Abstract

Half-metallic Co-based full-Heusler alloys with perpendicular magnetic anisotropy (PMA), such as Co2FeAl in contact with MgO, are receiving increased attention recently due to its full spin polarization for high density memory applications. However, the PMA induced by MgO interface can only be realized for very thin magnetic layers (usually below 1.3 nm), which would have strong adverse effects on the material properties of spin polarization, Gilbert damping parameter and magnetic stability. In order to solve this issue, we fabricated oxidized Co50Fe25Al25 (CFAO) films with proper thicknesses without employing the MgO layer. The samples show controllable PMA by tuning the oxygen pressure (PO2) and CFAO thickness (tCFAO), large perpendicular anisotropy field of ~8.0 kOe can be achieved at PO2 = 12% for the sample of tCFAO = 2.1 nm or at PO2 = 7% for tCFAO = 2.8 nm. The loss of PMA at thick tCFAO or high PO2 results mainly from the formation of large amount of CoFe oxides, which are superparamagnetic at room temperature but become hard magnetic at low temperatures. The magnetic CFAO films, with strong PMA in a relatively wide thickness range and small intrinsic damping parameter below 0.028, would find great applications in developing advanced spintronic devices.

Similar content being viewed by others

Introduction

The ferromagnetic (FM) thin films with perpendicular magnetic anisotropy (PMA) have been widely investigated for practical applications in nanoscale spintronic devices such as spin-transfer-torque magnetic random access memories (STT-MRAMs). The PMA devices were demonstrated to have great advantages over the in-plane ones, including strong thermal stability and low critical switching current density1,2. Although magnetization switching driven by spin-polarized current has been realized in various PMA systems, e.g. L10-ordered FePt thin films3,4, Co(Fe)/Pt (or Ni) multilayers2,5,6,7, amorphous rare earth-transition metal alloys8 and CoFeB/MgO systems9,10,11,12,13,14, the advances in high density MRAMs are not so great as expected. Continuing efforts should be made to seek advanced perpendicular thin films showing good performances of high spin polarization P, low Gilbert damping parameter α, small saturation magnetization MS and proper effective perpendicular magnetic anisotropic field Hk15.

Recently, as an alternative potential candidate, half-metallic ferromagnetic Co-based full-Heusler alloy film is receiving increased attention due to the full spin polarization. Interfacial PMA has been achieved in Co2FeAl (CFA) and Co2FeSi Heusler alloy films when they are placed adjacent to the MgO layer, which is believed to be the result of the hybridization between Co- or Fe-3d and O-2p electron orbitals at the interface of FM/MgO16,17,18,19,20. In addition, the Gilbert damping parameter for the perpendicularly magnetized CFA sample was reported to be 0.01218, much lower than the α value in most PMA structures. However, in spite of the advantages of high spin polarization and low damping parameter in such perpendicular FM/MgO systems, the PMA strength drops dramatically with increasing thickness of the magnetic layer. Usually the magnetization would rotate from out-of-plane to in-plane direction as the magnetic thickness is over ~1.3 nm. Such ultra-thin thickness will not only affect the magnetic stability and spin polarization, but increases the damping constant as well18,21. As a result, it is of vital importance to seek Co-based heusler alloy films with strong PMA and proper thickness. In this work, without employing the interfacial MgO layer, we have realized PMA in the oxidized CFA (CFAO) thin films with a thickness in the range of 1.0–3.0 nm. The influences of oxidation condition and CFAO thickness (tCFAO) on magnetic anisotropy will be presented. Moreover, considering that rare work has been performed on the magnetic dynamics for the perpendicular CFA system, we have performed a time-resolved optical pump-probe study. Laser-induced magnetization precession and damping behaviors have been characterized and a damping parameter lower than 0.028 is deduced.

