Abstract

We have created a simple model to analyze the restrictions on superluminal ring laser gyroscopes arising from the absorption of coating materials. For a ring laser gyroscope with a cavity length of 15 cm, the scale factor enhancement is nearly impossible due to absorption from the high dispersion mirror. In order to obtain a practical superluminal ring laser gyroscope, the extinction coefficient of coating materials should be less than 1E-10, which is a challenge at present.

Similar content being viewed by others

Introduction

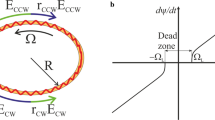

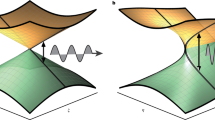

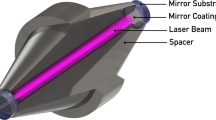

Superluminal effects have many potential applications, ranging from optical data buffers to sensitivity-enhanced interferometers1,2,3. One important application is the superluminal ring laser gyroscope4,5, which may enable purely self-contained navigation. It is also possible to detect the gravitational frame-dragging effect by measuring the Lense-Thirring rotation on the Earth6. Recently, several methods were proposed to enhance the sensitivity of ring laser gyroscopes with superluminal effects, such as alkali metal vapor cells7, coupled optical resonators8 and using multilayer optical coatings on the reflection mirror9. The latter is very attractive due to its compact configuration, vibration-robust mirror and broad bandwidth. However, strong dispersion systems are always accompanied by intense absorption. Therefore, the loss associated with dispersion should be considered before we could obtain a practical mirror for superluminal ring laser gyroscopes. In this short communication, we analyzed the restrictions of absorption losses in the multilayer coatings for a superluminal ring laser gyroscope. We found that the enhancement factor is greatly reduced due to coating losses and a practical superluminal ring laser gyroscope is hard to be obtained with any current coating technology.

Results

Even the best coating material has absorption, which is usually characterized by an extinction coefficient κ, or the absorption coefficient10,

where λ is the wavelength and κ wavelength-dependent.

Both theory and experiments have shown that absorption loss of dispersive dielectric mirrors is proportional to the group delay for high reflectance mirrors11. The rigid analysis can be obtained by calculating the power reflectivity of multi-layer mirrors with the transfer matrix method which is a very fundamental tool in thin film coating related books10. However, it is sufficient to use a simpler estimation method as described in12,13. If we denote the group delay time of the multi-layer coating for reflection as τg, the corresponding optical length is

where c is the speed of light in vacuum. The absorption loss can be written as

For high reflection mirrors, the absorption loss is very small, so we can approximate this as

where γ stands for the proportionality coefficient between the absorption loss and the group delay time13. With λ = 800 nm, κ = 10−4, c = 3 × 108m/s, we obtain γ = 2.355 × 1011 per second, which is roughly the same as the results from12,13. In14, analytic expressions are given for the reflection delay, penetration depth and absorption of a quarter wave mirror based on energy conservation considerations, which agrees with equation (4).

It is obvious that reducing the extinction coefficient κ could reduce absorption. However, even for the best coating materials and coating technologies, the extinction coefficient is still roughly κ = 10−6 15. The extinction coefficients of the usual coating materials are roughly 10–3 ~ 10–4 16,17. We assume the coating materials and technology are the best currently available, so we use γ = 2.355 × 109 for an estimate, which corresponds to κ = 10–6. A typical ring laser has a cavity length of about 15 cm, so the group delay time should be approximately 0.5 ns in order to obtain a good superluminal ring laser gyroscope. In this case, the absorption calculated using equation (4) is larger than 1, which makes it impossible to realize a laser. It should be noted that if the absorption is too large, the estimation method used above is not effective and rigid numerical calculations should be used.

From another perspective, the total loss of a typical mirror is less than 10–4 in a practical laser gyroscope18. This restricts the group delay time to 0.42 × 10–13 s. As such, the enhanced scale factor for a 15 cm-length ring laser gyroscope is9,

This means we cannot obtain an effective scale factor enhancement.

On the other hand, if we want to use a mirror with τg = 0.42 × 10–13 s to obtain a scale factor enhancement of 2, the cavity length of the ring laser gyroscope should be no larger than 0.0276 mm, which is impossible to realize, because the cavity length is roughly the same size as the coating thickness.

Discussion

The idea of a superluminal ring laser gyroscope with the multi-layer coating mirror is very attractive, but the absorption of the coating makes it difficult to produce with current technologies. If the extinction coefficient of the coating material could be reduced to ~10–10, this kind of ring laser gyroscope may be possible. However, other factors such as scattering would also need to be considered.

