Abstract

Copper sheath is the first choice for manufacturing high-Tc superconducting wires and tapes because of its high electrical and thermal conductivities, low-cost and good mechanical properties. However, Cu can easily react with superconducting cores, such as BSCCO, MgB2 and pnictides and therefore drastically decrease the transport Jc. Here, we report the fabrication of Cu-sheathed Sr1−xKxFe2As2 tapes with superior Jc performance using a simple hot pressing method that is capable of eliminating the lengthy high-temperature sintering. We obtained high-quality Sr1−xKxFe2As2 tapes with processing at 800 oC for 30 minutes and measured high Tc and sharp transition. By this rapid fabrication, Cu sheath does not give rise to apparent reaction layer and only slightly diffuses into Sr-122 core. As a consequence, we achieved high transport Jc of 3.1 × 104 A/cm2 in 10 T and 2.7 × 104 A/cm2 in 14 T at 4.2 K. The in-field Jc performance is by far the highest reported for Cu-sheathed high-Tc conductors. More importantly, Cu-sheathed Sr-122 tapes also showed a high Je value of 1.0 × 104 A/cm2 in 10 T at 4.2 K, which has reached the widely accepted practical level for applications. These results demonstrate that Cu is a very promising sheath for the practical application of pnictide conductors.

Similar content being viewed by others

Introduction

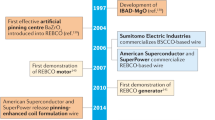

The discovery of the iron-based superconductors, with a relatively high critical temperature Tc, ultrahigh upper critical fields Hc2 and low anisotropy γ, has inspired worldwide research efforts1,2,3,4,5. Studies on single crystals and thin films reveal that iron-pnictides have large in-field critical current density Jc due to strong intrinsic flux pinning6,7,8. To explore the potential of using this new material for magnet applications, significant efforts had been focused on developing wires and tapes with in-field high Jc. Our research group prepared LaFeAsO1−xFx and SmFeAsO1−xFx superconducting wires using in-situ powder-in-tube (PIT) method5. A Ta tube or Fe tube with an inner Ti sheath was used to prevent the reaction between the tubes and the superconducting compounds. Zhang et al. systematically studied the effect of various sheath materials (Nb, Ta and Fe/Ti) on the microstructure and superconducting properties of SmFeAsO1−xFx wires and reported consistent formation of a thick reaction layer between the core and metal sheath, which hinders the performance of transport Jc9. Therefore, a key issue is to develop a technology that result in little or no reaction with iron-pnictides. Subsequently, Wang et al. reported Ag-sheathed Sr1−xKxFe2As2 (Sr-122) conductors with transport Jc of 1200 A/cm2 (at 4.2 K and self-field)10. The Sr-122/Ag interface was clear and no observable reaction layer, indicating that Ag sheath is benign in proximity to the compound at high sintering temperature. Fe-sheathed Sr-122 and Ba1−xKxFe2As2 (Ba-122) tapes were also fabricated by ex-situ PIT method11,12,13. Through optimization of sintering process and rolling texture, Jc of >104 A/cm2 in 10 T at 4.2 K was reported for Sr-122 tapes14. Recently, Ag-sheathed Ba-122 and Sr-122 conductors have been investigated intensively and high Jc exceeding 104 A/cm2 (Maximum Jc = 1.2 × 105 A/cm2) at 4.2 K and 10 T has been reported by applying uniaxial pressing, such as hot pressing (HP) and cold pressing (CP)15,16,17,18,19. By far, all pnictide wires and tapes with the high Jc-B performance (>104 A/cm2, at 4.2 K and 10 T) are prepared by using the expensive Ag or magnetic Fe sheath, which is similar to Ag-sheathed BSCCO and Fe-sheathed MgB2 conductors20,21,22,23.