Results

Fig. 1 shows the representative in-plane and out-of-plane magnetic hysteresis loops for Ta/Pd/CFAO/Ta films deposited at various oxygen partial pressure ratios (PO2). Although the Pd/CoFe interface has been known to favor a perpendicular anisotropy, it is not strong enough to overcome the large demagnetization energy of a thick CFA film. As shown in Fig. 1(a), the CFA layer in a thickness of 2.1 nm has an obvious in-plane easy axis. However, by reactive magnetron sputtering in proper Ar/O2 mixtures, the easy axis of CFAO film with the same thickness of 2.1 nm transforms from in-plane to out-of-plane direction, accompanied by a small perpendicular magnetic coercivity (Hc^) less than 20 Oe. Considering that the oxygen atom plays an important role on the observed PMA, we suspect the PMA in our CFAO films may also originate from the interfacial hybridization effect between Co- or Fe-3d and the adjacent O-2p orbitals22. However, note that the electronic hybridization of our samples is different from the aligned state in normal FM/oxide structures23,24, the mechanism for PMA could be different and further study will be performed to deeply understand it. The PMA strength of CFAO is very sensitive to the PO2. With increasing PO2 the effective perpendicular anisotropy field Hk increases firstly, showing a maximum value of ~7.8 kOe at PO2 = 12% and then decreases. Interestingly, further increasing PO2 up to 20%, no magnetic anisotropy is found. The in-plane and perpendicular hysteresis loops nearly overlap with each other, both with very small remanence and low saturation field, as shown in Fig. 1(e). From the greatly reduced saturation magnetization as the PO2 increases, we can speculate the observed variation in loop shape is probably related to the reduced ferromagnetism with the formation of oxidized Co and Fe.

Magnetic hysteresis loops of different oxygen pressure ratios.

The in-plane (solid squares) and out-of-plane (open circles) magnetic hysteresis loops for the samples with a structure of Ta(3) /Pd(10) /CFAO(2.1) /Ta(7) fabricated at various oxygen pressure ratios of (a) PO2 = 0%, (b) 7%, (c) 12%, (d) 17% and (e) 20%.

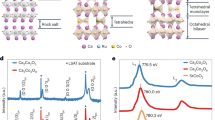

In order to clarify the oxidation effect on the crystalline structure and chemical states of the elements in the CFAO layer, x-ray diffraction and photoelectron spectroscopy (XPS) measurements were performed. We found no diffraction peaks related to Co, Fe, or CoFe alloy, implying that the CFAO layer is in amorphous or very fine nanocrystalline state. Figure 2 shows the XPS spectra for two typical samples of PO2 = 7% and 15%. The single peak observed in Fig. 2(a) at 74.4 eV corresponds to the binding energy of Al3+-2p, indicating that the Al was full oxidized for both samples due to the strong affinity of aluminum for oxygen. Figure 2(b) displays two sharp peaks of Co 2p3/2 and Co 2p1/2, located at 777.7 eV and 792.7 eV, respectively. However, as compared to the spectrum of PO2 = 7%, two additional satellite peaks (shown by arrows) appear for the case of PO2 = 15%, which suggests the Co was partially oxidized. In Fig. 2(c), although there exists a broad Co auger peak, the presence of a satellite peak for PO2 = 15% can also be identified from the main Fe 2p3/2 and 2p1/2 peaks. These results verify that at low PO2 the CFAO films are mainly composed of metallic CoFe particles separated by amorphous Al2O3 matrix. As the oxygen pressure increases, partial Fe and Co get oxidized. The formation of CoFe oxides should be responsible for the observed serious reduction of saturation magnetization and magnetic anisotropy at high PO2.