In conclusion, we analyzed the restrictions to the potential superluminal ring laser gyroscope with multi-layer coating mirrors due to coating absorption. It was found that in order to obtain a practical superluminal ring laser gyroscope, the extinction coefficient of the coating material should be less than 10–10, which is a challenge at present, since even the bulk materials have an extinction coefficient of roughly 10–10 15.

Methods

The absorption of multilayer coatings is calculated according to a simple analytic model as shown in the text, which is cited from several references. The enhanced scale factor is calculated based on formulas in9.

Additional Information

How to cite this article: Wang, Z. & Yuan, B. Practical Considerations on the Multi-layer Mirrors for Superluminal Ring Laser Gyroscopes. Sci. Rep. 5, 12026; doi: 10.1038/srep12026 (2015).

References

Shahriar, M.S. & Salit, M. Application of fast-light in gravitational wave detection with interferometers and resonators. J. Mod. Opt. 55, 3133 (2008).

Salit, M., Pati, G. S., Salit, K. & Shahriar, M. S. Fast-light for astrophysics: super-sensitive gyroscopes and gravitational wave detectors. J. Mod. Opt. 54, 2425 (2007).

Smith, D. D., Chang, H., Myneni, K. & Rosenberger, A. T. Fast-light enhancement of an optical cavity by polarization mode coupling. Phy. Rev. A 89, 053804 (2014).

Shahriar, M. S. et al. Ultrahigh enhancement in absolute and relative rotation sensing using fast and slow light. Phy. Rev. A 75, 053807 (2007).

Yum, H. N. et al. Superluminal ring laser for hypersensitive sensing. Opt. Express 18, 17658 (2010).

Schreiber, K. U. & Wells, J. R. Large ring lasers for rotation sensing. Rev. Sci. Instrum. 84, 041101 (2013).

Smith, D., Myneni, K., Odutola, J. A., & Diels, J. C. Enhanced sensitivity of a passive optical cavity by an intracavity dispersive medium. Phys. Rev. A 80, 011809(R) (2009).

Schaar, J. E., Yum, H. N., & Shahriar, S. M. Theoretical description and design of a fast-light enhanced helium-neon ring-laser gyroscope. Proc. SPIE 7949, 794914 (2011).

Qu, T. et al. Design of a superluminal ring laser gyroscope using multilayer optical coatings with huge group delay. Sci. Rep. 4, 7098 (2014).

Stenzel, O. Optical coatings material aspects in theory and practice. (Springer-Verlag, Berlin Heidelberg, 2014).

Ferencz, K., & Szipõcs, R. Recent developments of laser optical coatings in Hungary. Opt. Eng. 32, 2525 (1993).

Antal, P. G. & Szipõcs, R. Relationships among group delay, energy storage and loss in dispersive dielectric mirrors. Chin. Opt. Lett. 10, 053101 (2012).

Szipõcs, R. Dispersive properties of dielectric laser mirrors and their use in femtosecond pulse lasers. (SZTE TTK Szeged, Hungary, 2000).

Babic, D. I. & Corzine, S. W. Analytic expressions for the reflection delay, penetration depth and absorptance of quarter-wave dielectric mirrors. IEEE J. Quantum Electron. 28, 514 (1992).

Tang, J. F., Gu, P. F., Liu, X., & Li, H. F. Modern optical thin film technology. (Zhejiang University Press, Hangzhou, 2006).

Prato, M. et al. Multitechnique investigation of Ta2O5 films on SiO2 substrates: comparison of optical, chemical and morphological properties. J. Phys.: Conf. Ser. 228, 012020 (2010).

Hwangbo, K. et al. Optical properties of Ta2O5 thin films deposited by plasma ion-assisted deposition. J. Korean Phys. Soc. 46, S187 (2005).

Zanaveskin, M. L. et al. Correlation between the substrate roughness and light loss for interference mirror coatings. Crystallogr. Rep. 53, 701 (2008).

Acknowledgements

This work was supported by the National Science Foundation of China (Grant Nos. 61308059 and 61104199).

Author information

Authors and Affiliations

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wang, Z., Yuan, B. Practical Considerations on the Multi-layer Mirrors for Superluminal Ring Laser Gyroscopes. Sci Rep 5, 12026 (2015). https://doi.org/10.1038/srep12026

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep12026

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.