For practical applications of high-Tc superconductors including cuprate, pnictide and MgB2, the copper material is a desirable sheath because of many advantages24,25,26. Firstly, when compared with common Ag and Fe sheath, Cu is a low-cost and nonmagnetic material. Secondly, Cu sheath has good mechanical properties, which make the coil winding easier in magnet applications. Thirdly, high purity Cu has large residual resistivity ratio (RRR) value and provides both electromagnetic stabilization against flux jumps and quench protection27,28. It is well known that Cu material has been proved to be an effective sheath in the conventional NbTi and NbSn3 conductors. Cu is also used as stabilizer in high-Tc conductors, such as Nb/Cu/monel MgB2 wires29,30, for providing electrical stability of magnets and other devices during transients. However, since the discovery of cuprate superconductors in 1986, no high transport Jc-B performance (>104 A/cm2, at 4.2 K and 10 T) has been reported for Cu-sheathed high-Tc superconductors. Cu is highly reactive to superconducting core at high-temperature sintering31,32,33. The interfacial reaction layer and composition deviation of superconducting phase can lead to Jc degradation. In worse case, no transport Jc can be detected, because the thick reaction layer apparently prevented electric current from flowing from the sheath material to the superconducting core. Therefore, it is considered a grand challenge to develop a process for Cu-sheathed high-Tc superconductors with superior performance. In the present work, we report successfully fabricated Cu-sheathed Sr-122 tapes by an ex-situ PIT method. DC susceptibility of Sr-122 precursor powders was measured and the result is shown in Fig. 1. The significant shielding currents appear at about 36.0 K and increase as the temperature decreased, which is similar to that reported for high-quality precursors17. During the final heat treatment, we introduce a hot pressing process with combination of short-time sintering (800 °C/30 min or 700 °C/60 min) and low external pressure (~20 MPa). This rapid fabrication can effectively avert the formation of reaction layer and therefore result in a high transport Jc of 3.1 × 104 A/cm2 at 4.2 K and 10 T.

Results

Cu-sheathed Sr-122 tapes were finally hot pressed at 700 °C (HP700 tapes) and 800 °C (HP800 tapes). Fig. 2(a) shows a typical transverse cross-sectional optical image of HP800 tapes. After hot-pressing, the tape thickness of HP800 samples decreased from ∼0.40 mm to ∼0.29 mm. Fig. 2(b) displays a longitudinal cross-sectional optical microstructure of HP800 tapes. A uniform deformation of both superconducting core and Cu sheath along the length can be obviously seen, which is essential for the achievement of high transport Jc34,35. This uniformity is attributable to the good mechanical properties of Cu sheath.

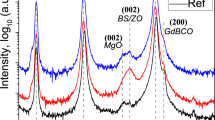

As shown in Fig. 3, the XRD analysis was performed on the planar surfaces of superconducting cores after peeling off Cu sheath. For comparison, the data for randomly orientated precursor powders is also included. The XRD patterns on the surfaces clearly exhibit a ThCr2Si2-type structure, ensuring that Sr-122 is the main phase for both HP700 and HP800 samples. Using a final short-time hot-pressing process, the formation of non-superconducting reaction layer at the interface seems to be prevented. More importantly, the transport critical current Ic may be measured and obtained in these Sr-122 tapes31. However, the impurity peaks are detected on the core surface, especially for HP800 samples. Some Cu reacted with Sr-122 phase, producing SrCuAs and Cu9.5As4 phases. This is consistent with large FWHM (full width at half-maximum) of (002) and (103) peaks for Sr-122 phase. On the other hand, the XRD patterns for the central planar sections of HP tapes after carefully polishing are also exhibited in Fig. 3. The diffraction peaks have some differences compared to those of the surfaces. The XRD patterns of central parts exhibit pure Sr-122 phase without detectable impurities. No Cu element can be detected in the central parts by further EDX identification. The peak characteristics are similar to those of textured Sr-122 tapes17,18,19, which have high transport Jc-B properties. We quantify the c-axis texture parameter F according to the Lotgering method36 with F = (ρ – ρ0)/(1 – ρ0), where ρ = ∑I(00l)/ I(hkl) and ρ0 = ∑I0(00l)/ I0(hkl). I and I0 are the intensities of corresponding XRD peaks measured for the textured and randomly oriented samples, respectively. F values of 0.41 and 0.44 were obtained for HP700 and HP800 tapes, demonstrating that c-axis oriented grains have been achieved in Cu-sheathed tapes. The larger F value in HP800 samples is in agreement with the previous reports confirming that the higher HP temperature, the larger degree of grain alignment18.