The influence of CFAO thickness on magnetic anisotropy was also examined. Samples with different tCFAO were prepared at a fixed PO2 of 7%. The effective perpendicular anisotropy field Hk, the saturation magnetization MS and the uniaxial magnetic anisotropy energy Ku were extracted from the magnetic hysteresis loops and plotted in Fig. 3 as a function of tCFAO. Similar to its dependence on PO2, the Hk also exhibits a non-monotonic variation behavior, reaching a maximum value about 8.0 kOe at tCFAO = 2.8 nm. In comparison, the MS slightly decreases at tCFAO < 2.1 nm, above which it begins to drop dramatically. Similar to Fig. 1(e), the sample of tCFAO > 3.6 nm also has no magnetic anisotropy, i.e. the magnetic loops measured at any field direction are the same and show zero remanence. The Ku value, calculated according to the relation of  , remains almost unchanged for tCFAO < 2.1 nm and then decreases monotonically, following a similar trend to that of MS. We should point out that the Ku value at tCFAO ≤ 2.1 nm approaches the magnitude of perpendicular [Co/Ni]N multilayers25, which is strong enough to maintain thermal stability of the spintronic elements. According to the XPS results, we know that the CFAO layer is composed of metallic CoFe nanoparticles dispersed in the amorphous Al2O3 matrix as the oxygen pressure is low. The sample presents a definite square magnetic hysteresis loop with out-of-plane easy axis. However, with increasing PO2 or tCFAO the CoFe grains become partially oxidized, both PMA and MS decrease simultaneously. In particular at PO2 > 20% or tCFAO ≥3.6 nm, no matter which direction the external magnetic field is applied, the magnetic loops always show superparamagnetic characteristics of no hysteresis and moderate saturation field. From the similar variation trend of PMA and MS, we infer that the serious reduction of PMA occurred at thicker tCFAO (also at higher PO2) should have the same origin as MS, being the result of the increased amount of CoFe oxides which has smaller magnetization and shows superparamagnetic behavior at RT.

, remains almost unchanged for tCFAO < 2.1 nm and then decreases monotonically, following a similar trend to that of MS. We should point out that the Ku value at tCFAO ≤ 2.1 nm approaches the magnitude of perpendicular [Co/Ni]N multilayers25, which is strong enough to maintain thermal stability of the spintronic elements. According to the XPS results, we know that the CFAO layer is composed of metallic CoFe nanoparticles dispersed in the amorphous Al2O3 matrix as the oxygen pressure is low. The sample presents a definite square magnetic hysteresis loop with out-of-plane easy axis. However, with increasing PO2 or tCFAO the CoFe grains become partially oxidized, both PMA and MS decrease simultaneously. In particular at PO2 > 20% or tCFAO ≥3.6 nm, no matter which direction the external magnetic field is applied, the magnetic loops always show superparamagnetic characteristics of no hysteresis and moderate saturation field. From the similar variation trend of PMA and MS, we infer that the serious reduction of PMA occurred at thicker tCFAO (also at higher PO2) should have the same origin as MS, being the result of the increased amount of CoFe oxides which has smaller magnetization and shows superparamagnetic behavior at RT.

In order to further clarify this, we measured the perpendicular magnetic hysteresis loops by PPMS at reduced temperatures for the samples of PO2 = 7% with various CFAO thicknesses of 2.1, 2.8 and 3.6 nm. As shown in Fig. 4(a), these magnetic hysteresis loops vary in a distinctly different way with decreasing temperature. For the sample with a relatively thin tCFAO of 2.1 nm, the perpendicular magnetic hysteresis loops exhibit a rectangle shape with a remanence ratio of 1. The Hc^ value increases moderately from 18 Oe at RT to 400 Oe at 30 K due to the decreased thermal effect of the ferromagnetic CoFe alloy. However, for the thick CFAO sample of 3.6 nm, the RT magnetic loop is very slanted with no hysteresis. The slanted loop gradually transforms to a two-step switching shape at a temperature below 150 K. Note that with the decrease of measurement temperature, the first step switching is still very gradual and almost no change occurs in the switching field. In contrast, the second step switching field increases surprisingly, even reaching a value as high as 9.2 kOe at T = 30 K. We consider that the first step loop arises from the contribution of small CoFe grains while the second step from the hard magnetic phase of CoFe oxides. The CoFe oxides were reported to own larger magnetic anisotropy, but much weaker MS and lower Curie temperature by comparison with the CoFe granules26,27. In our samples they are superparamagnetic at RT but become hard magnetic at low temperatures. Meanwhile, because of the existence of large amount of adjacent CoFe oxides in the 3.6 nm thick CFAO samples, the metallic CoFe also exhibits superparamagnetic behavior even at T = 30 K. Such two-step switching loop is just the superposition of magnetic responses from the hard magnetic CoFe oxides and the superparamagnetic metallic CoFe grains. As for the sample with an intermediate CFAO thickness of 2.8 nm, no two-step switching phenomenon takes place. The RT magnetic loop is also in a rectangle shape with a very small coercivity of 10–20 Oe, implying that the metallic CoFe grains are magnetically coupled. Therefore, at low temperatures the soft magnetic CoFe and hard magnetic CoFe oxides are rigidly exchange-coupled, behaving like a single magnet. The perpendicular coercivity Hc^ increases considerably as temperature decreases, showing 4.6 kOe at T = 30 K. However, this value is much smaller than the corresponding second step switching field of the 3.6 nm thick sample. It is understandable according to the two-phase theory, since the coercivity of the exchange-coupled hard-soft composite system usually depends on the degree of the exchange coupling and is surely lower than that of the corresponding single hard magnet28,29.

