO2 anode for robust, high-capacity lithium-ion batteries. Nano energy, 10, 53–62 (2014).

Zhang, Y. F. et al. Selective synthesis of hierarchical mesoporous spinel NiCo2O4 for high-performance supercapacitors. Nanoscale, 6, 4303–4308 (2014).

Xing, W. et al. Exaggerated capacitance using electrochemically active nickel foam as current collector in electrochemical measurement. J. Power Sources, 196, 4123–4127 (2011).

Kondrat, S. et al. Effect of pore size and its dispersity on the energy storage in nanoporous supercapacitors. Energ. Environ. Sci., 5, 6474 (2012).

Zhou, Q. W. et al. Ordered Assembly of NiCo2O4 multiple hierarchical structures for high-performance pseudocapacitors. Acs Appl. Mater. Interfaces, 6, 11394–11402 (2014).

Sun, G. H., Li, K. X. & Sun, C. G. Electrochemical performance of electrochemical capacitors using Cu(II)-containing ionic liquid as the electrolyte. Micropor. Mesopor. Mater., 128, 56–61 (2010).

Li, D. L. et al. Synthesis of nitrogen doped graphene from graphene oxide within an ammonia flame for high performance supercapacitors. Rsc Adv., 4, 55394–55399 (2014).

Biswas, S. & Drzal, L. T. Multilayered nanoarchitecture of graphene nanosheets and polypyrrole nanowires for high performance supercapacitor electrodes. Chem. Mater., 22, 5667–5671 (2010).

Acknowledgements

This work was supported by the National Nature Science Foundation of China (no. 11174227), the Fundamental Research Funds for the Central Universities (no. 20142020205), Shenzhen Science and Technology Research Grant (no. JCYJ20140419141154246) and National Key Technology R&D Program of the Hubei province (no. 2013BHE012).

Author information

Authors and Affiliations

Contributions

D.L., Y.Z. and C.P. conceived and designed the project. D.L., Y.G. and W.L. operated the experiments. Y.G. provided Fig. 1. D.L. provided Figs 2 and 5–6. Q.F. provided figs 3, 4(e) and 4(f). C.L. provided Fig. 4 (a)-(d). D.L. and C.P. wrote the paper. All authors contributed to discussions of the results. All authors reviewed the manuscript. Correspondence and requests for materials should be addressed to C.P.

Electrochemical properties of the CNS/NiCo2O4 core-shell sub-microspheres:

(a) CV curves at different scan rate, (b) GCD curves at different current densities, (c) the corresponding specific capacitance as a function of current density, (d) cycle performance at current density of 10 A/g, the inset shows charge/discharge curves.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Li, D., Gong, Y., Zhang, Y. et al. Facile Synthesis of Carbon Nanosphere/NiCo2O4 Core-shell Sub-microspheres for High Performance Supercapacitor. Sci Rep 5, 12903 (2015). https://doi.org/10.1038/srep12903

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep12903

This article is cited by

-

Enhanced electrochemical performance of NiMn2O4 nanomaterial synthesized using auto-combustion method

Journal of Sol-Gel Science and Technology (2024)

-

Simple solid-state synthesis of mesoporous NiCo2O4/N-doped reduced graphene oxide nanosheet composites with enhanced performance in electrochemical capacitors

Journal of Solid State Electrochemistry (2024)

-

Mixed ternary metal (Co/Zn/Cu) MOF for electrochemical energy-storage electrodes

Applied Physics A (2023)

-

Designing three-dimensional hierarchical porous chrysanthemum flower-like CoNiFe2O4/carbon spheres as high-performance electrode for supercapacitors and oxygen reduction reaction

Journal of Materials Science: Materials in Electronics (2021)

-

Enabling 2.4-V aqueous supercapacitors through the rational design of an integrated electrode of hollow vanadium trioxide/carbon nanospheres

Science China Materials (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.