XRD patterns for the planar surfaces and central sections of the superconducting cores of both HP700 and HP800 samples.

As a reference, the data for randomly orientated precursor powders is also included. The peaks of Sr1−xKxFe2As2 phase are indexed, while the peaks of impurity phases are also marked.

DC susceptibility measurements were conducted on HP700 and HP800 samples. Fig. 4(a) depicts two typical groups of the susceptibility curves under a 20 Oe magnetic field parallel to the tape plane. The superconducting transition of HP700 tapes begins at about 33.0 K. It is evident from the zero-field cooled (ZFC) signal that the susceptibility starts to decrease slowly and full shielding is reached at about 15 K. This behavior suggests the presence of inhomogeneity14,37. For HP800 samples, the shielding current occurs at 33.5 K, which may be ascribed to improvement in crystallization. When compared to HP700 samples, the HP800 samples exhibit sharper superconducting transition and reach full shielding at higher temperature (≈20 K). Obviously, enhanced uniformity in superconducting phase has been achieved in HP800 samples37. Fig. 4(b) shows resistivity versus temperature curves. We measured onset Tc values of 34.6 and 35.1 K for HP700 and HP800 tapes, respectively, which are comparable to Fe-sheathed and Ag-sheathed tapes17,19,38, but slightly smaller than those reported in ref. 18. The impurity of copper compound in present work does not significantly affect the superconducting transition. In addition, the resistivity of HP700 and HP800 tapes drops to zero Tc at 32.3 and 33.8 K, respectively. The larger onset Tc and smaller transition width for HP800 samples are consistent with the above magnetic results.

From the viewpoint of practical applications, superconducting wires must be able to carry large transport current density in high magnetic fields. We determined the transport Ic by the standard four-probe method. Fig. 5 displays the Jc-B properties of HP700 and HP800 tapes at 4.2 K. For HP700 tapes, the Jc values of 3.5 × 104 A/cm2 and 4.2 × 103 A/cm2 are obtained in self-field and 10 T, respectively. The striking result is that HP800 tapes show a great enhancement of Jc values in the whole field up to 14 T. Such an improvement can be attributed to improved texture, better homogeneity and crystallization. For HP800 tapes, the Jc data in self-field is not given because the transport Ic is too large to be measured by the measurement system we used. Excitingly, the transport Jc reaches 3.1 × 104 A/cm2 at 10 T. To our knowledge, this is by far the highest critical current density under high field ever reported for Cu-sheathed high-Tc superconductors. Importantly, due to its extremely small magnetic field dependence, the transport Jc still maintains a high value of 2.7 × 104 A/cm2 in 14 T. It is convincible that the Cu-sheathed Sr-122 tapes have a very promising future for use in high-field superconducting magnets.

We conducted SEM/EDX to investigate the influence of hot pressing process on the microstructure of Cu-sheathed Sr-122 tapes. As shown in Figs. 6(a,b), both HP700 and HP800 samples exhibit dense layered structure, which is similar to that of Bi-2223 tapes. HP700 samples have smaller grain size than that of HP800 samples. Fig. 6c exhibits a typical SEM micrograph of polished cross section of HP800 samples. It is noted that the boundary between Cu sheath and Sr-122 core is clear, further suggesting that there is no apparent reaction layer after hot pressing13. The corresponding EDX element mappings of HP800 tapes are presented in Figs. 6(d–i). From the Cu mapping, we observe a diffusion of Cu into Sr-122 area and the diffusion width is approximately 8 μm. This indicates that Cu element interfuses into Sr-122 core and reacts with it during heat treatment. For the elements of Sr-122 phase, Sr, K, Fe and As are detected locally in the core area, disappear almost completely at the border of the core area. Comparing with recent Ag-sheathed Sr-122 tapes18, we conclude that the slight depression of superconducting properties in this work is mainly due to the diffusion of Cu. At the same time, the diffusion also causes the inhomogeneous distribution of the superconducting elements in Sr-122 area, particularly in the diffusion region. In addition, the EDX mapping of HP700 samples is showed in Fig. 6(j). For each element, the content has a dramatic change at the border of Sr-122 core. Further analysis reveals that the diffusion width of Cu element is smaller than 3 μm in HP700 samples. Although the sintering time of 60 min is longer than that used for HP800 tapes (30 min), the width is much smaller.