Magnetic measurements at low temperatures.

(a) The perpendicular magnetic hysteresis loops measured by PPMS at various temperatures for samples with various CAFO thicknesses of 2.1, 2.8 and 3.6 nm. (b) Temperature dependence of the measured saturation magnetization MS (solid squares) and the corresponding fitted lines (dash dot) by Bloch’s T3/2 law.

Accompanied with the changes of Hc^ and loop shape, the saturation magnetization MS also varies with temperature. The proportion of the hard or soft magnetic phase can be identified by fitting the temperature dependence of MS shown in Fig. 4b. Clearly, for all the three samples, the MS increases monotonically with the decrease of temperature. For a ferromagnetic system the saturation magnetization is known to follow the Bloch’s T3/2 law. Considering that there are two kinds of magnetic phases in our samples, we propose a function which contains two terms of Bloch’s law to simulate the curves in Fig. 4(b),

where MS1(0) and MS2(0) are the effective saturation magnetization of the soft and hard magnetic phases at T = 0 K, respectively. Tc denotes the Curie temperature of the soft magnetic phase while Tb refers to the blocking temperature of the hard magnetic phase. Obviously, except for the points at very low temperatures of T < 50 K, all the other data can be well fitted by equation (1). The detailed fitting parameters are listed in Table 1. The calculated Tc is about 1100 K, nearly equal to the Curie temperature of CoFe alloy. The Tb is as low as 310 K, being in agreement with the superparamagnetic behavior of CoFe oxides at RT. As expected, with the increase of CFAO thickness, the effective MS1 and MS2 vary in an opposite way, i.e. the proportion of the soft magnetic part decreases while that of the hard magnetic part increases. For the 2.1 nm CFAO sample, almost no hard magnetic phase exists, thus the MS1 of 600.6 emu/cc corresponds to the actual saturation magnetization of the soft phase. So, we can roughly estimate the ratio δ of the soft phase to the whole CFAO layer by δ = MS1(0)/600.6, which is calculated to be 1.0, 0.60, 0.40 and 0.16 for tCFAO = 2.1, 2.8, 3.6 and 4.8 nm, respectively, verifying the increased amount of hard magnetic phase with tCFAO. Note that for 2.8 and 3.6 nm CFAO samples, the saturation magnetization deviates away from Bloch’s law at very low temperatures, which can be attributed to the effect of some paramagnetic impurities30,31. The deviation is more seriously for 3.6 nm sample, being indicative of the presence of more impurities in the thicker CFAO layer. So in order to obtain CFAO films with strong PMA, excessive oxidation should be avoided.