SEM microstructures of Sr-122 tapes:

(a) HP700 and (b) HP800 samples. (c) SEM image showing the interface between Cu sheath and Sr-122 core for HP800 tapes. (d) The corresponding EDX mapping image for HP800 samples; (e–i) Area mappings of Cu, Sr, K, Fe and As element, respectively. (j) The EDX mapping image for HP700 samples.

The diffusion of Cu and the composition deviation of superconducting phase easily induce severe porosity at the interface and apparently break the electrical contact between Cu sheath and Sr-122 core39,40. This disadvantageous phenomenon can be avoided by the simple HP method, because it can greatly reduce the pores and cracks by combining the deformation and heat treatment in a single step. As shown in Fig. 6c, the Cu sheath and Sr-122 core are tightly connected. As a result, high transport Ic values have been measured in our Cu-sheathed tapes.

For comparison, Cu-sheathed Sr-122 tapes were also sintered without hot-pressing and the detailed information is exhibited in Table 1. The transport Jc values for both HP tapes are much larger than those of corresponding tapes without hot-pressing. For example, the Jc value of HP800 tapes (3.1 × 104 A/cm2) is an order of magnitude higher than that of R800 tapes (3.0 × 103 A/cm2), indicating the great Jc enhancement by the hot-pressing method.

Discussion

Using copper sheath for superconducting tapes with large transport Jc is highly desirable for practical applications. By a modified hot-pressing method with combination of final short-time sintering and low external pressure, we successfully prepared Cu-sheathed Sr-122 conductors with large transport current. We demonstrated that the fabricating method developed in our lab can produce high-performance Cu-sheathed superconductors. First, a short-time hot-pressing process can form high-quality Sr-122 phase, which is supported by XRD and resistivity characterizations. For HP800 tapes, the resistivity data demonstrates that the onset Tc is 35.1 K with a transition width of about 1.5 K. Second, this fast fabrication does not give rise to the reaction layer even though the Cu sheath is used. As discussed by above EDX mappings, only a little bit of Cu diffuses into polycrystalline Sr-122 phase. Earlier studies reveal that the thick reaction layer induces the contamination of the superconducting phase to decrease Tc and prevents electric current from flowing from the sheath material to the superconducting core26,33. Third, the Cu sheath and Sr-122 core are tightly connected under external pressure and thus the current path can be enlarged. Meanwhile, the hot pressure can not only considerably increase the core density, but also effectively promote complete reaction of Sr-122 phase, which in return to solve the problem that is low sintering temperature (800 or 700 °C) and short-time reaction (30 or 60 min) yield poor re-crystallization and ordinary superconducting performance18,38. In summary, the simple hot pressing method ensures high-quality Sr-122 phase and inhibit the formation of reaction layer in Cu-sheathed Sr-122 tapes.

It is fascinating that the largest Jc value of 3.1 × 104 A/cm2 in 10 T has been obtained in our best Cu-sheathed tapes. Moreover, the Jc of 122-type pnictides have very weak field dependence in strong fields up to 28 T41, in accordance with ultrahigh Hc2 values5. Thus, the Jc data above 14 T is given by extrapolating from low fields, as presented in Fig. 7. The curve tendency shows that the crossovers with Cu-sheathed NbTi and Nb3Sn wires are around 9.5 and 18.5 T, respectively. This clearly strengthens the position of pnictide conductors as a competitor to the conventional superconductors for high-field applications. On the other hand, researchers are usually more concerned with the engineering (total cross section) current density Je in practical applications. As showed in Fig. 7, a high Je of about 1.0 × 104 A/cm2 at 10 T has been achieved in our Cu-sheathed Sr-122 tapes, which has reached the widely accepted practical level for applications28. This achievement is a significant technical breakthrough for the practical applications of Cu-sheathed high-Tc conductors. In the future, if the HP process can be properly adjusted to match the balance between the well re-crystalline reaction and little impurity phase, an even higher Je can be expected.