In addition, laser-induced magnetization precession and damping dynamics are studied by optical pump-probe technique based on the time-resolved magneto-optical Kerr effect (TR-MOKE)32,33. Figure 5(a) shows the typical TR-MOKE curves for the CFAO sample of tCFAO = 2.1 nm and PO2 = 7% under various external fields. The precession signals θk can be well fitted by an exponentially damped sinusoidal function of  34. Here a is the background signal. The second term is an exponential decaying signal representing the slow recovery process, where b is the amplitude and t0 is the characteristic relaxation time. The third term describes the magnetization precession dynamics, the A, f, φ and τ represent the oscillation amplitude, frequency, phase and decay time, respectively. For the case of small damping, the effective damping parameter αeff can be calculated approximately according to the relation of

34. Here a is the background signal. The second term is an exponential decaying signal representing the slow recovery process, where b is the amplitude and t0 is the characteristic relaxation time. The third term describes the magnetization precession dynamics, the A, f, φ and τ represent the oscillation amplitude, frequency, phase and decay time, respectively. For the case of small damping, the effective damping parameter αeff can be calculated approximately according to the relation of  35,36. The αeff contains intrinsic and extrinsic contributions. In the thinner magnetic films with PMA, the extrinsic damping mainly results from the inhomogeneous distribution of magnetization or magnetic anisotropy, which may arise from the interface roughness, thin layer thickness and other film defects37,38,39. By applying a large enough magnetic field, the extrinsic damping can be well suppressed. As shown in Fig. 5(b) the obtained αeff gradually decreases with increasing field and reaches nearly a stable value of 0.028 at H > 10 kOe, indicating the magnetic field over 10 kOe is strong enough to eliminate the effect of local magnetic inhomogeneities40. Furthermore, if the spin pumping effect of the Pd underlayer is also taken into consideration34,41, the intrinsic Gilbert damping α should be smaller than 0.028. Compared with the damping of CFA film reported by Cui et al.18, our α value is relatively higher, this is because the CFAO sample has much stronger PMA strength42. According to these experiments, we consider that the perpendicular CFAO film has the advantage of achieving low damping for STT switching.

35,36. The αeff contains intrinsic and extrinsic contributions. In the thinner magnetic films with PMA, the extrinsic damping mainly results from the inhomogeneous distribution of magnetization or magnetic anisotropy, which may arise from the interface roughness, thin layer thickness and other film defects37,38,39. By applying a large enough magnetic field, the extrinsic damping can be well suppressed. As shown in Fig. 5(b) the obtained αeff gradually decreases with increasing field and reaches nearly a stable value of 0.028 at H > 10 kOe, indicating the magnetic field over 10 kOe is strong enough to eliminate the effect of local magnetic inhomogeneities40. Furthermore, if the spin pumping effect of the Pd underlayer is also taken into consideration34,41, the intrinsic Gilbert damping α should be smaller than 0.028. Compared with the damping of CFA film reported by Cui et al.18, our α value is relatively higher, this is because the CFAO sample has much stronger PMA strength42. According to these experiments, we consider that the perpendicular CFAO film has the advantage of achieving low damping for STT switching.

Magnetization precession and Gilbert damping.

(a) Experimental magnetization precession and damping signals (open circles) and fitting curves (solid lines) for 2.1 nm CFAO sample at PO2 = 7%. The solid curves represent fittings with the damped sinusoidal functions. (b) Dependence of the effective damping parameter αeff on external magnetic field.

In summary, we have achieved strong perpendicular magnetic anisotropy in oxidized Co50Fe25Al25 films with a layer thickness of 1.0–3.0 nm by reactive magnetron sputtering. With increasing oxygen partial pressure or CFAO thickness, the effective perpendicular anisotropy field Hk shows a non-monotonic variation behavior, which initially increases and then decreases after reaching a maximum of ~8.0 kOe. Excessive oxidation will give rise to significant reduction of PMA and MS due to the presence of large proportions of superparamagnetic phase and paramagnetic impurities. Such CFAO magnetic films with the advantages of small coercivity, strong PMA, proper thickness and low damping parameter, could be used in spin valves or magnetic tunnel junctions as high performance magnetic memory elements.