The specific cost ($/kA·m) of superconducting wires and tapes must be considered in practical applications25,28. The price ($/kg) of Cu metal is 1-2 order of magnitude lower than that of expensive Ag metal. Tape conductors with high Je (104 A/cm2) sheathed in comparatively cheap copper have the strong potential for low specific cost. Moreover, Cu-sheathed conductors do not need additional stabilization or mechanical reinforcement. In contrast, the Ag sheathed wires usually need mechanical reinforcement. For example, the stainless steel or Ag0.5 wt%Al alloy sheath have been used in superconducting wires41,42,43, which decrease the engineering Je or increase the complexity and cost of fabrication process. From these view points, we can conclude that the comprehensive performances of our Cu-sheathed Sr-122 tapes are much more attractive for applications than the reported Ag sheathed tapes16,17,18,19, demonstrating that Cu is a very promising sheath for the pnictide wires and tapes.

Methods

Sample preparation

We fabricated Cu-sheathed Sr0.6K0.4Fe2As2 tapes by ex-situ PIT method. Sr fillings, K pieces and Fe and As powder with a ratio of Sr:K:Fe:As = 0.6: 0.5: 2: 2.05 were mixed for 12 hours by ball-milling method. The milled powders were packed into Nb tubes and then sintered at 900 °C for 35 h. As prepared Sr-122 superconducting powders were packed into Cu tubes with OD 6 mm and ID 4 mm. These tubes were sealed and then cold worked into tapes (~0.4 mm thickness) by swaging, drawing and flat rolling. Finally, hot pressing was performed on the 60 mm long tapes under ~20 MPa at two different sintering processes of 800 °C/30 min and 700 °C/60 min. These tapes are defined as HP800 and HP700 tapes, respectively.

Measurements

Phase identification of samples was characterized by X-ray diffraction (XRD) analysis with Cu Kα radiation. Magnetization versus temperature curves and resistivity measurements of the superconducting cores were carried out using a PPMS system. The cross sections were polished and then observed by optical images. Microstructure characterization was analyzed using SEM images and EDX scanning. The transport critical current Ic was measured at 4.2 K using short tape samples of 3 cm in length with the standard four-probe method and evaluated by the criterion of 1 μV/cm. The applied fields up to 14 T in transport Ic measurement were parallel to the tape surface.

Additional Information

How to cite this article: Lin, H. et al. Large transport Jc in Cu-sheathed Sr0.6K0.4Fe2As2 superconducting tape conductors. Sci. Rep. 5, 11506; doi: 10.1038/srep11506 (2015).

References

Kamihara, Y. et al. Iron-based layered superconductor La[O1−xFx]FeAs (x = 0.05-0.12) with Tc = 26 K. J. Am. Chem. Soc. 130, 3296 (2008).

Chen, X. et al. Superconductivity at 43 K in SmFeAsO1−xFx . Nature 453, 761 (2008).

Rotter, M. et al. Superconductivity at 38 K in the iron arsenide (Ba1−xKx)Fe2As2 . Phys. Rev. Lett. 101, 107006 (2008).

Putti, M. et al. New Fe-based superconductors: properties relevant for applications. Supercond. Sci. Technol. 23, 034003 (2010).

Ma, Y. Progress in wire fabrication of iron-based superconductors. Supercond. Sci. Technol. 25, 113001 (2012).

Yang, H. et al. Fishtail effect and the vortex phase diagram of single crystal Ba0.6K0.4Fe2As2 . Appl. Phys. Lett. 93, 142506 (2008).

Wang, X. et al. Very strong intrinsic flux pinning and vortex avalanches in (Ba, K)Fe2As2 superconducting single crystals. Phys. Rev. B 82, 024525 (2010).

Katase, T. et al. Advantageous grain boundaries in iron pnictide Superconductors. Nat. Commun. 2, 409 (2011).

Zhang, X. et al. Effect of sheath materials on the microstructure and superconducting properties of SmO0.7F0.3FeAs wires. Physica C 470, 104 (2010).

Wang, L. et al. Large transport critical currents of powder-in-tube Sr0.6K0.4Fe2As2/Ag superconducting wires and tapes. Physica C 470, 183 (2010).

Wang, L. et al. Textured Sr1-xKxFe2As2 superconducting tapes with high critical current density. Physica C 471, 1689 (2011).

Zhang, X. et al. Mechanism of enhancement of superconducting properties in a Ba1-xKxFe2As2 superconductor by Pb addition. Supercond. Sci. Technol. 25, 084024 (2012).

Yao, C. et al. Improved transport critical current in Ag and Pb co-doped BaxK1-xFe2As2 superconducting tapes. Supercond. Sci. Technol. 25, 035020 (2012).

Gao, Z. et al. High critical current density and low anisotropy in textured Sr1-xKxFe2As2 tapes for high field applications. Sci. Rep. 2, 998 (2012).

Togano, K. et al. Enhancement in transport critical current density of ex situ PIT Ag/(Ba, K)Fe2As2 tapes achieved by applying a combined process of flat rolling and uniaxial pressing. Supercond. Sci. Technol. 26, 115007 (2013).

Gao, Z. et al. Achievement of practical level critical current densities in Ba1-xKxFe2As2/Ag tapes by conventional cold mechanical deformation. Sci. Rep. 4, 4065 (2014).

Lin, H. et al. Strongly enhanced current densities in Sr0.6K0.4Fe2As2+ Sn superconducting tapes. Sci. Rep. 4, 4465 (2014).

Lin, H. et al. Hot pressing to enhance the transport Jc of Sr0.6K0.4Fe2As2 superconducting tapes. Sci. Rep. 4, 6944 (2014).

Zhang, X. et al. Realization of practical level current densities in Sr0.6K0.4Fe2As2 tape conductors for high-field applications. Appl. Phys. Lett. 104, 202601 (2014).

Yuan, Y. et al. Significantly enhanced critical current density in Ag-sheathed (Bi, Pb)2Sr2Ca2Cu3Ox composite conductors prepared by overpressure processing in final heat treatment. Appl. Phys. Lett. 84, 2127 (2004).

Larbalestier, D. C. et al. Isotropic round-wire multifilament cuprate superconductor for generation of magnetic fields above 30 T. Nat. Mater. 13, 375 (2014).

Hossain, M. S. A. et al. The enhanced Jc and Birr of in situ MgB2 wires and tapes alloyed with C4H6O5 (malic acid) after cold high pressure densification. Supercond. Sci. Technol. 22, 095004 (2009).

Herrmann, M. et al. Touching the properties of NbTi by carbon doped tapes with mechanically alloyed MgB2 . Appl. Phys. Lett. 91 082507 (2007).

Wilson, M. N. Superconducting Magnets (Clarendon, 1987).

Cooley, L. D. et al. Costs of high-field superconducting strands for particle accelerator magnets. Supercond. Sci. Technol. 18, R51 (2005).

Wozniak, M. et al. Study of short duration heat treatments of an in situ copper-sheathed MgB2 wire. Supercond. Sci. Technol. 23, 105009 (2010).

Larbalestier, D. C. et al. High-Tc superconducting materials for electric power applications. Nature 414, 368 (2001).

Scanlan, R. M. et al. Superconducting materials for large scale applications. Proceedings of the IEEE 92, 1639 (2004).

Tomsic, M. et al. Development of magnesium diboride (MgB2) wires and magnets using in situ strand fabrication method. Physica C 456, 203 (2007).

Sumption, M. D. et al. Transport properties of multifilamentary, in situ route, Cu-stabilized MgB2 strands: one metre segments and the Jc(B, T) dependence of short samples. Supercond. Sci. Technol. 19, 155 (2006).