Methods

Samples

All the samples, in a structure of Ta (3)/Pd (10)/CFAO (tCFAO = 1.2–4.8)/Ta(7) (thickness in unit of nm), were grown on Corning glass substrates by magnetron sputtering under a base pressure better than 8×10−8 Torr in a KJLC CMS-18 system. The bottom Ta(3)/Pd(10) layers were used as buffer layer while the top Ta (7) as capping layer. The deposition rates of Ta and Pd were 0.43 Å/s and 1.20 Å/s, respectively. The CFAO layer was formed by reactive sputtering the Co50Fe25Al25 target in a mixture of Ar and O2 gases at various oxygen partial pressures (PO2) ranging from 0 to 30%. The growth rate of metallic CFA film was 0.31 Å/s, it decreased with increasing PO2, about 0.22 Å/s at PO2 = 7% and 0.13 Å/s at PO2 = 15%.

Static magnetic properties measurement

X-ray photoelectron spectroscopy (XPS) was used to analyze the composition and chemical state of CFAO layer. Vibrating sample magnetometer (VSM) and Physical Property Measurement System (PPMS) were used to measure the magnetic hysteresis loops at room temperature (RT) and low temperatures, respectively.

Magnetization dynamics measurement

The time-resolved magneto-optical Kerr effect (TR-MOKE) measurements were performed at room temperature using a Ti:sapphire amplifier laser, with central wavelength of 800 nm, pulse duration of 100 fs and repetition rate of 1 kHz. We used linearly polarized intense pump laser pulses with energy density of 0.5 mJ/cm2 to excite the magnetization dynamics, while much weak probe pulses of 0.06 mJ/cm2 to detect the pump-induced changes. The transient MOKE signal was obtained in a polar geometry, with both pump and probe pulses at almost normal incidence so that the Kerr rotation is proportional to the out-of-plane component of the magnetization. The external magnetic field was applied at an angle of ~10° with respect to film plane in order to set the magnetization orientation away from the perpendicular easy axis.

Additional Information

How to cite this article: Wu, D. et al. Perpendicular magnetic anisotropy and magnetization dynamics in oxidized CoFeAl films. Sci. Rep. 5, 12352; doi: 10.1038/srep12352 (2015).

References

Nishimura, N. et al. Magnetic tunnel junction device with perpendicular magnetization films for high-density magnetic random access memory. J. Appl. Phys. 91, 5246–5249 (2002)

Mangin, S. et al. Current-induced magnetization reversal in nanopillars with perpendicular anisotropy, Nat. Mater. 5, 210–215 (2006).

Seki, T. et al. Spin-polarized current-induced magnetization reversal in perpendicularly magnetized L10-FePt layers. Appl. Phys. Lett. 88, 172504 (2006).

Yakushiji, K. et al. Spin-transfer switching and thermal stability in an FePt/Au/FePt nanopillar prepared by alternate monatomic layer deposition. Appl. Phys. Express 1, 041302 (2008).

Meng, H. & Wang, J. P. Spin transfer in nanomagnetic devices with perpendicular anisotropy. Appl. Phys. Lett. 88, 172506 (2006).

Tudosa, I., Katine, J. A., Mangin, S. & Fullerton, E. E. Perpendicular spin-torque switching with a synthetic antiferromagnetic reference layer. Appl. Phys. Lett. 96, 212504 (2010).

Sim, C. H., Lua, S. Y. H., Liew, T. & Zhu, J. G. Current driven oscillation and switching in Co/Pd perpendicular giant magnetoresistance multilayer. J. Appl. Phys. 109, 07C905 (2011).

Dai, B., Kato, T., Iwata, S. & Tsunashima, S. Temperature dependence of critical current density of spin transfer torque switching amorphous GdFeCo for thermally assisted MRAM. IEEE Trans. Magn. 49, 4359–4362(2013).

Ikeda, S. et al. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 9, 721–724 (2010).

Meng, H., Sbiaa, R., Wang, C. C., Lua, S. Y. H. & Akhtar, M. A. K. Annealing temperature window for tunneling magnetoresistance and spin torque switching in CoFeB/MgO/CoFeB perpendicular magnetic tunnel junctions. J. Appl. Phys. 110, 103915 (2011).

Wang, W. G. et al. Rapid thermal annealing study of magnetoresistance and perpendicular anisotropy in magnetic tunnel junctions based on MgO and CoFeB. Appl. Phys. Lett. 99, 102502 (2011).

Wang, W. X. et al. The perpendicular anisotropy of Co40Fe40B20 sandwiched between Ta and MgO layers and its application in CoFeB/MgO/CoFeB tunnel junction. Appl. Phys. Lett. 99, 012502 (2011).

Sato, H. et al. Perpendicular-anisotropy CoFeB-MgO magnetic tunnel junctions with a MgO/CoFeB/Ta/CoFeB/MgO recording structure. Appl. Phys. Lett. 101, 022414 (2012).

Yamane, K. et al. Spin torque switching of perpendicularly magnetized CoFeB-Based tunnel junctions with high thermal tolerance. IEEE Trans. Magn. 49, 4335–4338 (2013).

Mangin, S., Henry, Y., Ravelosona, D., Katine, J. A. & Fullerton, E. E. Reducing the critical current for spin-transfer switching of perpendicularly magnetized nanomagnets. Appl. Phys. Lett. 94, 012502 (2009).

Wen, Z. C., Sukegawa, H., Mitani, S. & Inomata, K. Perpendicular magnetization of Co2FeAl full-Heusler alloy films induced by MgO Interface. Appl. Phys. Lett. 98, 242507 (2011).

Li, X. Q. et al. Perpendicular magnetic anisotropy of full-Heusler films in Pt/Co2FeAl/MgO trilayers. Appl. Phys. Express 4, 043006 (2011).

Cui, Y. S. et al. Interfacial perpendicular magnetic anisotropy and damping parameter in ultra thin Co2FeAl films. Appl. Phys. Lett. 102, 162403 (2013).

Gabor, M. S., Petrisor, Jr. T., Tiusan, C. & Petrisor, T. Perpendicular magnetic anisotropy in Ta/Co2FeAl/MgO multilayers. J. Appl. Phys. 114, 063905 (2013).

Takamura, Y., Suzuki, T., Fujino, Y. & Nakagawa, S. Full-Heusler Co2FeSi alloy thin films with perpendicular magnetic anisotropy induced by MgO-interfaces. J. Appl. Phys. 115, 17C732 (2014).

Liu, X., Zhang, W., Carter, M. J. & Xiao, G. Ferromagnetic resonance and damping properties of CoFeB thin films as free layers in MgO-based magnetic tunnel junctions. J. Appl. Phys. 110, 033910(2011).

Yang, H. X. et al. First-principles investigation of the very large perpendicular magnetic anisotropy at Fe|MgO and Co|MgO interfaces. Phys. Rev. B 84, 054401 (2011).

Nistor, L. E., Rodmacq, B., Auffret, S. & Dieny, B. Pt/Co/oxide and oxide/Co/Pt electrodes for perpendicular magnetic tunnel junctions. Appl. Phys. Lett. 94, 012512 (2009).

Monso, S. et al. Crossover from in-plane to perpendicular anisotropy in Pt/CoFe/AlOx sandwiches as a function of Al oxidation: A very accurate control of the oxidation of tunnel barriers. Appl. Phys. Lett. 80, 4157 (2002).

Wu, D., Chen, S. H., Zhang, Z. Z., Ma, B. & Jin, Q. Y. Enhancement of perpendicular magnetic anisotropy in Co/Ni multilayers by in situ annealing the Ta/Cu under-layers. Appl. Phys. Lett. 103, 242401 (2013).

Yanagihara, H., Utsumi, Y., Niizeki, T., Inoue, J. & Kita, E. Perpendicular magnetic anisotropy in epitaxially strained cobalt-ferrite (001) thin films. J. Appl. Phys. 115, 17A719 (2014).

Manova, E. et al. Mechano-Synthesis, Characterization and magnetic properties of nanoparticles of cobalt ferrite, CoFe2O4 . Chem. Mater. 16, 5689–5696(2004).