Ding, Y. et al. Effects of cold high pressure densification on Cu sheathed Ba0.6K0.4Fe2As2 superconducting wire. Physica C 483, 13 (2012).

Nakamura, Y. et al. Effect of Bi2223 addition in precursor on the formation and Jc property of Bi2223 tapes sheathed with the Ag–Cu alloy. Supercond. Sci. Technol. 21, 035001 (2008).

Pachla, W. et al. Structural characterization of multifilament heat treated ex situ MgB2 superconducting wires with Cu and Fe sheaths. Supercond. Sci. Technol. 17, 1289 (2004).

Han, Z. et al. The mechanical deformation of superconducting BiSrCaCuO/Ag composites. Supercond. Sci. Technol. 10, 371 (1997).

Osamura, K. et al. Work instability and its influence on the critical current density of silver sheathed Bi2223 tapes. Supercond. Sci. Technol. 5, 1 (1992).

Lotgering, F. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures-I. J. Inorg. Nucl. Chem. 9, 113 (1959).

Palenzona, A. et al. A new approach for improving global critical current density in Fe(Se0.5Te0.5) polycrystalline materials. Supercond. Sci. Technol. 25, 115018 (2012).

Lin, H. et al. Effects of heating condition and Sn addition on the microstructure and superconducting properties of Sr0.6K0.4Fe2As2 tapes. Physica C 495, 48 (2013).

Husek, I. et al. Microhardness as a tool for the filament density and metal sheath analysis in MgB2/Fe/(Cu) wires. Supercond. Sci. Technol. 17, 971 (2004).

Flukiger, R. et al. Superconducting properties of MgB2 tapes and wires. Physica C 385, 286 (2003).

Gao, Z. et al. High transport Jc in magnetic fields up to 28T of stainless steel/Ag double sheathed Ba122 tapes fabricated by scalable rolling process. Supercond. Sci. Technol. 28, 012001 (2015).

Ochiai, S. et al. Thermally and mechanically induced residual strain and strain tolerance of critical current in stainless steel-laminated Bi2223/Ag/Ag alloy composite superconductors. Supercond. Sci. Technol. 21, 075009 (2008).

Kajbafvala, A. et al. High strength oxide dispersion strengthened silver aluminum alloys optimized for Bi2Sr2CaCu2O8+x round wire. Supercond. Sci. Technol. 26, 125012 (2013).

Acknowledgements

The authors thank Professors S. Awaji and K. Watanabe for the transport Ic measurements. We acknowledge suggestions and discussions with Dr. B. Ma at ANL. This work is partially supported by the National ‘973’ Program (grant No. 2011CBA00105), the National Natural Science Foundation of China (grant Nos. 51172230, 51320105015 and 51202243) and the Beijing Municipal Science and Technology Commission (grant No. Z141100004214002).

Author information

Authors and Affiliations

Contributions

Y.W.M. directed the research. H.L. designed the experimental plan and fabricated the tape samples. H.L. carried out XRD, magnetization, resistivity and microstructure characterizations. X.P.Z. and D.L.W. did the high-field Ic measurement. Q.J.Z. and C.H.D. helped with the tape preparation. C.Y. and H.T.Z. contributed to manuscript preparation. H.L. and Y.W.M. wrote the manuscript. All the authors contributed to discussion on the results for the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Lin, H., Yao, C., Zhang, H. et al. Large transport Jc in Cu-sheathed Sr0.6K0.4Fe2As2 superconducting tape conductors. Sci Rep 5, 11506 (2015). https://doi.org/10.1038/srep11506

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep11506

This article is cited by

-

Fabrication of FeSe 0 . 5 Te 0 . 5 Superconducting Wires by an Ex Situ Powder-in-Tube Method

Journal of Superconductivity and Novel Magnetism (2016)

-

Enhancement of Superconductivity in FeSe0.5Te0.5 by Furnace Cooling

Journal of Superconductivity and Novel Magnetism (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.