Hernando, A., Marín, P., Vázquez, M., Barandiarán, J. M. & Herzer, G. Thermal dependence of coercivity in soft magnetic nanocrystals. Phys. Rev. B 58, 366–370 (1998).

Zhao, H., Li, X., Zhang, Z. Z., Ma, B. & Jin, Q. Y. Study of spin valves with L10-FePt pinning layer and different pinned layers. IEEE Trans. Magn. 43, 2839–2841 (2007).

Maaz, K., Mumtaz, A., Hasanain, S. K. & Bertino, M. F. Temperature dependent coercivity and magnetization of nickel ferrite nanoparticles. J. Magn. Magn. Mater. 322, 2199–2202 (2010).

Morup, S. Comment on “Deviation from the Bloch T3/2 law in ferrite nanoparticles” by K. Mandal et al. Europhys. Lett. 77, 27003 (2007).

Van Kampen, M. et al. All-optical probe of coherent spin waves. Phys. Rev. Lett. 88, 227201 (2002).

Barman, A. et al. Time-Domain Study of Magnetization Dynamics in Magnetic Thin Films and Micro- and Nanostructures. Solid State Phys . 65, 1–108 (2014).

Mizukami, S. et al. Gilbert damping in perpendicularly magnetized Pt/Co/Pt films investigated by all optical pump-probe technique. Appl. Phys. Lett. 96, 152502 (2010).

Malinowski, G., Kuiper, K. C., Lavrijsen, R., Swagten, H. J. M. & Koopmans, B. Magnetization dynamics and Gilbert damping in ultrathin Co48Fe32B20 films without-of-plane anisotropy. Appl. Phys. Lett. 94, 102501 (2009).

Mills, D. L. & Rezende, S. M. Spin dynamics in confined magnetic structures. Vol. 2 (eds Hillebrands, B. & Ounadjela, K. ) Ch. 2, 27 (Springer, 2003).

Barman, A. et al. Ultrafast magnetization dynamics in high perpendicular anisotropy [Co/Pt ]n multilayers. J. Appl. Phys. 101, 09D102 (2007).

Schellekens, A. J. et al. Determining the Gilbert damping in perpendicularly magnetized Pt/Co/AlOx films. Appl. Phys. Lett. 102, 082405 (2013)

Walowski, J. et al. Intrinsic and non-local Gilbert damping in polycrystalline nickel studied by Ti: sapphire laser fs spectroscopy. J. Phys. D: Appl. Phys . 41, 164016 (2008).

Chen, Z. F. et al. Spin waves and small intrinsic damping in an in-plane magnetized FePt film. Appl. Phys. Lett. 101, 222402 (2012)

Chen, S. H. et al. Interfacial effect on the ferromagnetic damping of CoFeB thin films with different under-layers. Appl. Phys. Lett. 103, 032402 (2013).

Song, H. S. et al. Relationship between Gilbert damping and magneto-crystalline anisotropy in a Ti-buffered Co/Ni multilayer system. Appl. Phys. Lett. 103, 022406 (2013).

Acknowledgements

This work is supported by the National Basic Research Program of China (No. 2014CB921104), the National Natural Science Foundation of China (Grant Nos. 11474047, 51222103, 11274113 and 51171047) and the NCET Program (No. 12-0132). H. B. Zhao thanks the support of NSFC with the grant No. 61222407.

Author information

Authors and Affiliations

Contributions

Z.Z.Z. and Q.Y.J. planned and supervised the study. D.W. fabricated the samples and performed the V.S.M. and X.P.S. measurements. Z.Z. and H.B.Z. carried out the magnetization dynamics measurements. L.L. and J.W. performed the PPMS experiments. Z.Z.Z. and D.W. analyzed the data and wrote the paper. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wu, D., Zhang, Z., Li, L. et al. Perpendicular magnetic anisotropy and magnetization dynamics in oxidized CoFeAl films. Sci Rep 5, 12352 (2015). https://doi.org/10.1038/srep12352

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep12352

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.